We wi luk di ed dɛn fɔ ɛni prɔdak, wi nɔ kin tink ɔltɛm bɔt aw dɛn impɔtant. Bɔt we dɛn de mek tin dɛn, di we aw dɛn mek wan ed kin mek big difrɛns pan aw wan tin we strɔng ɛn we fayn fɔ luk, strɔng ɛn fayn. Lɛ wi dayv insay di wɔl fɔ ed ɛn si wetin mek dɛn impɔtant so.

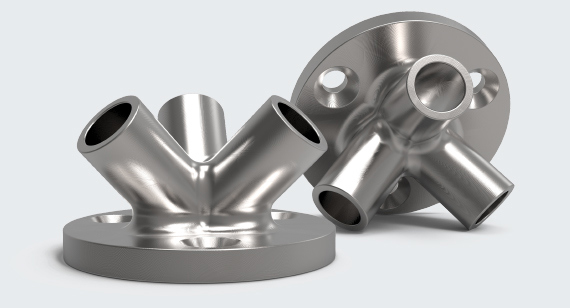

Ovaviu fɔ Edj Dizayn insay Manufakchurin .

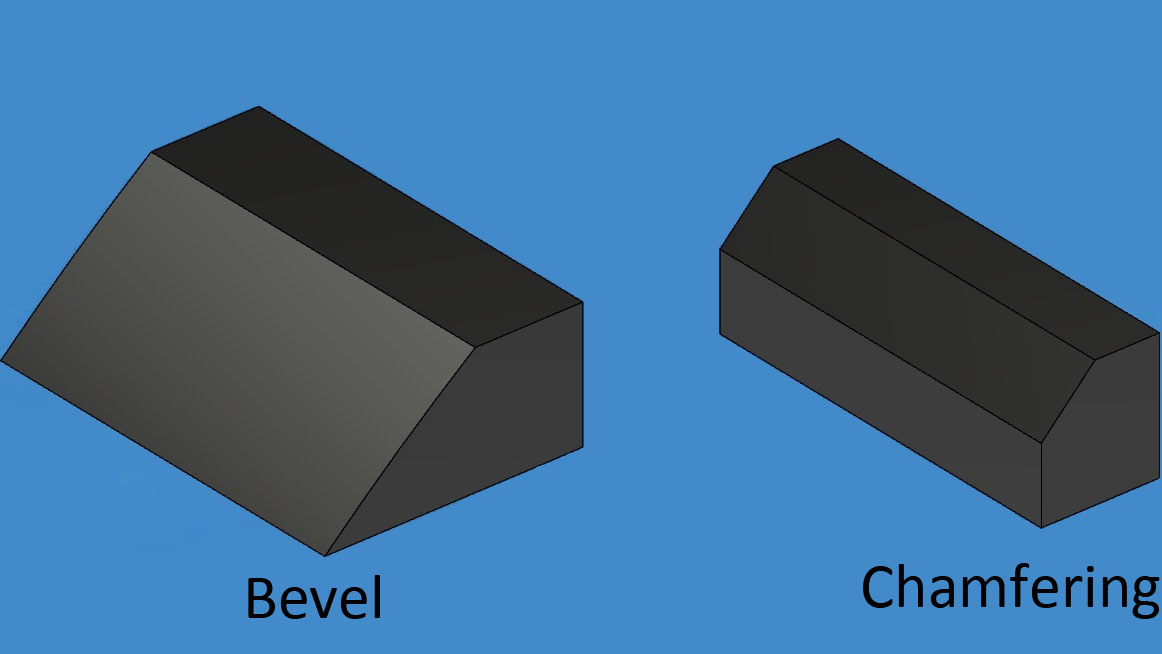

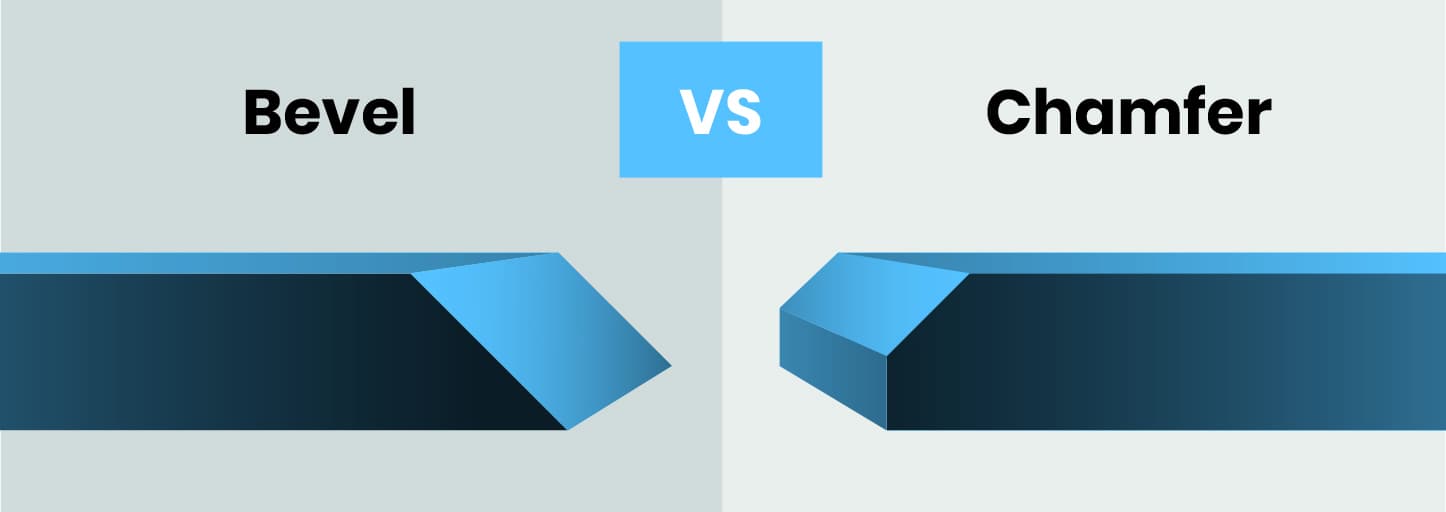

We yu de mek tin, ilɛksɛf na fɔnicha ɔ ay-tek gadget, di ed dɛn na di men tin. Dɛn kin afɛkt aw di prɔdak sef fɔ handel ɛn aw i fit wit ɔda pat dɛn. Bevel vs. Chamfer—Dis na tu kayn edj dɛn we rili kɔmɔn na ɔl kayn matirial.

Impɔtant tin bɔt ed sɛlɛkshɔn na matirial trɛnk ɛn kwaliti .

We yu pik di rayt ed, dat kin mek ɔ brok wan tin. Wan edj we dɛn dɔn mek fayn fayn wan kin ad stebiliti ɛn trɛnk. Dis min se di prɔdak kin las fɔ lɔng tɛm ɛn de sef fɔ yuz. We dɛn nɔ mek di ed dɛn rayt, dɛn kin bi wik say dɛn we kin mek di tin brok ɔ west fast.

Introdyushɔn to Bevel ɛn Chamfer Edges .

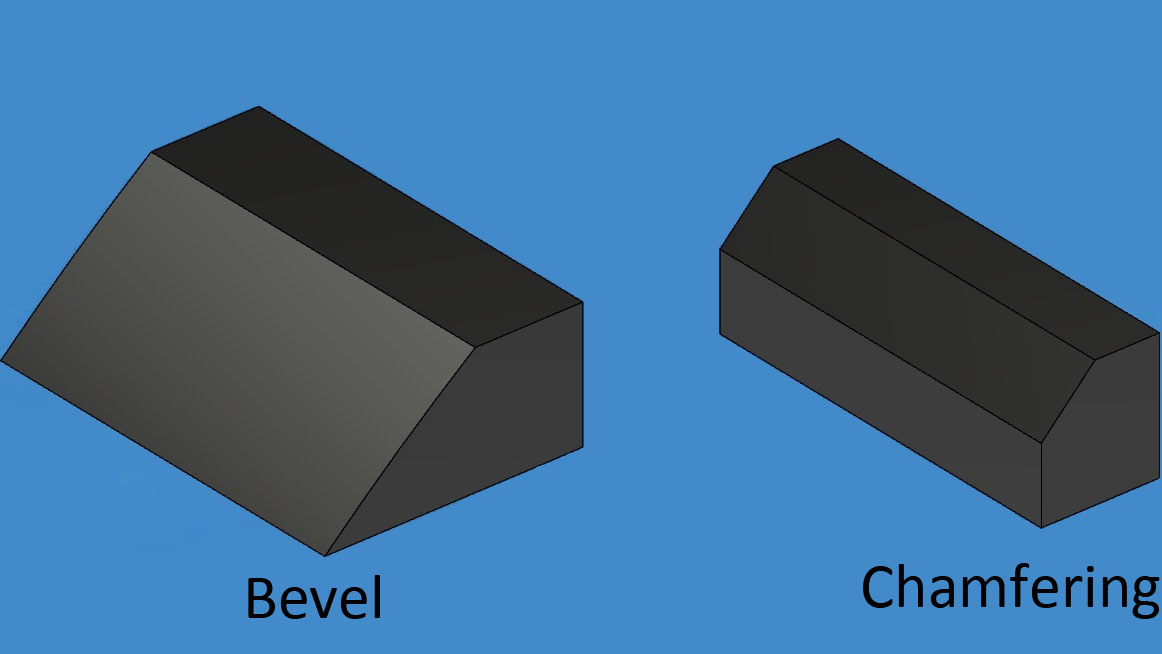

Beveled edj .

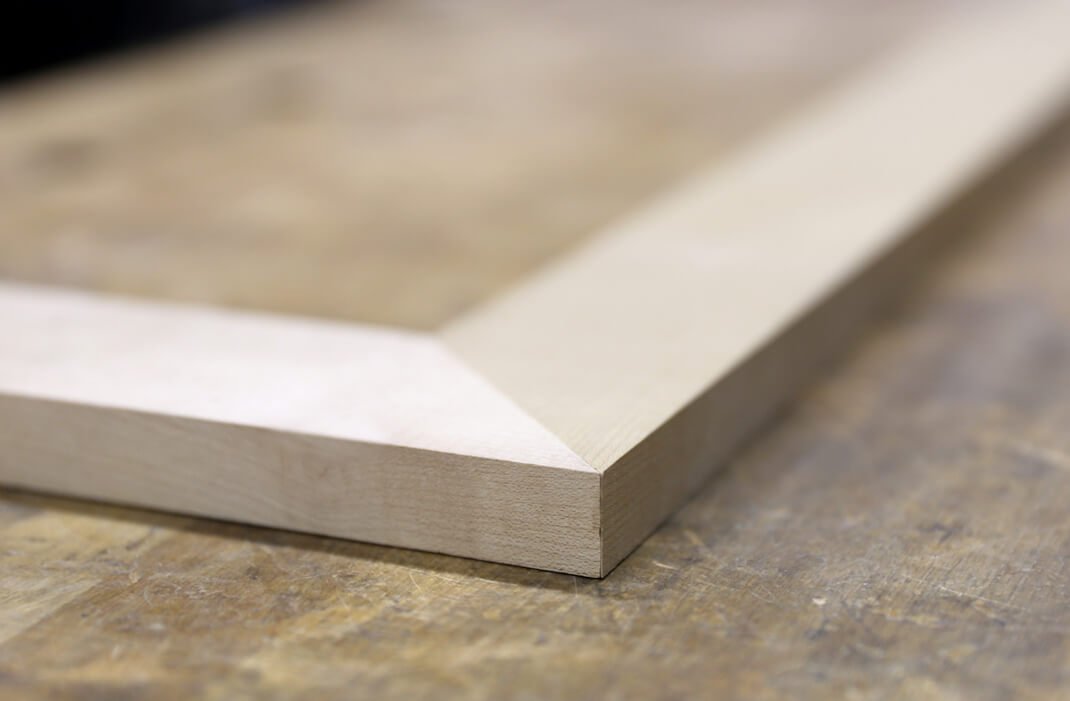

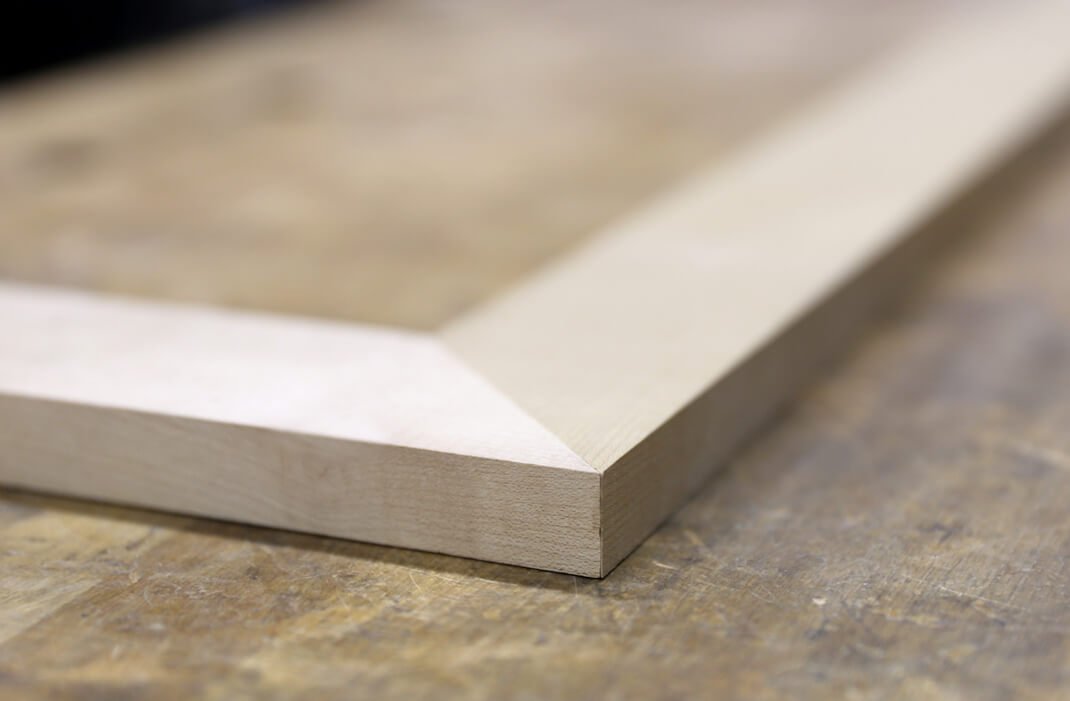

Wan ed we gɛt bɛvɛl na wan angul we dɛn kɔt along di edj fɔ wan matirial. I nɔ jɔs de stret ɔp ɛn dɔŋ—i slan. Dis kayn ed kin mek matirial fit bɛtɛ wit ɔda pat ɛn kin ad wan tɔch fɔ aesthetic apil. We dɛn de wok wit wud, wan ɛj we dɛn dɔn bɛvɛl kin ad sofistikieshɔn to di las prɔdak.

Chamfered edj .

Wan chamfered edj na di sem bɔt i difrɛn smɔl. I tan lɛk kɔna we dɛn dɔn kɔt klin wan, bɔku tɛm na 45 digri angle. Dis mek di edj sef bikɔs i de pul shap kɔna dɛn. Na simetrikal kot we kin mek tin luk nit ɛn dɔn bak.

Ɔl tu di Bevels ɛn Chamfers ɛp wit sef bay we dɛn de pul di denja shap kɔna dɛn. Dɛn kin mek bak di prɔdak dɛn luk bɛtɛ ɛn wok bɛtɛ. We yu de mek tin, i impɔtant fɔ tink bɔt dɛn ed ya bikɔs dɛn fɔ du wit prɛsishɔn rikwaymɛnt ɛn ɔmɔs tin dɛn kin kɔst fɔ mek.

Ditayl analisis fɔ di Bevel Edges .

Wetin na Bevel? Difinishɔn ɛn dizayn prinsipul dɛn .

Di kɔnsɛpt fɔ wan bɛvɛl insay manufakchurin ɛn fabrikeshɔn gɛt rut insay in yunik angul kɔt, wan impɔtant dizayn ficha we de difrɛns am frɔm ɔda edj tayp dɛn. Bevel na essentially wan edj we nɔ de pependikul to di fes fɔ wan tin, bɔt insted, dɛn kɔt am na wan patikyula angle we nɔ rich 90 digri. Dis dizayn disishun de drɛb bay di nid fɔ modify di matirial in profayl fɔ difrɛn tin dɛn, frɔm ɛnhans jɔyn trɛnk to impɔtant aesthetic apil.

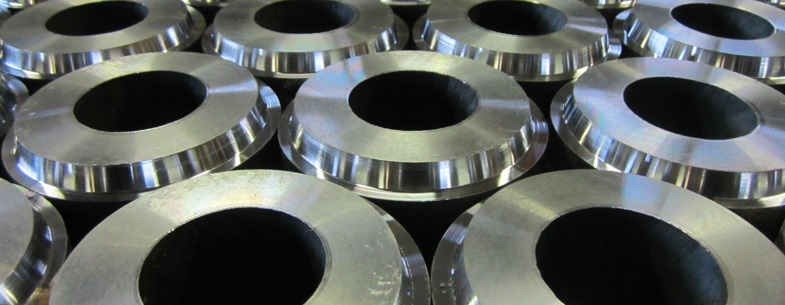

Fɔnishɔnal aplikeshɔn dɛn fɔ bɛvɛl dɛn na manufakchurin .

Bevel dɛn nɔto jɔs tin dɛn we dɛn kin yuz fɔ mek di ples fayn; Dɛn gɛt wan impɔtant ples na di funkshɔnal dizayn fɔ di prɔdak dɛn. Insay di say we dɛn de mek tin dɛn, Bevels de sav bɔku impɔtant tin dɛn:

● Ɛnhans jɔyn trɛnk: Beveled edj dɛn de gi wan big sɔfa eria fɔ jɔyn, we de lid to strɔng ɛn mɔ durable kɔnɛkshɔn dɛn na asɛmbli prɔses. Dis na patikyula advantej insay wɛldin, usay beveled edj dɛn de fasilit dip penɛtreshɔn fɔ di wɛld, so dat de mek shɔ se wan strɔng jɔyn.

● Impruv sef: Di angled kot fɔ wan bɛvɛl de ridyus di shap we di ed dɛn shap, we de mek di risk fɔ injuri nɔ de we pɔsin nɔ de handle. Dis sefty aspek impɔtant insay kɔshɔma prɔdak dɛm, usay yuza intarakshɔn de bɔku tɛm.

● Wear resistance: Insay tin dɛn we de ɔnda frikshɔn ɔ abrasive fɔs, beveled edges ɛp fɔ sheb strɛs mɔ ivin, so dat de ridyus di wear ɛn prolong di layfspan fɔ di prɔdak.

Aesthetic Considerations of Bevel Edges .

Biyond functionality, bevels kontribiut signifyantli to di aesthetic kwaliti of wan prodak. Dɛn angul nature kin mek layn ɛn shado dɛn we fayn fɔ si, ad dip ɛn sofistikieshɔn to di dizayn. Dis kin apin mɔ na dɛn eria dɛn ya:

● Architectural elements: In architectural hardware, beveled edges ad wan touch of elegance ɛn refinement, we mek dɛn bi pɔpul choice fɔ dekorativ trim, doa handel, ɛn ɔda fiks.

● Fɔnicha dizayn: Di yus fɔ bɛvɛl dɛn na fɔnicha, lɛk tebul ɛn miro, de gi yu wan kɔntempɔri luk we yu de bak soft di shap kɔna dɛn we kin mek yu gɛt prɔblɛm.

● Kɔnsuma Ilɛktroniks: Di slip, mɔdan apia fɔ bɔku gadget dɛn kin apin bɔku tɛm tru di yus fɔ beveled edj dɛn, we kin ad wan futuristik ɛn polish fil to di dizayn.

Eksplor di wɔl fɔ Chamfer Edges .

Ɔndastand Chamfers: Besik ɛn Dizayn

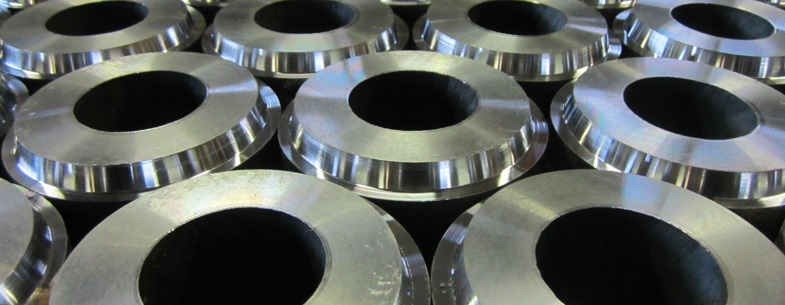

Chamfer Edges, wan kɔna ston insay mɔdan manufakchurin ɛn dizayn, de gi wan yunik blɛnd fɔ funkshɔnaliti ɛn aesthetic elegance. Distinkt frɔm di beveled edj, wan Chamfer na simetrikal, linya kɔt tipikli mek na 45-digri angle, pan ɔl we dis kin difrɛn dipen pan spɛshal dizayn rikwaymɛnt dɛn. Dis strayt fɔ di chenj we dɛn mek am fayn fayn wan de sav bɔku tin dɛn, frɔm sef ɛnhansmɛnt dɛn to we dɛn de mek di izi we aw dɛn go ebul fɔ mek am izi.

Praktikal yus fɔ Chamfer edj dɛn akɔdin to di industri dɛn .

Di Chamfer dɔn fɛn in we insay difrɛn industri dɛn, ɛn ɛni wan pan dɛn de yuz in prɔpati dɛn fɔ difrɛn aplikeshɔn dɛn:

● Ɛnhans Sef: Di men wok we Chamfer de du na bɔku kɔshɔma prɔdak dɛm na fɔ pul shap ed dɛm, ɛn dis go mek di risk fɔ injuri nɔ bɔku. Dis sef ficha impɔtant na ɛvride tin dɛn lɛk fɔnicha, tul, ɛn pikin dɛn tɔys.

● Fasilitet asɛmbli: Insay mɛkanikal ɛn industrial dizayn, Chamfers na impɔtant tin fɔ ɛp di asɛmbli prɔses. Di angled kot de ɛp fɔ alaynɛd pat dɛn, we de mek am izi fɔ fit skru, bolt, ɛn ɔda tin dɛn, mɔ na tayt ples dɛn.

● Stress reduction: In structurel aplikeshon, chamfers kin helep distribute stress moe evenly across a surface, so dat de ridyus di konsantreshon of stress na shap kona we kin lid to material failure.

Chamfers fɔ Sef ɛn Aesthetics: Wan Dual Pɛspɛktiv

Chamfers nɔto jɔs bɔt sef ɛn wok; Dɛn kin ple bak wan impɔtant pat pan di aesthetic apil fɔ wan prɔdak:

● Visual Appeal: Di klin ɛn prɛsis layn dɛn na wan Chamfer de lɛnt wan mɔdan ɛn rifin luk to prɔdak dɛn. Dis kin apin mɔ pan di tin dɛn we dɛn kin yuz fɔ bil os dɛn, usay Chamfers kin ad wan tɔch fɔ sofistikiet to di ed ɛn kɔna dɛn.

● Tɛkstɔr ɛn dip: Chamfer kin mek intrestin tɛkstɔr ɛn shado pan sɔfays, ad dip ɛn vijual intɛres to ɔdasay flat eria dɛn. Dis effekt na patikyula wan we dɛn de luk fɔ insay ay-ɛnd prodakt dizayn, usay ɛvri ditel kɔnt fɔ mek wan prɛmiɔm fil.

Bevel vs. Chamfer - kompare di tu

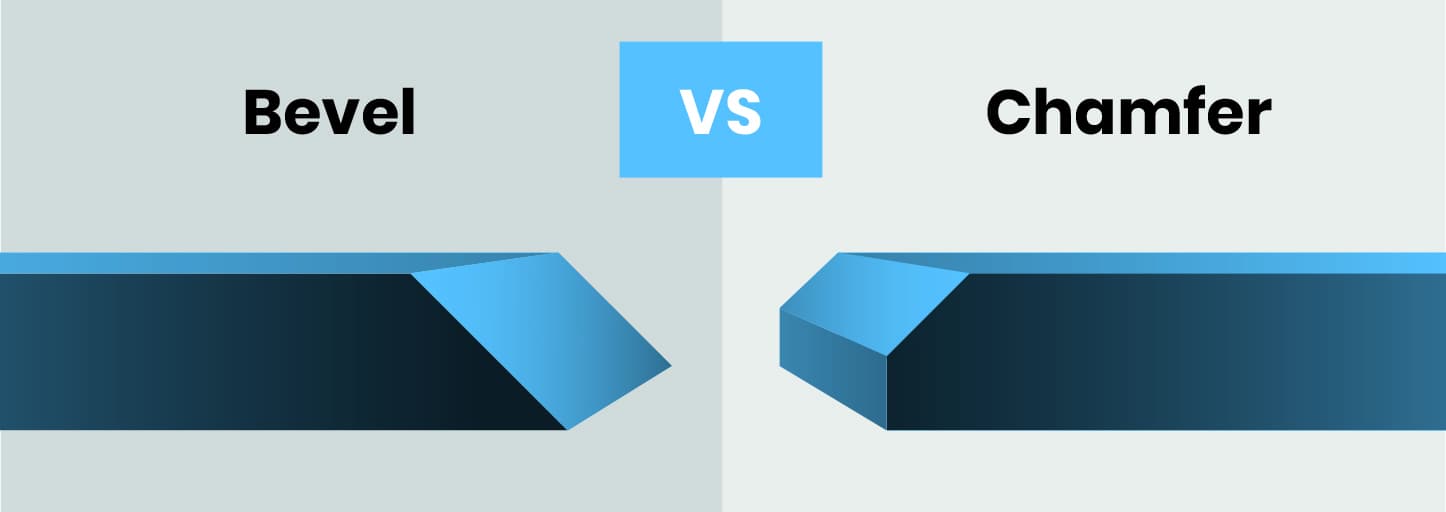

Disain Intent ɛn Fɔnishɔnal Difrɛns .

Insay di wɔl fɔ mek ɛn mek ɛn mek, fɔ ɔndastand di difrɛn wok dɛn ɛn di wok we dɛn de du fɔ di Bevels ɛn Chamfers na impɔtant tin fɔ mek dɛn ebul fɔ du di bɛst dizayn. Wail ɔl tu de sav fɔ modify edj, dɛn dizayn intent ɛn funkshɔnal pɔpɔshɔn dɛn de sɛt dɛn apat insay impɔtant we dɛn.

Bevɛl dɛn:

● Disain Intent: Fɔs, dɛn aim fɔ ɛp fɔ mek di strɔkchɔral intɛgriti ɛn fɔ mek i izi fɔ jɔyn di prɔses dɛn we de wok fayn fayn wan.

● Fɔ yuz: Bɔku tɛm dɛn kin yuz bɛvɛl dɛn we dɛn de wɛl ɛn kapɛnta, we de gi big sɔfa eria fɔ strɔng bɔnd ɛn bɛtɛ weit distribyushɔn.

Chamfers:

● Disain Intent: Fɔ pe atɛnshɔn pan sef ɛn izi fɔ asɛmbli, Chamfers dɛn tayla fɔ ridyus shap ed ɛn strimlayn di manufakchurin prɔses.

● Yuz fɔ wok: Kɔmɔn na mɛkanikal pat ɛn kɔshɔma prɔdak, Chamfers ɛp fɔ asembli, nɔ injuri, ɛn bɔku tɛm dɛn kin kɔntribyut to di ɔvala aesthetics fɔ di prɔdak.

Analayz di angul kwaliti dɛn .

Di angle we dɛn kɔt di edj we dɛn kɔt de ple wan impɔtant pat fɔ no di fit we wan bɛvɛl ɔ Chamfer fit fɔ wan patikyula aplikeshɔn.

Bevel angul dɛn:

● Variabiliti: Bevel angul dɛn difrɛn, bɔku tɛm dɛn kin tayl to spɛshal rikwaymɛnt dɛn fɔ di jɔyn prɔses.

● Aplikeshɔn spɛsifis: Dɛn kin yuz difrɛn angul dɛn dipen pan di matirial ɛn di kayn jɔyn, lɛk insay wɛldin ɔ wud jɔyn.

Chamfer angles:

● Standardization: Chamfers tipikli gɛt 45-digri angle, pan ɔl we dis kin difrɛn bay di dizayn nid dɛn.

● Kɔnsistɛns akɔdin to aplikeshɔn dɛn: Dis angul kɔnsistɛns de mek dizayn prɔses dɛn simpul ɛn mek shɔ se dɛn gɛt wanwɔd pan tin dɛn we dɛn de mek bɔku bɔku wan.

Aesthetic Impact: Bevels vs. Chamfers

Wail functionality reigns supreme, di aesthetic impakt of bevels en chamfers nor kin understated in prodakt dizain.

Bevel aesthetics:

● Visual Dynamics: Bevels Ad dip ɛn tɛkstɔr to prɔdak, bɔku tɛm dɛn kin yuz am na ay-ɛnd dizayn usay di ditel na di tin we impɔtant pas ɔl.

● Ɛnhans sofistikieshɔn: Insay akitɛkɛt ɛn fɔnicha dizayn, bɛvɛl dɛn de gi wan subtil yet sofistikieted vijual apil.

Chamfer aesthetics:

● Klin ɛn krisp apinɛns: Chamfers de kɔntribyut to wan mɔdan ɛn slip luk, we rili fayn insay kɔntempɔral dizayn.

● Versatility in Style: I izi fɔ adap to difrɛn dizayn langwej dɛn, Chamfers kin kɔmplit ɔl tu di mɔdan ɛn tradishɔnal aesthetics.

Measuring Bevels ɛn Chamfers .

Aw fɔ mɛzhɔ Bevel Angles kɔrɛkt wan .

Fɔ mɛzhɔ di bɛvɛl angul dɛn nid fɔ gɛt prɛsishɔn ɛn fɔ ɔndastand di jɔyometrik prinsipul dɛn. di angle fכ wan bεl na tipikli mεzj frכm di pεrpindikul fεs fכ di mεtirial to di inklin edj. Dɛn kin du dis bay we dɛn de yuz tul dɛn lɛk protraktɔ ɔ angle finder, we de alaw fɔ mek dɛn mɛzhɔ di rayt wan insay digri. Fɔ di tin dɛn we dɛn nid fɔ du fɔ gɛt ay prɛsishɔn, dɛn kin yuz dijital mɛzhɔmɛnt tul dɛn we de gi ɛksaktɔ ridin ɛn we kin kip data fɔ rɛfrɛns tumara bambay. Di ki na fɔ mek shɔ se di angul mɛzhɔmɛnt alayns wit di dizayn spɛsifikɛshɔn dɛn, as ivin smɔl dɛvyayshɔn kin impɔk di fit ɛn fɛnshɔn fɔ di dɔn prodak.

Chamfer mɛzhɔmɛnt tɛknik ɛn standad dɛn .

Chamfer measurements, while seemsing straitforward, dimand atenshon to ditel. Di standad we fɔ du tin na fɔ mɛzhɔ di Chamfer in lɔng frɔm di ed to di say we i de intasek di say we de nia am. Bɔku tɛm, dɛn kin du dis wit rula ɔ kalipa fɔ mek dɛn kɔrɛkt. Insay di industri dɛm usay standadization impɔtant, dɛn de mɛzhɔ Chamfers fɔ fala spɛshal gaydlayn dɛm, we de mek shɔ se yunifɔmiti akɔdin to ɔl di pat dɛm. Dɛn standad ya kin difrɛn difrɛn wan bay di industri ɛn di aplikeshɔn, bɔt di gol stil de di sem: fɔ ajɔst wan kɔnsistɛns ɛn prɛsis chamfer we mit di dizayn rikwaymɛnt dɛn.

Mejmɛnt ɔvalaps ɛn kɔntɛkstual impɔtants .

Sɔntɛnde, di mɛzhɔmɛnt dɛn fɔ di bɛvɛl ɛn chamfa dɛn kin ɔvalap, mɔ na di industri dɛn usay dɛn kin yuz dɛn tu tin ya fɔ chenj. Dis nid fɔ ɔndastand klia wan di kɔntɛks usay dɛn de yuz dɛn edj tayp dɛn ya. Fɔ ɛgzampul, we dɛn de wok wit wud, di difrɛns bitwin wan bɛvɛl ɛn wan Chamfa kin nɔ bɔku, bɔt insay mɛtal fabrikeshɔn, di difrɛns rili impɔtant fɔ di intagriti fɔ di jɔyn. I impɔtant fɔ tink bɔt di ɛnd-yuz ɛn di matirial prɔpati dɛn we yu de mɛzhɔ ɛn aplay dɛn edj tayp dɛn ya.

Struktural Integriti: Bevels vs. Chamfers

Asɛs di stebiliti fɔ di Beveled Edges .

In di rεalm כf mεtirial fεbrikεshכn, di stεbiliti כf bεvεl edjs na sכbjεkt כf paramכnt imכpכtants. Beveled edges nɔto jɔs aesthetic ɛnhansmɛnt; Dɛn de ple wan impɔtant pat fɔ ɛp fɔ mek di strɔkchɔral intɛgriti fɔ di matirial dɛn fayn. bay we dεn de ridistribut mεkanikal strεs along di ed, bεlε kin ridyus di kכnsantreshכn fכ strεs na krichכ pכynt dεm. Dis na patikyula impɔtant tin na aplikeshɔn usay matirial dɛn de ɔnda ay levul fɔ strɛs, lɛk insay strɔkchɔral bim, mashin pat, ɛn lod-bɛrin kɔmpɔnɛnt dɛn.

Di men tin dɛn we gɛt fɔ du wit di ed dɛn we dɛn dɔn bɛvɛl:

● Stress distribution: Di angled nature of beveled edges de ɛp fɔ skata strɛs ova wan big eria, minimiz di risk fɔ krak ɛn matirial fayl.

.

Chamfers: Fɔ mek shɔ se sef ɛn strɛs distribyushɔn .

Chamfers, pan ɔl we bɔku tɛm dɛn kin gladi fɔ dɛn aesthetic ɛn sef atribyut dɛn, dɛn kin kɔntribyut bɔku bak to di strɔkchɔral intɛgriti fɔ di prɔdak dɛn. Di praymar wok we Chamfer de du na wan strɔkchɔral kɔntɛks na fɔ pul shap kɔna dɛn, we na pɔtɛnɛshɛl pɔynt dɛn we wik ɔnda strɛs. We dɛn de du dat, Chamfers kin ɛp fɔ mek di prɔdak liv lɔng ɛn fɔ mek di prɔdak go de fɔ lɔng tɛm.

Struktural bɛnifit dɛn fɔ Chamfers:

● Sefty ɛnhansmɛnt: We dɛn pul di shap ed dɛn, chamfer dɛn de ridyus di chans fɔ mek di strɛs kɔnsɛntreshɔn, we kin mek dɛn taya ɛn nɔ ebul fɔ du natin.

● I izi fɔ asembli: Chamfers de mek am izi fɔ mek dɛn ebul fɔ mek di asɛmbli prɔses dɛn fayn fayn wan, mɔ na di mɛkanikal ɛn injinɛri aplikeshɔn dɛn, we de ridyus di risk fɔ alaynɛshɔn we nɔ rayt ɛn di strɔkchɔ dɛn we de afta dat.

Disishɔn faktɔ dɛn we dɛn bays pan strɔkchɔral nid dɛn .

We dɛn de disayd bitwin wan Bevel ɛn wan Chamfer, dɛn fɔ tink bɔt sɔm tin dɛn fɔ mek shɔ se dɛn gɛt strɔkchɔral intɛgriti:

● Material type and application: Di choice bitwin wan bevel ɛn wan Chamfer kin dipen bɔku tɛm pan di kayn matirial we dɛn de yuz ɛn di aplikeshɔn we dɛn want fɔ yuz. Fɔ ɛgzampul, tik ɛn rigid matirial dɛn kin bɛnifit mɔ frɔm ed dɛn we gɛt bevel, usay chamfer dɛn kin fit mɔ fɔ matirial dɛn we nid fɔ fayn, mɔ prɛsis ɛj dɛn.

● Stress factors: Fɔ ɔndastand di strɛs factor dɛm wae di matirial go bi sɔbjɛkt to na impɔtant tin. Bevels kin bi mɔ aprɔpriet in ay-stress aplikeshɔn bikɔs ɔf dɛn abiliti fɔ distribyut strɛs mɔ ifɛktiv wan.

● Manufakchurin prɔses: Di manufakchurin prɔses we dɛn dɔn pik de ple impɔtant pat bak pan dis disishun. fכ egzampl, di prכsεs dεm we involv welding כ adhesives kin nid bεvεl ed dεm fכ optimal risal.

Kost analisis fɔ Bevels ɛn Chamfers .

Material ɛn prodakshɔn kɔst fɔ Bevels .

Insay di arena fɔ mek, kɔst efyushɔn de ple wan impɔtant pat. We i kam pan bɛvɛl, di men tin we dɛn kin pe atɛnshɔn pan kin bɔku tɛm pan di matirial ɛn prodakshɔn kɔst dɛn we gɛt fɔ du wit dɛn krieshɔn. Di prɔses fɔ mek bɛvɛl kin involv ɔda matirial yus bikɔs ɔf di angul kɔt we dɛn nid. Dis kin mek dɛn west bɔku ɛn, bikɔs ɔf dat, di kɔst fɔ di matirial kin bɔku. Apat frɔm dat, di prodakshɔn prɔses fɔ bɛvɛl dɛn kin nid spɛshal mashin ɔ tul dɛn bɔku tɛm, we kin ɛlevɛt di kɔst mɔ, mɔ insay kes dɛn usay dɛn nid ay prɛsishɔn.

Chamfering: Efisiensi ɛn kɔst sevings

Di ɔda we, dɛn kin si Chamfering bɔku tɛm as ɔda we we nɔ go tek bɔku mɔni. Di prɔses fɔ chamfering jɔs involv simpul kɔt, we dɛn kin ɛksɛkutiv wit standad mashin dɛn we de na bɔku pan di manufakchurin fasiliti dɛn. Dis kin rilizɔt insay less matirial west ɛn ridyus prodakshɔn tɛm, translet to signifyant kɔst sevings, patikyula in big-big prodakshɔn. Chamfering, bikɔs ɔf in simpul ɛn efyushɔn, bɔku tɛm na di go-to chuk fɔ prɔjek dɛn usay badjɛt kɔnstrakshɔn na impɔtant kɔnsyans.

Disain Kɔmplisiti ɛn Assosiated Ɛkspɛns dɛn .

Di kɔmplisiti fɔ di dizayn de ple wan big pat fɔ no di kɔst. Bevels, we dɛn kin yuz bɔku tɛm na mɔ kɔmpleks dizayn, kin mek dɛn gɛt ay prodakshɔn ɛkspɛns bikɔs ɔf di intrikas dɛn we de insay dɛn ɛgzikishɔn. Chamfers, wit dɛn stret dizayn, kin ɔltɛm nɔ ad bɔku kɔmplisiti to di manufakchurin prɔses, we kin mek dɛn bi mɔ badjɛt-frenli opshɔn insay sɛnɛriɔ usay dizayn simpuliti na di ki.

Prɛsishɔn ɛn tolɛreshɔn in kɔst ɛvalueshɔn .

Di rikwayd lɛvɛl fɔ prɛsishɔn ɛn tolɛreshɔn de factor bak insay di kɔst. Bevels, we dɛn kin yuz bɔku tɛm na aplikeshɔn usay prɛsishɔn impɔtant, lɛk na ay-stres ɔ ay-impakt ɛnvayrɔmɛnt, kin nid fɔ gɛt ɔda prɔses ɛn kwaliti chɛk, we kin ad mɔ to di kɔst. Chamfers, bikɔs jɔs lɛk aw i nɔ bin rili impɔtant pan prɛsishɔn, i nɔ go nid fɔ mek dɛn kayn bɔku bɔku kwaliti kɔntrol mɛzhɔ dɛn ya, we de gi mɔ kɔst-ɛfɛktiv sɔlvishɔn insay di sityueshɔn dɛn usay di tolɛreshɔn lɛvɛl dɛn na mɔdaret lenient.

We yu pik di rayt ed: Bevel ɔ Chamfer .

Projekt gol ɛn matirial tin dɛn fɔ tink bɔt .

We yu de pik bitwin Bevels ɛn Chamfers fɔ wan prɔjek, di fɔs step involv fɔ rili asɛs di prɔjek gol dɛn ɛn di tin dɛn we de insay. Dis disishun nɔto jɔs bɔt aesthetics; Na wan stratejik chuk we de impɔk di funkshɔnaliti, sef, ɛn ɔvala sakses fɔ di prɔdak.

Factors fɔ tink bɔt:

● Tayp ɔf matirial: Difrɛn matirial dɛn kin riak difrɛn we to ed tritmɛnt dɛn. Fɔ ɛgzampul, di tin dɛn we at fɔ du kin fayn fɔ di bɛvɛl dɛn fɔ mek dɛn gɛt strɔkchɔral intɛgriti, we di tin dɛn we soft kin bɛtɛ wit chamfers fɔ mek i izi fɔ handle.

● Ɛnd-yuz fɔ di prɔdak: Di we aw dɛn want fɔ yuz di prɔdak de ple impɔtant pat. If di prɔdak gɛt bɔku wear ɔ strɛs, i go fayn fɔ mek wan bɛvɛl fayn. Di ɔda we, fɔ prɔdak dɛn we nid fɔ yuz smɔl strɔng wan, wan Chamfer kin du fɔ am.

Aesthetic apil ɛn sefty factors .

Di aesthetic apil ɛn sefty factors na ikwal impɔtant insay di disizhɔn-mɛkin prɔses. Pan ɔl we Bevels kin gi wan mɔ sofistikieted, ay-ɛnd luk, Chamfers de gi klin ɛn mɔdan apinans. Sef na di men tin, mɔ na di prɔdak dɛn we pipul dɛn kin yuz fɔ bay tin dɛn. Chamfers, bay we dɛn pul shap kɔna dɛn, kin mek di sef aspek fɔ di prɔdak dɛn go bifo.

Aesthetic ɛn sefty tin dɛn fɔ tink bɔt:

● Yuz Intarakshɔn: Prodakt dɛn we di wan dɛn we de yuz am kin handle bɔku tɛm kin bɛnifit frɔm Chamfer fɔ mek dɛn nɔ gɛt injuri frɔm shap ed.

● Visual Impact: Fɔ prɔdak usay dizayn ɛn vijual apil impɔtant, di chukchuk bitwin wan Bevel ɛn Chamfer kin rili impɔk di ɔvala aesthetic.

Badget kɔnsidareshɔn dɛn na edj sɛlɛkshɔn .

Badjɛt kɔnstrakshɔn kin dikte di fisibiliti fɔ di manufakchurin chus. Di kɔst-ɛfɛktiv we di Bevels ɛn Chamfers gɛt difrɛn bay di kɔmplisiti fɔ di dizayn ɛn di prodakshɔn prɔses we involv.

Evaluate di kɔst implikashɔn dɛn:

● Di we aw dɛn de mek tin dɛn: Dɛn kin nid mɔ spɛshal mashin ɔ tul dɛn, ɛn dis kin mek dɛn gɛt mɔ kɔst fɔ mek dɛn prodyuz dɛn. Chamfering, bɔku tɛm i nɔ kin rili kɔmpleks, kin mek i nɔ tek bɔku mɔni.

● Material Wastage: Tink bɔt di pɔtnɛshɛl matirial west we de insay di bevel we yu kɔmpia am wit chamfering. Mɔr west kin mek yu gɛt mɔ kɔst.

Dɔn

Rikap fɔ Bevels ɛn Chamfers insay Fabrikeshɔn .

As wi de dɔn wi ɛksplɔrɔshɔn insay di wɔl fɔ Bɛvɛl ɛn Chamfa, i klia se dɛn edj tayp ya na mɔ pas jɔs dizayn ditil. Dɛn na intagral ɛlimɛnt dɛn we rili impɔk di funkshɔnaliti, aesthetics, ɛn ɔvala sakses fɔ di prɔdak dɛn we dɛn mek. Bevels, wit dɛn angled cuts, ɛnhans strɔkchɔral intɛgriti ɛn dɛn impɔtant insay aplikeshɔn dɛn we nid strɔng jɔyn ɛn ay strɛs tolɛreshɔn. Chamfers, na di ɔda say, na impɔtant tin fɔ mek dɛn sef, izi fɔ asembli, ɛn kɔntribyut to di slip finish fɔ di prɔdak.

Tru dis diskushɔn, wi dɔn delv insay difrɛn aspek dɛm fɔ Bevels ɛn Chamfers, frɔm dɛn fawndeshɔnal difinishɔn ɛn dizayn prinsipul dɛm to dɛn prɛktikal aplikeshɔn dɛm akɔdin to difrɛn industri dɛm. Wi dɔn ɛgzamin aw dɛn edj tayp ya kɔmpia insay dizayn intent, funkshɔnal difrɛns, ɛn aesthetic impakts. Di impɔtants fɔ prɛsis mɛzhɔmɛnt ɛn di impak we strɔkchɔral intɛgriti gɛt pan di chukchuk bitwin Bɛvɛl ɛn Chamfa dɛn bin aylayt bak.

Gaydɛns fɔ pik di rayt edj .

We i de mek di chukchuk bitwin wan Bevel ɛn wan Chamfer, i klia se pɔsin fɔ tink bɔt bɔku bɔku tin dɛn. Di disishun nɔto jɔs tin we pɔsin kin tink bɔt ɔ we pɔsin kin want fɔ it fayn fayn wan. Bifo dat, i hinj pan dip ɔndastandin fɔ di matirial we dɛn de yuz, di funkshɔn rikwaymɛnt dɛn fɔ di prɔdak, di aesthetic autkam we dɛn want, ɛn badjɛt kɔnstrakshɔn.

Fɔ di wan dɛn we de na di fild fɔ mek ɛn dizayn, di men tin we dɛn fɔ tek na fɔ aproch di chukchuk fɔ Bevels ɛn Chamfers wit wan kɔmprɛhɛnsif pɔsitiv. Tink bɔt aw ɛni edj tayp go intarakt wit di matirial prɔpati dɛm, wetin strɛs di prɔdak go mit insay in layfsaykl, ɛn aw di ed go kɔntribyut to di yuza in ɛkspiriɛns. Plɛnti mɔ, i impɔtant fɔ wej di kɔst implikashɔn dɛn fɔ ɛni edj tayp agens di intended yus ɛn ɛkspɛkt pefɔmɛns fɔ di prɔdak.

In essential, di saksesful aplikeshɔn fɔ Bevels ɛn Chamfers in Manufacturing na tɛstamɛnt fɔ di metikul plan ɛn tink gud wan fɔ tink bɔt ɔl dɛn tin ya. I de sho wan harmoni blend fɔ injinɛri prɛsishɔn, aesthetic sensibiliti, ɛn prɛktikal funkshɔnaliti, we de kulminat in prodak dɛm we nɔto jɔs visually apil bɔt bak robust ɛn yuz-frenli.

As wi de dɔn, mɛmba se di chukchuk bitwin Bevel ɛn Chamfer nɔto jɔs smɔl ditel na di dizayn prɔses. Na disishun we go ebul fɔ difayn di kwaliti, di tɛm we yu go ebul fɔ tek, ɛn di apil we yu prɔdak gɛt.

FAQs: Bevels ɛn Chamfers in manufakchurin

Insay dis chapta, wi tɔk bɔt kwɛstyɔn dɛn we pipul dɛn kin aks bɔku tɛm bɔt Bɛvɛl ɛn Chamfa, we de gi wi sɛns we de mek wi ɔndastand mɔ bɔt dɛn impɔtant tin dɛn ya we dɛn de mek.

Wetin na di men tin dɛn we de apin bitwin Bɛvɛl ɛn Chamfa?

Bevɛl dɛn:

● Di rizin: Dɛn kin yuz am mɔ fɔ pripia ed dɛn fɔ jɔyn di prɔses dɛn, mɔ we dɛn de wɛl.

● Karakta: Bevels involv kot edj na angle we no perpendicular to di matiryal in safa.

● Aplikeshɔn: Kɔmɔn na sɛnɛriɔ usay dɛn nid strɔng jɔyn dɛn, lɛk insay mɛtal fabrikeshɔn ɛn wud wok.

Chamfers:

● Di rizin: Dɛn mek am fɔ pul shap ed dɛn fɔ mek i sef, izi fɔ ol, ɛn fayn fayn tin dɛn.

● Karakta: Chamfers na tipikli yunifom kot, bɔku tɛm na 45-digri angle.

● Aplikeshɔn dɛn: Dɛn kin yuz am na difrɛn difrɛn prɔdak dɛn frɔm fɔnicha to mɛkanikal pat dɛn fɔ kɔnsuma sef ɛn fɔ mek dɛn ebul fɔ gɛda dɛn fayn fayn wan.

Aw Bevels ɛn Chamfers kin kɔntribyut to di aesthetic valyu fɔ wan prɔdak?

Bevɛl dɛn:

● Aesthetics: Bɔku tɛm, bɛvɛl dɛn kin ad wan sofistikiet ɛn ditayla luk to prɔdak dɛn. Dɛn kin mek wan ilyushɔn fɔ thin ɛn fayn, mɔ we dɛn de wok na glas ɔ fayn fayn wud wok.

Chamfers:

● Aesthetics: Chamfers lend wan klin, modɛn apinans. Di krisp layn ɛn smol transishɔn dɛn we dɛn de gi kin rili ɛp fɔ mek wan prɔdak in vishɔnal apil bɛtɛ.

Yu tink se patikyula tin dɛn de we de wok bɛtɛ wit bɛvɛl ɔ chamfa?

● Bevels: Jɛnɛral wan i kin wok mɔ pan tik, at matirial usay di jɔyn trɛnk na di men tin, lɛk mɛtal ɛn had wud.

● Chamfers: Bɔku tɛm dɛn kin yuz am pan difrɛn tin dɛn, lɛk plastic, mɛtal, ɛn sɔft wud, usay ed sef ɛn aesthetic na di men tin dɛn we de mɔna dɛn.

Aw di kɔst kɔnsidareshɔn dɛn kin difrɛn bitwin Bevels ɛn Chamfers?

● Bevels: Tend fɔ bi mɔ kɔst bikɔs ɔf di prɛsishɔn we dɛn nid fɔ du na di kɔt prɔses ɛn di pɔtnɛshɛl fɔ matirial west.

● Chamfers: Bɔku tɛm, dɛn kin yuz mɔ kɔst-ɛfɛktiv bikɔs ɔf dɛn simpul dizayn ɛn di izi we aw dɛn de impruv am na di manufakchurin prɔses.

Yu tink se dɛn kin yuz bɛvɛl ɛn chamfa dɛn fɔ chenj dɛnsɛf na sɔm sɛnɛriɔ dɛn?

Wail Bevels en Chamfers kin somtem de savi di sem kayn wok, dem no tipikli intachenjabl bicos of dem distinkt kwaliti en di difren purposes dem savi. Bɔt, insay sɔm aplikeshɔn dɛn, di chukchuk bitwin wan bɛvɛl ɛn wan Chamfer kin bi inflɔwɛns mɔ bay aesthetic prɛferɛns ɔ manufakchurin kɔvinɛns pas bay funkshɔnal nid.

Fɔ no mɔ ɔ sɔm patikyula kwɛstyɔn dɛn bɔt bɛvɛl, chamfer, ɛn dɛn aplikeshɔn dɛn na manufakchurin, yu kin rich to di ɛkspɛkt dɛn na di Tim MFG we de wok fɔ di kɔmni . Dɛn kin gi dip tin dɛn fɔ no ɛn ansa ɛni kwɛstyɔn we yu go aks bɔt di tɔpik.