Wetin na CNC mashin ripa?

Di we aw yu de si di pikchɔ dɛn: 0

Aks fɔ aks kwɛstyɔn dɛn .

Wetin na CNC mashin ripa? Ɔndastand di impɔtant tin fɔ mek dɛn kɔntinyu fɔ gɛt ɛn mek di CNC ikwipmɛnt dɛn bak .

Sho:

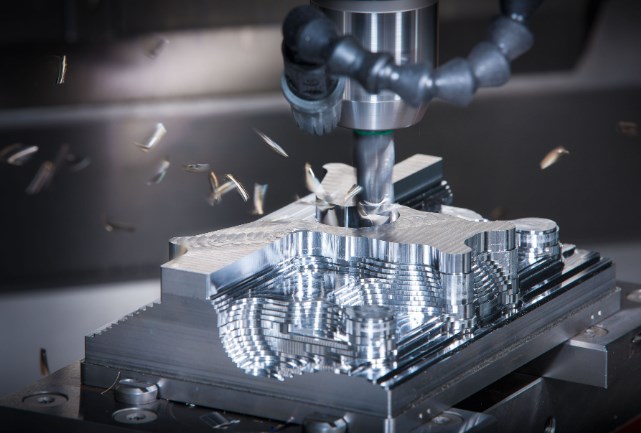

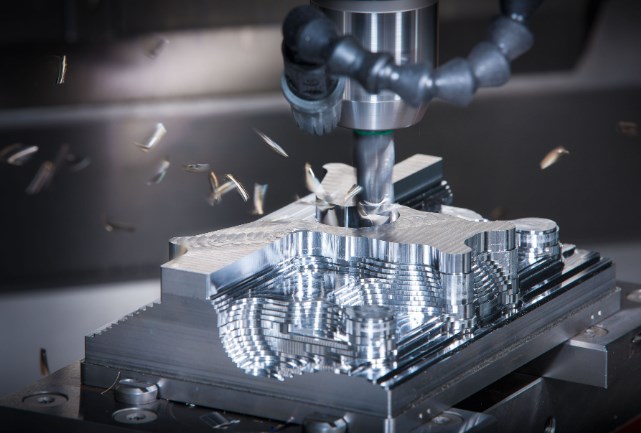

Insay di advans manufakchurin land skay tide, . CNC (kɔmpyuta nɔmba kɔntrol) mashin dɛn de ple wan impɔtant pat fɔ prodyuz intrikɛt ɛn prɛsis kɔmpɔnɛnt dɛn akɔdin to difrɛn industri dɛn. Dɛn sofistikieted mashin dɛn ya de abop pan kɔmpleks sistɛm ɛn kɔmpɔnɛnt dɛn fɔ wok fayn fayn wan. Bɔt, lɛk ɛni mɛkanikal ɔ ilɛktronik ikwipmɛnt, CNC mashin dɛn kin izi fɔ wɛr, te, ɛn nɔ wok fayn as tɛm de go. Na de CNC mashin ripa de kam in ple. Insay dis atikul, wi go fɛn ɔl wetin CNC mashin ripa ɛntayl ɛn wetin mek i impɔtant fɔ mek dɛn kɔntinyu fɔ gɛt di bɛst pefɔmɛns fɔ dɛn kɔt-ɛj manufakchurin tul dɛn ya.

Difinishɔn fɔ CNC mashin ripa:

CNC mashin ripa de tɔk bɔt di prɔses fɔ no, no, ɛn sɔlv di prɔblɛm dɛn we kin apin na CNC mashin dɛn. I involv skilled teknishian ɔ spɛshal pipul dɛn we gɛt dip no bɔt CNC sistɛm, programin langwej, ɛn mɛkanikal kɔmpɔnɛnt dɛn. Di praymar gol fɔ CNC mashin ripa na fɔ briŋ bak di ikwipmɛnt to in optimal funkshɔn stet, minimiz dauntaym, ɛn mek shɔ se kɔrɛkt ɛn rilibul prodakshɔn.

Di we aw fɔ no bɔt di sik:

We CNC mashin mit wit wan malfunction ɔ i de sho sayn dɛm fɔ diminished pefɔmɛns, di ripa prɔses tipikli bigin wit wan thorough diagnostic assessment. Di tɛknishian dɛn we gɛt ɛkspiriɛns kin yuz bɔku bɔku tul dɛn, sɔftwɛl dɛn, ɛn di we aw dɛn kin du tɛst fɔ no di men tin we mek di prɔblɛm apin. Dis kin min fɔ chɛk di mistek lɔg dɛn, fɔ du inspekshɔn dɛn we dɛn kin si, fɔ tɛst di ilɛktronik kɔmpɔnɛnt dɛn, ɛn fɔ chɛk if di mɛkanikal pat dɛn kɔrɛkt.

Mekanikal Ripair dɛn:

CNC mashin dɛn kin gɛt difrɛn mɛkanikal kɔmpɔnɛnt dɛn lɛk spindl, tul chenj, aks, ɛn bia. As tɛm de go, dɛn kɔmɔpɛnshɔn ya kin gɛt wear, misalignment, ɔ damej, we kin mek dɛn nɔ du di wok fayn ɔ dɛn kin brok kɔmplit wan. CNC mashin ripa kin involv fɔ ripɛnt ɔ riples dɛn mɛkanikal tin ya fɔ mek di mashin wok bak. Skiled teknishian dɛn kin yuz spɛshal tul dɛn ɛn fala prɛsis prosidyuz fɔ mek shɔ se dɛn alaynɛshɔn fayn, lɔbrik, ɛn kalibreshɔn fɔ dɛn impɔtant pat dɛn ya.

Ilɛktrik ɛn ilɛktronik ripɛnt dɛn:

CNC mashin dɛn kin rili abop pan ilɛktrik ɛn ilɛktronik sistem fɔ kɔntrol dɛn opareshɔn. Fɔ mek ilɛktrik ɛn ilɛktronik tin dɛn, na fɔ sɔlv prɔblɛm dɛn ɛn fɔ mek tin dɛn fayn we gɛt fɔ du wit waya, kɔnɛkshɔn, pawa saplai, motoka drayv, ɛnkɔda, ɛn sɔrkwit bɔd dɛn. Teknishian dɛn we sabi fɔ ɔndastand di intrikɛt waya dayagram ɛn ilɛktrik skematik fɔ CNC mashin dɛn kin no di fɔlt dɛn ɛn ripɛnt ɔ riples di kɔmpɔnɛnt dɛn we nɔ fayn fɔ mek dɛn ebul fɔ du di rayt wok bak.

Softwe ɛn programin:

CNC mashin dɛn de wok tru kɔmpyuta softwe we de chenj dijital dizayn dɛn to prɛsis instrɔkshɔn fɔ di mashin. Fɔ mek di softwe ɔ di program aspek dɛn fɔ CNC mashin dɛn, na fɔ sɔlv prɔblɛm dɛn we de mek dɛn nɔ ebul fɔ sɔlv di prɔblɛm, fɔ sɔlv di prɔblɛm dɛn we gɛt fɔ du wit di kɔmpitishɔn, ɛn fɔ ɔpdet ɔ tink bak bɔt di softwe fɔ mek shɔ se di mashin ɛn di kɔntrol sistem kɔrɛkt kɔrɛkt wan. Skiled teknishian dɛn kin nid fɔ wok klos wit programma dɛn fɔ kɔrɛkt prɔblɛm dɛn we gɛt fɔ du wit sɔftwɛl fayn fayn wan.

Prɛventiv Mentɛnans: .

Apat frɔm di ripɛnt, CNC mashin mentenɛns de pe atɛnshɔn pan di tin dɛn we dɛn fɔ du fɔ mek dɛn nɔ gɛt bɔku prɔblɛm fɔ mek dɛn nɔ gɛt bɔku prɔblɛm ɛn fɔ mek di mashin in layfspan nɔ bɔku. Dis inklud rutin inspekshɔn, klin, lɔbrikeshɔn, ɛn kalibreshɔn prosidyuz. Rigyul prɛvɛntiv mentenɛns schedule dɛn de ɛp fɔ no di prɔblɛm dɛn we kin apin bifo dɛn go bifo, ridyus di dawt tɛm we dɛn nɔ plan ɛn maksimayz di prodaktiviti ɛn lɔng layf we di CNC ikwipmɛnt gɛt.

Dɔn:

CNC mashin ripa savis na wan impɔtant aspek fɔ mentɛn di efyushɔn ɛn rilaybiliti fɔ . CNC mashin dɛn na di mɔdan manufakchurin ɛnvayrɔmɛnt dɛn. Wit dɛn kɔmpleks mɛkanikal, ilɛktrik, ɛn softwea sistem, dɛn mashin ya nid spɛshal no ɛn skil fɔ no ɛn sɔlv prɔblɛm dɛn fayn fayn wan. Bay we dɛn de invɛst insay di rayt tɛm ripɛnt, prɛvɛntiv mentenɛns, ɛn di ɛkspɛriɛns we skilful tɛknishian dɛn gɛt, di wan dɛn we de mek dɛn kin mek shɔ se dɛn CNC mashin dɛn de wok we dɛn de wok fayn, dɛn kin mek di tɛm we dɛn de wok nɔ bɔku, dɛn kin mek dɛn gɛt mɔ prɔdaktiviti, ɛn dɛn kin mek dɛn wok go bifo.