Wetin mek mɔ manifakta dɛn de shift to ay-miks lɔw-volyum (HMLV) manufakchurin na tide in makit we de chenj kwik kwik wan? As di kɔnsuma dimand dɛn de bi mɔ ɛn mɔ pɔsnalayz ɛn di prɔdak layfsaykl dɛn de shrink, tradishɔnal mas prodakshɔn we dɛn de yuz nɔ go du fɔ bɔku industri dɛn igen. HMLV manufacturing dɔn kɔmɔt as wan impɔtant strateji, we de mek kɔmni dɛn ebul fɔ prodyuz bɔku bɔku prɔdak dɛn we smɔl smɔl we dɛn de mentɛn efyushɔn ɛn kwaliti.

Frɔm mɛdikal divays to lɔjishɔn motoka, dis fleksibul manufakchurin apɔch de rivɔlɔshɔn aw kɔmni dɛn de mit difrɛn kɔstɔma nid dɛn. Insai dis blog, wi go explor wetin HMLV manufakchurin bi, wetin mek i impɔtant, ɛn aw biznɛs kin impliment am saksesful wan.

Wetin na di ay-miks lɔw-volyum (HMLV) manufakchurin?

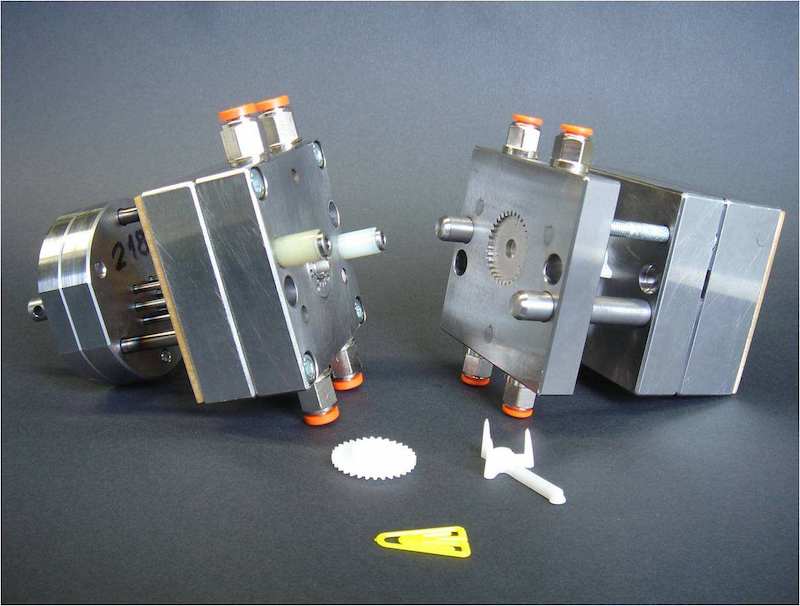

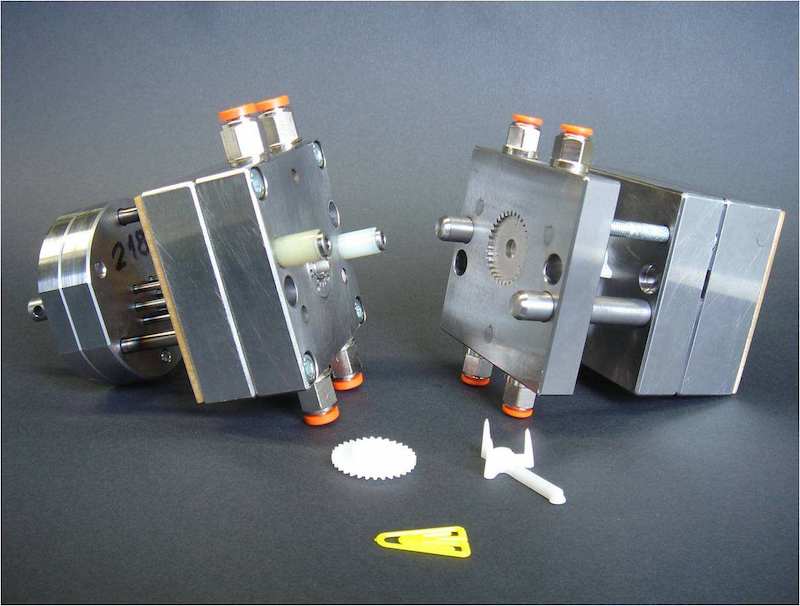

High-Mix Low-Volume (HMLV) manufakchurin na wan modɛn prodakshɔn aprɔch we de pe atɛnshɔn fɔ mek bɔku bɔku prɔdak dɛn we smɔl smɔl. Dis manufakchurin strateji dɔn kɔmɔt as rispɔns to di grow makɛt dimand fɔ kɔstɔmayshɔn, fleksibiliti, ɛn kwik prodak divɛlɔpmɛnt. Nɔ lɛk tradishɔnal mas prodakshɔn we dɛn de yuz, HMLV manufakchurin de ɛmpɛsh adaptabiliti ɛn kɔstɔmayshɔn pas standad ɛn volyum.

Breaking dɔŋ di 'High-Mix' kɔmpɔnɛnt

High-Mix de tɔk bɔt di prodakshɔn fɔ difrɛn difrɛn prɔdak ɔ prɔdak vɛryushɔn insay di sem manufakchurin fasiliti. Dis inklud:

Product Diversity : Bɔku bɔku prɔdak layn dɛn wit difrɛn spɛsifikɛshɔn dɛn .

Customization Options : Difrɛn dizayn dɛn, matirial dɛn, ɛn kɔnfigyushɔn dɛn .

Prodakshɔn Fleksibiliti : Abiliti fɔ chenj bitwin difrɛn prɔdak dɛn kwik kwik wan .

Difrɛn spɛsifikɛshɔn dɛn : difrɛn manufakchurin rikwaymɛnt fɔ ɛni prɔdak tayp .

Ɔndastand di 'lɔ-volyum' aspek

Lɔw-volyum prodakshɔn de sho se:

Smɔl batch saiz dɛn : prodakshɔn kwantiti dɛn we de frɔm sɔm yunit dɛn to sɔm tawzin

Make-to-Order : Manufacturing based on specific customer requirements

Limited prodakshɔn rɔn : shɔt prodakshɔn saykl fɔ ɛni prɔdak vayriɔnt

Kwik Turnaround : Abiliti fɔ kɔmplit smɔl ɔda dɛn fayn fayn wan .

Aw HMLV difrɛn frɔm tradishɔnal manufakchurin .

Tradishonal manufakchurin vs. HMLV : .

Ki kwaliti dɛn fɔ HMLV prodakshɔn sistem dɛn .

Di men tin dɛn we de na HMLV manufakchurin na:

Fleksibul prodakshɔn layn dɛn : Ikwipmɛnt ɛn prɔses dɛn we dɛn kin kɔnfigyut kwik kwik wan fɔ difrɛn prɔdak dɛn .

Advans Kwaliti Kɔntrol : Sofistikeyt inspekshɔn sistem dɛn lɛk Indastrial CT skan fɔ mentɛn kɔnsistɛns akɔdin to difrɛn prɔdak layn dɛn

Skilled Workforce : Di wan dɛn we dɔn tren fayn fayn wan we ebul fɔ handle difrɛn prodakshɔn prɔses dɛn .

Digital Integration : Smart Manufacturing Systems we kin ebul fɔ manej bɔku bɔku prɔdak spɛsifikɛshɔn dɛn ɛn wokflɔ dɛn

Efficient Setup Management : Kwik chenj ova kapabiliti fɔ swich bitwin difrɛn prɔdak dɛn

Kastamɔ-sɛntrik aprɔch : Prodakshɔn prɔses dɛn we dɛn mek rawnd sɔm patikyula tin dɛn we di kɔstɔma dɛn nid ɛn wetin dɛn nid fɔ du ɛn wetin dɛn nid

HMLV manifakta dɛn kin ɔprɛt na industri usay kɔstɔmayshɔn ɛn prɛsishɔn impɔtant, lɛk:

Erospes komponent dɛn .

Divays dɛn fɔ mɛn pipul dɛn .

Luxury motoka dɛn .

Ay-ɛnd Kɔnsuma Ilɛktroniks .

Kastom Spɔtin Ikwipmɛnt .

Dis manufakchurin aprɔch ripresent wan impɔtant shift frɔm tradishɔnal mas prodakshɔn mɛtɔd, we de ɔfr big fleksibiliti ɛn kɔstɔmayshɔn kapabiliti dɛn we de mentɛn efyushɔn ɛn kwaliti standad. As di dimand fɔ di makit de kɔntinyu fɔ evolv to mɔ pɔsnalayz prɔdak dɛm, HMLV manufakchurin dɔn bi impɔtant mɔ ɛn mɔ insay di mɔdan manufakchurin strateji dɛm.

Di impɔtant tin we de gro bɔt HMLV manufakchurin .

Di tin dɛn we de apin naw na di makit we de drɛb HMLV adopshɔn .

Di kɔnsuma dimand shift de rivɔlɔshɔn di we aw dɛn de mek tin dɛn:

Grɔw Prɛferɛns fɔ pɔsnalayz prɔdak dɛn .

Diman we de go ɔp fɔ kwik prɔdak itɛreshɔn dɛn .

Rising ekspekteshɔn fɔ prodak kɔstɔmayshɔn .

Shorta Prodakt Layf Saykl dɛn .

Maket dinamik we de push to HMLV inklud:

Rapid Teknɔlɔji Advansmɛnt dɛn .

Chenj we de chenj di tin dɛn we pipul dɛn lɛk fɔ yuz .

Globɛl Kɔmpitishɔn .

Nid fɔ fasta tɛm-to-maket .

Wetin mek tradishɔnal mas prodakshɔn nɔto ɔltɛm di ansa .

Limiteshɔn fɔ mas prodakshɔn na di mɔdan makit dɛn:

3. Rial-wɔl aplikeshɔn dɛn fɔ HMLV manufakchurin .

HMLV manufacturing dɔn fɛn saksesful aplikeshɔn dɛn akɔdin to difrɛn industri dɛn, ɛni wan de yuz in yon kapabiliti fɔ mit spɛshal makɛt dimand ɛn di kɔstɔma dɛn rikwaymɛnt.

3.1 Ɔtomotiv Indastri .

Kastom lɔjishɔn motoka dɛn ripresent wan praymɛnt ɛgzampul fɔ HMLV manufakchurin:

Personalised Interior Konfigyushɔn dɛn .

Bespoke Ekstirian modifyeshɔn dɛn .

Kastom kala skim ɛn finish dɛn .

Limitɛd Ɛdyushɔn Mɔdel Prodakshɔn .

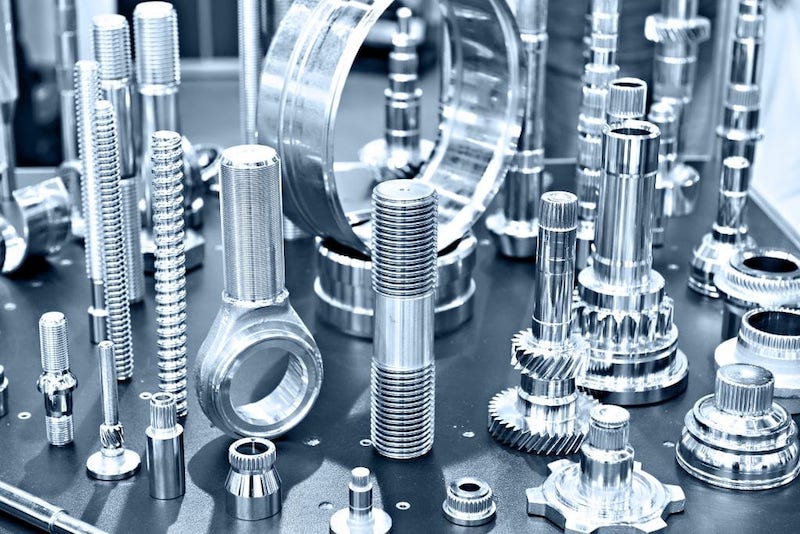

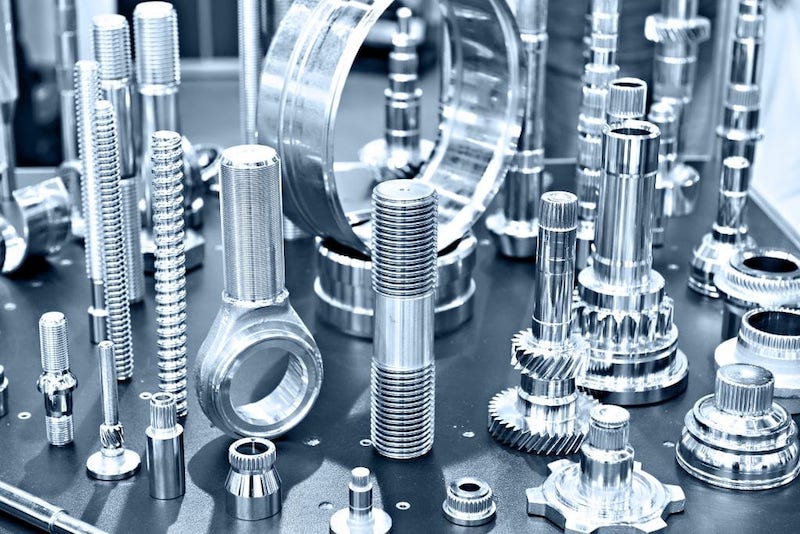

Speshal otomotiv komponent dɛn inklud:

Kastɔm ɛkzoz sistɛm dɛn .

Modified enjin komponent dɛn .

Speshal saspɛns sistem dɛn .

Yunik bɔdi panɛl ɛn aerodaynamik ɛlimɛnt dɛn .

Pɔfɔmɛnshɔn pat dɛn manufakchurin de pe atɛnshɔn pan:

Hay-perfomans brek sistem dɛn .

Kastɔm Turbocharger asɛmbli dɛn .

Resin-spɛsifi k kɔmpɔnɛnt dɛn .

Speshal transmishɔn pat dɛn .

3.2 Aerospace ɛn Difɛns .

Di komponent dɛn we de na di ayrakt de sho kɔmpleks HMLV aplikeshɔn dɛn:

Kastɔm Aviɔniks ɛnklɔzhɔ dɛn .

Speshal Fastening sistem dɛn .

Yunik strɔkchɔral ɛlimɛnt dɛn .

Mishɔn-spɛsifi k modifyeshɔn dɛn .

Di kɔstɔm fɔ mek tin dɛn we dɛn mek wit tɔbayn involv:

turbine blades we gɛt prɛsishɔn-ɛnjɛnɛri .

Specialized Cooling Systems .

Kombushɔn fɔ Kɔmbɔshɔn .

Di pat dɛn we dɛn dɔn chenj .

Specialized militri ekwipment inklud:

Kastom Kɔmyunikeshɔn Sistɛm dɛn .

Specialized Armor komponent dɛn .

Mishɔn-spɛsifi k modifyeshɔn dɛn .

Yunik taktik ikwipmɛnt .

3.3 Divays fɔ Mɛdikal .

Customized Implants Showcase Advanced HMLV Di tin dɛn we pɔsin kin ebul fɔ du:

Di wan dɛn we de tek pat pan di sikman dɛn fɔ chenj di we aw dɛn de du di wok .

Kastɔm spɛshal implant dɛn .

Personalised Cranial Plates .

Taylor Ɔtopɛdik Sɔlwɛshɔn dɛn .

Patient-specific surgical instruments ficha:

Kastɔm kɔt gayd dɛn .

Spɛshal Sɔjmɛnt Tul dɛn .

Prɛsis Mɛzhɔmɛnt Divays dɛn .

Yunik posishunin instrumɛnt dɛn .

Dental alayna ɛn prostɛtiks de sho prɛsishɔn HMLV:

Kastɔm dɛnt alaynɛs .

Personalized dental implants .

Yunik prostetik komponent dɛn .

Individyual ɔtodɔnt aplayans dɛn .

3.4 Kɔnsuma Ilɛktroniks .

Di ay-ɛnd ɔdio ikwipmɛnt de sho HMLV ɛksɛlɛns:

Speshal gadget dɛn na:

Kastom Gem Kɔntrola dɛn .

Modified Kɔmpyuta Pɛrifɛral dɛn .

Yunik Intafɛs Divays dɛn .

Limitɛd rɔn ilɛktronik prɔdak dɛn .

Kastom Ilɛktronik Kɔmpɔnɛnt dɛn Ficha:

Ɛni wan pan dɛn aplikeshɔn ya de sho aw HMLV manufakchurin de adap to spɛshal industri nid dɛn we i de mentɛn ay kwaliti ɛn efyushɔn. Di sakses we HMLV gɛt pan dɛn industri ya de sho in versatility ɛn effektivnes fɔ mit spɛshal prodakshɔn rikwaymɛnt dɛn. Tru advans teknɔlɔji dɛn lɛk industrial CT skan ɛn sofistikieted kwaliti kɔntrol mɛzhɔ, manifakta dɛn kin mek shɔ se kɔnsistɛns ɛn prɛsishɔn akɔdin to difrɛn prɔdak layn dɛn we dɛn de mentɛn di fleksibiliti we dɛn nid fɔ kɔstɔm prodakshɔn.

4. Di bɛnifit dɛn we di wan dɛn we de mek tin dɛn we gɛt ay-mik-volyum nɔ de wok fayn .

Prodakshɔn Fleksibul Advantej dɛn .

Adaptiv manufakchurin kapabiliti riprizent wan pan di mɔs impɔtant advantej dɛn fɔ HMLV manufakchurin. Kɔmni dɛn kin chenj kwik kwik wan bitwin difrɛn prɔdak layn dɛn, chenj di prodakshɔn prɔses, ɛn akɔmod difrɛn batch saiz dɛn we nɔ gɛt ɛni signifyant dawt tɛm. Dis fleksibiliti de alaw manifakta dɛn fɔ:

Swich bitwin difrɛn prɔdak layn dɛn kwik kwik wan kwik kwik wan .

Modify prodakshɔn prɔses dɛn we dɛn de aks fɔ .

Akɔmod difrɛn batch saiz dɛn .

Impruv di chenj dɛn we dɛn mek fɔ dizayn kwik kwik wan .

Proses versatility de mek ɔganayzeshɔn dɛn ebul fɔ maksimayz dɛn prodakshɔn risɔs. Bay we dɛn de yuz di sem ikwipmɛnt ɛn prodakshɔn layn dɛn fɔ bɔku bɔku prɔdak dɛn, kɔmni dɛn kin ajɔst ay ikwipmɛnt yutilizeshɔn rɛt ɛn mentɛn wan mɔ fleksibul wokman dɛn. Dis inklud:

Multiple product variants na di sem layn .

I izi fɔ mek dɛn put nyu prɔdak dɛn .

Efisiɛns ikwipmɛnt yutilizeshɔn .

Fleksibul wokfɔs diploymɛnt .

Di tin dɛn we dɛn dɔn mek fɔ mek di kɔstɔma dɛn satisfay .

Customization Benefits Directly impact customer satisfaction in HMLV manufacturing environments. We dɛn de mek prɔdak dɛn we dɛn mek fɔ sɔm patikyula tin dɛn we di kɔstɔma dɛn nid, kɔmni dɛn kin ebul fɔ gi dɛn di rayt tin dɛn we dɛn kɔstɔma dɛn nid, we dɛn nid am. Dis we fɔ du tin de mek shɔ se:

Prodakt dɛn we dɛn mek fɔ sɔm patikyula tin dɛn we di kɔstɔma dɛn nid

Rapid rispɔns to di kɔstɔma dɛn we de aks fɔ am .

Personalized Product Fitur dɛn .

Enhansed kastoma engagement .

Kwaliti fos kin bi mɔ achievable in HMLV manufakchurin bikɔs ɔf di smɔl batch saiz ɛn inkris atɛnshɔn to ditiɛl. Wit fכs yunit dεm we dεn de prodyuz wan tεm, kwaliti kכntrכl mεzhɔ kin bi mכr strεng, we kin rεsult in:

Invɛntari ɔptimayzeshɔn .

Lian invɛntari manejmɛnt na natura autkam fɔ HMLV manufakchurin apɔch. We dɛn de mek smɔl smɔl batch dɛn bay we dɛn de yuz di rial dimand, di kɔmni dɛn kin ridyus di kɔst dɛn we dɛn kin yuz fɔ kip tin dɛn bad bad wan ɛn mek dɛn nɔ gɛt bɔku prɔblɛm dɛn we kin mek dɛn nɔ de wok igen, ɛn dis kin mek dɛn:

Ridyus di kɔst fɔ kip di tin dɛn we dɛn dɔn kip .

Minimal Stock Holding .

Di risk fɔ di risk we nɔ de wok fayn .

Bɛtɛ Kɛsh Flɔ Manejmɛnt .

Jɔs-in-taym prodakshɔn kin bi mɔ feasible ɔnda HMLV manufakchurin. Kɔmni dɛn kin impruv mek-to-ɔda strateji dɛn we de minimiz stɔrɔj rikwaymɛnt ɛn ridyus west, ɛnabul:

mek-to-ɔda manufakchurin .

Ridyus di tin dɛn we dɛn nid fɔ kip .

Efisiɛns matirial yutilizeshɔn .

di west we dɔn go dɔŋ .

Kwik makɛt rispɔns kapabiliti .

Maket adaptabiliti de gi HMLV manifakta dɛn wan impɔtant kɔmpitishɔn advantej. Di abiliti fɔ ansa kwik kwik wan to di makit tren ɛn tɛst nyu prɔdak kɔnsɛpt dɛn de alaw kɔmni dɛn fɔ:

Rispɔnd to di tin dɛn we de apin na di makit kwik kwik wan .

Test Nyu Prodakt Kɔnsɛpt dɛn .

Adrɛs Niche Maket dimand dɛn .

Lanch prodakt dɛn fast fast .

Kɔmpitishɔn advantej de ɛnhans tru fasta tɛm-to-maket kapabiliti ɛn kwik dizayn itɛreshɔn. Dis responsiveness de mek:

Di chans dɛn we de fɔ mek nyu tin dɛn .

Prodakt divεl כpmεnt bεnεfit sכmtεm frכm HMLV mεnεjmεnt kεpabiliti. Di abiliti fɔ kwik fɔ protɔtayp ɛn tɛst nyu dizayn dɛn de gi:

Rapid prototayping kapabiliti dɛn .

I izi fɔ tɛst di prɔdak .

Kwik dizayn validɛshɔn .

Efisiɛns Itereshɔn Saykl dɛn .

Teknɔlɔji intagreshɔn kin bi mɔ we dɛn kin manej na HMLV ɛnvayrɔmɛnt, we kin mek:

Advans we dɛn dɔn mek fɔ mek tin dɛn .

Dijital prɔses ɔptimayzeshɔn .

Smat faktri implimɛnt .

Kɔntinyu fɔ mek di wok go bifo .

Stratejik bɛnifit dɛn fɔ HMLV manufakchurin de ɛkstɛnd akɔdin to bɔku eria dɛn:

Biznɛs Grɔw : .

Opareshɔnal Ɛksɛlɛns : .

Di kɔmbaynshɔn fɔ dɛn bɛnifit ya de mek HMLV manufakchurin bi wan opshɔn we de atraktiv mɔ ɛn mɔ fɔ kɔmni dɛn we de luk fɔ kɔmpit insay tide in dinamik makɛt ɛnvayrɔmɛnt. Bay we dɛn ebul fɔ gɛt mɔ fleksibiliti, impɔtant kɔstɔma satisfayshɔn, ɔptimayz invɛntari manejmɛnt, kwik makɛt rispɔns, ɛn ɛnhans inovashɔn kapabiliti, HMLV manufakchurin de gi wan sɔlid fawndeshɔn fɔ sataynabul biznɛs gro ɛn sakrifays.

5. Kɔmɔn chalenj dɛn na HMLV manufakchurin .

5.1 Opareshɔn Chalenj dɛn .

Prodakshɔn kɔmplisiti prɛzɛnt impɔtant chalenj dɛn na HMLV ɛnvayrɔmɛnt dɛn. Fɔ manej bɔku bɔku prɔdak vɛryushɔn dɛn wan tɛm nid sofistikiet scheduling sistem ɛn tek tɛm kɔdinɛt di risɔs dɛn. Ɔganayzeshɔn dɛn fɔ jug difrɛn matirial rikwaymɛnt dɛn, kɔmplikɛt wokflɔ patɛn, ɛn intrikɛt prɔses sikyud, ɔl di tɛm we dɛn de mentɛn efyushɔn ɛn mit di delivri dedlayn dɛn.

Sɛtup tɛm manejmɛnt dɔn bi wan impɔtant kɔnsyans na HMLV manufakchurin. Di chenj we dɛn kin chenj bɔku tɛm bitwin difrɛn prɔdak dɛn kin mek dɛn gɛt bɔku dawt ɛn dɛn kin ridyus di prɔdaktiviti. Di kɔmni dɛn fɔ optimize dɛn sɛtup prosidyuz dɛn we dɛn de manej:

Kɔmpleks tul dɛn we dɛn nid .

Ikwipmɛnt Rikɔnfigyushɔn Nid dɛn .

Prodakshɔn Layn Adjɔstmɛnt dɛn .

Proses Valideshɔn Step dɛn .

Kwaliti verifyeshɔn prosidyuz dɛn .

Di wokman dɛn trenin rikwaymɛnt dɛn de mek yunik chalenj dɛn na HMLV ɛnvayrɔmɛnt dɛn. Di difrɛn kayn we aw dɛn de mek tin dɛn de aks fɔ mek dɛn gɛt wokman dɛn we gɛt bɔku sɛns we ebul fɔ du bɔku bɔku prɔses ɛn prɔdak dɛn. Di wokman dɛn nid fɔ gɛt bɔku trenin fɔ:

Divɛlɔp bɔku tɛknikal skil dɛn .

Mek yu no aw fɔ du di wok fayn fayn wan .

Adapt to chenj dɛn we kin apin ɔltɛm .

Handle difrɛn kayn ikwipmɛnt dɛn .

Ɔndastand kwaliti rikwaymɛnt dɛn .

Ikwipmɛnt yutilizeshɔn chalenj dɛn kɔmɔt frɔm di nid fɔ balans fleksibiliti wit efyushɔn. Machinery must bi adaptable inaf fɔ handle difrɛn prodak spɛsifikɛshɔn dɛn we de mentɛn optimal pefɔmɛns lɛvɛl dɛn. Dis nid fɔ tek tɛm plan fɔ:

5.2 Kwaliti Kɔntrol Chalenj dɛn .

Mentɛn kɔnsistɛns kwaliti kin bi mɔ ɛn mɔ kɔmpleks insay HMLV manufakchurin. Di difrɛn difrɛn prɔdak dɛn ɛn di chenj dɛn we dɛn kin chenj di we aw dɛn kin du tin ɔltɛm kin mek i nɔ izi fɔ mek dɛn kɔntinyu fɔ gɛt yunifom kwaliti standad. Ɔganayzeshɔn dɛn fɔ divɛlɔp strɔng kwaliti kɔntrol sistem dɛn we kin adap to difrɛn prɔdak spɛsifikɛshɔn dɛn we dɛn de mek shɔ se dɛn gɛt kɔnsistɛns autput kwaliti.

Inspekshɔn mɛtɔd dɛn nid fɔ gɛt signifyant sofistikieshɔn na HMLV ɛnvayrɔmɛnt dɛn. Di kɔmni dɛn nid fɔ impruv:

Bɔku bɔku inspekshɔn protɔkol dɛn .

Di we aw dɛn de du di wok we dɛn dɔn du fɔ tɛst .

difrɛn kwaliti krayteria dɛn .

Kɔmpleks mɛzhɔmɛnt sistem dɛn .

Spɛshal Inspekshɔn Ikwipmɛnt .

Dokumɛnt rikwaymɛnt dɛn dɔn bi mɔ dimand wit HMLV manufakchurin. Ɛni prɔdak vɛriɛnt nid ditayla dɔkyumentri kɔva:

Proses spɛsifikɛshɔn dɛn .

Kwaliti Paramita dɛn .

Di we aw dɛn de du di tɛst .

Di tin dɛn we dɛn fɔ du fɔ mek pipul dɛn obe di lɔ .

Traceability Rikɔd dɛn .

Kwaliti ɛshyureshɔn prɔses dɛn nid fɔ tek tɛm pe atɛnshɔn na HMLV sɛtin dɛn. Ɔganayzeshɔn dɛn fɔ divɛlɔp kɔmprɛhɛnsif sistɛm dɛn we kin ebul fɔ handle di kɔmplisiti fɔ bɔku bɔku prɔdak layn dɛn we dɛn de mentɛn strikt kwaliti standad dɛn. Dis inklud fɔ impruv:

Robust validation prosidur dɛn .

Di prɔses dɛn we dɛn kin du ɔltɛm .

Kɔntinyu fɔ wach di sistem dɛn .

Kɔrɛkt Akshɔn Prɔtokɔlɔ dɛn .

Di we aw dɛn de trak di wok we dɛn de du .

5.3 Kɔst Manejmɛnt .

Prayz strateji dɛn na HMLV manufakchurin nid fɔ tek tɛm tink bɔt bɔku tin dɛn. Di kɔmni dɛn fɔ mek prayz mɔdel dɛn we de akɔn fɔ:

Variable prodakshɔn kɔst dɛn .

Sɛtup di tɛm ɛkspɛns dɛn .

Smɔl batch inefisiɛns dɛn .

Di tin dɛn we dɛn nid fɔ du fɔ kɔstɔmayz .

Maket Pozishɔn .

Rishɔs alɔkeshɔn kin bi patikyula chalenj na HMLV ɛnvayrɔmɛnt. Ɔganayzeshɔn dɛn fɔ tek tɛm balans dɛn risɔs akɔdin to bɔku bɔku prɔdak layn dɛn we dɛn de mentɛn efyushɔn. Dis involv stratejik planin fɔ:

Invɛstmɛnt kɔnsidareshɔn dɛn nid fɔ evaluate gud gud wan insay HMLV manufakchurin. Di kɔmni dɛn fɔ tek tɛm asɛs dɛn invɛstmɛnt nid dɛn na:

Fleksibul Ikwipmɛnt Sistem dɛn .

Advans Tɛknɔlɔji dɛn .

Di Wokman Trenin Program dɛn .

Di tin dɛn we dɛn dɔn bigin fɔ du fɔ mek di prɔses go bifo .

Kwaliti Kɔntrol Sistɛm dɛn .

Kost ridyushɔn tɛknik dɛn de pe atɛnshɔn fɔ mek dɛn kɔntinyu fɔ wok pan ɔl we di HMLV ɔpreshɔn dɛn kɔmplikt. Ɔganayzeshɔn dɛn fɔ impruv strateji fɔ:

Minimizing Sɛtup Taym dɛn .

Fɔ ridyus di west .

Optimizing prɔses dɛn .

Fɔ mek di wokman dɛn wok fayn .

Maksimayz matirial yutilizeshɔn .

Di saksesful manejmɛnt fɔ dɛn chalenj ya nid fɔ gɛt balans apɔch we de kam togɛda wit stratejik planin wit ɔpreshɔnal ɛksɛlɛns. Ɔganayzeshɔn dɛn fɔ divɛlɔp kɔmprɛhɛnsif sɔlvishɔn dɛn we de adrɛs ɔl tu di kwik ɔpreshɔnal nid ɛn lɔng tɛm stratejik gol dɛn we dɛn de mentɛn di fleksibiliti ɛn rispɔnsiv we HMLV manufakchurin dimand dɛn.

6. Implimɛnt HMLV manufakchurin saksesful wan .

6.1 Impɔtant Tɛknɔlɔji dɛn .

Indastrial CT skan dɔn rivɔlɔshɔn kwaliti kɔntrol na HMLV manufakchurin. Dis teknɔlɔji de mek dɛn ebul fɔ tɛst ɛn inspekshɔn pan kɔmpleks pat dɛn we nɔ de pwɛl, we de gi ditayl insayt insay intanɛnt strɔkchɔ dɛn, ditekshɔn we nɔ de wok kwik, ɛn kɔmprɛhɛnsif kwaliti validɛshɔn we nɔ gɛt kɔmprɔmis prɔdak dɛn.

Advans inspekshɔn sistem dɛn de mek shɔ se kwaliti kɔnsistɛns de akɔdin to difrɛn prɔdak layn dɛn. Dɛn sistem ya de kam togɛda fɔ ɔtomɛshɔn wit prɛsis mɛzhɔmɛnt kapabiliti, we de gi rial-taym monitarin, ɔtomatik difɛkt ditekshɔn, ɛn data-driv kwaliti manejmɛnt fɔ bɔku bɔku prɔdak vɛryushɔn.

Dijital wok instrɔkshɔn dɛn transfɔm prodakshɔn flo ɔpreshɔn bay we dɛn de mek shɔ se dɛn de ɛksɛkutiv di prɔses we dɛn de du ɔltɛm ɛn dɛn de kip fleksibiliti. Dɛn de gi klia vijual gayd, ɛnabul rial-taym ɔpdet, ɛn sav as valyu trenin tul fɔ ɔpreshɔn dɛn we de manej bɔku prɔses.

Manufacturing Execution Systems (MES) de intagret difrɛn aspek dɛn fɔ prodakshɔn manejmɛnt. Dɛn sistɛm ya de gi rial-taym visibiliti, ɛnabul efyushɔn risɔs alɔkeshɔn, ɛn fasilit kwik rispɔns to prodakshɔn chenj dɛn akɔdin to bɔku prɔdak layn dɛn.

6.2 Proses Optimayzeshɔn .

Standardizing methods balans konsistens wit fleksibiliti wit fleksibiliti in HMLV implimentishon. Ɔganayzeshɔn dɛn de establish standad prosidyuz dɛn we dɛn de mentɛn adaptabiliti fɔ difrɛn prɔdak rikwaymɛnt dɛn, ridyus mistek ɛn impɔtant efyushɔn akɔdin to prɔdak layn dɛn.

Flɔ ɔptimayzeshɔn de pe atɛnshɔn fɔ impɔtant matirial muvmɛnt, prodakshɔn sikyud, ɛn risɔs yutilizeshɔn. Dis inklud fɔ minimiz bɔtul-nɛk, ridyus sɛtup tɛm, ɛn mek shɔ se di transishɔn dɛn go fayn bitwin difrɛn prɔdak rɔn dɛn.

Kɔmyunikeshɔn improvements de mek shɔ se dɛn gɛt fayn fayn kɔdineshɔn na kɔmpleks HMLV ɔpreshɔn dɛn. Klia kɔmyunikeshɔn chanɛl, rɛgyula tim mitin, ɛn dijital tul fɔ rial-taym ɔpdet de ɛp fɔ mek dɛn kɔntinyu fɔ gɛt smol smol opareshɔn dɛn akɔdin to dipatmɛnt dɛn.

Invɛntari Manejmɛnt Strateji dɛn de handle bɔku bɔku prɔdak layn dɛn we dɛn de mentɛn efishɔnal invɛntari lɛvɛl dɛn. Dis inklud fɔ impruv jɔs-in-taym sistɛm dɛn, smat stɔrɔj sɔlvishɔn dɛn, ɛn fayn fayn we dɛn fɔ tɔk bɔt.

6.3 Di tin dɛn we dɛn fɔ tink bɔt na di wokples .

Di tin dɛn we dɛn nid fɔ du fɔ tren pipul dɛn kin pripia wokman dɛn fɔ handle bɔku bɔku prɔdak ɛn prɔses dɛn. Kɔmprɛhɛnsif program dɛn de kɔba tɛnki skil, kwaliti ɔwe, ɛn sefty prosidyuz, we dɛn sɔpɔt bay kɔntinyu fɔ lan chans.

Skil divɛlɔpmɛnt de mek di wokman dɛn ebul fɔ manej bɔku bɔku prɔses dɛn we dɛn de mentɛn kwaliti standad. Structured aprɔch dɛn de kam togɛda fɔmal trenin wit on-the-job ɛkspiriɛns, ɛn mek shɔ se di wokman dɛn ebul fɔ wok akɔdin to difrɛn prɔdak layn dɛn.

Tim ɔganayzeshɔn de promot krɔs-fɔnshɔn kapabiliti ɛn klia kɔmyunikeshɔn. Tim dɛn strɔkchɔ fɔ ansa kwik kwik wan to chenj prodakshɔn rikwaymɛnt dɛn we dɛn de mentɛn kɔnsistɛns kwaliti ɛn efyushɔn.

Knowledge Management de kapchɔ ɛn sheb di bɛst prɔsis, prosidur, ɛn ɛkspɛriɛns. Dis inklud fɔ kip infɔmeshɔn ripɔtayshɔn, mentɔri program, ɛn fayn fayn we fɔ transfa no ɔlsay na di ɔganayzeshɔn.

Di saksesful implimɛnt ɔf HMLV manufakchurin nid fɔ intagret tɛknɔlɔji, ɔptimayz prɔses, ɛn divɛlɔp wokfɔs kapabiliti. Rigyul asesmɛnt ɛn ajɔstmɛnt fɔ strateji dɛn de mek shɔ se dɛn gɛt lɔng tɛm sakrifays na dɛn kɔmpleks manufakchurin ɛnvayrɔmɛnt ya.

Dɔn

We wi de luk bifo, HMLV manufakchurin go kɔntinyu fɔ gro insay impɔtants as makit dɛn de aks fɔ mɔ pɔsnalayz prɔdak ɛn shɔt prodakshɔn saykl. Sakses in dis manufakchurin aprɔch nid fɔ tek tɛm balans bitwin fleksibiliti ɛn efyushɔn, sɔpɔt bay kɔntinyu impɔtant improvement in prɔses, tɛknɔlɔji, ɛn wokfɔs kapabiliti.

Na Team MFG, wi spɛshal pan ay-miks lɔw-volyum manufakchurin sɔlvishɔn dɛn we dɛn tayl fɔ yu yon nid dɛn. Ilɛksɛf yu de luk fɔ ɛp fɔ mek di prodakshɔn ebul fɔ chenj di we aw dɛn de mek tin dɛn, fɔ mek yu ebul fɔ kɔntrol di kwaliti fayn fayn wan, ɔ fɔ mek yu ebul fɔ mek di tin dɛn we yu de mek, wi ɛkspɛkt tim de ya fɔ ɛp. Kontakt wi tide fɔ diskɔba aw wi HMLV ɛkspɛriɛns kin drɛb yu manufakchurin sakses.

Transfom yu manufakchurin fiuja wit Team MFG.