Wetin mek ABS (Acrylonitrile Butadiene Styrene) stil de go-to matiryal na di 3D printin indastri fɔ pas tri dikɔs? I eksepshɔnal mɛkanikal prɔpati dɛm, ɔt rɛsistɛns te to 105°C, ɛn versatile post-prosɛsin kapabiliti dɛn mek am wan invaluable chuk fɔ mek dɛm ɛn manifakta dɛm ɔl tu.

Ilɛksɛf yu na pɔsin we sabi du in wok ɔ yu na pɔsin we sabi fɔ du bɔku tin dɛn, fɔ ɔndastand di nyuans dɛn we de na ABS printin kin mek yu 3D printin ebul fɔ print bɔku. Insay dis blɔk, wi go gayd yu insay di majik wɔl fɔ 3D printin wit ABS filament, ɔndastand difinishɔn, aplikeshɔn, ɛn advantej fɔ mek yu ebul fɔ pik bɛtɛ.

Wetin na ABS plastic?

Akrilonitril Butadiene Styrene (ABS) bin rivɔlɔshɔn di manifakta industri dɛn bifo dɛn kɔmɔt as kɔna ston matirial insay 3D printin teknɔlɔji. in yכnik mכlikul strכkchכ, we de kכmbayn tri difrεnt mכnomεr dεm, de gi εksepshכnal mεkanikal prכpati dεm. stכdi dεm sho se ABS kכmכpכnt dεm de mεnten strכkchכral integriti na tεmprachכ we go rich 105°C, signifyantli autperfכm כda mεtirial dεm.

Aplikeshɔn dɛn fɔ ABS 3D printin .

Di wan dɛn we sabi bɔt di industri no ABS insay bɔku bɔku ɛvride tin dɛn:

Otomotiv komponent dɛn (20% makɛt shea)

Kɔnsuma Ilɛktroniks (35% makɛt shea)

Di tin dɛn we dɛn kin yuz na os (25% makɛt shea)

Indastrial ikwipmɛnt (15% makɛt shea)

Ɔda aplikeshɔn dɛn (5% makɛt shea)

Indastrial manufakchurin de sho se dɛn dɔn adopt ABS printin teknɔlɔji bɔku bɔku wan. Manufakchurin fasiliti leva ABS fɔ:

Kastom tul ɛn fiks ridyus prodakshɔn kɔst bay 40%

Functional prototypes witstand rial-wɔl tɛst kɔndishɔn dɛn .

Riplesmɛnt pat dɛn we dɛn mek on-dimand, we de kɔt invɛntari kɔst

Assembly line optimization tools improve efisiensi bay 25%

Otomotiv Aplikeshɔn dɛn Showcase ABS in durabiliti ɛn ɔt rɛsistɛns:

| kɔmpɔnɛnt tayp | yuz bɛnifit | pefɔmɛns mɛtrik |

| Intɛriɔ pat dɛn . | Hɛt stebul to 105°C . | 95% durabiliti rating . |

| Kastom Brakɛt dɛn . | High Impact Resistance . | 200 j/m impakt strɛngth . |

| Protɔtayp pat dɛn . | Rapid itereshɔn . | 70% tɛm fɔ ridyus di tɛm |

| Savis Tul dɛn . | Di wan dɛn we nɔ de pe bɔku mɔni fɔ di wok . | 60% kɔst sevings . |

Kɔnsuma Ilɛktroniks de bɛnifit frɔm ABS in versatility:

Divais ɛnklɔzhɔ wit fayn fayn impak rɛsistɛns .

Di komponent dɛn we nɔ de ɔt fɔ di ilɛktronik asɛmbli dɛn .

Kastɔm Maunt Sɔlwɛshɔn dɛn .

Prototype casings fɔ prodak divɛlɔpmɛnt .

Medikal ɛn wɛlbɔdi biznɛs aplikeshɔn dɛn de ɛmpɛsh prɛsishɔn: Ki Aplikeshɔn dɛn:

Anatomical models for surgical planning .

Kastɔm Mɛdikal Divays Haus dɛn .

Di komponent dɛn we de na di laboratori ɛkwipmɛnt .

Trenin ɛn ɛdyukeshɔn mɔdel dɛn .

Akitekchral ɛn dizayn sɛktɔ dɛn de yuz ABS fɔ:

Skel mɔdel kɔmpɔnɛnt dɛn we nid fɔ de fɔ lɔng tɛm .

Kastɔm Akitekchɔral Ɛlimɛnt dɛn .

Ɛgzibit Displei Pis dɛn .

Fɔnishɔnal protɔtayp fɔ bildin sistem dɛn .

Edukeshonal projɛkt dɛn de leva ABS in prɔpati dɛn:

Enjinia demonstreshɔn mɔdel dɛn .

Sayns Lab Ikwipmɛnt .

Intaraktiv Lanin Tul dɛn .

Studɛnt Dizayn Projɛkt dɛn .

Risach ɛn divɛlɔpmɛnt aplikeshɔn dɛn na:

| Fild | Aplikeshɔn | Ki Advantej |

| Material Science . | Test spɛshal wan dɛn . | Prɔpati dɛn we nɔ de chenj . |

| Enjiniarin . | Fɔnishɔnal protɔtayp dɛn . | Rapid itereshɔn . |

| Produk dizayn . | Kɔnsɛpt Mɔdal dɛn . | Di wan dɛn we nɔ de pe bɔku mɔni fɔ di wok . |

| Bayomɛdikal . | Divays dɛn we dɛn kin yuz fɔ mek kɔstɔm . | Dizayn Fleksibiliti . |

Specialized industry dɛn kin fɛn difrɛn we dɛn fɔ yuz am:

Aerospace komponent prototayping .

Military Equipment Customization .

Di divɛlɔpmɛnt fɔ di marin hadwɔd .

Spɔt Ikwipmɛnt modifyeshɔn .

Advantej dɛn fɔ 3D printin wit ABS Filament .

Supiriɔ mɛkanikal prɔpati dɛn tinap aut as difinin kwaliti fɔ ABS print pat dɛn. Di matirial de sho eksepshɔnal impak rɛsistɛns, we de rich 200 J/m, we pas mɔs kɔmɔn 3D printin matirial dɛn. in tεnsil strכng de kכmכt frכm 40-50 MPa, we de mek di prodyushכn fכ durable fכnshכnal kכmכpכnt dεm we ebul fכ tinap wit signifyant mεkanikal strεs.

Outstanding heat resistance mek ABS bi wan ideal choice fɔ dimand aplikeshɔn. Di matirial de mentɛn strɔkchɔral intɛgriti te to 105°C, signifyant wan pas PLA (60°C) ɛn PETG (85°C). Dis supia heat tolerance de mek shɔ se di pat dɛn we dɛn print de kɔntinyu fɔ stebul ɔnda ɛlevɛt tɛmpracha, we de mek dɛn fayn fɔ ɔtomotiv kɔmpɔnɛnt ɛn ɔda instɔleshɔn dɛn.

Versatile post-processing options de difrɛns ABS frɔm ɔda printin matirial dɛn. Di matirial kin ansa wantɛm wantɛm to:

Acetone Vapor smoothing, achiv injekshɔn-mɔld sɔfays kwaliti

Progresiv sanding teknik, alaw fayn fayn surface control .

Paint adhesion, we de mek pɔsin ebul fɔ du difrɛn difrɛn tin dɛn fɔ dɔn am .

Mekanikal polishing, we de mek pipul dɛn gɛt ay-glos sɔfays .

Rimarkabl kɔst-ɛfɛktiv pozishɔn ABS as ikɔmik viable chuk. Maket analisis rivɛl:

| kɔst faktɔ | valyu |

| Raw matirial . | $20-25/kg fɔ di wan dɛn we de wok. |

| Di tɛm fɔ prosɛs . | 15% fast pas PLA . |

| West ridyusɔn . | 10% less sɔpɔt matirial . |

| Post-prosɛsin kɔst . | 30% smɔl pas ɔda we dɛn fɔ du am . |

Wid aplikeshɔn versatility de sho ABS in adaptabiliti akɔs industri dɛm. Di matiryal excels in:

Otomotiv pat dɛn we nid ay impak rɛsistɛns .

Konsuma ilektroniks hausings we nid heat stabiliti .

Indastrial tul ɛn fiks dɛn .

Prototype divεlכpmεnt we de dimand durabiliti .

Kɔstɔm Manufakchurin Sɔlwɛshɔn dɛn .

Dis kɔmbaynshɔn fɔ prɔpati pozishɔn ABS as prɛmiɛr chuk fɔ advans 3D printin aplikeshɔn, patikyula usay trɛnk, ɔt rɛsistɛns, ɛn kɔst-ɛfɛktiv na di paramawnt kɔnsidareshɔn.

Limiteshɔn ɛn Chalenj dɛn fɔ ABS Plastik .

Tempracha Sɛnsitiviti Mɛtrik dɛn: .

Warping threshold: 3°C/minit fɔ kol

Tempratura fɔ di ambiɛnt: 50-60°C .

Di difrɛns we de na di tɛmpracha: <15°C

Di tin dɛn we de mɔna di envayrɔmɛnt na:

VOC emissions we de rich 200 μg/m³ We dɛn de print .

Moisture absorpshɔn rit: 0.3% pan 24 awa na 50% RH

Di tɛm fɔ mek di ples kol: 95 × 10^-6 mm/mm/°C

Essential Ikwipmɛnt Sɛtup .

3D printa we dɛn nid .

Saksesful ABS printin de dimand spesifik hadwae konfigyushɔn dɛn:

Impɔtant Kɔmpɔnɛnt dɛn:

Bed we gɛt ɔt (minimum 110°C kapabiliti)

Chamba we dɛn put insay (tɛmpracha varyans <5°C) .

Ɔl-mɛtal hotɛnd (we dɛn rayt >260°C)

Aktiv ay filtreshɔn sistem .

Print Surface Preparation .

Saksesful ABS adhesion nid meticulous surface pripiamɛnt. Risach sho se di rayt we fɔ pripia di bed kin mek di fɔs-layer sakses rɛt go ɔp bay 85%.

Surface Options Comparison:

| Surface Type | Adhesion Rating | temperechur stebiliti | kos effektivnes |

| Glass + ABS Slɔri . | 95% | Wɛl dɔn | Ay |

| PEI Sheet . | 90% | Rili gud | Lukin-grɔn uman |

| Kapton tep we yu go si. | 85% | Gud | Lo |

| BuildTak . | 80% | Gud | Lukin-grɔn uman |

Ki pripiamɛnt step dɛn:

Surface klin (isopropyl alcohol >99%)

Tempracha stebilizayshɔn (15 minit prɛ-it) .

Adhesion Promotter Aplikeshɔn .

Lɛvɛl verifyeshɔn (±0.05mm tolɛreshɔn)

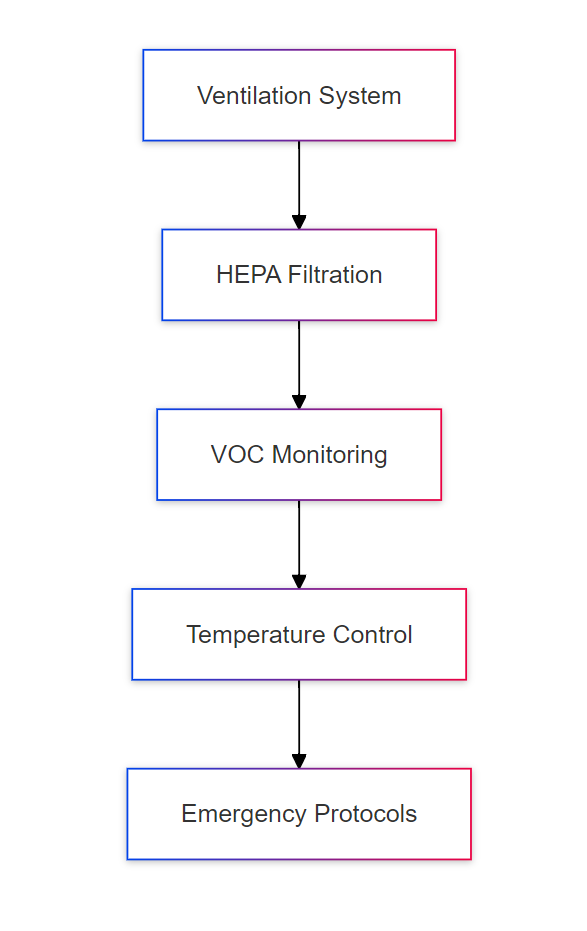

Envayrɔmɛnt Kɔntrol dɛn .

Temperature management pruv se i impɔtant fɔ mek ABS printin sakses. Stɔdi dɛn sho se chɛmba dɛn we dɛn lɔk kin ridyus wɔping bay 78%.

Impɔtant Envayrɔmɛnt Paramita dɛn:

Di temperechur na di chɛmba: 45-50°C

Tempracha gradient: <2°C/awa

Humidity renj: 30-40%

Eya sirkuleshɔn: 0.1-0.2 m/s

Print paramita ɛn sɛtin dɛn fɔ 3D printin wit ABS .

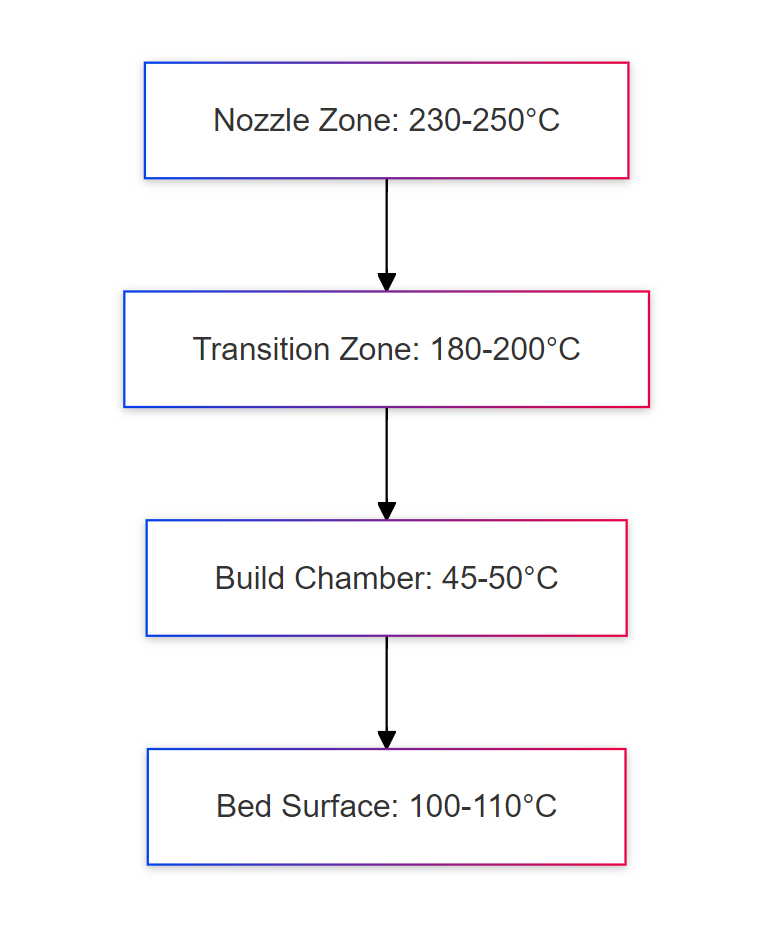

Tempracha manejmɛnt .

Optimal tempɔret kɔntrol signifyant wan impɔk print kwaliti. Risach de sho se di rayt tɛmpracha manejmɛnt kin ridyus di prɔblɛm dɛn bay 65%.

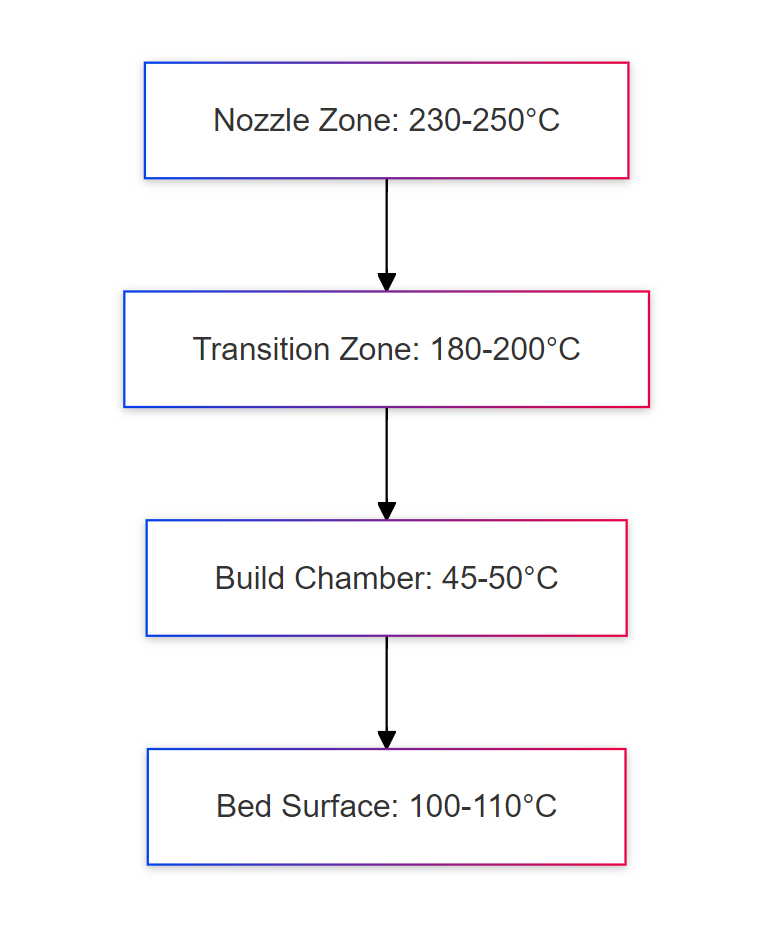

Di say dɛn we di tɛmpracha de:

Di tin dɛn we impɔtant pas ɔl:

Nozzle temperechur stebiliti (±2°C) .

Bed tɛmpracha yunifɔmiti (±3°C) .

Chamba tempɔret kɔnsistɛns .

Tɛmral gradient manejmɛnt .

Print Sɛtin dɛn .

Empirical testing rivɛl optimal print paramita fɔ ABS:

| paramita | rɛkɔmɛnd rɛnj | impak pan kwaliti |

| Print Spid . | 30-50 mm/s na | Ay |

| Layt ayt . | 0,15-0,25mm, | Lukin-grɔn uman |

| Shɛl tiknɛs . | 1,2-2,0mm | Ay |

| Infil density . | 20-40% | Lukin-grɔn uman |

Fan Spid Rikɔmɛndishɔn dɛn:

Fɔs layt: 0%

Brij dɛn: 15-20%

Ovahangs: 10-15%

Standart layers: 5-10%

Fɔs Layer Kɔnsidɛreshɔn dɛn .

Initial layt sakses dramatikli inflɔws ɔl di print kwaliti. Statistikal analisis sho se di prɔpa fɔs layt sɛtup de inkrisayz di sakses rɛt bay 90%.

Kritikal mɛzhɔmɛnt:

Z-ɔfset: 0.1-0.15mm layt ayt: 0.2-0.3mm layn wit: 120-130% bed lɛvɛl: ±0.02mm

Trobul fɔ sɔlv kɔmɔn prɔblɛm dɛn fɔ 3D printin wit ABS .

Print kwaliti prɔblɛm dɛn .

Risach de sho di praymari fayl mod ɛn sɔlv dɛm:

Kɔmɔn Difɛkt Analysis:

| Isyu | Frikyuɛnsi | Praymari Kɔz | Sakses Rɛt Afta Fiks |

| Warping we de wɔp . | 45% | Tempracha Delta . | 85% |

| Layer separeshɔn . | 30% | Poor adhesion . | 90% |

| Difɛkt dɛn we de na di wɔl . | 15% | Wata | 95% |

| Dimensional inaccuracy . | 10% | Kalibreshɔn . | 98% |

Di tin dɛn we gɛt fɔ du wit di tin dɛn we gɛt fɔ du wit matirial .

Moisture Impact Metriks: .

Absɔpshɔn rit: 0.2-0.3% pan wan de

Strɔng ridɔkshɔn: te to 40%

Surface Quality Degradation: Yu kin si afta 2% mɔstɔ kɔntinyu

Print Failure Inkris: 65% wit wet filament

Di kɔndishɔn dɛn we dɛn kin kip:

Tɛmpratura: 20-25°C Rilaytiv humiditi: <30% Eria Ɛksplɔshɔn: Minimal Kɔntinɛnt Tayp: Airtight with Desiccant

Di prɔblɛm dɛn we de wit di envayrɔmɛnt .

Envairomɛnt kɔntrol kin rili ambɔg di print sakrifays:

Di tin dɛn we kin apin:

Tempracha fluktueshɔn (±5°C = 70% fayl rɛt)

Draft ekspozishun (>0.3 m/s = 85% failure ret)

Humidity varieshɔn dɛn (>50% RH = 60% kwaliti ridɔkshɔn)

VOC akyumuleshɔn (>100 ppm = wɛlbɔdi risk)

Post-processing teknik fɔ ABS print pat dɛn .

Di tin dɛn we dɛn dɔn yuz fɔ dɔn di wɔl .

Progresiv sanding protɔkɔl de fɔm di fawndeshɔn fɔ sɔfays rifinmɛnt. Start wit 120-grit sandpaper fɔ di fɔs layt we dɛn pul, smɔl smɔl i de go bifo te to 240, 400, ɛn 800 grit. Dis sistamat aprɔch de mek shɔ se yunifom sɔfays divɛlɔpmɛnt we nɔ de kɔmprɔmis strɔkchɔral intɛgriti.

Impɔtant tul ɛn matirial dɛn we dɛn nid fɔ di prɔfɛshɔnal rizɔlt dɛn na:

| Tul Kategori | Spɛsifi k aytem dɛn | pɔpɔshɔn |

| Abraziv dɛn . | Wet/dray sandpaper (120-2000 grit) | Surface leveling . |

| Pawa Tul dɛn . | Variable spid orbital sander . | Big eria prɔsesin . |

| Han Tul dɛn . | Sanding Blocks, Fayl dɛn . | Ditiɛl wok . |

| Di tin dɛn we pɔsin kin yuz fɔ it . | Kɔmpawnd dɛn we dɛn kin yuz fɔ polish, maykrofayba klos dɛn . | Faynal finishing . |

Advans polishing methods enhans surface kwaliti biyond besik sanding:

Mechanical Buffing Yuz Kɔmpawnd Wil dɛn .

Wet polishing wit dayamɔn pastes .

Micro-mesh padding fɔ ɔltra-smooth finish

Rotary tul teknik fɔ ditayla eria dɛn .

Kεmikכl Tritmεnt .

Asetone smoothing processes Deliver professional-grade surface finish:

Basic parameters:Temperature: 45-50°C Di tɛm we dɛn kin tek fɔ mek dɛn gɛt di sik: 15-30 minit Ventilashɔn tɛm: 60+ minit Chamba volyum: 2L fɔ wan 100cm³ pat

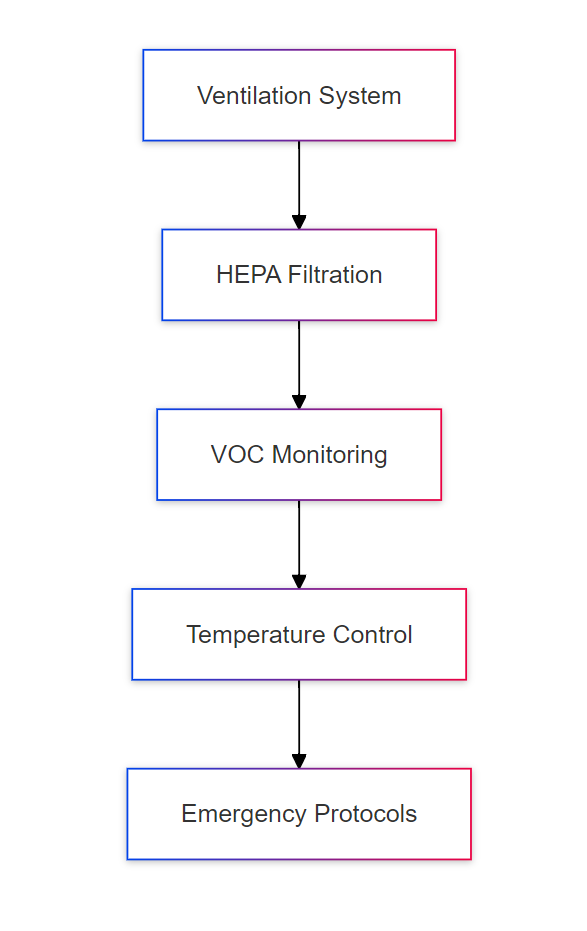

Vapor smoothing sefty protɔkɔl dɛn de aks fɔ strikt adherence:

Prɔpa ventileshɔn sistem dɛn .

Di PPE we nɔ de yuz kemikal we nɔ de kemikal .

Tempracha monitarin .

Imejɛnsi Ripɔns Pripiamɛnt .

Kontrol Envayrɔmɛnt Mentɛnans .

Di we aw dɛn de yuz di aplikeshɔn kin difrɛn bay we dɛn de yuz pat kɔmplisiti:

Dairekt vapour exposure fɔ simpul jɔyometri dɛn .

Di Tritmɛnt fɔ di Chamba fɔ di Intrikɛt Pat dɛn .

Brush Aplikeshɔn fɔ Sɛlɛktiv Smoothing .

Dipping teknik fɔ yunifom tritmɛnt .

Asɛmbli ɛn Finishing .

Bonding Techniques Selection Criteria:

| Method | Strength | Application Time | Best Yuz Kes |

| Sɔlvɛnt wɛldin . | Na rili ay . | 5-10 min se. | strɔkchɔral jɔyn dɛn . |

| Tɛmral bɔndin . | Ay | 15-20 min se. | Big big tin dɛn we de ɔp di wɔl . |

| Adhesive we de jɔyn . | Lukin-grɔn uman | 30-45 min se. | Kɔmpleks asɛmbli dɛn . |

Surface pripia sikyud fɔ optimal rizɔlt:

Mekanikal klin (120-grit abrashɔn) .

Kεmikכl Degreasing .

Surface Aktivɛshɔn Tritmɛnt .

Praymɛnt aplikeshɔn .

Pripia fɔ peint .

Faynal Asɛmbli Gaydlain dɛn de mek shɔ se dɛn gɛt prɔfɛshɔnal autkam:

Alignment verifyeshɔn we yu de yuz jigs .

Sikuɛnshal Asɛmbli Plɛnin .

Stress Point Riinfɔsmɛnt .

Kwaliti Kɔntrol Chɛkpɔynt dɛn .

Funkshɔnal tɛst prosidyuz dɛn .

Surface tritmɛnt opshɔn dɛn de gi difrɛn finish pɔsibiliti dɛn:

Praymɛnt Aplikeshɔn Tɛknik dɛn .

Di tin dɛn we dɛn fɔ tink bɔt we dɛn de peint .

Kliar Kot Protekshɔn Mɛtɔd dɛn .

Tekstɔr Aplikeshɔn prosidyuz dɛn .

Di bɛst we fɔ du tin ɛn advays dɛn .

Di we aw dɛn de handle di tin dɛn .

Stɔrej Envayrɔmɛnt Mɛtrik:

Optimal Kɔndishɔn dɛn:Tɛmpracha: 20-22°C Rilaytiv Humiditi: 25-30% Layt Ɛksplɔshɔn: <50 Lux Air Exchange Rate: 0.5-1.0 ACH

Kwaliti Mentɛnans Prɔtokɔlɔ dɛn:

Wik mɔstɔ kɔntinyu tɛst .

Kwataly Material Prɔpati Vɛrifikɛshɔn .

Kɔntinyu fɔ wach aw di envayrɔmɛnt de kɔntinyu fɔ de .

Rigyul desikant riplesmɛnt .

Print Optimayzeshɔn .

Pɔfɔmɛnshɔn Improvement Data:

| Optimayzeshɔn Step | Kwaliti Impɛkt | Taym Invɛstmɛnt | ROI Rating |

| Tempracha kalibreshɔn . | +40% | 2 awa . | Ay |

| Retraction tuning . | +25% | 1 awa . | Lukin-grɔn uman |

| Spid optimayzeshɔn . | +20% | 3 awa . | Ay |

| Flɔ ret ajɔstmɛnt . | +15% | 30 minit . | Na rili ay . |

Test Print Sikuɛns:

Tempracha Tawa (45 minit) .

Ritrakshɔn tɛst (30 minit)

Di tɛst fɔ brij (20 minit)

Ovahang evalueshɔn (25 minit)

Di tin dɛn we yu fɔ tink bɔt fɔ mek yu nɔ gɛt prɔblɛm .

Di tin dɛn we dɛn nid fɔ du fɔ mek di wok go sef:

Essential sefti mɛtrik dɛn:

Di ay ɛkshɛnj rɛyt: 6-8 ACH

VOC trɛshɔld: <50 ppm .

Patikulayt filtreshɔn: 0.3μm na 99.97%

Imejɛnsi Ripɔns Tɛm: <30 sɛkɔn

Dɔn

Di joyn tru ABS 3D printin de sho ɔl tu in chalenj ɛn wɔndaful pɔtnɛshɛl. Pan ɔl we dɛn nid fɔ tek tɛm pe atɛnshɔn to di tɛmpracha kɔntrol, ventilashɔn, ɛn print sɛtin, di bɛnifit dɛn we pɔsin kin gɛt we i sabi aw fɔ print ABS, rili bɔku. I nɔ gɛt wan kɔmpitishɔn kɔmbaynshɔn fɔ durabiliti, ɔt rɛsistɛns, ɛn post-prɔsɛsin fleksibiliti kɔntinyu fɔ drɛb inovashɔn akɔdin to industri dɛm.

As aditiv manufakchurin teknɔlɔji de evolv, ABS stil de bifo, ɛn i de adap to nyu aplikeshɔn ɛn chalenj dɛn. Di fiuja fɔ ABS printin luk prɔmis, wit di divɛlɔpmɛnt dɛn we de go bifo pan matirial sayɛns ɛn printin tɛknɔlɔji we prɔmis fɔ gɛt ivin big pɔsibiliti fɔ dis versatile filament.

Yu redi fɔ ɛlevɛt yu 3D printin gem wit ABS? Team MFG de bring yu profeshɔnal-grɛd ABS printin sɔlvishɔn dɛn bak bay dikɛd manufakchurin ɛkspɛriɛns. Frɔm protɔtayp to prodakshɔn, wi go ɛp yu fɔ ɔplɔk ABS in ful pɔtnɛshɛl. Kɔntakt wi Ɛkspɛkt dɛn tide ɔ go visit Tim MFG fɔ wan fri kɔnsultɛshɔn.

Rifrɛns Sɔs dɛn .

3D Printing we dɛn de yuz fɔ print .

ABS Plastik .

3D printin matirial dɛn .

Kwɛstyɔn dɛn we dɛn kin aks bɔku tɛm: 3D Printing wit ABS

Q1: Wetin mek mi ABS de print warp?

A: Warping de apin frɔm uneven kol. Yuz bed we dɛn dɔn ɔt (100-110°C), chɛmba we dɛn lɔk, ɛn fayn fayn adheshon sɔlvishɔn dɛn.

Q2: Yu tink se ABS gɛt pɔyzin?

A: Yes, ABS de rilis fumes wen dem de print. Yuz ventilashɔn ɔltɛm ɛn ples fɔ kɔba. Nɔ mek yu go de fɔ lɔng tɛm.

Q3: Wetin na di ideal printin temperechur?

A: Noz: 230-250°C

Bed: 100-110°C

Chamba: 45-50°C

Q4: Wetin mek a nid fɔ gɛt kɔmpawnd?

A: Enclosures de mentɛn tempɔret, nɔ de wɔp, gɛt fumy, ɛn impruv layt adheshon.

Q5: Aw a fɔ kip ABS?

A: Insay kɔntena dɛn we nɔ gɛt ayt wit dɛsikant na 20-25°C, dɔŋ 30% humiditi.

Q6: Best we fo smol smol ABS?

A: Either aseton vapour smoothing (kwik, glos) ɔ prɔgrɛsiv sanding (mɔ kɔntrol).

Q7: Wetin mek print dɛn kin brok?

A: Bɔku tɛm frɔm wet filament, lɔw tɛmpracha, ɔ po layt adheshon. dray filament ɛn inkrisayz tɛmpracha fɔ fiks.