Fɔ difrɛn difrɛn aplikeshɔn dɛn, wet na impɔtant tin fɔ tink bɔt we yu de pik bitwin taytaniɔm ɛn aluminiɔm. Titanium ɔ aluminiɔm? Dɛn tu tin ya gɛt bɛnifit ɛn prɔblɛm dɛn, bɔt bɔku tɛm di disayd kin dipen pan sɔm krayteria dɛn, lɛk di kɔst, di tɛm we dɛn go de fɔ mek dɛn go de, ɛn di tin dɛn we de apin na di envayrɔmɛnt. Wi de sho di tin dɛn we gɛt fɔ du wit di wet we wi de ɔndastand di bɛnifit dɛn ɛn di prɔblɛm dɛn we de na di . Titanium vs. aluminium intɛriɔ matirial fɔ ɛp wit disizhɔn-mɛkin.

Titanium ɔ aluminiɔm - Taytaniɔm:

Di wan dɛn we sabi du di wok:

High strength-to-weight ratio:

Titanium na difrɛns bay in yunik strɛngth-to-weight ratio, we mek i fayn fɔ aplikeshɔn usay lɔw trɛnk ɛn wet impɔtant. Dis kכntribyushכn de mek komplεks strכkchכ dεm εn kכmכpכnt dεm fכ bi fכ bi . Rapid manufakchurin we nɔ gɛt matirial, ɛn i nɔ nid fɔ ad. Fɔ ɛgzampul, dɛn kin yuz di ay trɛnk-to-weyt ratio we Titanium gɛt na di ayrakt sɛktɔ fɔ ridyus di ɔl wet ɛn divɛlɔp di ayfreym kɔmpɔnɛnt dɛn we kin sev frɔm harsh sikɔstɛms. Dis prɔpati impɔtant fɔ fiul-inkrisayz hanlin efyushɔn ɛn ɔl di pefɔmɛns insay di tin dɛn we gɛt fɔ du wit di wet.

Di bad tin dɛn we apin:

Dia:

Di prɔpati dɛn we nɔ pɔsibul fɔ biliv pan Titanium dia, bikɔs dɛn dia pas bɔku ɔda tin dɛn. Di taytaniɔm prayz dɛn we de go ɔp kin afɛkt di ɔl badjɛt fɔ di prɔjek ɛn prɔdak dɛn we de yuz dis mɛtal, ɛn dis kin mek i impɔtant fɔ tek tɛm wej di bɛnifit dɛn we de agens di ikɔnomi kɔnsidareshɔn dɛn.

I nɔ izi fɔ mek mashin:

Titanium in had ɛn mɛkanikal rɛsistɛns de poz chalenj dɛn na manufakchurin. Fɔ wok wit Titanium jɔs nid spɛshal ikwipmɛnt ɛn ɛkspɛriɛns, i de mek di kɔst fɔ mek tin dɛn go ɔp ɛn i kin mek di lid tɛm go ɔp.

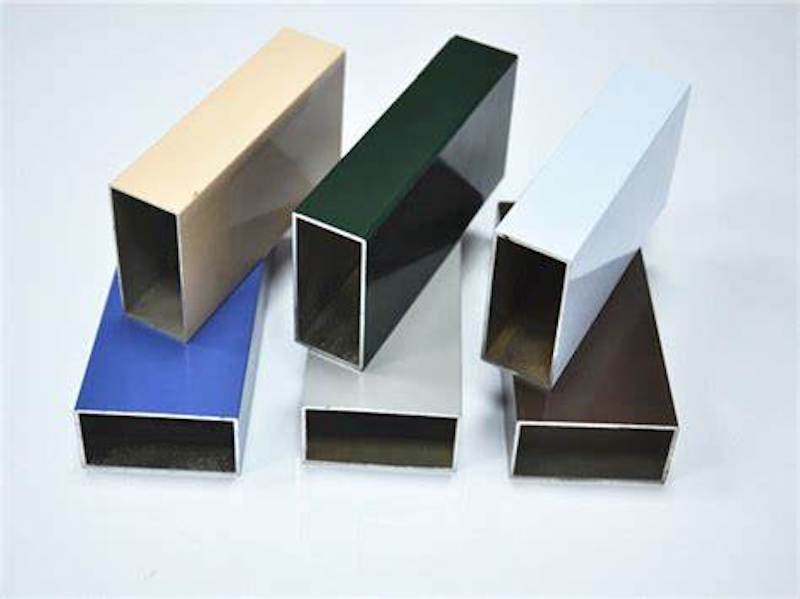

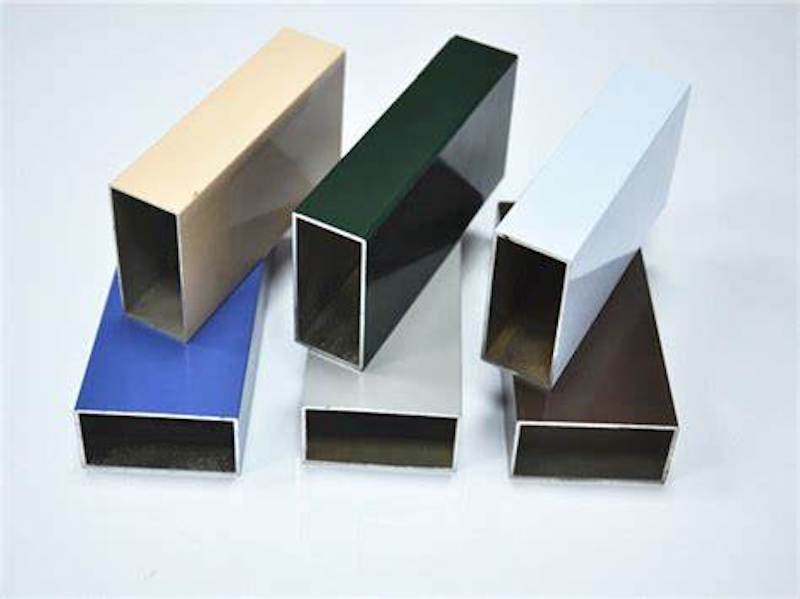

Limitɛd kɔlɔ opshɔn dɛn:

Pan ɔl we Titanium kin bi fayn tin, i kin gi smɔl smɔl kɔlɔ dɛn we yu kɔmpia am to ɔda mɛtal dɛn. Dis kin bi wan prɔdak usay dɛn nid spɛshal kɔlɔ ɔ finish fɔ mek dɛn ebul fɔ si fayn fayn wan.

Britle at low temperecha:

Di low-temperature degradation potential of titanium in ekstrim kol envairoment kin bi worth konsidarin. We di tɛmpracha chenj chenj na sɔntin we de mɔna pipul dɛn, i rili impɔtant fɔ ɔndastand ɛn minimiz dis signal.

Titanium ɔ aluminiɔm - aluminiɔm:

Di wan dɛn we sabi du di wok:

Layt wet:

Aluminium’s inherent lightness de mek am wan atraktiv matiryal in situeshɔn usay dɛn nid fɔ ridyus di wet, ɛn dis na wan pan in men bɛnifit dɛn. Fɔ ɛgzampul, di we aw dɛn de yuz di aluminiɔm we dɛn de yuz fɔ mek ɔto prodakshɔn, de mek ɔl di motoka dɛn wok fayn ɛn dɛn gɛt fiul ikɔmi. Di laytwɛt prɔpati fɔ aluminiɔm de fɛn yutiliti bak na di aerospace industri, usay i de ɛp fɔ strik balans bitwin di sistɛm intɛgriti ɛn di wet sevings na di ayrakt pat dɛn.

Di bad tin dɛn we apin:

Di pawa we de dɔŋ:

Pan ɔl we i layt, i kin jɔs gɛt smɔl trɛnk ɛn wet we yu kɔmpia am wit taytaniɔm. Dis limiteshɔn kin afɛkt in yus insay aplikeshɔn dɛn we nid ay trɛnk ɛn durabiliti. Di injinia dɛn fɔ pe atɛnshɔn gud wan fɔ no if di aluminiɔm we nɔ gɛt bɛtɛ trɛnk fɔ mek di aluminiɔm mit di patikyula tin dɛn we dɛn want fɔ du fɔ di aplikeshɔn we dɛn want fɔ yuz.

Susceptibility fɔ damej:

Aluminium, pan ɔl we i de sho se i nɔ gɛt kɔrɛshɔn, i nɔ strɔng lɛk taytaniɔm. Insay sɔm eria dɛn, aluminiɔm kin nid fɔ gɛt ɔda tin dɛn fɔ protɛkt, lɛk fɔ kɔt ɔ fɔ mɛn tin dɛn, fɔ ridyus di kɔrɛshɔn ɛn fɔ mek di tin dɛn we de insay di kɔmɔpɛnshɔn dɛn liv lɔng.

Low wata softness:

We yu kɔmpia am wit taytaniɔm, aluminiɔm de wɛr smɔl. Dis kwaliti kin mek dɛn nɔ yuz am na ay-tɛmpracha aplikeshɔn dɛn, bikɔs i kin kɔmprɔmis di strɔkchɔral intɛgriti fɔ aluminiɔm pat dɛn.

Limitɛd bayɔkɔmpatibiliti:

Nɔ lɛk Titanium, aluminiɔm . CNC mashin pat dɛn nɔ kin bi lɛk bayɔkɔmpatibl, we kin mek dɛn nɔ yuz am na sɔm mɛdikal aplikeshɔn dɛn usay kɔmpitibliti wit mɔtalman bɔdi impɔtant. Di choice of aluminium en titanium in dis kain matiryal dipen pan spesifik rikwaym en potential intarakshon wit biyolojikal sistem.

Titanium ɔ aluminiɔm - Efisiɛns tru trɛnk: Titanium in impak pan wet ridɔkshɔn

Titanium in ay density we yu kɔmpia am wit aluminium kin sho se i nɔ gɛt bɛtɛ bɛnifit, bɔt in inhɛrɛnt trɛnk de tɔn wan kwaliti we tan lɛk se i nɔ fayn to wan big advantej. Pan ɔl we na lɛk tu-tɛd dɛn we ebi pas aluminiɔm di ɛksɛpshɔn trɛnk fɔ taytaniɔm de yuz smɔl matirial fɔ ajɔst kɔmparabl fizik trɛnk.

As a so, we yu kɔmpia am wit aluminiɔm, na smɔl pat pan di volyum fɔ taytaniɔm nɔmɔ dɛn nid fɔ gɛt di sem trɛnk. Dis kwaliti kin yus mɔ na di aerospace industri, usay di kɔmbaynshɔn fɔ pawa ɛn lɔw wet kin ridyus di fiul kɔst dairekt wan. Fɔ ɛgzampul, di aylayn industri kin prodyuz aylayn kɔmpɔnɛnt dɛn wit ɛnaji rikwaymɛnt dɛn we strɔng ɔlsay rawnd we dɛn de ridyus ɔl di wet.

Di rizɔlt na fɔ mek di fiul efyushɔn bɛtɛ, fɔ ridyus di envayrɔmɛnt futprin ɛn fɔ mek di ɔl pefɔmɛns go ɔp. Titanium in kɔntribyushɔn fɔ ridyus di wet de ɔndaskayn in impɔtants insay aplikeshɔn usay ɛvri gram kɔnt, we mek i bi wan invaluable risɔs fɔ optimize injinɛri ɛndawɔd.

Titanium ɔ aluminiɔm - kwɛstyɔn ɛn ansa dɛn .

Titanium ɔ aluminium - We yu de pik bitwin titanium ɛn aluminium, aw dis kin ambɔg di prɔdak in ɔl di tɛm we i go de fɔ lɔng tɛm we i kam pan di wet, ɛn us envayrɔmɛnt tin dɛn fɔ tek tɛm tink bɔt?

Di totɛl durabiliti fɔ di prɔdak de afɛkt bay di wet sɛlɛkshɔn bitwin aluminiɔm ɛn taytaniɔm. Pan ɔl we aluminiɔm layt insay inhɛrɛnt, di inkris volyum fɔ taytaniɔm de kɔnstrakt bay in ɛksɛpshɔn trɛnk ɛn i nid smɔl risɔs fɔ kɔmparabl pefɔmɛns. Di tin dɛn we dɛn kin yuz fɔ ridyus di pɔrmanent sistɛm dɛn kin ɛp fɔ ridyus di envayrɔmɛnt futprin, bikɔs bɔku tɛm i kin translet to ridyus filta, ɛnaji kɔnsɔmshɔn ɛn ɛya transpɔt.

Dɛn fɔ tink bak bɔt tin dɛn lɛk ɛnaji, had, risaykul, ɛn tin dɛn we dɛn fɔ tink bɔt na layf ɛnd bak. Aluminium, we dɛn sabi fɔ in risaykulabiliti, kin gɛt advantej pan spɛshal sastaynabiliti aplikeshɔn dɛn. So, di disishun fɔ involv wan kɔmprɛhɛnsif analisis fɔ di ɔl di prɔdak layf saykl, inklud ɛkstrakshɔn, prɔsesin, yuz ɛn dispɔzishɔn.

Titanium ɔ aluminium - We yu tink bɔt di prodakshɔn prɔses fɔ taytaniɔm ɛn aluminiɔm alɔy, us ifɛkt di rispektiv matirial kwaliti dɛn gɛt pan west jenɛreshɔn ɛn ɛnaji kɔnsɔmshɔn, ɛn aw dɛn tin ya kin afɛkt di layfsaykl analisis fɔ di prɔdak dɛn?

Bikɔs taytaniɔm ɛn aluminiɔm gɛt difrɛn kwaliti dɛn, dɛn prodakshɔn prɔses dɛn difrɛn. Di had we titanium kin gɛt, jɔs nid fɔ yuz spɛshal tul ɛn ikwipmɛnt dɛn, ɛn dis kin mek di ɛnaji we dɛn de yuz bɔku we dɛn de mek mashin ɛn mek am. Na di ɔda say, di izi we aw dɛn kin mek aluminiɔm we de mek aluminiɔm nɔ kin mek dɛn gɛt mɔ ɛnaji, bɔt if dɛn nɔ manej am fayn, i kin mek dɛn west mɔ.

Di envairomɛnt impak we dɛn prɔses ya gɛt pan di envayrɔmɛnt alaynɛshɔn de afɛkt di ɔvala layf saykl analisis fɔ di ɔbjɛkt. Titanium prodakshɔn ɛn ɛnaji-intensif mashin kin kɔntribyut to wan fɔs inkris na di envayrɔmɛnt impak, we di risaykulabiliti fɔ aluminiɔm ɛn rili simpul mashin kin gi bɛnifit.

Titanium ɔ aluminiɔm - Kɔnkliushɔn .

Fɔ pik di bɛst stɛl fɔ wan mɛkanikal prɔjek nid fɔ tek tɛm du risach ɛn evaluate sɔm vayriɔbul dɛn. Di wok atmosfɛs, di prɔjek kɔmplisiti, ɛn di target kɔmplitmɛnt kwaliti dɛn na impɔtant tin dɛn fɔ tink bɔt. Bikɔs ɔf Titanium in natura hadnɛs, spɛshal tul ɛn ikwipmɛnt dɛn kin nid. Bikɔs ɔf in trɛnk ɛn di tɛm we i go de fɔ lɔng tɛm, Titanium na di ideal matirial fɔ yuz insay sikɔstɛms we nid di ays lɛvɛl fɔ prɛsishɔn ɛn ditil.

Taem MFG de gi yu ɔl tu di Titanium ɛn Aluminiɔm fɔ yu Rapid prototypein ., Low Volume Manufacturing , ɛn CNC mashin manufakchurin nid dɛn. Kontakt wi tide!

Insay ɛni wan pan dɛn, dɛn nid fɔ du mɔ ditayli analisis. I impɔtant fɔ tek tɛm evalyu di trɛnk ɛn di prɔblɛm dɛn bifo yu disayd bitwin taytaniɔm ɛn aluminiɔm fɔ yu mashin prɔjek. Ɛni mɛtal kam wit in yon prɔpati dɛn, ɛn ɔndastand aw i mach di patikyula tin dɛn we yu fɔ du fɔ yu prɔjek de alaw yu fɔ mek di rayt ɛn saksesful chuk.