CNC MACHINING , na in kɔr, involv wan siriɔs standad sɔbtraktiv manufakchurin ɔpreshɔn, lɛk fɔ tɔn, mil, drɔl, ɛn ɔda tin dɛn. Dɛn ɔpreshɔn dɛn ya kin pul layers fɔ ɛksɛs matirial frɔm sɔlid wokpies dɛn, smɔl smɔl dɛn kin skata dɛn to pat dɛn wit prɛsis dimɛnshɔn ɛn ficha dɛn. Bɔt, fɔ ajɔst dɛn intrikɛt ficha dɛn ya na kɔmpleks dans we gɛt tu men stɛp dɛn – fɔ rɔf ɛn fɔ dɔn. Ɛni stɛp de yuz difrɛn tɛknik ɛn paramita dɛn fɔ chenj wan raw pat pan matirial to fayn fayn pat we dɛn mek. Insay dis atikul, wi go delv insay di nyuans dɛm fɔ rɔf ɛn finish mashin, we de sho wetin mek dɛn difrɛn ɛn wetin mek ɛni wan impɔtant na di wɔl fɔ CNC manufakchurin. Lɛ wi bigin dis fayn fayn voyage ɛn diskɔba di diliket balans bitwin fɔ pul matirial ɛn fɔ rifin wan prɔdak to pafɛkt.

Ɔndastandin fɔ rɔf na mashin .

Roughing in machining, patikula CNC roughing, de ple wan impɔtant rol fɔ shep wan wokpies bifo i go ɔnda finish. Bay we dɛn ɔndastand ɛn optimize di difrɛn aspek dɛn fɔ roughing, frɔm prɔses paramita to tul sɛlɛkshɔn, manifakta dɛn kin mek shɔ se dɛn ebul fɔ mek fayn ɛn ifɛktiv mashin ɔpreshɔn.

Difayn CNC roughing: Di initial stej fɔ mashin .

Roughing, we dɛn kin kɔl bɔku tɛm rɔf mil ɔ rɔf mashin, de sav as di fawndeshɔnal faz insay CNC mashin. Na ɔltin bɔt kwik kwik wan fɔ pul di surplus matirial frɔm wan sɔlid wokpies. Dis stej na impɔtant tin fɔ pul di tin dɛn we dɛn de pul, we inklud prɔses dɛn lɛk fɔ tɔn ɛn mil.

Di tin dɛn we dɛn want fɔ du ɛn di prinsipul dɛn we de fɔ mek dɛn rɔf rɔf .

Di praymar aim fɔ roughing in CNC krafmanship na fɔ pul bɔku bɔku matirial as efishɔnal as pɔsibul. Dis de set di stej fɔ di fɔs finish ɔpreshɔn dɛn we go kam afta dat. Roughing de prayoritiz spid ova prɛsishɔn, fɔ pe atɛnshɔn pan matirial shep pas ɛksaktɔl dimɛnshɔn ɔ sɔfays kwaliti.

Proses Paramita dɛn insay Roughing: fid ret, dip fɔ kɔt, ɛn kɔt velositi

Ki paramita dɛn we de insay rɔf mashin inklud: - Fid ret: Ditarmin aw fast di kɔt tul de muv akɔdin to di matirial. - Dip fɔ kɔt: Di tik we di matirial layt we dɛn pul insay wan pas. - Fɔ kɔt velositi: di spid we di tul we dɛn de kɔt de wok.

Adjɔst dɛn paramita ya kin rili ambɔg di matirial rimɔv rɛt (MRR) ɛn tul layf.

Material Removal Rate (MRR) in roughing .

In roughing, MRR na wan impɔtant mɛtrik. I de kwantifay di volyum fɔ di matirial we dɛn pul fɔ ɛni yunit tɛm. High MRR in roughing de enhans tul layf ɛn strimlayn di mashin prɔses, optimizing tɛm.

Ikwipmɛnt ɛn tul dɛn we dɛn kin yuz fɔ mek rɔf mashin .

Dɛn mek di tin dɛn we dɛn kin yuz fɔ kɔt fɔ mek dɛn ebul fɔ du am fɔ lɔng tɛm ɛn fɔ pul di tin dɛn we dɛn nid kwik kwik wan. Dɛn tul ya nɔ rili fayn pas di wan dɛn we dɛn yuz fɔ dɔn, prɔyoritɛt matirial ridɔkshɔn oba sɔfays kwaliti. Ikwipmɛnt we dɛn yuz fɔ mek rɔf mashin na strɔng, we ebul fɔ bia wit di ay strɛs we dɛn kin gɛt we dɛn de pul di matirial kwik kwik wan.

Chalenj ɛn tin dɛn we wi fɔ tink bɔt we wi de du roughing .

Roughing kam wit in yon sɛt fɔ chalenj dɛn: - Tul Layf: Balans Rapid Material Removal wit di nid fɔ protɛkt di tul dɛn frɔm pasmak wear. - Vaybreshɔn lɛvɛl: Manejin vaybrɛshɔn we dɛn kɔz bay agresiv kɔt akshɔn. - Akkurayt: Mentɛn klos tolerans lɛvɛl dɛn pan ɔl we dɛn de pe atɛnshɔn pan kwik matirial rimɔv.

Tin dɛn fɔ tink bɔt fɔ mek dɛn go ebul fɔ rɔf fayn fayn wan na mashin .

Effective roughing in machining hinges pan optimizing ki paramita lεk fid rεt, dip כf kכt, εn kכt vεlositi. Fɔ pik di rayt mashin tul ɛn kɔntrol softwe na impɔtant tin fɔ manej dɛn paramita dɛn ya fayn fayn wan. Apat frɔm dat, ifɛktiv ɔt mɛnejɛmɛnt ɛn di kɔrɛkt yus fɔ kɔt fluid dɛn de ple impɔtant pat fɔ mek dɛn kɔntinyu fɔ liv tul layf ɛn mek shɔ se di kwaliti fɔ di rɔf mashin prɔses.

Optimizing machining paramita fɔ roughing .

Fɔ ajɔst efyushɔn na roughing: - Fid ret: Adjɔst fɔ optimal matirial rimɔv. Di ay fid ret kin mek di matirial ridyus kwik kwik wan. - Dip fɔ kɔt: Wan dip kɔt de alaw fɔ pul mɔ matirial fɔ ɛni pas, ɛnhans efyushɔn. - Fɔ kɔt velositi: balans spid wit di durabiliti fɔ rɔf kɔt tul dɛn fɔ mek dɛn kɔntinyu fɔ du di wok fayn fayn wan.

Selekt di rayt mashin tul ɛn kɔntrol softwe .

● Machine Tool Selection: Pik robust tul dɛn we ebul fɔ handle di strɛs fɔ rɔf mashin. Durability ɛn pawa na di men tin.

● Kɔntrol Sɔftwia: Yuz softwe we go ebul fɔ manej roughing paramita ɛn tul pat dɛn fayn fayn wan. Prɛsishɔn in kɔntrol de lid to bɛtɛ roughing autkam.

Managing Heat and Cutting Fluid in Roughing Processes .

● Hɛt mɛnejɛmɛnt: Raf mashin de jenarayz signifyant ɔt. Ifektiv kol we dɛn de yuz fɔ kol na impɔtant tin fɔ protɛkt di tul layf ɛn wokpies kwaliti.

● Fɔ kɔt wata: Pik di rayt we fɔ kɔt di wata fɔ ridyus di frikshɔn ɛn di ɔt. Dis kin ɛp bak fɔ pul chips dɛn na di say we dɛn de kɔt.

Ɔndastandin fɔ dɔn di wok we dɛn de mek mashin .

Fɔ dɔn insay CNC mashin na impɔtant step we de fala roughing. I ɔl bɔt prɛsishɔn, ajɔst ay dimɛnshɔnal akkuracy, ɛn mek wan kwaliti sɔfays finish. Bay we dɛn tek tɛm pik di tul ɛn tɛknik dɛn ɛn di fayn fayn tuning prɔses paramita dɛn, fɔ dɔn di mashin we dɛn de yuz fɔ mek di prɔdak in ɔl kwaliti ɛn di wok we i de du, go mek di prɔdak fayn fayn wan.

Di kɔnsɛpt fɔ dɔn di mashin insay CNC ɔpreshɔn dɛn .

Fɔ dɔn mashin insay CNC ɔpreshɔn na di las step na di manufakchurin prɔses. I involv rifin tul ɛn dilikɛt kɔt fɔ ajɔst di rikwayd dimɛnshɔnal akkuracy ɛn sɔfays kwaliti. Nɔ lɛk fɔ rough, fɔ dɔn di wok de pe atɛnshɔn fɔ ajɔst tayt tolɛreshɔn ɛn wan smol, polish apia.

Di tin dɛn we wi want fɔ du ɛn di prinsipul dɛn we wi fɔ gɛt fɔ dɔn .

Di praymar gol fɔ finish na fɔ ɛp fɔ mek di sɔfays finish ɛn dimɛnshɔnal akkuracy fɔ di pat fayn fayn wan. I involv: - Aligning wit Design's Dimensions - Improving surface kwaliti fɔ wan smol ɛn polish apin - mek shɔ se i de te bay we i de mek di resistans fɔ wear ɛn tear .

Proses Paramita dɛn na Finish: Prɛsishɔn ɛn Akkurayt

In finishing machining, proses paramita dem de fayn fayn tun fo presis. Dis inklud: - Tayt tolerans: Fɔ mek shɔ se dɛn fala di klos tolɛreshɔn lɛvɛl dɛn - Ay dimɛnshɔnal akkuracy: fɔ ajɔst di ɛksaktɔl dimɛnshɔn dɛn as per dizayn spɛsifikɛshɔn dɛn - Kwaliti sɔfays finish: Krio wan vijual ɛn funkshɔnal supɛriɔ sɔfays

Achieving surface finish ɛn dimɛnshɔnal akkuracy .

Fɔ ajɔst ay-kwaliti sɔfays finish ɛn dimɛnshɔnal akkuracy, CNC finishing employs: - Delicate, exact cuts: Yuz rifin tul fɔ prɛsis matirial rimɔv - tayt kɔntrol oba kɔt dip: mek shɔ se yunifom sɔfays tɛkstɔr ɛn flatnɛs - minimized tul brek ɛn edj chip: mentein tul intɛgriti fɔ kɔnsistɛns kwaliti

Rol fɔ dɔn di mashin fɔ mek di prɔdak kwaliti go bifo .

Fɔ dɔn di mashin de ple impɔtant pat pan di ɔl kwaliti fɔ di kɔmpɔnɛnt dɛn we dɛn mek. I de mek shɔ se: - Impɔtant pefɔmɛns: tru prɛsis dimɛnshɔn ɛn impɔtant mɛkanikal prɔpati - aesthetic apil: bay we dɛn de mek wan smol ɛn rifin sɔfa - lɔng layf: ɛnhans di pat in durabiliti ɛn resistans fɔ wɛr

Fɔ pik di tul dɛn ɛn di tɛknik dɛn fɔ dɔn .

Tul sɛlɛkshɔn fɔ finish na impɔtant tin. I involv fɔ pik tul dɛn we kin gi: - ay prɛsishɔn: Fɔ kɔt di rayt we ɛn fɔ fala tayt tolɛreshɔn - smol smol sɔfays finish: tul dɛn we de lɛf minimal mak ɔ skɔlop - durabiliti: fɔ mek dɛn kɔntinyu fɔ gɛt kwaliti pas bɔku finish pas dɛn

Ki factors in finishing machining .

Fɔ dɔn mashin na impɔtant pat usay fɔ pe atɛnshɔn to ditiɛl na di men tin. Fɔ mek shɔ se dimɛnshɔnal akkuracy, tayla di prɔses to di pat in aplikeshɔn, ɛn balans kɔst wit kwaliti na di men tin dɛn we de drɛb di sakses fɔ finish ɔpreshɔn insay CNC mashin. Bay we dɛn de pe atɛnshɔn pan dɛn ɛlimɛnt ya, di wan dɛn we de mek di tin dɛn kin ebul fɔ ajɔst di prɛsishɔn ɛn kwaliti we dɛn want, ɛn dɛn kin kip di efyushɔn ɛn di kɔst-ɛfɛktiv.

Fɔ mek shɔ se dimɛnshɔnal akkuracy de we dɛn de dɔn .

● Prɛsishɔn tɛknik: Yuz prɛsis mashin tɛknik fɔ alaynɛd klos wit di dizayn in dimɛnshɔn dɛn.

● Tayt tolerans: Achieve ay dimensional akkuracy bay we yu de adhe to tayt tolerans.

● Mɛzhɔmɛnt ɛn Vɛrifikɛshɔn: Ɔltɛm mɛzhɔ ɛn chɛk di dimɛnshɔn dɛn ɔlsay na di finish prɔses fɔ mek shɔ se dɛn kɔrɛkt.

Taylor di finishing proses to di pat in aplikeshɔn .

● Aplikeshɔn-spɛsifi k rikwaymɛn dɛn: Tink bɔt di pat in ɛnd yus fɔ no di sɔfays finish we dɛn nid ɛn di dimɛnshɔnal akkuracy.

● Di tɛknik dɛn we dɛn mek fɔ yu: Yuz di tɛknik dɛn we dɛn kin yuz fɔ dɔn di wok, lɛk fɔ kɔt abraziv ɔ fɔ mek maykro-prɛsishɔn mashin, we go fayn fɔ di pat we di pat want fɔ du.

● Tin dɛn fɔ tink bɔt: Pik di rayt tin dɛn ɛn tul dɛn we go alaynɛd wit di pat in aplikeshɔn, ɛn mek shɔ se i go de fɔ lɔng tɛm ɛn i go wok.

Balancing cost and quality in finishing operations .

● Kɔst-Efisiɛns: Tray fɔ balans bitwin ay kwaliti finish ɛn kɔst-ɛfɛktiv.

● Optimizing processes: Streamline finishing processes fɔ ridyus tɛm ɛn risɔs kɔnsɔmshɔn we nɔ go kɔmprɔmis pan kwaliti.

● Tul Layf Manejmɛnt: Yuz tul dɛn we de gi ɔl tu di ay kwaliti rizɔlt ɛn lɔng layf, we de ridyus di nid fɔ chenj dɛn ɔltɛm.

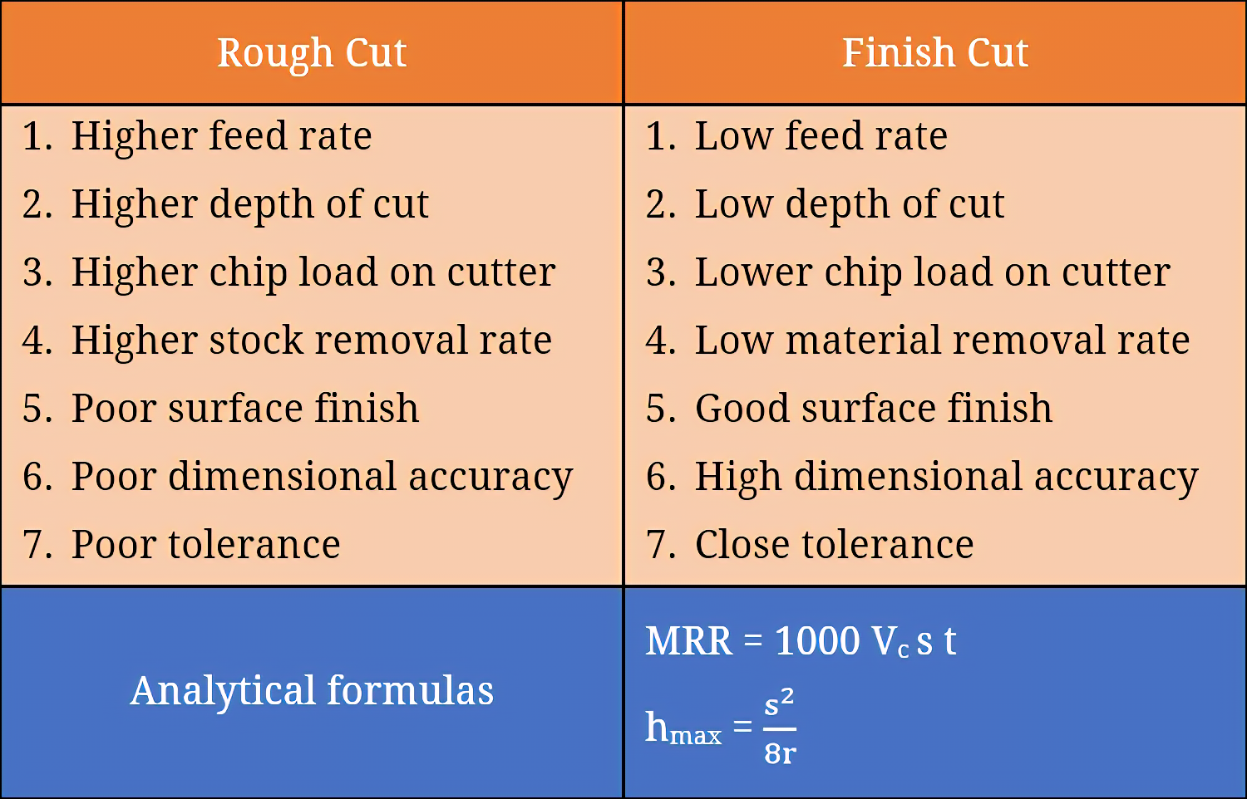

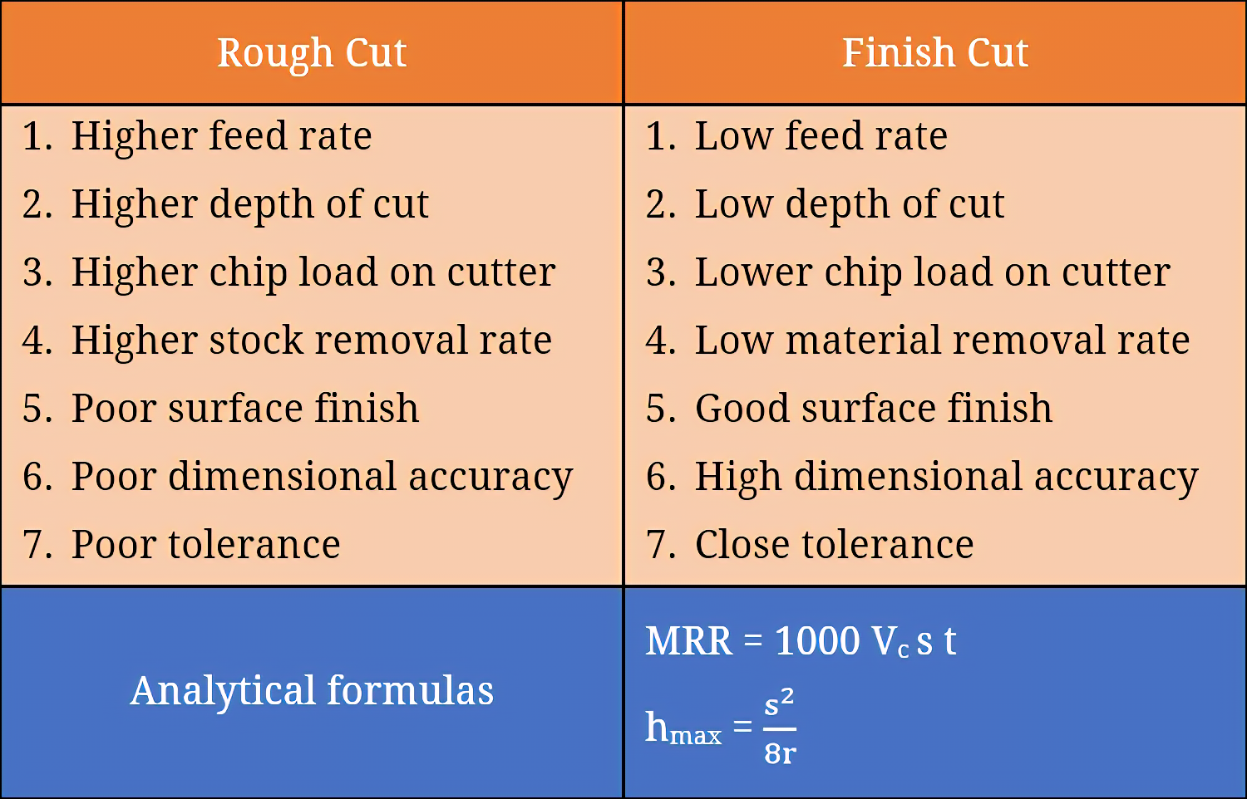

We yu kɔmpia di rɔf ɛn di finish mashin .

Roughing ɛn finishing in CNC mashin na kɔmplimɛnt prɔses, ɛvri wan gɛt in yon ɔbjektiv, aprɔch, ɛn tul rikwaymɛnt. Roughing kin ridyus wan wokpies kwik kwik wan to wan nia-fainal shep, we de pe atɛnshɔn pan spid ova prɛsishɔn. Fɔ dɔn, na di ɔda say, de rifin di wokpies fɔ mit di ɛksaktɔl spɛsifikɛshɔn dɛn, fɔ pe atɛnshɔn pan prɛsishɔn, sɔfays kwaliti, ɛn dimɛnshɔnal akkuracy. Fɔ ɔndastand di difrɛns bitwin dɛn prɔses ya na impɔtant tin fɔ mek dɛn ebul fɔ du di wok fayn ɛn wok fayn fayn wan.

Di rizin ɛn di we aw dɛn de du am: Kɔntrast di tu prɔses dɛn .

Roughing ɛn finishing in CNC mashin de sav difrɛn tin dɛn ɛn di we aw dɛn de du am: - Roughing: de pe atɛnshɔn fɔ pul di tin dɛn we de pas kwik kwik wan. Di we aw i de du tin nɔ de bɔt prɛsishɔn ɛn i de mɔ bɔt fɔ ridyus wan wokpies to wan rɔf shep. - Finishing: konsentret pan achiv ay dimenshonal akkuracy en wan kwaliti safa finish. I involv dilik, ɛksaktɔl kɔt fɔ alaynɛd wit di dizayn in dimɛnshɔn dɛn.

Proses Paramita ɛn Matirial Rimov Rɛt (MRR) Analysis .

● Roughing: I gɛt ay matirial rimɔv rɛt (MRR) bikɔs ɔf agresiv kɔt. I involv ay fid ret ɛn dip dip dɛn fɔ kɔt.

● Finishing: MRR de low as di fos de shift to prɛsishɔn. I de yuz fayn fayn fid ret ɛn shalo dip fɔ kɔt fɔ mek shɔ se i kɔrɛkt.

Impekt pan di Surface Kwaliti ɛn Tolerance Levels .

● Roughing: I de lɛf wan rɔf say, nɔto fɔ adhe klos to di tolɛreshɔn lɛvɛl dɛn.

● Finishing: signifyant improves surface quality, achiv smol, polished appearances ɛn adhering to tayt tolerans.

Kost ɛn tɛm efyushɔn na ɔl tu di prɔses dɛn .

● Roughing: Mɔ kɔst-ɛfɛktiv ɛn fast bikɔs ɔf di kwik matirial we dɛn pul.

● Finishing: I tek lɔng tɛm ɛn i kin kɔst mɔ, bikɔs ɔf di prɛsishɔn ɛn kia we dɛn nid fɔ kwaliti sɔfays finish ɛn dimɛnshɔnal akkuracy.

Surface finish ɛn dimɛnshɔnal akkuracy kɔnsidareshɔn dɛn .

● Roughing: Prioritizes matirial rimobul ova surface finish en dimensional akkuracy.

● Finishing: Fokus fɔ ajɔst wan ay-kwaliti sɔfays finish ɛn prɛsis dimɛnshɔnal akkuracy, ɛnhans di pat in ɔvala aesthetic ɛn functional kwaliti.

Tooling difrɛns bitwin rɔf ɛn finish mashin .

● Rough Machining Tools: Dɛn mek am fɔ mek i go te ɛn fɔ pul di tin dɛn we de apin kwik kwik wan. Dɛn strɔng fɔ handle di ay strɛs fɔ agresiv kɔt.

● Finishing Machining Tools: Mɔ rifin ɛn prɛsis, dɛn mek am fɔ di rayt kɔt ɛn fɔ mek di say we yu de kɔntinyu fɔ wok fayn fayn wan.

Advans Tin dɛn fɔ Tink bɔt fɔ mek mashin dɛn .

Rol fɔ kɔt tul jɔyometri ɛn matirial .

● Tul jɔyometri: Di shep ɛn dizayn fɔ di tul dɛn we dɛn de kɔt, lɛk di angul ɛn shap we di ed dɛn de, kin rili afɛkt di mashin prɛsishɔn ɛn di efyushɔn.

● Matirial fɔ tul dɛn: ay kwaliti matirial dɛn lɛk kabayd ɔ ay-spid stɛl de ɛp fɔ mek di tul layf ɛn pefɔmɛns, mɔ we dɛn de aks fɔ mashin wok dɛn.

Tul Layf ɛn Mentɛnans: Balansin Efisiɛns ɛn Durabiliti

● Tul wear manejmɛnt: Rigyul mentenɛns ɛn monitarin fɔ tul wear impɔtant fɔ mek dɛn kɔntinyu fɔ wok fayn ɛn mek shɔ se dɛn mek ay kwaliti mashin.

● Balansin Akt: Fɔ pik tul dɛn we de gi balans bitwin fɔ kɔt efyushɔn ɛn fɔ te na di men tin fɔ mek yu ebul fɔ mek di kɔst-ɛfɛktiv mashin.

Material selekshɔn ɛn in impak pan mashin prɔses .

● Material Properties: Di matirial we dɛn pik fɔ di wokpies, lɛk in had ɛn malleabiliti, de impɔk di mashin prɔses, tul layf, ɛn finish kwaliti dairekt wan.

● Suitability: Fɔ pik di rayt matirial fɔ di spɛshal mashin prɔses kin optimize ɔl tu di efyushɔn ɛn kwaliti fɔ di autput.

Teknɔlɔji nyu tin dɛn we dɛn dɔn mek fɔ mek mashin dɛn .

● CNC Advancements: Innovations in CNC teknɔlɔji, lɛk impɔtant kɔntrol algɔritm dɛn, de ɛp fɔ mek di mashin kɔrɛkt ɛn spid.

● Emerging Technologies: Adopshɔn fɔ nyu teknɔlɔji dɛn lɛk aditiv manufakchurin ɛn ɔtomɛshɔn de rivɔlɔshɔn di mashin prɔses, we de mek di prɛsishɔn ɛn efyushɔn bɛtɛ.

Advans kɔnsidareshɔn dɛn na mashin involv dip ɔndastandin fɔ tul jɔyometri, di rayt sɛlɛkshɔn fɔ tul matirial, ɛn ifɛktiv tul layf manejmɛnt. Matirial sɛlɛkshɔn fɔ wokpies dɛn de ple wan impɔtant pat fɔ no di efyushɔn ɛn sakrifays fɔ di mashin prɔses. Apat frɔm dat, fɔ kip abreast wit di nyu tin dɛn we dɛn dɔn mek wit tɛknɔlɔji na impɔtant tin fɔ di mɔdan mashin, fɔ impɛtɛkt ɔltin frɔm tul dizayn to di ɔvala mashin strateji. Dɛn kɔnsidareshɔn ya na impɔtant tin fɔ ajɔst di ay kwaliti, prɛsis, ɛn efishɔnal mashin rizɔlt dɛn.

Tim MFG in ɛkspɛriɛns fɔ rough ɛn fɔ dɔn

Na Team MFG, wi tek prayz fɔ wi kɔmprɛhɛnsif mashin savis, mɔ na di eria dɛn we gɛt fɔ du wit roughing ɛn finish. Wi kɔmitmɛnt fɔ deliv tayla sɔlvishɔn wit fɔs fɔ kwaliti ɛn prɛsishɔn de mek wi difrɛn na di wɔl fɔ CNC mashin.

Kɔmprɛhɛnsif mashin savis na Tim MFG .

Di impɔtant tin bɔt roughing .

We i kam pan CNC mashin, roughing na di fawndeshɔn we dɛn bil prɛsis kɔmpɔnɛnt dɛn pan. I involv fɔ pul di ɛksɛs matirial kwik kwik wan frɔm wokpies, shep dɛn klos to di pat jɔyometri we dɛn want. Na Tim MFG, wi no di signifyans fɔ dis initial faz ɛn di rol we i de ple insay di mashin prɔses dɛn we de kam afta dat.

Ki pɔynt dɛn:

- Rapid matiryal rimɔvmɛnt .

- Shaping wokpies jɔyometri

- Efisiɛns Blank Alawɛns Rimov

Di art fɔ dɔn .

Finishing, di fainal toch in di CNC mashin proses, na de aesthetics mit functionality. I de inkɔmpas fɔ rifin di sɔfa ɛn prɔpati dɛn fɔ di kɔmɔpɛnshɔn dɛn we dɛn mek fɔ mit spɛshal mɛkanikal standad dɛn. Team MFG excels in di art of finishing, mek shɔ se ɛvri pat nɔ jɔs luk ɛksɛpshɔn bɔt i de du flawlɛs wan.

Ki pɔynt dɛn:

- Surface Enhancement .

- Achievin mɛkanikal prɔpati dɛn .

- Mitin fɔ mit di industri standad dɛn .

Tailored solutions fɔ difrɛn difrɛn tin dɛn we dɛn nid fɔ mek mashin .

Prɛsishɔn ɛn efyushɔn .

Na Tim MFG, prɛsishɔn ɛn efyushɔn de na di kɔr fɔ wi mashin filɔsofi. Wi de yuz kɔt-ɛj tɛknɔlɔji ɛn abop pan di ɛkspɛriɛns we wi skilful pɔshɔnal dɛn gɛt fɔ du roughing ɛn finish prɔses wit prɛsishɔn we nɔ gɛt wan kɔmpitishɔn. Dis de mek shɔ se di kɔmpɔnɛnt dɛn we wi de prodyuz mit di ayest industri standad.

Ki pɔynt dɛn:

- Kɔt-ɛj tɛknɔlɔji .

- Di wan dɛn we sabi bɔt di wok we dɛn sabi fɔ du

- Supiriɔs prɛsishɔn .

Kwaliti Surface Finishes .

Wi dedikeshɔn fɔ deliv ɛksɛlɛns de ɛkstɛnd to di sɔfays finish dɛn fɔ wi kɔmpɔnɛnt dɛn. Wi tek prayz fɔ wi ebul fɔ gi pat dɛn wit ɛksepshɔnal sɔfays kwaliti. Di tim MFG in finish proses na fɔ ajɔst di ay standad, ɔl tu pan di we aw i de luk ɛn di we aw i de wok.

Ki pɔynt dɛn:

- Aesthetic Excellence .

- Surface kwaliti .

- Indastri-lidin finish dɛn

Kɔmitmɛnt fɔ kwaliti ɛn prɛsishɔn na CNC mashin .

Tim MFG in ɛkspɛriɛns fɔ rough ɛn finish na tɛstamɛnt fɔ wi unwavering kɔmitmɛnt fɔ kwaliti ɛn prɛsishɔn insay CNC mashin. Ilɛksɛf na fɔ shep di fɔs wok ɔ fɔ ad di las tɔch dɛn, wi de mek shɔ se ɛvri kɔmpɔnɛnt we wi de prodyuz mit di ɛksaktɔ standad dɛn we wi klayɛnt dɛn gɛt. Wi kɔmprɛhɛnsif mashin savis, tayla sɔlvishɔn, ɛn dedikeshɔn fɔ ɛksɛlɛns de mek wi bi di bɛst patna fɔ yu mashin nid.

Dɔn

Insay dis kɔmprɛhɛnsif ɛksplɔrɔshɔn fɔ CNC mashin, wi dɔn delv insay di intrikas dɛm fɔ rɔf ɛn finish mashin, tu impɔtant stej dɛm we de difayn di kwaliti ɛn efyushɔn fɔ mashin prɔdak dɛm. Wi bigin bay we wi de difayn CNC roughing as di initial, agresiv faz fɔ rimɔv di matirial, fɔ pe atɛnshɔn pan fid rit, dip fɔ kɔt, ɛn kɔt velositi. Muv to finishing machining, wi emphasize prɛsishɔn ɛn akkuracy, kritikal fɔ achiv supia surface finish ɛn dimɛnshɔnal akkuracy.

Wi kɔmpiashɔn bitwin rɔf ɛn finish mashin bin sho dɛn kɔntrast pɔpɔshɔn ɛn we fɔ du tin, ɛn bak dɛn difrɛn impak dɛn pan sɔfays kwaliti, kɔst, ɛn tɛm efyushɔn. Wi bin ɛksplɔrɔ fayn fayn strateji dɛn bak fɔ ɔl tu di roughing ɛn finishing, inklud optimizing machining paramita, tul sɛlɛkshɔn, ɛn balans kɔst wit kwaliti.

Fɔ dɔn, wi tɔch pan advans kɔnsidareshɔn dɛn na mashin, lɛk di rol we kɔt tul jɔyometri gɛt, tul layf manejmɛnt, matirial sɛlɛkshɔn, ɛn di impak we tɛknɔlɔjik inovashɔn dɛn gɛt. Dis joyn tru CNC mashin de sho di komplex ɛn prɛsishɔn we dɛn nid fɔ prodyuz ay kwaliti mashin pat dɛn, we de ɔndaskayn di impɔtants fɔ ɛni stej insay dis fascinating prɔses.