Di fes mil prɔses na impɔtant tin na di eria fɔ prɛsishɔn ɛn efyushɔn na mɛkaniks. Fɔ gɛt ɔndastandin fɔ fes mil, frɔm in difinishɔn to yusful hint, kin rili ɛp fɔ mek di mɛkanikal pefɔmɛns bɛtɛ. Dis essay delv mɔ insay dis prosidur, dissect in intricacies ɛn ɔfr insightful no to ɔl tu inexperienced ɛn sizin mɛkaniks.

Fes mil: Dip difinishɔn .

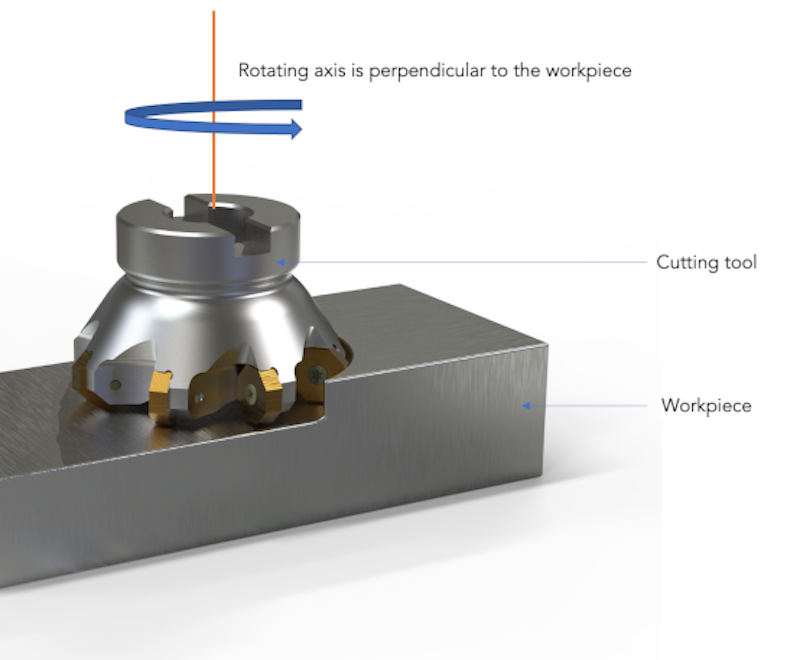

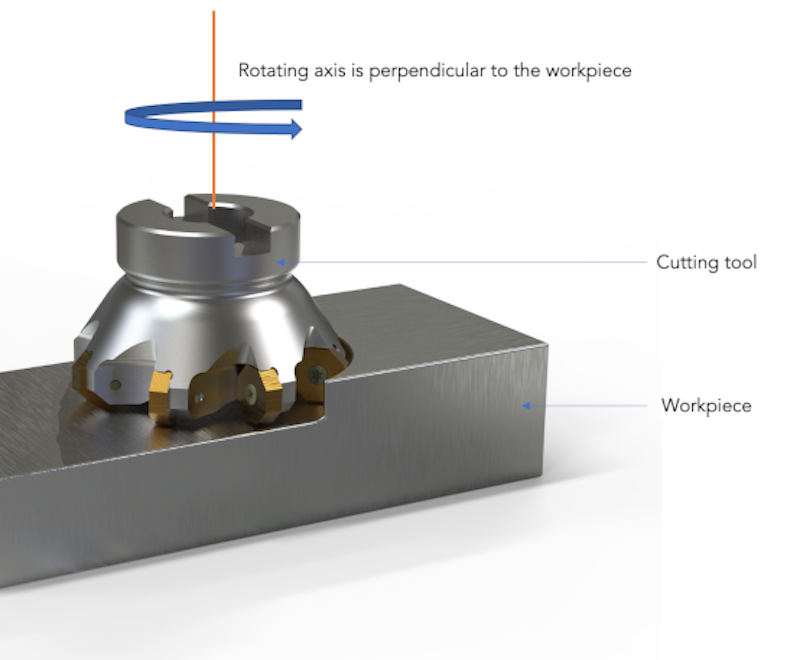

Fes CNC Milling , na in kɔr, na mɛkanikal prɔses we dɛn aim fɔ prodyuz flat sɔfays pan wokpies. Nɔ lɛk ɔda mil tɛknik, dis wan de fɔs na di ays lɛvɛl, we de rili mek i smol ɛn ivin prɛsishɔn. Di prɔses nid fɔ yuz spɛshal ikwipmɛnt, bɔku tɛm na wan mɔlti-kat frɔnt saw. Dis we ya de alaw fɔ pul mɔ efyushɔn, we de mek fes mil indispɛns na difrɛn industri dɛm.

Di tin dɛn we dɛn dɔn lan bɔt tɛknɔlɔji dɔn mek dɛn ebul fɔ mek dɛn fes milin, ɛn dis dɔn mek mashinman dɛn ebul fɔ du di rayt tin dɛn we dɛn nɔ ɛva si yet ɛn di spid we dɛn de spid. Frɔm tradishɔnal an mil to mɔdan kɔmpyuta-kɔntrol CNC mashin dɛn, di joyn fɔ fes mil de sho di kɔnstant purshut fɔ pafɛkt insay . Rapid Manufakchurin.

Fes mil prɔses stɛp-by-stɛp disɛkshɔn .

Ikwipmɛnt sɛlɛkshɔn: Di joyn bigin wit di tek tɛm sɛlɛkshɔn fɔ di rayt ikwipmɛnt. Wan frɔnt pɔkit wit insɛt dɛn we dɛn mek fɔ mek gud kɔt impɔtant fɔ mek dɛn ebul fɔ du di tin we yu want.

Wok aytem ripa: Mek shɔ se dɛn pak di wok fayn ɛn ɔganayz am na di men tin. Eni twist durin dis period kin kompromi di integriti of di fainal prodak.

Instɔlɛshɔn fɔ mil mashin: Dɛn dɔn sɛt di kɔt spid, fid ret ɛn dip fɔ kɔt fɔ mek shɔ se di mil mashin kɔrɛkt. Prɛsishɔn na dɛn sityueshɔn ya na impɔtant tin fɔ mek dɛn gɛt sakrifays fɔ masaj di fes.

Eksekyutiv fɔ fes mil ɔpreshɔn: Wans di sɛtin dɔn, di fes mil ɔpreshɔn bigin. Rotating shia dɛn na di frɔnt mil de intarakt wit di wok, pul di matirial ɛn flat am.

Kwaliti Kɔntrol: I de du post-rɔl, inspɛkt gud gud wan, ɛn mɛzhɔ di prɔdak dɛn we dɔn dɔn fɔ mek shɔ se dɛn kɔnfɔm. Kwaliti kɔntrol na di las chɛk na di fɔdɔm mil prɔses.

Difrɛns pan di we aw dɛn de du mi fes fɔ mil .

Pan ɔl we Face Milling de sheb di sem tin dɛn wit ɔda we dɛn fɔ mil, di spɛshal kwaliti dɛn we i gɛt de mek i difrɛn. Nɔ lɛk ɛnd mil, we de pe atɛnshɔn fɔ mek ficha dɛn lɛk slot ɛn poket, fes mil de prayoritɛt di jɛnɛreshɔn fɔ flat sɔfays. Dis fundamental difrɛns de mek fes mil ideal usay dɛn nid sɔfays finish, lɛk kɔmpɔnɛnt fɔ ɔtomotiv, aerospace ɛn industrial aplikeshɔn.

Apat frɔm dat, di bɛnifit dɛn we pɔsin kin gɛt we i de mil fes pas di spɛshal ples we dɛn put am. Di prɔses de mek am mɔ efyushɔn, as big eria dɛn na di wok kin bi mashin wan tɛm. Bɔt i impɔtant fɔ gri se di tin dɛn we dɛn nɔ ebul fɔ du, lɛk di prɔblɛm we dɛn gɛt fɔ handle kɔmplisiti we yu kɔmpia am wit ɔda we dɛn, lɛk di ɛnd mil.

Praktikal tips fɔ ifektiv fes mil .

Fɔ gɛt di bɛst rizɔlt frɔm fes mil nid mɔ pas jɔs tɛknikal skil dɛn. Teknishian dɛn nid fɔ tink bɔt difrɛn tin dɛn, we dɛn bigin wit fɔ pik di rayt ikwipmɛnt. Matirial dɛn de ple impɔtant pat fɔ afɛkt tul jɔyometri ɛn kɔt spid. Apat frɔm dat, fɔ ɔndastand di rilayshɔn bitwin di fid ret, spid ɛn dip fɔ kɔt na impɔtant tin fɔ mek dɛn ebul fɔ wok fayn ɛn ridyus di tul dɛn we de pwɛl di tul dɛn.

Fɔ dil wit di prɔblɛm dɛn we dɛn kin gɛt we dɛn kin gɛt fes mil, dɛn kin nid fɔ du am wit sɛns. Adjɔst di fid ret ɛn spid, optimiz di ikwipmɛnt jɔyometri, ɛn yuz di efyushɔn kɔling we dɛn de yuz na di men tin dɛn fɔ sɔlv prɔblɛm dɛn. Bɔku tɛm, di injinia dɛn we dɔn gɛt sakrifays kin abop pan wan kɔmbaynshɔn fɔ tɛknikal ɛkspɛriɛns ɛn prɛktikal ɛkspiriɛns fɔ sɔlv dɛn prɔblɛm dɛn ya we nɔ gɛt wan prɔblɛm.

Kes Stɔdi ɛn Ɛgzampul: I de pe atɛnshɔn pan di versatility ɛn impak we fes mil de gi

Dayv insay di rich tapestry fɔ rial-wɔl aplikeshɔn, ɛn yu go fɛn bɔku ɛgzampul usay fes mil de kɔntinyu fɔ bi wan step, we de sho se i nɔ gɛt wan kɔmpitishɔn fɔ yuz am ɛn i go wok fayn. Di prɛsis tin dɛn fɔ du fɔ layf-sɛvin mɛdikal divays dɛn de apia na di pazl fɔ fes-miling prodakshɔn pafɛkt as kiston.

In di eria fɔ ay-pɔfɔmɛnshɔn injin, frɔnt grindin de sho in prowes wit inkridibul resiliɛns kɔmpɔnɛnt dɛn. Di indelible mak we fes mil de left echo across industry corridors en na testament to in abiliti fɔ chenj in impakt across industry.

Sakses stori dɛm frɔm dɛn aplikeshɔn ya go bifo pas jɔs anekdɔt dɛm; Dɛn kin bi pawaful stori dɛn we de tɔk mɔ bɔt di impɔtant tin we impɔtant fɔ mek dɛn sabi di we aw dɛn de yuz fes fɔ mil. Dɛn stori ya nɔto jɔs fɔ mek pej dɛn we nɔ gɛt mistek, bɔt na fɔ rifin di stori bɔt ɔtomɛshɔn. Front grindin gɛt transfɔmativ abiliti nɔto jɔs fɔ impɔtant prodak kwaliti bɔt bak fɔ impɔtant manufakchurin efyushɔn.

Frɔm di diliket prɛsishɔn we dɛn nid fɔ mɛdikal brek-ɔp to di strɔng dimand fɔ ay-pɔfɔmɛnshɔn tɛnkɔlɔji, fes mil wev dɛn insay di ɔtomɛshɔn fɔ nyu tɛkstayl dɛn. Dɛn ɛgzampul ya tinap as beakɔn, we de gi wan we we injinia dɛn kin yuz am fɔ layt dɛn intrɛstin kraft.

Kwɛshɔn ɛn Ansa Sɛkshɔn:

Wetin na di men tin we mek dɛn de mil dɛn fes?

Di men tin we dis patikyula we fɔ mil na fɔ flat di wok.

Aw frɔnt mil difrɛn frɔm ɛnd mil?

We CNC Machining End Milling na geared to kriet ficha lek slot en poket, front milling focus onli pan flat surface.

Wetin na di men tin dɛn we yu fɔ tink bɔt we yu de pik fes mil tul dɛn?

We dɛn de pik di tul dɛn fɔ mil, dɛn fɔ tek tɛm tink bɔt sɔm impɔtant tin dɛn fɔ mek shɔ se di mashin wok fayn fayn wan. Fɔs, matirial dɛn de ple impɔtant pat, bikɔs difrɛn matirial dɛn nid fɔ gɛt prɛsis kɔt tul ɛn kɔtin fɔ efyushɔn ɛn kɔrɛkt rizɔlt. Tul jɔyometri na impɔtant nyu tin, ɛn tin dɛn lɛk fɔ kɔt di rit, rayk angul, ɛn ɛliks angul afɛkt di tul in ebul fɔ pul di matirial fayn fayn wan.

Di spid we dɛn de kɔt ɛn di fid ret fɔ mach di tul ɛn di matirial ɛn mek shɔ se dɛn mek mɛkanayzeshɔn. Dɔn bak, di tul dayamita ɛn di wit we dɛn tink bɔt we i kam pan wokpies saiz ɛn sɔfa eria rili impɔtant fɔ mek dɛn ebul fɔ ajɔst di sɔfa ɛn shep we dɛn want. As di mil prɔses na kɔmpleks, mashin tul ɛn wok, inklud fɔ ol, de afɛkt bak di pefɔmɛns fɔ di tul. Fɔ dɔn, dɛn fɔ chɛk di kɔst dɛn we dɛn dɔn tink bɔt ɛn di layf we dɛn de op fɔ di ikwipmɛnt fɔ no di ɔl di ikɔmik bɛnifit fɔ wan angul grinda we dɛn pik fɔ wan patikyula aplikeshɔn.

Aw dɛn go ebul fɔ sɔlv di prɔblɛm dɛn we dɛn kin gɛt we dɛn de mek dɛn fes bak?

Di tin dɛn we dɛn kin du na fɔ wɛr di divays ɛn tɔk bɔt am. Di sɔlv chenj di fid ret, spid, ɛn divays jɔyometri.

Ɛni patikyula sef prɛkoshɔn de we dɛn fɔ fala we dɛn de mek frɔntal lɔk?

Yɛs, i impɔtant fɔ wɛr di rayt tin dɛn fɔ protɛkt yu ɛn fala di divays dɛn fɔ protɛkt yusɛf.

Dɔn

Fɔ sɔma, fes mil na wan impɔtant tɛknik insay mɛkanikal injinɛri we de gi akkuracy ɛn prodaktiviti. Dis atikul dɔn gi insayt fɔ di intrikɛt wɔl fɔ fes piercing, inklud ɔltin frɔm intrikɛt tɛminɔlɔji ɛn akitekchɔ to ɔndastand di difrɛns ɛn yusful advays. Ɔtomɛshɔn nɔ kin jɔs gi guds we nɔ gɛt mistek bɔt i kin tek mɛkanikal injinɛri ɛn sayɛns bak to nyu ayt bay we i de mek dis we fɔ du tin pafɛkt. Lɛ wi bigin di fes mil prɔses ɛn transfɔm di matirial dɛn we dɛn nɔ dɔn prosɛs to wok dɛn we dɛn mek wit sɛns fɔ mek art.

Tim MFG de aplay CNC mashinin in . Rapid protɔtayp savis dɛn ., Low volume manufacturing fɔ mit yu nid dɛn. Kontakt wi tide!