Mansinw ye bi fɛn dilanni jɔnjɔn ye, nka suguya jumɛn bɛ bɛn i magow ma? Yala aw ka kan ka milling machine horizontale walima vertical sugandi wa? Nin masin suguya fila ninnu bɛ danfara danfaralenw na minnu bɛ nɔ bila baarakɛcogo ni musaka la. Ni mɔgɔ bɛnnen sugandi, o bɛ se ka danfara bɛɛ don i ka baarakɛcogo ɲuman na.

Nin sɛbɛn in kɔnɔ, aw bɛna fɛn kolomaw dɔn minnu bɛ kɛ ni jirituru masinw ye minnu bɛ ɲɔgɔn kan ani minnu bɛ jɔ. An bɛna u ka nafaw, u ka dɛsɛw, ani u ka ɲininiw sɛgɛsɛgɛ walasa k’aw dɛmɛ ka latigɛ kɛ aw ka masinko magow kan.

Mill ye mun ye?

Mili ye masinw ye minnu bɛ tigɛ-tigɛ-minɛnw wuli ka bɔ baarakɛminɛn jɔlen dɔ la. O fɛɛrɛ in nafa ka bon fɛn dilanni na ni a cogoya ni a bonya tigitigiw ye. Mili masinw bɛ iziniw dɛmɛ i n’a fɔ mobili, aerospace ani baarakɛminɛnw dilanni ka ɲɛ. Mili ye fɛn caman ye, a bɛ se ka nɛgɛw, plastikiw ani fɛn wɛrɛw tigɛ.

mansinw suguya minnu bɛ kɛ .

Machines de millage horizontales .

Milling machines horizontales bɛ u ka spindle (spindle) bila ka kɛɲɛ ni baarakɛtabali ye. O dilan in b’a to u bɛ se ka fɛn girinmanw, minnu ka bon kosɛbɛ ani ka tigɛ juguw kɛ ka ɲɛ. U ka ɲi kosɛbɛ iziniw ma, teliya, fanga ani fɛn caman sɔrɔli nafa ka bon yɔrɔ minnu na, i n’a fɔ mobili ni aerospace.

Machines verticales .

Milling machines verticals bɛ ni spindle oriented perpendicular to the worktable ye. U bɛnnen don kosɛbɛ baara tigitigiw ma, dilancogo gɛlɛnw, ani yɔrɔ fitininw. A ka ca a la, a bɛ sɔrɔ nɛgɛko ni prototyping la, o masinw bɛ se ka kɛ fɛn caman ye, wa u baara ka nɔgɔn baara gɛlɛnw kama.

Mansin-masin suguya wɛrɛw .

Mansin-masin suguya wɛrɛw fana bɛ yen:

Universal milling machines : min bɛ ni spindles horizontal ani vertical ye, o bɛ sɛgɛsɛgɛli kɛ baara suguya caman na.

Turret milling machines : A bɛ se ka lamaga caman kɛ siraw la minnu tɛ kelen ye, minnu bɛnnen don baara misɛnninw ma minnu ɲɛfɔlen don kosɛbɛ.

Bed Milling Machines : Baarakɛminɛnw dilanni min bɛ kɛ ni baarakɛminɛnw ye, minnu bɛ kɛ ka baara kɛ ni baarakɛminɛnw ye minnu ka bon, minnu ka gɛlɛn.

Machines de millage horizontales .

ɲɛfɔli ni fɛn kolomaw .

Milling machines horizontales bɛ ni spindle mont parallèle ye ni baarakɛ-tabali ye. U bɛ tɛmɛ tigɛ-tigɛ-baara gɛlɛnw kan ani ka baarakɛminɛnbaw minɛ. U ka dilancogo barikama bɛ sira di:

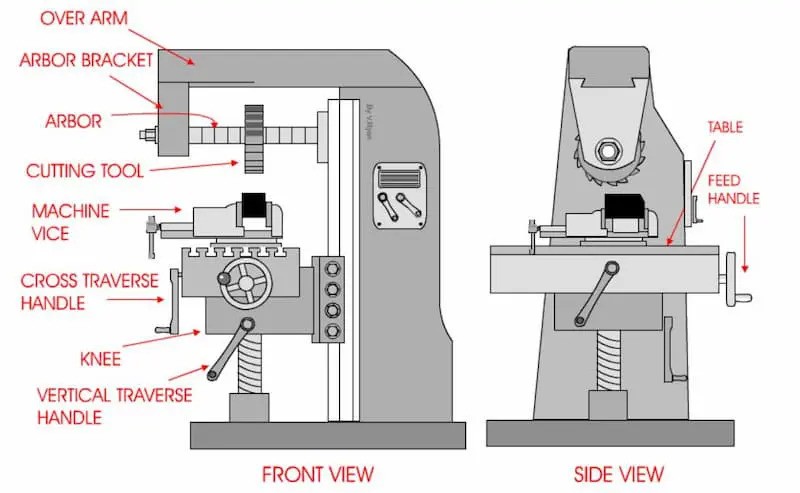

Image source . Fractory .

Spindle orientation ani a nɔfɛkow .

Spindle horizontal orientation bɛ nafa caman di:

chip evacuation ɲɛnabɔlen .

Sumaya hakɛ dɔgɔyali baarakɛminɛn kan .

Tigɛcogo ɲuman yiriwali baarabaw kama .

Tabali ni baarakɛminɛnw lamagacogo .

Horizontal mansinw bɛ baara kɛ cogoya la:

Tabali wulilen dɔ ye min bɛ kɛ ka ɲɛsin fɛɛrɛw ma minnu bɛ kɛ ni fɛn caman ye .

Lamaga-lamagali minnu bɛ Kɛ ni 'sèn ye X, Y ani Z 'kɔnɔ .

Clamping systems barikamaw ka ɲɛsin baarakɛminɛn lakananenw ma .

Tigɛ baarakɛminɛnw ni baarakɛcogo .

Face Mills .

Slab Mills .

Side ani ɲɛda mansinw .

Chip bɔli ni nɛnɛ .

Horizontal Mills ka fisa ni chip ɲɛnabɔli ye:

Gravité-Assistée chip evacuation .

nɛnɛmadalan sɔrɔli ɲɛnabɔli yɔrɔw la tigɛyɔrɔw la .

Farati min bɛ sɔrɔ chip seginni na .

versatility ani setup complexité .

Hali ni a bɛ fɛn caman di yɔrɔ gɛlɛnw ma, a ka ca a la, mansinw bɛ kɛ minnu bɛ kɛ ni jiri ye, olu bɛ ɲini:

Feed Control

| Feature | ɲɛfɔli . |

| Balo automatique . | Fɛnw bɔli tigitigi, min bɛ kɛ tuma bɛɛ . |

| Balo manuel . | Baarakɛlaw ka kɔlɔsiliba ka ɲɛsin baara kɛrɛnkɛrɛnnenw ma . |

Bɛn ni otomatiki sitɛmuw ye .

Horizontal Mills bɛ ɲɔgɔn sɔrɔ koɲuman ni:

Sɛnɛfɛnw dilanni nafa ani u bonya .

A ka ɲi kosɛbɛ ka ɲɛsin fɛn caman sɔrɔli ma ka da a kan:

Flexibilité ani a ladilanni nɔgɔya .

Hali ni u tɛ se ka wuli ka bɔ ɲɔgɔn na ka tɛmɛ mansinw kan minnu bɛ wuli, u bɛ:

Baarakɛla ka seko wajibiyalenw .

Operating Horizontal Mills demandes:

Dɔnniya min bɛ sɔrɔ masinw ka sariyakolow kan .

Dɔnniya sɔrɔli sigicogo gɛlɛnw na .

CNC porogaramuw sɔrɔli (CNC modɛliw kama) .

Mills Horizontal ka baarakɛcogo n’a nafaw .

Machining min bɛ baara kɛ ni baara gɛlɛn ye .

Horizontal Mills ka fisa ni iziniw ye minnu bɛ masinw seko barikamaw ɲini:

Mobili industrie .

Motɛri blokiw: Kɔnɔna sigicogo gɛlɛnw ka sɔgɔli tigitigi .

Transmission Housings: Fɛnba hakɛ bɔli ka ɲɛ .

Chassis components: alloys barikamaw cogoya tigitigi .

Aerospace industrie .

Wings: contouring intricate de structures belebelebaw, minnu ka nɔgɔn .

Spars: doni-ta-yɔrɔw sɔgɔli ni tiɲɛniba ye .

Fuselage Sections (Fuselage Sections): Yɔrɔ minnu ka bon kosɛbɛ, olu dilanni ka ɲɛ .

A sabatili ni a tiɲɛni bɛ caya .

Horizontal Mills bɛ sabatili ɲuman di, ka masinw bɛɛ lajɛlen ka tiɲɛni bonya:

Yɛrɛyɛrɛli dɔgɔyali tigɛtigɛw waati la .

Surface Finish qualité ɲɛtaa .

Tolerances sirilenw yɔrɔ gɛlɛnw kan .

| Feature | Benefit |

| Spindle design robust . | A bɛ deflection dɔgɔya tigɛ gɛlɛn waati . |

| Gravité-Assistée chip evacuation . | A bɛ segin-ka-bɔ bali, ka surface quality ɲɛ . |

| Baarakɛminɛn caman bɛ sɔrɔ yɔrɔ caman na . | A bɛ a to a ka kɛ cogo la min bɛ to ka kɛ yɔrɔbaw la . |

Baarakɛminɛnw ɲɛnamaya ɲɛtaa .

Horizontal milling machines bɛ dɛmɛ don baarakɛminɛnw ɲɛnamaya janya la:

Puce bɔli ɲuman, ka dɔ bɔ funteni caman sɔrɔli la .

nɛnɛmadalan jiginni ka ɲɛ ka taa tigɛyɔrɔw la .

Tigɛyɔrɔ ɲumanw, baarakɛminɛnw degun min bɛ dɔgɔya .

O kow bɛ na ni ninnu ye:

Baarakɛminɛnw musakaw dɔgɔyali .

Baarakɛminɛn caman bɛ Changé, ka dɔ fara baarakɛcogo kan .

Yɔrɔ ɲuman min bɛ to sen na ka tɛmɛ sɛnɛfɛnw bɔli kan minnu ka jan .

Machines verticales .

Mili masin jɔlenw bɛ ni spindle oriented perpendicular to the worktable ye. O labɛncogo bɛ dɔ fara fɛn caman kan, ka yecogo, ani ka baara gɛlɛnw kɛ. Spindle vertical bɛ sira di baarakɛminɛnw caman cili ma nɔgɔya la ani fɛnw bɔli ka ɲɛ, kɛrɛnkɛrɛnnenya la nafa bɛ u la ka ɲɛsin sɔgɔli ni sɔgɔli baara ma.

Tabali ni baarakɛminɛnw lamagacogo .

O mansinw bɛ kɛ cogoya la:

X ni Y axis tabali lamagacogo .

z axis lamagacogo ka tɛmɛ spindle walima quill fɛ .

Tilting sekow kan modeli kɔrɔlen dɔw la tigɛtigɛw la .

Tigɛ baarakɛminɛnw ni baarakɛcogo .

Miliw jɔlenw bɛ tigɛminɛn suguya caman ladon, u kelen-kelen bɛɛ bɛ baara kɛrɛnkɛrɛnnenw kɛ:

End Mills: A bɛ se ka kɛ fɛn caman ye ɲɛda sɔgɔli kama, a ka profiling, ani a ka slot tigɛcogo .

Drills: A bɛ kɛ ka dingɛ dilanni baara tigitigiw kɛ .

TAPS: Ka kɔnɔna jiriw dabɔli nɔgɔya, tuma caman na ni otomatiki sɛrɛkiliw ye CNC modɛliw kɔnɔ .

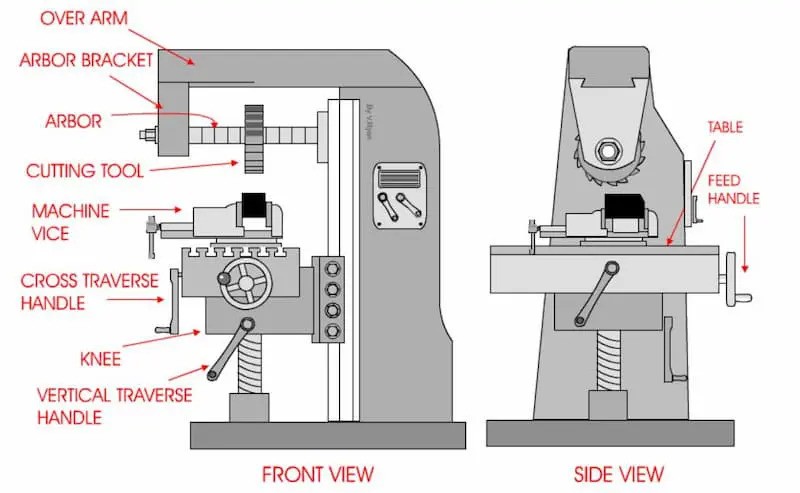

Image source . Fractory .

mansinw jɔlen suguyaw .

Turret Mills (Bridgeport-type walima gɛnɛgɛnɛw) .

O masin minnu bɛ se ka kɛ fɛn caman ye, olu bɛ bɛn yɔrɔ misɛnw ma fo ka se yɔrɔ cɛmancɛw ma. U bɛ gɛnɛgɛnɛ lamaga-lamagali jira walasa ka ladilanni jɔlenw kɛ, minnu ka di baarakɛyɔrɔw la ani prototyping sigidaw la.

Bed Milling Machines .

U dabɔra baarakɛminɛnw kama minnu ka bon, u bɛ ni dilan jɔlen ye ni spindle kunkolo lamagannen ye, o bɛ sabatili ɲuman di u ma walasa ka baara kɛ ka ɲɛ.

Balo kɔlɔsili ni otomatiki bɛnkan .

Miliw jɔlenw bɛ balocogo ni otomatiki balocogo fila bɛɛ di. U bɛ don ɲɔgɔn na kosɛbɛ ni otomatiki siraw ye, i n’a fɔ baarakɛminɛnw caman cili, palɛtiw, ani robow donitaw, ka baarakɛcogo ɲɛ ani ka se ka baara kɛ min tɛ mɔgɔ ta.

Sɛnɛfɛnw dilanni nafa ani u sɛgɛsɛgɛli .

A bɛnnen don kosɛbɛ ka ɲɛsin hakɛ dɔgɔman ma fo ka se hakɛ cɛmancɛ ma, o masinw bɛ tɛmɛ sigidaw kan minnu bɛ fɛn caman Changements de changements (Yɛlɛma caman) wajibiya. U bɛ u yɛrɛ ladamu nɔgɔya la masinw ka fɛɛrɛw la minnu tɛ kelen ye, o b’a to u ka ɲi kosɛbɛ denbaya suguya caman na.

Baarakɛla ka seko wajibiyalenw .

Baarakɛlaw mago bɛ:

Basic to intermediate machining dɔnniya .

Tigɛminɛn suguya caman dɔnni n’u baarakɛcogo .

CNC porogaramu seko ka ɲɛsin otomatiki sitɛmuw ma .

Mills verticales ka baarakɛcogo n’a nafaw .

Fɛn caman kɛli ani ladamuni .

Miliw jɔlenw bɛ tɛmɛ fɛn dilanni sigida suguya caman kan. U bɛ ɲɔgɔn falen nɔgɔya la baara suguya caman cɛ, k’u kɛ fɛn ɲumanw ye baarakɛyɔrɔw ni fɛnw na minnu mago bɛ fɛn caman na.

Baara kɛcogo ɲuman ani baara kɛcogo ɲuman .

Spindle vertical configuration bɛ sira di yecogo ɲuman ma ani ka a kunbɛn. O b’a to o masinw bɛnnen don kɛrɛnkɛrɛnnenya la yɔrɔ gɛlɛnw ma minnu bɛ ɲini ka ɲɛ kosɛbɛ.

Prototyping ani ladamu baara .

U ka se ka fɛnw sɛgɛsɛgɛ ani ka u ka setup nɔgɔya, o bɛ kɛ sababu ye ka mansinw jɔ minnu bɛ kɛ ka mɔgɔw bila u ka baara la:

Prototyping rapide de designs kuraw .

Baara min bɛ kɛ ni fɛn ye min bɛ kɛ ka kɛɲɛ ni mɔgɔw sago ye .

A bɛ se ka ladamu teliya la ka kɛɲɛ ni fɛn caman yeli ye .

Senna-tɛgɛrɛ ni musaka dɔgɔyali .

A ka c’a la, mansin jɔlenw bɛ duguma yɔrɔ dɔgɔya ka tɛmɛ u ɲɔgɔnna tilennenw kan. O ni u ka musaka fɔlɔw dɔgɔyali, o b’a to u bɛ kɛ sugandili ye min bɛ mɔgɔ ɲɛnajɛ:

Butigi misɛnninw ni yɔrɔ danma .

Jagokɛlaw bɛ ka daminɛ dɔrɔn .

Yɔrɔ minnu b’a ɲini k’u ka masinko seko bonya musaka-nɔgɔya la .

| Feature | Benefit . |

| Spindle vertical . | yecogo ni kɔrɔsili min bɛ bonya . |

| Baarakɛminɛn caman bɛ sɔrɔ . | Adamadabɛli baara suguya caman na . |

| A ye a ka baara kɛ ni a ka baara ye . | Baara kɛcogo ɲuman ni butiki yɔrɔ ye . |

| A daminɛ musaka dɔgɔyara . | Jagokɛyɔrɔ fitininw sɔrɔli . |

Danfaraba minnu bɛ Mills Horizontal ni verticale cɛ,

| olu bɛ | Mills | vertical Mills fan fɛ . |

| Spindle orientation . | paralɛli ni baarakɛ-tabali . | Perpendicular to worktable . |

| Tigɛ baarakɛminɛnw . | A surunyalen don, a ka bon (misali la, slab mills, ɲɛda mansinw) | A ka jan, a ka fin (misali la, a laban mansinw, a ka drills, a ka pɔmpiw) |

| Aplikasiɔn ɲumanw . | Baarakɛminɛnbaw, yɔrɔ gɛlɛnw, fɛn caman dilanni . | Yɔrɔ fitininw, baara tigitigi, baarakɛcogo caman . |

| Setup complexité . | A ka gɛlɛn kosɛbɛ, a bɛ waati caman ta . | A ka nɔgɔn, a bɛ se ka faamuya . |

| Surface Finish . | A bɛ bɛn yɔrɔbaw ma minnu ka bon, minnu bɛ kɛ . | A ka ɲi kosɛbɛ ka kunnafoni gɛlɛnw sɔrɔ . |

| A daminɛ musaka . | sanfɛ . | Ka lajigin |

| Labɛn | A ka gɛlɛn kosɛbɛ . | A ka nɔgɔn . |

| Baarakɛminɛnw sɔrɔli . | A ka ca ni masin ye min tɛ se ka sɔrɔ, a bɛ se ka kɛ fɛn caman ye . | yecogo ɲuman ni sɔrɔli . |

| chip evacuation . | Gravité-Dɛmɛn, a bɛ baara kɛ ka ɲɛ . | bɛ se ka dalajɛ tigɛyɔrɔ la . |

| Baarakɛminɛnw ɲɛnamaya . | Jɛnkulu ka jan ka da a nɛnɛni kan ka ɲɛ . | bɛ se ka fɛn caman Changements de quelques de la . |

| Masiniw ka tiɲɛni . | Superior ka ɲɛsin yɔrɔbaw ma . | A ka ɲi kosɛbɛ yɔrɔ fitininw na minnu ka gɛlɛn . |

| Masina senna . | Dugukolo yɔrɔba, yɔrɔ jɔlen baarakɛcogo ɲuman . | Senna-tɛgɛrɛ fitinin, yɔrɔ-kɔnɔ-fɛn min bɛ se ka kɛ . |

Milling masin baarakɛcogo jateminɛw .

Faamuyali min bɛ kɛ mansinw ka baarakɛcogo jateminɛw na, o nafa ka bon kosɛbɛ walasa ka minɛn ɲumanw sugandi fɛn dilanni mago kɛrɛnkɛrɛnnenw kama. O jateminɛw bɛ danfara ka bɔ ɲɔgɔn na jirisunw ni ɲɔgɔn cɛ, minnu bɛ nɔ bila u ka bɛnkan na baara suguya wɛrɛw kama.

Baarakɛcogo jiralanw

| Metric | Horizontal Mills | vertical Mills . |

| Tigɛ juguya hakɛ maksimali . | fo ka se santimɛtɛrɛ 12 ma . | fo ka se santimɛtɛrɛ 6 ma . |

| Tabali bonya . | 50 x 20 inci (a ka ca a la) . | 30 x 12 inci (a ka ca a la) . |

| Spindle teliya hakɛ . | 500 - 3000 RPM . | 1000 - 5000 RPM . |

| Seko ni dɔnko . | 5 - 15 HP . | 2 - 7,5 HP . |

Spindle fanga ni torque .

A ka c’a la, mansinw bɛ ɲɔgɔn sɔrɔ minnu bɛ se ka kɛ ni sɔgɔli fanga ni girinya ye, o b’a to u bɛ se ka tigɛ gɛlɛnw ni baarakɛminɛnbaw minɛ. Mansinw jɔlenw, hali ni u fanga ka dɔgɔ, olu bɛ girinya bɛrɛ di masinw ka baara fanba ma.

tabali doni seko ni taama .

Horizontal Mills ka fisa ni tabali doni ye, a ka c’a la, a bɛ baarakɛminɛn girinmanw dɛmɛ. A ka c’a la, u bɛ tabali taama caman di, ka yɔrɔbaw masinw nɔgɔya. Mansinw jɔlenw, k’a sɔrɔ u dan ka bon o fanw na, u bɛ seko caman di masinko baara caman ma minnu bɛ kɛ tuma caman na.

Masina hakɛ bɛɛ lajɛlen ani a girinya .

Horizontal mansinw ka teli ka bonya ani ka girinya, o bɛ duguma yɔrɔ caman wajibiya. O bonya bonya bɛ dɔ fara u ka sabatili kan tigɛ gɛlɛnw senfɛ. Miliw jɔlenw, k’a sɔrɔ u ka dɔgɔ, olu bɛ nafa sɔrɔ yɔrɔ la, minnu bɛ se ka kɛ yɔrɔ la, baarakɛyɔrɔ fitininw na.

Bɛn ni CNC sitɛmuw ye .

Mills horizontal ani vertical fila bɛɛ bɛ don koɲuman ni CNC systems ye. CNC controleurs modernes bɛ suguya fila ninnu sekow bonya, ka o dilan:

Lamaga-lamagali tigitigi .

Otomatiki baarakɛminɛn caman cili .

Machining multi-axis complexe .

Aplikasi typique .

Mills horizontal:

Yɔrɔbaw ka masina girinmanw .

Mobili ni aerospace yɔrɔw .

Multi-side machining in setup kelen .

Miliw jɔlenw:

Tiɲɛni baara kɛ yɔrɔ fitininw kan .

Prototyping ani ladamu masinw .

Baara minnu bɛ kɛ ni fɛn bɛɛ ye, olu bɛ kɛ fɛn ye .

Ka mansin ɲuman sugandi i magow kama .

Ka mansin ɲuman sugandi, o nafa ka bon kosɛbɛ walasa ka baara kɛcogo ɲuman, tiɲɛni ani musakabɔcogo ɲuman sɔrɔ i ka fɛn dilanni na. Ni i ye mansin tilennen walima jɔlen dɔ sugandi, o bɛ bɔ fɛn caman na, minnu bɛɛ ka kan ka bɛn i ka baarakɛcogo kɛrɛnkɛrɛnnenw ma.

Fɛn minnu ka kan ka jateminɛ ni aw bɛ mansin dɔ sugandi .

Baarakɛminɛn hakɛ ni a gɛlɛya : mansinw jiginni yɔrɔbaw la, yɔrɔ minnu ka gɛlɛn, ka sɔrɔ mansin jɔlenw ka ɲi baara misɛnninw na, minnu ka gɛlɛn.

Wajibiyalen ni dugukolo sanfɛla labɛnni : Miliw jɔlenw bɛ tiɲɛniba di baara caman ma, ka sɔrɔ mansin tilennenw bɛ tɛmɛ fɛn gɛlɛnw bɔli kan.

A dilanni hakɛ : Walasa ka fɛn caman dilan, mansinw jiginni bɛ fɛnw bɔ teliya la, ka sɔrɔ mansin jɔlenw bɛnnen don batch runs misɛnninw ma.

Dugukolo yɔrɔ ni budget min bɛ sɔrɔ : Mili jɔlenw bɛ yɔrɔ caman ta ani u bɛ se ka sɔrɔ ka caya, ka sɔrɔ mansinw jiginni ka teli ka yɔrɔ caman de wajibiya ani ka wari bila fɔlɔ.

Nafa minnu bɛ sɔrɔ mansinw na minnu bɛ kɛ ɲɔgɔn fɛ .

Mili-masinw minnu bɛ ɲɔgɔn kan, olu bɛ sabatili ɲuman ni fɛnw bɔli hakɛw di baara gɛlɛnw na. O nafaw b’a to u bɛnnen don kosɛbɛ:

Baarakɛminɛnbaw : Yɔrɔ belebelebaw minɛcogo minnu bɛ tigɛ jugumanw wajibiya.

Masina caman-caman : Yɔrɔ gɛlɛnw ka kan ka baara kɛ ka bɔ yɔrɔw la minnu tɛ kelen ye, k’a sɔrɔ u ma to ka segin-ka-bɔ.

Fɛn girinmanw bɔli : Sɛnɛfɛnw dilanniba bɛ kɛ iziniw kɔnɔ i n’a fɔ mobili ni aerospace.

Nafa minnu bɛ sɔrɔ mansin jɔlenw na baara kɛrɛnkɛrɛnnenw kama .

Mili jɔlenw bɛ se ka kɛ fɛn caman ye ani u musaka ka dɔgɔ, u bɛ baara misɛnninw kɛ ka ɲɛ ani ka baara nɔgɔya. U bɛ tɛmɛ nin kan:

Precision baara : dafalen don tigɛ gɛlɛnw na ani surface fini ɲumanw na.

Prototyping ani Custom Jobs : A ka ɲi kosɛbɛ ka ɲɛsin fɛnw ma minnu bɛ kɛ ka ɲɛ, minnu bɛ kɛ siɲɛ kelen walima minnu bɛ kɛ ni fɛn fitininw ye.

Baara minnu bɛ kɛ ni nafolo dɔgɔyali ye : ka senna-tɛgɛrɛ fitinin di ani ka musakaw dɔgɔya ka kɔn o ɲɛ, o b’a to u bɛ se ka don butiki misɛnninw na.

Aplikasi kɛrɛnkɛrɛnnenw ka baarakɛcogo ani ko kɛlenw sɛgɛsɛgɛli

Complex cavity machining : horizontal mansinw bɛ cavités complexes (kɔgɔjida gɛlɛnw) ɲɛnabɔ ni u bɛ sira di tigɛ juguw ma ani puce (puce) bɔli ɲuman ma, o min nafa ka bon kosɛbɛ iziniw kɔnɔ i n’a fɔ mould-making (sɔgɔli).

Sceped surface machining : mansinw jɔlenw ka ɲi kosɛbɛ masinw senfɛ, yɔrɔ minnu na tigitigi ani ladilanni ka ɲɛ, olu ye fɛnba ye.

Materiel machining min ka gɛlɛn kosɛbɛ : mansinw jiginni ka fisa ni masinw ye minnu ka gɛlɛn kosɛbɛ i n’a fɔ nɛgɛ, k’a sababu kɛ u tigɛ fanga ka bon.

Small-batch, high-variety production : Mills verticals bɛ yeelen bɔ misɛnw na, suguya caman na, yɔrɔ minnu na sigicogo caman yeli ye wajibi ye.

Automation Line Retrofitting : Ka ɲɛsin tɔnw ma minnu b’a fɛ ka automatique lines retrofit, horizontale mansinw bɛ bɛnkan di ni automatiques systemes avancés ye, ka productivité (sɔrɔli) yiriwa mass production (jamaba) la.

| Baarakɛcogo | Ladilikan Mill suguya | Key Benefit . |

| Cavité complexe machining . | Dalen | Tigɛ jugumanw, puce bɔli baarakɛcogo ɲuman . |

| Senna-yɔrɔ-masinw . | Jɔ̀len | Tiɲɛni ni ladilanni nɔgɔman . |

| Matériel machinage min ka gɛlɛn kosɛbɛ . | Dalen | Tigɛ fanga belebeleba . |

| Batch-batch, fɛn suguya caman sɔrɔli . | Jɔ̀len | Yɛlɛma teliyalen, masinw ɲɛfɔlenw . |

| Otomatiki layini retrofitting . | Dalen | Bɛnkanba min bɛ kɛ ni otomatiki sitɛmuw ye . |

Ka mansin ɲuman sugandi, o bɛ bɔ i mago kɛrɛnkɛrɛnnenw, i ka baarakɛnafolo ani i ka fɛn dilanni kuntilenna balancogo la. Miliw minnu bɛ ɲɔgɔn kan ani minnu bɛ jɔ, olu fila bɛɛ bɛ nafa danfaralenw di, wa ni i ye mɔgɔ ɲuman sugandi, o bɛ se ka i ka fɛn dilanni nafa bonya kosɛbɛ.

Kuncɛli

Mili masinw ni ɲɔgɔn cɛ minnu bɛ jɛgɛn ani minnu bɛ jɔ, olu bɛ danfara Bɔ kosɛbɛ spindle orientation (spindle) ɲɛsincogo la, setup (dafalen) gɛlɛya la, ani a kɛcogo la. Horizontal mansinw ka ɲi baara gɛlɛnw na, ka sɔrɔ mansinw jɔlenw bɛ tɛmɛ baara kan min bɛ kɛ ka ɲɛ. U fanga n’u barika faamuyali nafa ka bon kosɛbɛ walasa ka baara kɛcogo ɲuman sɔrɔ.

Ka mansin ɲuman sugandi, o bɛ bɔ i ka baarakɛminɛn hakɛ la, a dilanni hakɛ la, ani a tiɲɛni wajibiyalenw na. O mansin suguya fila bɛɛ bɛ se ka ɲɔgɔn dafa masin feereyɔrɔ la min lamininen don koɲuman. Ni aw ye aw magow jateminɛ, aw bɛ se ka aw ka mansin nafolo labɛn ani k’a labɛn ka ɲɛ walasa ka baara kɛcogo ɲuman ni baarakɛcogo ɲuman sɔrɔ.