Milin mashin dɛn na kɔna ston fɔ di mɔdan manufakchurin, bɔt us tayp yu nid? Yu fɔ pik wan ɔrizɔntal ɔ vertikal mil mashin? Dɛn tu kayn mashin ya gɛt difrɛn difrɛns dɛn we de ambɔg di pefɔmɛns ɛn di kɔst. We yu pik di rayt wan, i kin mek ɔl di difrɛns na yu prodakshɔn efyushɔn.

Insay dis post, yu go lan di men tin dɛn we de na ɔl tu di ɔrizɔntal ɛn vertikal miling mashin dɛn. Wi go fɛn ɔl dɛn pros, kɔns, ɛn aplikeshɔn fɔ ɛp yu fɔ mek wan infɔm disizhɔn fɔ yu mashin nid dɛn.

Wetin na mil?

Milin na wan mashin we dɛn kin yuz fɔ mek di tin dɛn we dɛn kin yuz fɔ kɔt di tin dɛn we dɛn kin yuz fɔ kɔt di tin dɛn we dɛn kin yuz fɔ kɔt di tin dɛn we dɛn kin yuz fɔ kɔt di tin dɛn we dɛn kin yuz fɔ kɔt di tin dɛn we dɛn kin yuz fɔ kɔt di tin dɛn we dɛn kin yuz fɔ kɔt di tin dɛn we dɛn kin yuz fɔ kɔt. Dis we ya impɔtant fɔ mek pat dɛn we gɛt prɛsis shep ɛn saiz. Milin mashin dɛn de ɛp industri dɛn lɛk ɔtomotiv, aerospace, ɛn tul-mɛkin efyushɔn prodyuz kɔmpɔnɛnt dɛn. Milin na tin we pɔsin kin yuz fɔ du bɔku tin, i kin ebul fɔ kɔt mɛtal, plastic, ɛn ɔda tin dɛn.

Di kayn mashin dɛn we dɛn kin yuz fɔ mil .

Mashion dɛn we de mek fɔ mil ɔrizɔntal mil .

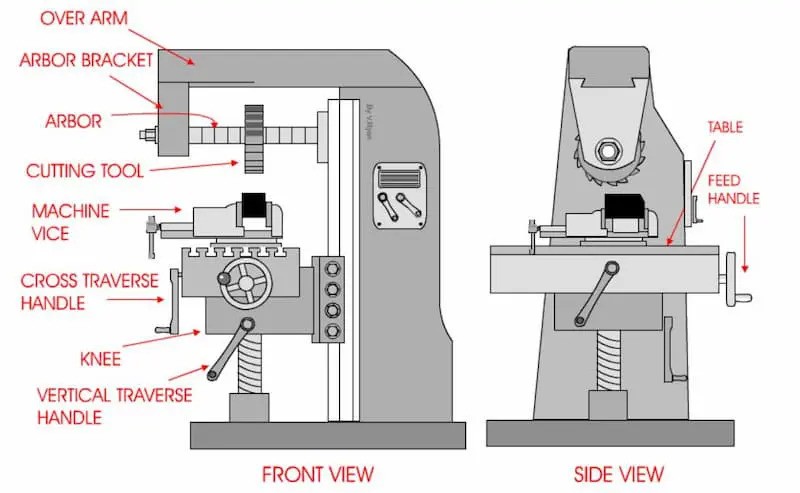

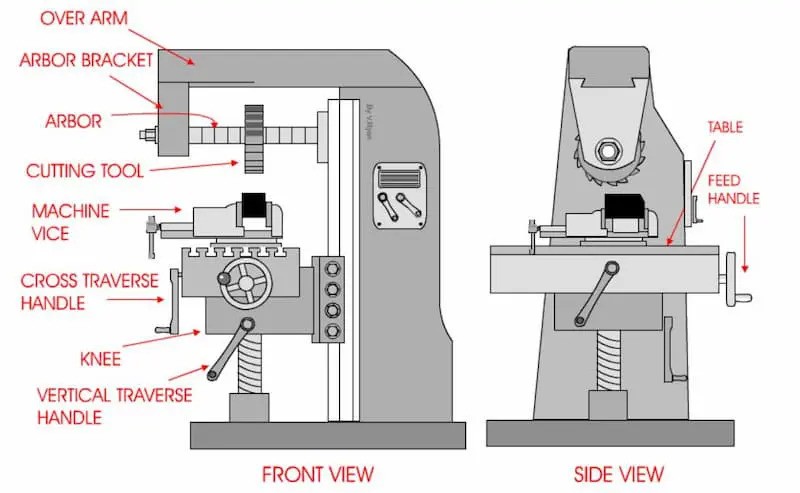

Ɔrizɔntal mil mashin dɛn de posishun dɛn spindle paralel to di wok tebul. Dis dizayn de alaw dɛn fɔ handle hevi, big matirial ɛn du dip kɔt fayn fayn wan. Dɛn fayn fɔ industri usay spid, trɛnk, ɛn ay-volyum prodakshɔn impɔtant, lɛk ɔtomotiv ɛn ɛrospɛs.

Vɛtikal mil mashin dɛn .

Vɛtikal mil mashin dɛn gɛt spindle ɔriɛnted pɔrpindikul to di wok tebul. Dɛn kin bɛtɛ fɔ mek dɛn du prɛsishɔn wok, fɔ mek dɛn fayn fayn wan, ɛn fɔ mek dɛn smɔl smɔl pat dɛn. Dɛn kin fɛn am na mɛtal wok ɛn protɔtayp, dɛn mashin dɛn ya kin rili yuz ɛn i izi fɔ wok fɔ kɔmpleks wok dɛn.

Ɔda kayn mashin dɛn we dɛn kin yuz fɔ mil .

Ɔda kayn mil mashin dɛn de bak:

Universal Milling Machines : I gɛt ɔl tu di ɔrizɔntal ɛn vertikal spindl dɛn, we de gi fleksibiliti fɔ difrɛn wok dɛn.

Turret Milling Machines : Alaw fɔ mek mɔ muvmɛnt na difrɛn say dɛn, we fayn fɔ smɔl, mɔ ditayla wok.

Bed Milling Machines : Fiks wok tebul dizayn, we dɛn kin yuz fɔ big, ebi wokpies dɛn we ebi.

Mashion dɛn we de mek fɔ mil ɔrizɔntal mil .

Difinishɔn ɛn di men tin dɛn we gɛt fɔ apin .

Ɔrizɔntal mil mashin dɛn gɛt spindle we dɛn dɔn mawnt paralel to di wok tebul. Dɛn kin du wɛl pan di ɔpreshɔn dɛn we dɛn kin du fɔ kɔt di ebi ebi wok ɛn fɔ ol big wok dɛn. Dɛn strɔng dizayn de alaw fɔ:

simultaneously use of multiple cutters .

Efishin matirial rimɔvmɛnt .

Enhanced stabiliti durin dip kots .

Imej Sɔs . Fraktɔri .

Spindle oriɛnteshɔn ɛn implikashɔn dɛn .

Di ɔrizɔntal spindle ɔriɛnteshɔn de gi sɔm bɛnifit dɛn:

Impɔtant Chip Ɛvakyushɔn .

Ridyus di ɔt bildup pan di wokpies .

Enhansed cutting efficiency fɔ big-big opareshɔn dɛn .

Tebul ɛn Wokpies muvmɛnt .

Horizontal mils tipikli employ:

Wan rotary tebul fɔ multi-ɛngl aprɔch .

Linear muvmɛnt dɛn along x, y, ɛn z aks dɛn .

Robust Clamping Systems fɔ Sikyu Wokpies Holdin .

Di tul dɛn ɛn di opareshɔn dɛn we dɛn de du fɔ kɔt .

Fes Mills .

Slab mil dɛn .

Sayd ɛn fes mil dɛn .

Chip Rimoval ɛn kol .

Horizontal Mills Excel in Chip Manejmɛnt:

Chip Evakueshɔn we gɛt graviti we gɛt graviti .

Improved kulant akses to kot zon .

Ridyus di risk fɔ mek dɛn pul di chip bak .

Versatility ɛn sɛtup kɔmplisiti .

Pan ɔl we dɛn kin gi ay versatility fɔ kɔmpleks pat dɛn, bɔku tɛm ɔrizɔntal mil dɛn kin nid:

Fid Kɔntrol

| Ficha | Diskripshɔn . |

| Otomatik fid . | Prɛsis, kɔnsistɛns matirial rimɔvmɛnt . |

| Manual fid . | Big big ɔpreshɔn kɔntrol fɔ spɛshal wok dɛn . |

Kompatibiliti wit ɔtomɛshɔn sistem dɛn .

Horizontal mils intagret wel wit:

Prodakshɔn efyushɔn ɛn volyum .

Ideal fɔ ay-volyum prodakshɔn bikɔs ɔf:

Fleksibul ɛn izi fɔ ajɔst .

Pan ɔl we dɛn nɔ kin chenj pas vertikal mil dɛn, dɛn kin gi:

Di tin dɛn we dɛn nid fɔ du fɔ mek di wok go bifo .

Opereting Horizontal Mills Dimand dɛn:

Advans no bɔt mashin prinsipul dɛn .

Ɛkspɛriɛns insay kɔmpleks sɛtup prosidyuz dɛn .

Profisiɛns insay CNC programin (fɔ CNC mɔdel dɛn)

Aplikeshɔn ɛn bɛnifit dɛn fɔ ɔrizɔntal mil dɛn .

Hevi-duti we de mek mashin fɔ mek mashin .

Horizontal Mills Excel in industri dɛn we nid robust mashin kapabiliti:

Ɔtomotiv Indastri .

Enjin blɔk: prɛsis mil fɔ kɔmpleks intanɛnt strɔkchɔ dɛn .

Transmishɔn Hausin: Efisiɛns Rimov big matirial volyum dɛn .

Chassis komponent dɛn: Akkurayt shep fɔ ay-strɛngth alɔy dɛn .

Indastri fɔ Erospɛs .

Wings: Intricate contouring of big, laytwɛt strɔkchɔ dɛn

Spars: ay-prɛsishɔn mil fɔ lod-bɛrin kɔmpɔnɛnt dɛn

Fuselage sections: Efficient mashin fɔ di ɛkspɛnsif sɔfayz eria dɛn .

Inkris stebiliti ɛn akkuracy .

Horizontal mils ofa supia stebiliti, enhancing ovalayz mashin akkuracy:

Ridyus di vaybreshɔn we dɛn de du dip kɔt .

Impruv Surface Finish Kwaliti .

tayt tolerans pan kɔmpleks pat dɛn .

| Ficha | bɛnifit |

| Robust spindle dizain . | Minimizes deflection durin hevi cutting . |

| Chip Evakueshɔn we gɛt graviti we gɛt graviti . | I de mek dɛn nɔ du ri-kɔt, impruv di kwaliti fɔ di sɔfays . |

| Multi-point wokpies sɔpɔt . | I de mek shɔ se kɔnsistɛns akkuracy de akɔdin to big pat dɛn . |

Enhansed Tool Layf .

Ɔrizɔntal mil mashin dɛn de kɔntribyut to ɛkstend tul layf tru:

Efficient chip removal, ridyusin heat buildup

Improved Coolant Delivery to Cutting Zones .

Optimal kot angul, minimiz tul strɛs .

Dɛn tin ya kin mek:

Ridyus di kɔst fɔ di tul dɛn .

Di chenj dɛn we de na di tul nɔ bɔku, di we aw dɛn de mek di tin dɛn we dɛn de yuz fɔ wok go bɔku .

Kɔnsistɛnt pat kwaliti ova lɔng prodakshɔn rɔn dɛn .

Vɛtikal mil mashin dɛn .

Vɛtikal mil mashin dɛn gɛt spindle ɔriɛnted pɔrpindikul to di wok tebul. Dis konfigyushɔn de ɛp fɔ mek pɔsin ebul fɔ du bɔku tin, fɔ mek i ebul fɔ si tin, ɛn fɔ mek i ebul fɔ du tin dɛn we nɔ izi fɔ ɔndastand. Di vertikal spindle alaw izi tul chenj ɛn efishɔnal matirial rimɔv, patikyula bɛnifit fɔ drɔ ɛn tap ɔpreshɔn.

Tebul ɛn Wokpies muvmɛnt .

Dɛn mil dɛn ya kin gi:

X ɛn Y aks tebul muvmɛnt .

z aks muvmɛnt via di spindle ɔ quill .

Tilting kapabiliti pan sɔm advans mɔdel fɔ angled kɔt .

Di tul dɛn ɛn di opareshɔn dɛn we dɛn de du fɔ kɔt .

Vɛtikal mil dɛn kin akɔmod difrɛn tin dɛn fɔ kɔt, ɛni wan pan dɛn kin gi sɔm patikyula tin dɛn fɔ du:

End Mills: Versatile fɔ fes mil, profayl, ɛn slot kɔt

Drills: Dɛn kin yuz am fɔ mek dɛn du di rayt wok we dɛn de du fɔ mek ol dɛn we gɛt ol dɛn .

Taps: Fasilitet intanal thread krieshɔn, bɔku tɛm wit ɔtomatik saykl dɛn na CNC mɔdel dɛn .

Imej Sɔs . Fraktɔri .

Tayp dɛn fɔ Vɛtikal Mil dɛn .

Turret Mills (Bridgeport-Type ɔ Knee Mills)

Dɛn mashin dɛn ya we dɛn kin yuz fɔ du bɔku tin dɛn kin fit smɔl to midul saiz pat dɛn. Dɛn gɛt wan knee we dɛn kin muv fɔ mek dɛn ajɔst dɛn vertikal wan, we pipul dɛn lɛk na wok shɔp ɛn protɔtayp ɛnvayrɔmɛnt dɛn.

Bed mil mashin dɛn .

Dɛn mek dɛn fɔ big wokpies, dɛn gɛt wan fiks bed wit wan muv spindle ed, we de gi ɛnhans stebiliti fɔ prɛsishɔn wok.

Fid kɔntrol ɛn ɔtomɛshɔn kɔmpitibliti .

Vɛtikal mil dɛn de gi ɔl tu di manual ɛn ɔtomatik fid opshɔn dɛn. Dɛn de intagret fayn fayn wan wit ɔtomɛshɔn sistem, we inklud tul chenja, palet sistem, ɛn rɔbɔt lod, ɛnhans prodaktiviti ɛn ɛnabul ɛkstend unmanned ɔpreshɔn.

Prodakshɔn efyushɔn ɛn fleksibiliti .

Dɛn mashin dɛn ya fayn fayn wan fɔ mek dɛn gɛt smɔl to midul volyum, dɛn mashin dɛn ya kin du wɛl na say dɛn we dɛn kin nid fɔ chenj ɔltɛm. Dɛn kin adap izi wan to difrɛn mashin strateji dɛn, we kin mek dɛn fayn fɔ difrɛn pat famili dɛn.

Di tin dɛn we dɛn nid fɔ du fɔ mek di wok go bifo .

Di wan dɛn we de wok de nid:

Besik to intamɛdiet mashin no bɔt .

Familiariti wit difrɛn kɔt tul dɛn ɛn dɛn aplikeshɔn dɛn .

CNC programin skills fɔ ɔtomatik sistem dɛn .

Aplikeshɔn ɛn bɛnifit dɛn fɔ vertikal mil dɛn .

Versatility ɛn adaptabiliti .

Vɛtikal mil dɛn kin ɛksɛl insay difrɛn difrɛn manufakchurin ɛnvayrɔmɛnt dɛn. Dɛn kin izi fɔ chenj bitwin difrɛn opareshɔn dɛn, we kin mek dɛn fayn fɔ wok shɔp ɛn fasiliti dɛn we gɛt difrɛn difrɛn prodakshɔn nid dɛn.

Prɛsishɔn ɛn ditil wok .

Di vertikal spindle konfigureshɔn alaw fɔ fayn fayn visibiliti ɛn kɔntrol. Dis mek dɛn mashin dɛn ya rili fayn fɔ di pat dɛn we gɛt bɔku bɔku tin dɛn we nid ay prɛsishɔn.

Prototyping ɛn kɔstɔm wok .

Dɛn fleksibiliti ɛn izi fɔ sɛtup de mek vertikal mil dɛn pafɛkt fɔ:

Smɔl futprin ɛn kɔst-ɛfɛktiv .

Vɛtikal mil dɛn jɔs de ɔkup less floor space pas dɛn ɔrizɔntal kɔmpin dɛn. Dis, we dɛn jɔyn wit dɛn lɔwa initial kɔst, de mek dɛn bi atraktiv opshɔn fɔ:

Smɔl smɔl shɔp dɛn we gɛt smɔl ples fɔ slip .

Biznɛs dɛn jɔs de bigin fɔ wok .

Fasiliti dɛn we de luk fɔ mek dɛn ebul fɔ du mɔ fɔ mek dɛn ebul fɔ mek dɛn mashin dɛn we dɛn go ebul fɔ du fɔ mek dɛn ebul

| Ficha | bɛnifit |

| Vɛtikal spindle . | Enhansd visibiliti ɛn kɔntrol . |

| Versatile tul dɛn . | Adaptabiliti to difrɛn opareshɔn dɛn . |

| Kɔmpakt dizayn . | Efficient yus fɔ shop spɛs . |

| Lɔwa initial kɔst . | Aksessibiliti fɔ smɔl biznɛs dɛn . |

Ki difrɛns bitwin ɔrizɔntal ɛn vertikal mil dɛn

| aspek | ɔrizɔntal mil dɛn | vertikal mil dɛn . |

| Spindle oriɛnteshɔn . | Paralel to wok tebul . | Pɛrpindikul to Woktɛbul . |

| Tul dɛn we dɛn kin yuz fɔ kɔt . | shɔt, tik (ɛgz., slab mil, fes mil) | Long, tina (eg, end mil, drill, tap) |

| Ideal aplikeshɔn dɛn . | Big wokpies, komplex pat, ay-volyum prodakshɔn | Smɔl pat dɛn, prɛsishɔn wok, versatile ɔpreshɔn dɛn |

| Sɛtup kɔmplisiti . | Mɔ kɔmpleks, we de tek bɔku tɛm . | Simpul, mɔ intuitiv . |

| Surface Finish . | Konsistent pan big, flat surfaces . | Eksɛlɛnt fɔ di ditel dɛn we gɛt bɔku bɔku tin dɛn fɔ no bɔt . |

| Initial Kɔst . | Di wan dɛn we ay pas ɔl . | Ridyus |

| Mek say we dɔn pwɛl | Mɔ Kɔmpleks . | Simpul wan dɛn . |

| Wokpies Aksessibiliti . | Less aksesbul, multi-sayd mashin kapabiliti | Bɛtɛ Visibiliti ɛn Akses . |

| CHIP EVƐKUƐSHƆN . | Graviti-asist, efishɔnal | kin akumulet na di kɔtin pɔynt . |

| Tul Layf . | Jɛnɛral lɔng bikɔs ɔf bɛtɛ kol . | I kin nid fɔ chenj mɔ ɛn mɔ . |

| Di akkuracy fɔ mek mashin . | Superior fɔ big big sɔfays dɛn . | Eksɛlɛns fɔ smɔl, intrikɛt pat dɛn . |

| mashin futprin . | Big big flo spɛs, efishɔnal vertikal spɛs yuz | Smɔl futprin, spɛs-efishin |

Milling Machine Performance Metrics .

Ɔndastand di mil mashin pefɔmɛns mɛtrik impɔtant fɔ pik di rayt ikwipmɛnt fɔ spɛshal manufakchurin nid dɛn. Dɛn mɛtrik ya kin difrɛn bitwin ɔrizɔntal ɛn vertikal mil dɛn, we kin ambɔg dɛn fit fɔ difrɛn aplikeshɔn dɛn.

Ki Performance Indicators

| Metric | Horizontal Mills | Vɛtikal Mill dɛn . |

| Maksimum dep we de kɔt . | i go rich 12 inch . | i go rich 6 inch . |

| tebul saiz . | 50 x 20 inch (tipik) | 30 x 12 inch (tipik) |

| Spindle spid renj . | 500 - 3000 RPM | 1000 - 5000 RPM |

| Pawa ɔtput . | 5 - 15 hp we de na di . | 2 - 7,5 hp |

Spindle pawa ɛn tɔk .

Ɔrizɔntal mil dɛn jɔs de gi ay spindle pawa ɛn tɔk, we de mek dɛn ebul fɔ handel di kɔt dɛn we ebi ɛn big wokpies dɛn. Vɛtikal mil, pan ɔl we tipikli nɔ gɛt bɛtɛ pawa, de gi sufayf tɔk fɔ mɔs jenɛral mashin wok dɛn.

Tebul lod kapasiti ɛn travul .

Horizontal mils excel in tebul lod kapasiti, plenti taims sopot hevi wokpies. Dɛn kin ɔltɛm gi big tebul travul, fasilit mashin fɔ big pat dɛn. Vɛtikal mil dɛn, pan ɔl we dɛn nɔ gɛt bɛtɛ pat pan dɛn aspek ya, dɛn de gi bɔku kapasiti fɔ mɔs kɔmɔn mashin opareshɔn dɛn.

Di dimɛnshɔn dɛn we de ɔlsay na di mashin ɛn di wet .

Ɔrizɔntal mil dɛn kin big ɛn dɛn kin ebi, dɛn kin nid fɔ gɛt mɔ ples fɔ de na di flɔ. Dis inkris saiz de kɔntribyut to dɛn stebiliti we dɛn de du ebi ebi kɔt ɔpreshɔn. Vɛtikal mil dɛn, bikɔs dɛn gɛt mɔ kɔmpakt, dɛn de gi advantej dɛn we go sev di spes na smɔl wokshɔp dɛn.

Kompatibiliti wit CNC sistem dɛn .

Ɔl tu di ɔrizɔntal ɛn vertikal mil dɛn de intagret fayn fayn wan wit CNC sistem dɛn. Modan CNC kontrola dem de enhans di kapabiliti dem fo di tu taip dem, ofa:

Tipik Aplikeshɔn dɛn .

Ɔrizɔntal mil dɛn:

Hevi-duti mashin fɔ big pat dɛn .

Otomotiv ɛn aerospace kɔmpɔnɛnt dɛn .

Multi-sayd mashin in wan single setup .

Vɛtikal mil dɛn:

Prɛsishɔn wok pan smɔl pat dɛn .

Prototyping ɛn kɔstɔm mashin .

Jɛnɛral-pɔpɔs mil wok dɛn .

Fɔ pik di rayt mil fɔ yu nid dɛn .

Fɔ pik di rayt mil mashin rili impɔtant fɔ mek shɔ se yu yuz di we aw yu de mek tin dɛn fayn fayn wan, kɔrɛkt wan, ɛn we nɔ go tek bɔku mɔni we yu de mek di tin dɛn we yu de mek. If yu pik wan ɔrizɔntal ɔ vertikal mil mashin dipen pan sɔm tin dɛn, ɔl dɛn tin ya fɔ alaynɛd wit yu patikyula aplikeshɔn rikwaymɛnt dɛn.

Factors fɔ tink bɔt we yu de pik wan mil mashin .

Wokpies saiz ɛn kɔmplisiti : ɔrizɔntal mil dɛn bɛtɛ fɔ big, ebi pat, we vertikal mil dɛn fayn fɔ smɔl, intrikɛt wok.

Rikwayd akkuracy ɛn sɔfays finish : vertikal mil dɛn de gi big prɛsishɔn fɔ ditayla wok dɛn, we ɔrizɔntal mil dɛn ɛksɛl insay rɔf matirial rimɔv.

Prodakshɔn Volyum : Fɔ mek dɛn prodyuz ay-volyum, ɔrizɔntal mil dɛn de gi fasta matirial rimɔv, we vertikal mil dɛn fayn fɔ smɔl batch rɔn.

Di flo spɛs ɛn badjɛt we de : vertikal mil dɛn kin tek smɔl ples ɛn dɛn kin afɔdabul mɔ, we ɔrizɔntal mil dɛn kin nid mɔ spɛs ɛn ay initial invɛstmɛnt.

Advantej dɛn fɔ ɔrizɔntal mil fɔ spɛshal aplikeshɔn dɛn .

Ɔrizɔntal mil mashin dɛn de gi bɛtɛ stebiliti ɛn matirial rimɔv rɛt fɔ hevi-duti wok dɛn. Dɛn bɛnifit ya de mek dɛn fayn fɔ:

Big wokpies : Handling bulky parts we nid dip kot.

Multiple-side Machining : Kɔmpleks pat dɛn we nid fɔ wok frɔm difrɛn angul dɛn we nɔ gɛt frɛkuɛnt ritul.

Hevi Material Removal : Big prodakshɔn de rɔn na industri dɛn lɛk ɔtomotiv ɛn aerospace.

Advantej dɛn fɔ vertikal mil fɔ spɛshal aplikeshɔn dɛn .

Vɛtikal mil dɛn kin yuz bɔku tin dɛn ɛn dɛn nɔ kin tek bɔku mɔni, dɛn kin gi ay prɛsishɔn ɛn izi fɔ yuz fɔ smɔl wok dɛn. Dɛn kin du wɛl na:

Precision Work : Pafɛkt fɔ intrɛstin kɔt ɛn fayn fayn sɔfays finish dɛn.

Prototyping ɛn kɔstɔm wok : I fayn fɔ ditayla, wan-ɔf dizayn ɔ smɔl batch prodakshɔn.

Lower-budget operations : we de gi smɔl futprin ɛn lɔwa apfrɔnt kɔst, we de mek dɛn ebul fɔ akses to smɔl smɔl shɔp dɛn.

Speshal Aplikeshɔn Sɛnario ɛn Kes Stɔdi

Kɔmpleks Kaviti Machin : Ɔrizɔntal mil dɛn de handle kɔmpleks kaviti dɛn bay we dɛn alaw fɔ dip kɔt ɛn efyushɔn chip rimɔv, we impɔtant na industri dɛn lɛk mold-mɛkin.

Stepped Surface Machining : Vɛtikal mil dɛn fayn fɔ mashin step sɔfays, usay prɛsishɔn ɛn fayn ajɔstmɛnt na di ki.

High-Hardness Material Machining : Ɔrizɔntal mil dɛn kin bɛtɛ fɔ mashin ay-hadnɛs matirial dɛn lɛk stɛl, bikɔs ɔf dɛn big kɔt pawa.

Smɔl-batch, ay-vayriet prodakshɔn : vertikal mil dɛn de shayn insay smɔl-batch, ay-vɛriet prodakshɔn sɛtin, usay chenj dɛn we de chenj ɔltɛm nid fɔ de.

Automation Line Retrofitting : Fɔ kɔmni dɛn we de luk fɔ retrofit ɔtomɛshɔn layn dɛn, ɔrizɔntal mil dɛn de gi kɔmpitibliti wit advans ɔtomɛshɔn sistem, ɛnhans prodaktiviti insay mas prodakshɔn.

| Aplikeshɔn | Rikɔmɛnd Mil Tayp | Ki Benefit |

| Komplex cavity machin . | Bifo ɛn biɛn | Dip kot, efishɔnal chip rimobul |

| Stepped Surface Machining . | Ɔp ɛn dɔŋ | Prɛsishɔn ɛn izi ajɔstmɛnt . |

| Material we gɛt ay at we de mek mashin dɛn we de mek mashin dɛn we de wok togɛda . | Bifo ɛn biɛn | Greater Cutting Power . |

| Smɔl-batch, ay-vayriet prodakshɔn | Ɔp ɛn dɔŋ | Kwik Sɛtup Chenj dɛn, Ditayl Machining |

| Automation line retrofitting na di . | Bifo ɛn biɛn | High kompitibiliti wit ɔtomɛshɔn sistem dɛn . |

Fɔ pik di rayt mil de dipen pan fɔ balans yu patikyula nid, badjɛt, ɛn prodakshɔn gol dɛn. Ɔl tu di ɔrizɔntal ɛn vertikal mil dɛn de gi difrɛn bɛnifit dɛn, ɛn we yu pik di rayt wan, dat kin mek yu ebul fɔ mek di we aw yu de mek tin dɛn fayn fayn wan.

Dɔn

Horizontal ɛn vertikal mil mashin dɛn difrɛn mɔ pan spindle oriɛnteshɔn, sɛtup kɔmplisiti, ɛn aplikeshɔn. Ɔrizɔntal mil dɛn fayn fɔ wok dɛn we gɛt ebi ebi wok, ɛn vertikal mil dɛn kin du wɛl pan prɛsishɔn wok. Fɔ ɔndastand dɛn trɛnk ɛn wikɛd tin dɛn rili impɔtant fɔ mek dɛn ebul fɔ du di wok fayn fayn wan.

Fɔ pik di rayt mil dipen pan yu wokpies saiz, prodakshɔn volyum, ɛn akkuracy rikwaymɛnt. Dɛn tu kayn mil dɛn ya kin kɔmplit dɛnsɛf na wan mashin shɔp we dɛn dɔn rayt fayn fayn wan. We yu asɛs yu nid dɛn, yu kin plan ɛn kɔnfigyut yu mil risɔs dɛn fayn fayn wan fɔ mek yu ebul fɔ wok fayn fayn wan ɛn fɔ mek yu gɛt mɔ prɔdaktiviti.