Ramuka na zaren suna da mahimmanci a cikin masana'antar zamani, suna aiki a matsayin tushen ingantattun abubuwa waɗanda ke tallafawa duka abubuwan samarwa da ƙira. Wannan talifin zai bayyana duk abin da kuke buƙatar sani game da wannan abin sihiri. Bari mu bincika cikakkun bayanai game da ramuka na zaren!

Ma'anar da nau'ikan ramuka

Menene ramuka masu rufewa?

Bayyanannun rufewa sune budewar silili da aka tsara don karban masu ɗaukar hoto kamar sukurori ko kusoshi. A farfajiya na ciki na waɗannan ramuka yana da helical helical-ake kira zaren - wanda ke hana shi tare da zaren waje a cikin sauri. Wannan tsarin yana haifar da haɗi mai ƙarfi, haɗin da aka halitta,, ajiye abubuwan da aka aminta da aminci. Ramuka na zaren suna taka muhimmiyar rawa a masana'antu, gami da motoci, lantarki kwanciyar hankali da sauƙi suna da mahimmanci.

Nau'in ramuka

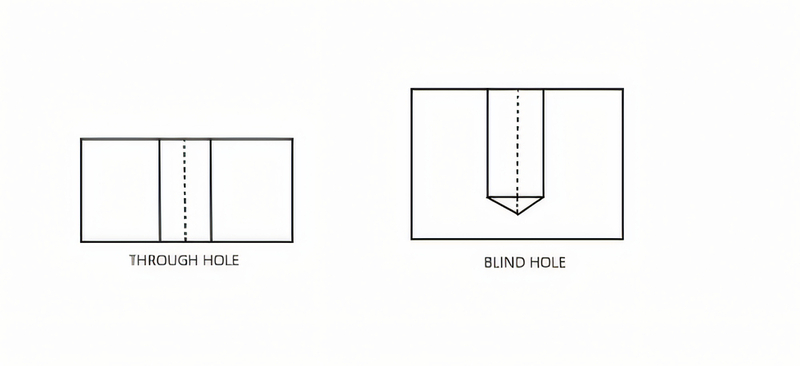

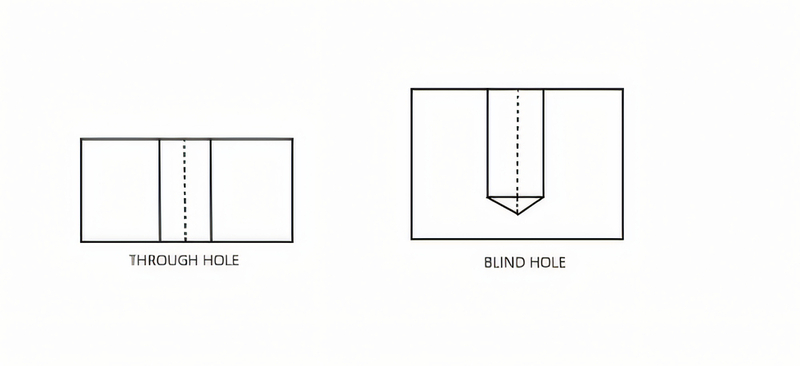

Akwai nau'ikan nau'ikan ramuka guda biyu da aka sanya ramuka iri biyu dangane da zurfinsu da ƙira da ƙira da ramuka na makafi . Don cikakken taƙaitaccen taƙaitattun nau'ikan ramuka a cikin injiniya, zaku iya nufin namu Jagora akan nau'ikan rami iri.

Ta hanyar ramuka : Wadannan ramuka sun tsawaita gaba daya ta hanyar kayan, ba da izinin ɗaukar hoto don wucewa daga wannan gefe zuwa wancan. Su ne gama gari a aikace-aikacen inda mafi dako dole ne ya shiga bangarorin biyu na aikin. Misali, a cikin majalisarki mai kayatarwa, ta hanyar ramuka suna ba da ramuka da za a kiyaye shi tare da kwayoyi a gefen kishiyar gefe.

Ramin Maka : Ba kamar ta hanyar ramuka ba, ramuka na makafi ba su shimfiɗa duk hanyar ta hanyar kayan. Zurfin an sarrafa shi don haka Fastener bai fito a wannan gefen ba. Holornoƙwalwar makafi sau da yawa suna da ƙasa mai faɗi ko kuma ya dace da aikace-aikacen da kayan aiki ko ayyukan lantarki ko na'urori. Don ƙarin cikakken bayani game da ramuka na makafi, duba namu Mataki na a kan ramuka na makaho a Injiniya da Mamfara.

Don ƙirƙirar waɗannan ramuka na zaren, machan mashin suna amfani da dabaru daban-daban. Tryping da Milling sune hanyoyi gama gari, amma hanyoyin da ba su da-socking, ana amfani da su don kayan da ke tattare da su ko lokacin da ƙarin ƙarfin ake buƙata. Wadannan hanyoyin yawanci sun hada da Ka'idodin CNC don ingantaccen daidaito da daidaito.

Kwatancen kwatancen: Ta hanyar ramuka vs. Muban makafi ya zama

| ta | hanyar ramuka | makaho ramuka |

| Zurfi | Shimfiɗa ta hanyar kayan | Bangare mai zurfi, baya ratsa |

| Yi amfani da yanayin | Lokacin da fuxener yana buƙatar wucewa ta bangarorin biyu | Ausethetically boye, fastener bai fito ba |

| Tsarin kasa | Bude a bangarorin biyu | Yawanci lebur ko conical |

Dukansu nau'ikan suna ba da cikakken iko, amma sau da yawa zaɓi ya dogara ne akan bukatun tsarin aikin, kayan ado, ko iyakokin abu.

Haske ramuka vs. Fitar ramuka

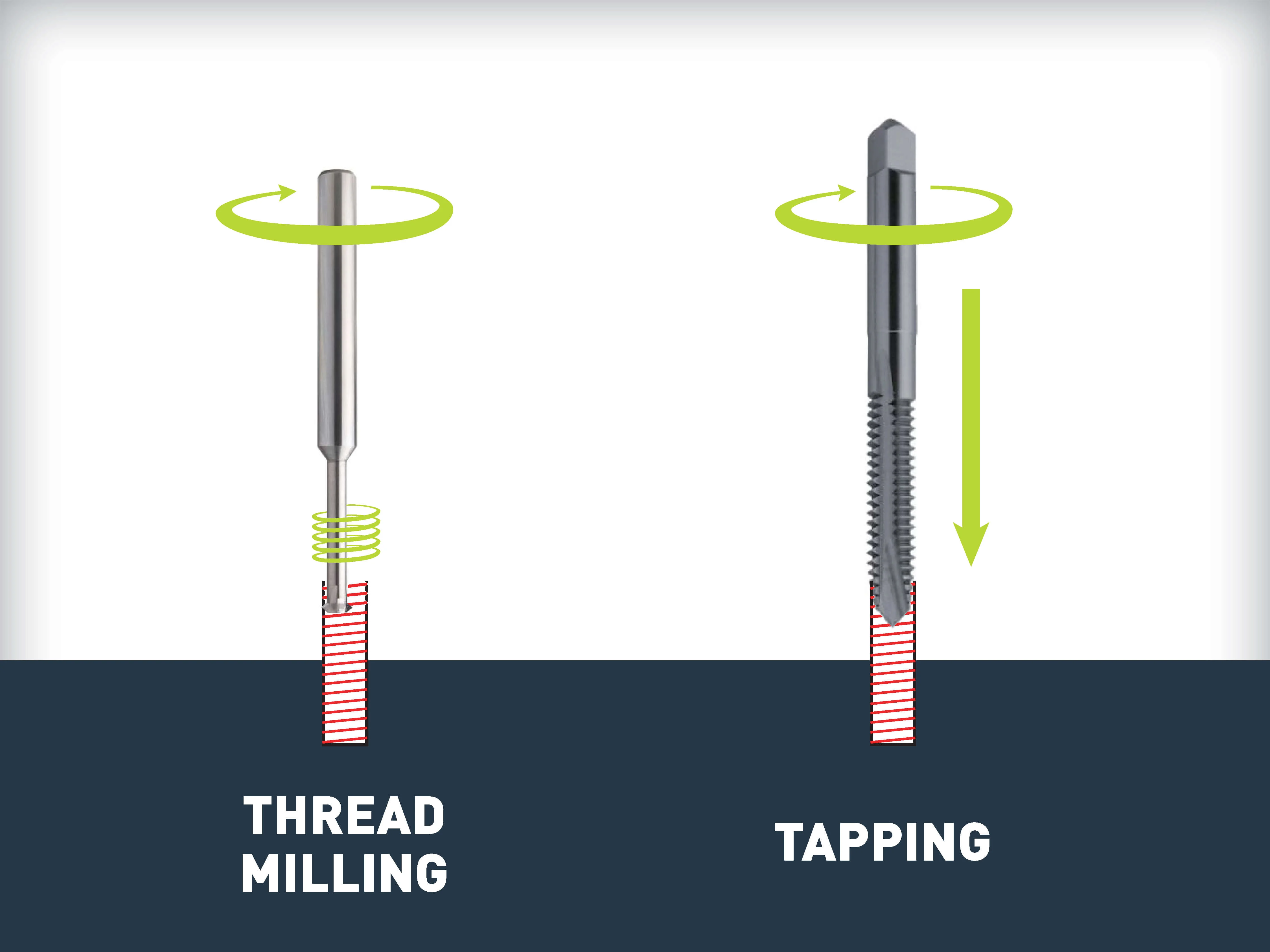

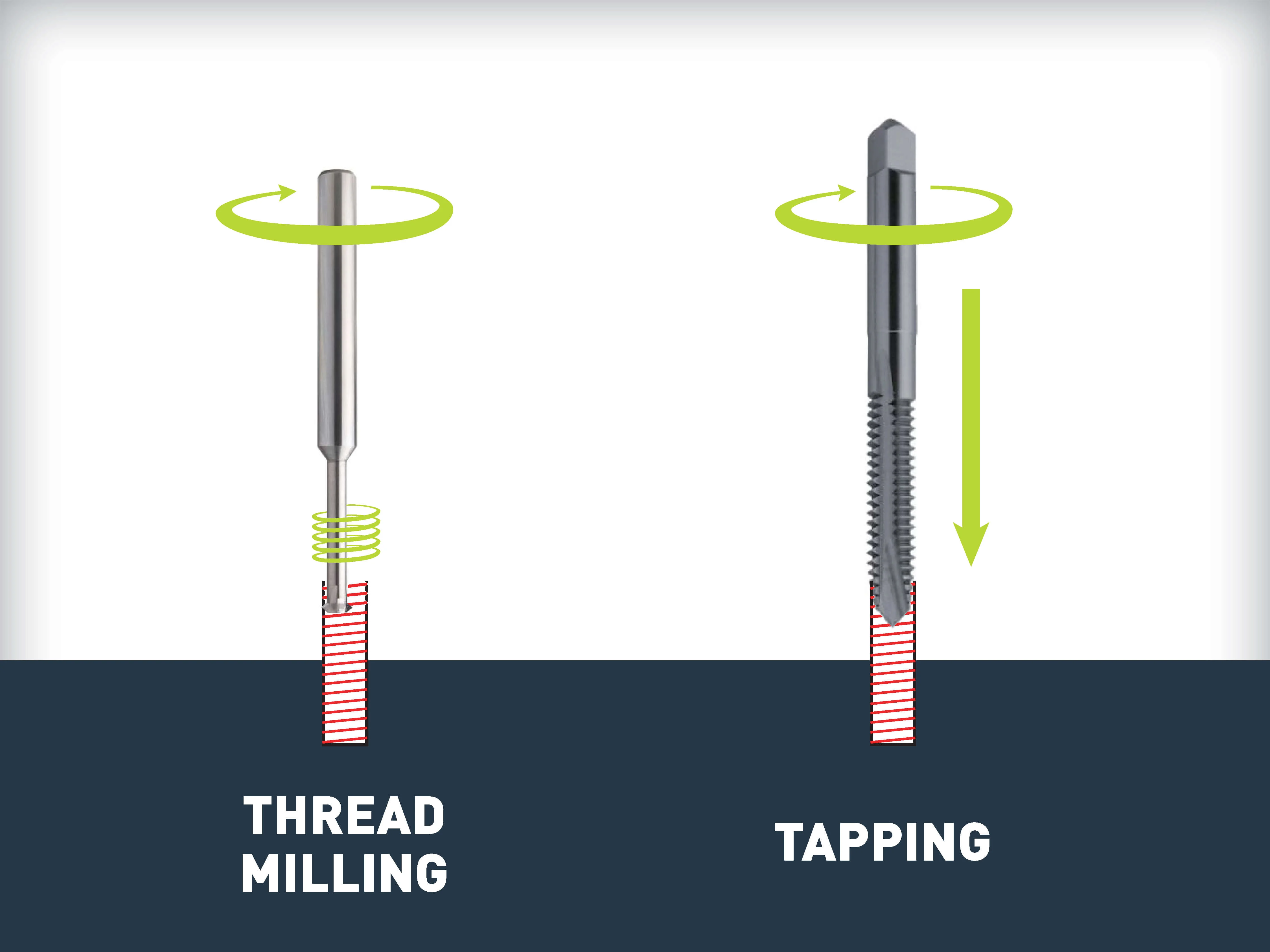

Fitar da kalmomin magana: thering vs. Taping

Rikicewa sau da yawa sun taso yayin tattauna da ramuka da aka buga. Duk da yake ana amfani da waɗannan sharuɗɗan wani lokaci, a zahiri suna magana ne game da keɓaɓɓen matakai da sakamako.

Thereting:

Haifar da zaren waje akan sanduna, bolts, ko sukurori

Ya shafi yanke tsagi grooves a kusa da saman abu na cylindrical

Tapping:

Samar da zaren ciki a cikin rami mai fadi

Fim sunada karyar karyar a cikin kayan kamar karfe, itace, ko filastik

Aiki da aiwatar da bambance-bambance

Ramin ramuka:

Mafi yawan lokuta an ƙaddara shi a cikin simintin

Galibi ana samunsu a cikin sassan da aka samar

Bayar da ingancin zaren

Na iya buƙatar ƙarancin aiki

Ramuka na Takaddun:

Wanda aka kirkira ta hanyar yankan zaren a cikin rami mai gudana

Bayar da sassauƙa don aikace-aikacen al'ada

Za a iya yi akan-site ko kamar yadda ake buƙata

Ana buƙatar ingantaccen kayan aiki da fasaha

| Halin | Hanya Hannun | Ramuka |

| Samarwa | Yayin masana'antu | Bayan-hakowa |

| Daidaituwa | M | M |

| M | Iyakance | Sosai m |

| Kayan aiki | Molds molds | Taps da rawar soja |

| Kuɗi | Ƙananan don girma | Ƙananan don ƙananan batuka |

Key la'akari:

Abubuwan kayan abu

Da ake buƙata karfin zaren

Girma

Bukatar Bukatar Majalisar

Tasiri

Tafiyar matakai a bayan ramuka masu dauke da murya

Forming, tafa, da threading: Binciken tsari na hanyoyin

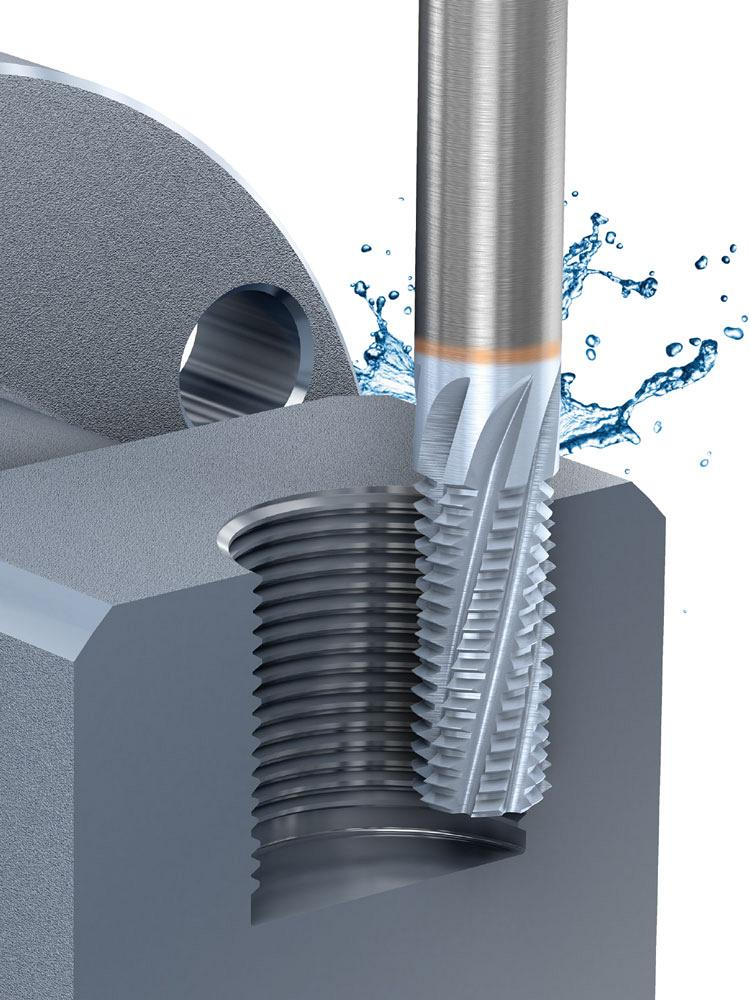

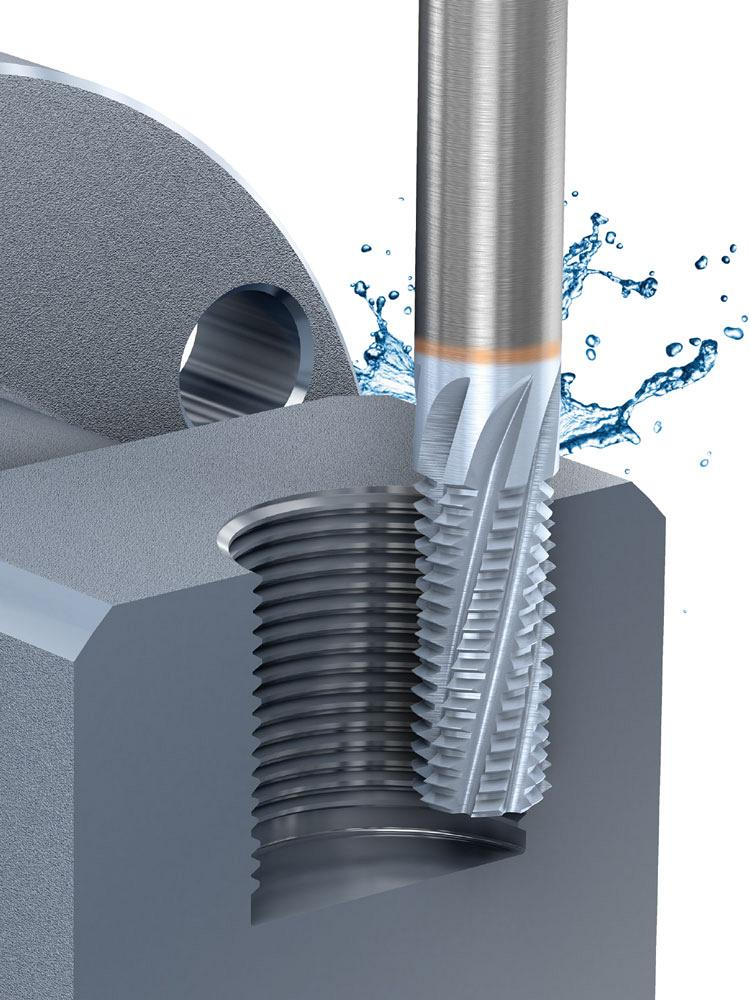

Kirkirar ramuka masu rubutu sun ƙunshi dabaru daban-daban, kowannensu ya dace da kayan daban-daban da aikace-aikace. Wadannan hanyoyin yawanci amfani Ka'idodin CNC don ingantaccen daidaito da inganci. Bari mu bincika manyan hanyoyin:

Kafa

Yana amfani da matsi don gudun hijira

Yana haifar da zaren mai ƙarfi ba tare da cire kayan ba

Mafi dacewa ga karafa na softer da robobi

Zata matsa

Yanyaye zaren ciki zuwa ramuka pre-fari

Yana ba da daidai da abin da ke gabani

Ya dace da kewayon kayan da yawa

Zare

Yawanci yana nufin ƙirƙirar zaren waje

Za a iya amfani da ramuka na ciki a wasu hanyoyin

Sau da yawa ana amfani da shi a cikin haɗin tare da taping

| Hanyar | karfin | abubuwa |

| Kafa | Babu sharar gida na duniya, zaren mai karfi | Iyakance ga kayan softer |

| Zata matsa | M, madaidaici | Na iya rage tsarin kayan |

| Zare | Ingantacce ga zaren waje | Kadan gama gari don ramuka na ciki |

Mataki na mataki-mataki don sanya ramuka na zaren: Matakai masu sauƙi

Kirkirar ramuka mai dauke da liyafa ba dole ne ya zama da wahala ba. Bi wadannan matakan don cin nasara, wanda za'a iya amfani da shi ga daban-daban Iri na inji na CNC :

Tsoma baki: Yi amfani da wani mitan mit ɗan ƙarami kaɗan fiye da girman zaren da ake so. Wannan ana kiranta girman blam.

Chamf da rami: Createirƙiri karamin chamfer a ƙofar ko amfani da babban kayan aiki mai yawa ko kayan aiki mai lamba. Yana taimakawa jagorar famfo.

Sa mai da famfo: shafa ruwa ko mai a famfo. Yana rage gogayya da zafi, taimaka wa famfo famfo a sauƙaƙe.

Fara famfo: Sanya tip na matsa cikin rami na Chamfeed. Aiwatar da matsin lambar haske kuma a hankali juya alamar agogo.

Ci gaba da bugawa: Ci gaba da juyawa. Bayan kowane rabin juyawa gaba, juya baya matsa kashi ɗaya juyawa don karya kwakwalwan kwamfuta.

Kammala rami: Ci gaba har sai famfo ya wuce ta hanyar aikin ko kuma zurfin da ake so. Juya baya famfo daga cikin rami.

7.Tsaftace zaren: Yi amfani da iska mai laushi ko buroshi don cire duk wani kwakwalwan kwamfuta ko tarkace daga zaren sabo.

Pro shawarwari:

Yi amfani da jagorar bugawa don zaren mai ban tsoro

Aiki akan kayan Scrap farko

Dauki mai jinkirin don guje wa fashewa

Nau'in kumburin da aka yi amfani da shi a cikin rami

Tempence na nau'ikan abubuwan da suke amfani da su

Ana amfani , kowanne tare da halayenta da aikace-

Taper Taps:

Da a hankali taper a karshen

Mafi dacewa don fara zaren a cikin ramuka na makafi ko kayan m

Rarraba yankan yankewa akan zaren da yawa

Toshe matsa lamba:

Da ɗan gajeren taper biye da cikakken zaren

An yi amfani da shi don sake kunnawa ta hanyar ramuka ko bayan tap

Ya dace lokacin da rami yake da ma'ana

Bottoming Taps:

Da ɗan gajeren tsirai da cikakkun zaren kusan zuwa ƙarshe

Amfani da makulli kusa da kasan ramuka na makaho

Na bukatar rami mai zurfi sosai don saukar da famfo

Karkace maki kumburi:

Da karkace flute wanda ke tura kwakwalwan kwamfuta a gaba

Manufa ta hanyar ramuka a cikin kayan da ke yiwuwa har zuwa dogon, chips

Amfani da shi a cikin Ayyukan CNC

Karkace suttura ta kumfa:

Karkace Folutes waɗanda ke jan kwakwalwan kwamfuta daga cikin rami

An yi amfani da shi don ramuka na makafi inda farashin guntu yake da mahimmanci

Taimaka hana Chip Sacking da Kayan Kayan Kayan aiki

| da nau'ikan matsa lamba da yawa a cikin rami mai ɗaukar | hoto | aikacenta |

| Taper | A hankali | Fara zaren, ramuka na makafi, kayan m |

| Toshe | Gajere | Ta hanyar ramuka, bayan tapl |

| Kastsi | Gajere | Thereting kusa da kasan makafi ramuka |

| M | - | Ta hanyar ramuka, kayan da kwakwalwan kwamfuta |

| Karkace slute | - | Ramin Makaho, Chididdigar Chip |

Zabi da matattarar dama don takamaiman kayan da aikace-aikace

Zabi wanda ya dace ya dogara ne akan kayan kuma nau'in rami:

Kayan m (aluminum, tagulla, filastik):

Yi amfani da taper ko toshe famfo don ta hanyar ramuka

Karkace flute mits aiki da kyau ga ramukan makafi

Mafi girman saurin gudu da kuma mai gadi ramuka ana bada shawarar

Kayan wuya (karfe, bakin karfe, titanium):

Fara da taper Tap Matsa, mai biyo bayan famfo don ramuka

Yi amfani da Taper Tapam, to, kasan ƙasa don ramuka na makafi

Saurin saurin gudu, lafar tsami, da lubrication mai ƙarfi ya zama dole

Ta hanyar ramuka:

Raunin Maka:

Fara da tapa matsar da jagora don jagorantar da

Bi tare da famfo mai ƙasa zuwa zaren kusa da ƙasa

Karkace flushe strs yana taimakawa tare da guntu fitarwa

Nasihu masu taimako don cikakkiyar ramuka

Ingirƙirar madaidaicin ramuka na dorewa yana buƙatar kulawa da cikakkun hanyoyi da ingantattun dabaru. Ga wasu nasihu masu mahimmanci don taimaka muku samun kyakkyawan sakamako:

Kurakurai gama gari don kauce wa

Yin amfani da madaidaicin rawar da ba daidai ba:

Rashin yin chamfer ƙofar rami:

Tapping da sauri:

Ba amfani da lubrication:

Yana ƙaruwa da tashin hankali da zafi, yana haifar da ingancin ƙimar zaren mara kyau

Aiwatar da ruwa mai ruwa ko mai da ya dace da kayan

Rashin share kwakwalwan kwamfuta:

Na iya haifar da fakitin chiping da kayan aikin kayan aiki

Juya da famfo don karya kwakwalwan kwamfuta, ko amfani da flute flute matsa don ramukan makafi

Inganta daidaito da karkatarwa na ramuka

Yi amfani da famfo na dama don aikin:

Yi la'akari da kayan, nau'in rami, da kuma bukatun zaren

Zaɓi nau'in matsa da ya dace da girman

Fara famfo kai tsaye:

Babu shakka, iya haifar da ingancin zaren

Yi amfani da jagora matsa ko kuma matsakaicin matse don tabbatar da farawa

Kula da saurin yanke sauri da matsin lamba:

Karya kwakwalwan kwamfuta a kai a kai:

Tsaftace zaren sosai:

Yana cire tarkace wanda zai iya tsoma baki da sauri

Yi amfani da iska mai sauƙaƙe, buroshi, ko kayan aikin tsabtace rami

Tabbatar da ingancin zaren:

Duba don girman, farar, da kuma tsari daidai

Yi amfani da ma'aunin zare ko masu kulawa na gani don mahimman aikace-aikace

Don ƙarin bayani game da daidaito da haƙuri, koma zuwa Jagorarmu Motocikin Kayayyakin

| Tsabtace | CLN |

| Yi amfani da girman hoton da aka yi | Cikakken girman zaren |

| Compfer Hole ƙofar | Mafi sauƙaƙa farawa |

| Gudanar da saurin sauri | Rage zafi da sutura |

| Yi amfani da lubrication | Inganta ingancin zaren |

| Share chips akai-akai | Hana guntu packing da breadage |

| Fara famfo Madaidaici | Guji giciye-threading |

| Kula da sauri da matsin lamba | Mafi kyau duka daidai da rayuwar kayan aiki |

| Tsabtace zaren sosai | Tabbatar da ingantaccen sauri ya dace |

| Tabbatar da ingancin zaren | Haduwa da bukatun daidaito |

Saboda cimma babban matakin daidaito a cikin ramuka na zaren, la'akari da amfani Ka'idojin CNC na CNC .

Mahimmancin ramuka a cikin masana'antu

Ramuka na zaren suna taka rawa sosai a cikin masana'antar masana'antu, samar da amintaccen haɗin haɗin da aka gyara don kayan gini daban-daban da taro.

Key fa'idodi

Askar : dace da yawan aikace-aikace da yawa a kan masana'antu

Turi : bayar da ƙarfi da kuma haɗi da haɗi masu haɗi

Daidaici : Yana ba da damar daidaitawa da sanya sassan sassa

Sauƙin jama'a sauƙaƙe : a sauƙaƙe ingantaccen taro

Rearsible : ba da izinin rudani da sake rubutawa ba tare da yin sulhu da amincin ba

Ramin ramuka suna da mahimmanci a cikin masana'antu, suna ba da daidaiton ƙarfi, daidai, da kuma gaci. Tsarin da suka dace da aiwatarwa suna da mahimmanci don tabbatar da ingancin samfuri, aminci, da kuma wasan kwaikwayon a saman masana'antu.

Faqs game da ramuka

Menene ramuka masu ɗaukar hoto suke amfani da su?

Ana amfani da ramuka na zaren don amintaccen saukaka kayan haɗin tare ta amfani da sukurori, bolts, ko wasu masu ɗaukar hoto. Suna da mahimmanci a masana'antu kamar mota, Aerospace, Wutar lantarki, da kuma gini don amintattu, haɗin ba su da na dindindin.

Menene banbanci tsakanin rami mai ɗaukar hoto da rami mai ɗorawa?

Wani rami mai dauke da rami ne tare da zaren ciki, wanda aka kirkira ta hanyoyi kamar Tramping, milling, ko mirgina. Wani rami mai yaki musamman yana nufin rami wanda aka yanke rami ta amfani da famfo, sanya shi wani subed na ramuka.

Ta yaya zan zabi tsakanin ramin makulli da ramuka?

Ramin makafi yana da kyau lokacin da mafi karancin kada a wuce gaba-gaba gaba ɗaya ta hanyar abu, sau da yawa don ganyayyaki ko dalilai na adana sarari. Ta hanyar ramuka suna ba da izinin ɗaukar hoto zuwa duk hanyar ta hanyar kayan aikin, wanda aka fi so don ƙarfi, amintaccen haɗin haɗi.

Wadanne abubuwa za a iya shafa ko zaren

Yawancin metals (kamar ƙarfe, aluminum, da tagulla), robobi, ana iya tazara da itace. Koyaya, kayan Soft na na iya buƙatar kulawa ta musamman ko abun shiga don tabbatar da zaren da aka ɗauka.

Menene hanya mafi kyau don ƙirƙirar ramuka masu ɗauke da kaya?

Hanya mafi kyau ta dogara da aikace-aikacen. Tuba yana da tasiri don daidaitattun ramuka, zaren rolling yana ƙarfafa kayan kewaye don aikace-aikacen canji, da kuma milling yana ba da daidaito don ayyukan al'ada ko rikitarwa.

Ta yaya zan iya hana zaren zaren?

Don kauce wa zaren da ya dace, yi amfani da girman girman da ya dace, ka guji awo-daurewa, ka kuma yi amfani da lubricants lokacin da zare. Don Aikace-aikacen High-Hanya, Yi la'akari da amfani da abubuwan haɗin zaren don ƙarfafa zaren.

Za a iya gyara ramuka masu lalacewa?

Haka ne, ana iya gyara ramuka masu lalacewa ta amfani da dabaru kamar sake bugawa da kayan haɗi kamar Heli-Coils. Waɗannan hanyoyin suna mayar da zaren kuma suna kula da ƙarfin ramin.