Shigowa da

1.1. Takaitaccen dabarun dabarun

Mactining tsari ne mai mahimmanci a masana'antu wanda ya shafi dinga da kuma gama albarkatun kasa cikin abubuwa daidai sassan da abubuwan haɗin. Wannan tsari yana da mahimmanci don ƙirƙirar samfurori masu inganci a cikin masana'antu daban-daban, daga motoci masu wucewa da kayan masu amfani. Wasu manyan dabarun motsi sun haɗa da:

● Milling

● Tsabtace

● Juyawa

Nika

Daga cikin waɗannan dabaru, hering yana da mahimmanci musamman don ƙirƙirar ramuka a cikin sassan mikiku. Ramuka suna bauta wa dalilai daban-daban, kamar suna ba da izinin nassi na ruwa, da kuma samar da kariya ga masu zargi, da kuma kunna Majalisar ayyukan da yawa.

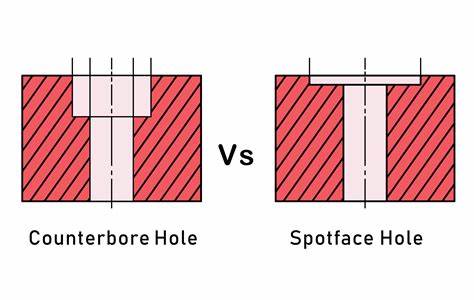

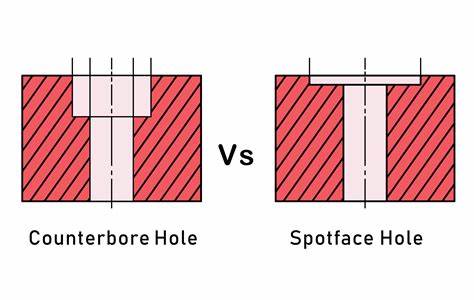

1.2. Spotface vs. Ramin Kayayyaki

Idan ya zo ga ramuka da makullai, nau'ikan guda biyu suna da tabo da ramuka masu ƙima. Yayin da suke iya bayyana kwatankwacin kallo na farko, akwai bambance-bambance na dabam tsakanin su biyun.

● Tallace ramuka ba su da nutsuwa, recessededs mai lebur wanda ke ba da santsi, matakin farfajiya don masu ɗaukar nauyi don zama a kan.

● A gefe guda, a gefe guda, suna zurfafa reshe wanda ya ba da damar ɗaukar fansa tare da ko a ƙasa da farfajiya na aikin.

Wadannan ramuka suna taka rawa wajen tabbatar da jeri mai kyau, amintaccen sauri, da kuma kyakkyawan yanayi, bayyanar da ƙwararru a cikin sassan.

1.3. Muhimmancin ramuka a cikin sassan

Daidaici shine paramount a cikin inji, kuma wannan gaskiya ne musamman idan ya zo Kirkirar ramuka . Ramuka masu kyau da ramuka na iya haifar da matsaloli, gami da:

● Rashin daidaituwa na kayan aikin

Rashin Ingantawa

● leaks da kasawa a tsarin ruwa

● rage ingancin gaba daya da aikin na karshe

Ta hanyar ƙirƙirar tabo da ƙima, masana'antun za su iya tabbatar da cewa wuraren da za su iya biyan manyan ka'idodi da ayyuka.

1.4. Makasudin makasudin wannan jagorar

A cikin wannan jagora mai jagora, zamu nisantar zurfafa cikin duniyar almara. Manufofinmu sune:

1.Cirly ma'anar da bambanci tsakanin totple da kuma ramuka masu ƙima

2.Explore takamaiman aikace-aikacensu da fa'idodi a cikin injin

3. Bayar da tukwici masu amfani da dabaru don ƙirƙirar samfuri da ramuka masu ƙima

4.Hide na hakika-duniya misalai da kuma nazarin shari'o'i na shari'ar da ke nuna mahimmancin waɗannan ramuka a cikin masana'antu daban-daban

A karshen wannan jagorar, zaku sami ingantaccen fahimtar wuri da ramuka masu ƙima da kuma yadda za su haɗa su cikin hanyoyin sarrafa ku.

Fahimtar samfuri

2.1. Ma'anar da halaye na takunan almara

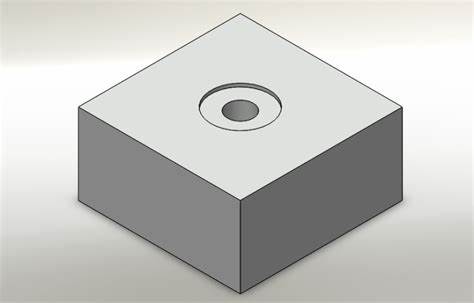

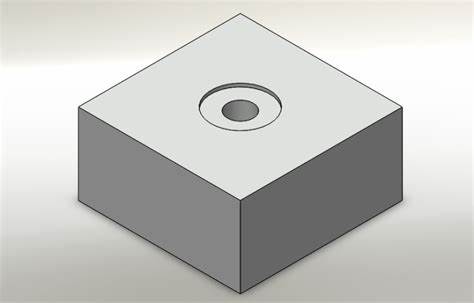

Totle, wanda kuma aka sani da pootfacing, wani hutu ne, wucin gadi-bleededed inced incinece. Yawancin lokaci ana ƙirƙira shi a kusa da rami mai gudana ko a takamaiman wurin da mafi sauri, kamar kuɗaɗe, za a zauna. Babban dalilin tabo shine samar da santsi, ko da farfajiya don saurin hutawa.

Spotffes suna sanannu da zurfin zurfinsu, yawanci kawai isa ya haifar da ɗakin kwana. Suna da siffar madauwari da diamita wanda ya dace da girman kai mai sauri ko bangariyar ta hanyar bangarori. A kasan potface ne perpendicular zuwa axis na rami, tabbatar da daidaitaccen jeri da hulɗa da sauri.

Ana amfani da samfuran rubutu a cikin yanayi inda ainihin farfajiya na aikin ba shi da kyau, m, ko kuma ba perfendicular ga ɗakin ramin. Ta hanyar ƙirƙirar tabo, injinan na iya tabbatar da cewa mafi kyawun abin da yake zaune a kan farfajiyar ɗakin ƙasa, yana ba da tabbataccen haɗin kai.

2.2. Kan aiwatar da kirkirar tabo

Don ƙirƙirar tabo, mama masara kuma suna bin waɗannan ayyukan gaba ɗaya:

- Wurin da: Kammaci inda ake buƙatar ƙirƙirar wurin da aka danganta da wuri mai sauri da ƙirar aikin.

2.Drrill farkon rami: idan ana ƙara siginar zuwa wani rami mai gudana, tsallake wannan matakin. In ba haka ba, rawar rami wani rami a ƙayyadadden wurin, tabbatar da shi shine perpendicular zuwa farfajiya.

3.Zara kayan aiki kayan aiki: Zabi kayan aiki mai dacewa tare da diamita da ya dace da ƙarfin zurfin bayyanawa.

4.Set sama inji kayan aiki a cikin injin spindle da daidaita saurin aiki da darajar samar da kayayyakin kayan aiki da kayan aikin kayan aiki.

5.Create Spotface: a hankali ƙananan kayan aiki na wuri cikin aikin, kula da perpendicularity zuwa farfajiya. Kayan aiki zai yanke kayan aikin don ƙirƙirar ɗakin kwana, m ƙasa farfajiya.

6.na misali: auna diamita da zurfin tabo don tabbatar da cewa ya cika ka'idodin da aka ƙayyade. Gani duba farfajiya don kowane irin ra'ayi ko lahani.

Ta bin waɗannan matakan, masujada na iya haifar da daidai da daidaitattun abubuwan tabo wanda ke inganta inganci da babban taro na ƙarshe.

2.3. Aikace-aikace da fa'idodi na b holes

Take ramuka suna ba da fa'idodi da yawa kuma ana amfani dasu a aikace-aikace daban-daban a kan masana'antu. Wasu aikace-aikace gama gari sun haɗa da:

Murmushi mai ɗaukar hoto: spopfrees suna ba da ɗakin kwana, har ma da farfajiya don ɗaukakewa don zama a gaba, tabbatar da jeri mai kyau da amintaccen haɗi.

● Teta'idodin saman: A cikin tsarin ruwa, spotfrfes na iya ƙirƙirar abubuwa masu santsi don gasuwa ko o-zobba don rufe, hana leaks.

● Fuskantattun abubuwa: Spotfffes na iya samar da ɗakin kwana, perpendicular surface don ɗaukar fansa don tabbatar da sa da kuma tabbatar da juyawa mai laushi.

Abubuwan haɗin lantarki na lantarki: A cikin na'urorin lantarki: spoprffes na iya ƙirƙirar ɗakin kwana don abubuwan haɗin kamar sauya ko masu haɗin kai zuwa Dutsen ko masu haɗin kai tsaye da ayyukan da yakamata.

Misalan misalai na yau da kullun na wuraren shakatawa a cikin aiki sun hada da:

● Ajiye injuna: Ana amfani da fasoto a kan silinder shugabannin don samar da shimfidar lebur don kujerar kusoshi zuwa wurin zama da kuma kyakkyawan hatimi.

● Abubuwan da aka gyara na Aerospace: A cikin tsarin jirgin sama, ana amfani da fasikanci a kusa da ramuka masu sauri don samar da daidaito, farfajiya ta shimfidar fuska da inganta amincin taron.

Ta hanyar haɗe da ramuka na tabo a cikin ƙirar, injiniyoyi da na'urori masu amfani na iya:

● Ingantaccen wurin zama da jeri

● Inganta aikin hatimi

● rage sutura akan abubuwan da aka zana

● Tabbatar da ayyukan ingantattun ayyukan lantarki

● CIGABA DA KYAUTATA KYAUTATA DA KYAUTA NA FARKO

Abubuwan da ke ramuka na iya zama kamar karamin daki-daki, amma suna taka muhimmiyar rawa wajen tabbatar da wasan kwaikwayon da taro da taro.

Binciko ramuka masu amfani

3.1. Menene ramukan da aka yi?

Wani rami mai taushi wani nau'in ramin da aka yi kagarar ruwa wanda ya ƙunshi wani rami mai girma diamita wanda ya bushe a hankali a kan ƙaramin rami. Ana kiransa babbar rami, kuma yana shimfidawa kawai ta hanyar aikin. Karamin rami, wanda aka sani da rami na matukin jirgi, yawanci yana tafiya gaba ɗaya.

Mahimmin halayen rami na tururi sun hada da:

Bayani mai zurfi mai nunawa tare da diamita biyu na daban

● Trainan ƙasa mai lebur

● Zurfin da zai ba da damar da kanta don saukar da shugaban mafi sauri

Idan aka kwatanta da ramuka na tabo, ramuka masu ƙima suna da hutu mai zurfi da kuma karin magana a tsakanin firam biyu. Duk da yake spotfredes da farko ake amfani da su don ƙirƙirar ɗakin ɗakin ɗakin kwana, ƙawancen an tsara su ne don ɓoye kawance mai ɗaukar hoto a cikin aikin.

3.2. Amfani da aikace-aikacen ramuka

Ramuka na hana suna ba da ayyuka da yawa masu mahimmanci a cikin na'ura kuma ana amfani dasu a cikin kewayon aikace-aikace. Wasu daga cikin manyan abubuwan amfani da ramuka na tursasawa sun hada da:

1.Ammaƙarin shugabannin da sauri: Adireshin suna ba da izinin shugaban maƙarƙashiya, dunƙule, ko wasu masu sauri don zama ja da ko a ƙasa da farfajiya. Wannan yana samar da bayyanar mai tsabtace kuma yana hana karfin kai daga tsoma baki tare da sassan bangarorin.

2. SPROVIVED CEUFIN, A wasu halaye, ana amfani dasu don samar da share kayan aiki ko wasu abubuwan da ke buƙatar wucewa cikin rami.

3.Sana babban taro: Countsepores na iya taimakawa daidaitawa da kuma gano sassan matarko yayin taro, yana sauƙaƙa da sauƙi kuma mafi inganci.

Misalan ramuka na kantuna a aikace-aikacen masana'antu sun hada da:

● Aut Kutsiya: A cikin injiniyoyi na injiniyoyi, ana amfani da su don ɓoye kawunan kututturen da suka amintar da shugaban silinda, ƙirƙirar ƙasa mai santsi don tsabar kuɗi don rufe.

● Aerospace: ramuka masu ƙima sun zama ruwan dare a cikin tsarin jirgin sama, inda ake amfani da su don ƙirƙirar fannonin freshraft da sauran masu sauri, rage ja da inganta tashar jirgin ruwa.

● Wutar lantarki: A cikin buga da'irar allon (inji), ana amfani dasu don haifar da Represses don kayan aiki yana haifar da ja-gora tare da farfajiyar.

3.3. Ramin kwamfuta a cikin zane na Injiniya: Daidai alamun

A zane-zane na injiniya, ana wakiltar ramuka masu amfani ta amfani da takamaiman alamomi da sanarwa. Fahimtar wadannan alamomin yana da mahimmanci ga Madin da injiniyoyi su fassara da samarwa samarwa da ramuka masu tazara.

Alamar asali don rami na ƙira akwai da'irar tare da ƙaramin da'irar a ciki. Ginin waje yana wakiltar diamita na tururi, yayin da da'irar ciki tana wakiltar matukin matukin jirgi. More girma, kamar zurfin rami mai zurfi da zurfin rami (idan akwai wani rami mai zurfi), yawanci ana kiranta amfani da Lines na Jagora.

Ga misalin yadda za a iya wakiltar rami mai taurin kai a cikin zane na injiniya:

⌴ 10.0 x 5.0

⌴ 6.0 thru

A cikin wannan misalin: - Circle Circle tare da '⌴ ' alamomi yana wakiltar kanta, tare da diamita na 10.0 mm da zurfin 5.0 mm da zurfin 5.0 mm. - Smallerarancin da'irar ciki yana wakiltar rami na matuka, tare da diamita na 6.0 mm wanda ke tafiya cikin duka aikin (thru).

Ta hanyar sanin kansu da waɗannan alamomin da sanarwa, injiniyoyi da injiniyan zasu iya sadarwa da cewa ana kera ramuka na ƙira da tabbacin ƙayyadaddun ƙayyadaddun.

Bincike na misali: Spotface vs. Ramin ramuka

Bambancin bambance-bambance da kamanninmu

Totpled da ramuka masu ƙima suna ba da wasu kamanceceniya, amma ma suna da bambance-bambance daban. Dukansu suna yawansu na sililin da ke cikin aikin aiki, yawanci a kusa da rami mai gudana. Koyaya, zurfin, sifar, da alamomin waya suna keɓe su baya.

Zurfin shine mabuɗin mabiya. Countervores suna zurfi, wanda aka tsara don cikakken saukin ɗaukar shugaban mafi kusa da ke ƙasa. Da bambanci, sppotffffes suna da nasara, yana ba da isasshen zurfin ƙirƙirar ɗakin kwana, santsi na santsi don kai mai sauri don zama flush a kan.

Game da siffar, spotffes suna da tsari mai sauƙi tare da ɗakin kwana. Countervores kuma suna da siffar silima amma yana nuna bayanin martaba na juzu'i, tare da buɗewa diamita na diamita ya canza zuwa ƙaramin ramin diamita.

Alamar Fayil akan zane-zane Injiniya sun bambanta spotfreds daga comporebores. Bayanan bayanai suna amfani da Alamar Hada (⌴) tare da 'SF ' a ciki, yayin da suke amfani da alamomin yanayi kawai, tare da diamita mai zurfi.

Bambance-bambance na aiki: Kasancewa da manyan shugabannin

Bambancin aiki na farko tsakanin spootfredes da kuma studers karya ne a cikin yadda suka saukar da shugabannin masu ɗaukar hoto. Counterbores an tsara su don cikakken hutu kai tsaye daga wani fastener, kamar kudu ko dunƙule, a ƙasa da farfajiya na aikin. Wannan yana haifar da bayyanar haske ko kuma yana hana mai ɗaukar hoto daga protruping.

On the other hand, spotfaces provide a flat, smooth surface for the fastener head to rest against, ensuring proper seating and alignment. Suna da amfani musamman lokacin da kayan aikin motsa jiki ba shi da daidaituwa ko kuma lokacin da aka buƙaci a shigar da mafi kyawun abin da ya fi dacewa da digiri aya 90.

Fotprees suna taka muhimmiyar rawa wajen tabbatar da cewa masu fashinya suna zaune daidai kuma suna amfani da matsi da suka dace ba tare da lalata yanayin aikin ba.

Zurfin da tsarin ƙira: Bayanin keɓewa

Zurfin spopfredes da kuma masu ba da labari kai tsaye suna da dangantaka da aikace-aikacen ƙira. Counterbores suna zurfi, yawanci daidai da tsawo na shugaban mafi daraja. Wannan zurfin yana ba da damar ɗaukar hoto don zama a cikin hutu, ƙirƙirar bayyanar ko bayyanawa. Ana amfani da ƙwararrun hanyoyin da ake amfani da su lokacin da ake so a cikin tsari mai ban sha'awa, wanda ba shi da izini don ado don dalilai na aiki.

Da bambanci, fannonin suna da zurfin mai ma'ana, yawanci kawai isa ya ƙirƙiri ɗakin kwana, har zuwa farfajiya don kai mai daraja. Zurfin mai tabo ne yawanci ƙasa da 5 mm, kamar yadda manufar ta farko ita ce samar da sanannun wurin zama a sarari maimakon cikakken ɓoye kai.

Hukuncin tsakanin amfani da tabo ko kuma ya dogara da takamaiman buƙatun ƙira, kamar buƙatar bayyanar da haske, ƙaddarwar mawuyacin hali, ko kuma gaban tsohuwar dabbar ta hanyar.

Siffa | Bunga | Turare |

Zurfi | M, yawanci kasa da 5 mm, kawai isa ya kirkiri ɗakin kwana, m farfajiya | Mai zurfi, yawanci dacewa da tsawo na shugaban mafi sauri, wanda aka tsara don cikakken ɗaukar nauyin da ya fi sauƙi |

Siffa | Tsarin cylindric mai sauƙi tare da ƙasa mai lebur | Tsarin siliki tare da bayanin martaba na diamita, ya fi girma diamita diamita ta canza zuwa karamin ramin diamita |

Alamar Callout | Yana amfani da alama ta wayar tarho (⌴) tare da 'sf ' a ciki | Yana amfani da alama ta wayar tarho (⌴) ita kadai, tare da diamita da zurfin girma |

Aiki | Yana samar da ɗakin kwana, santsi na m don zauna a gaba, tabbatar da zama da kyau da jeri | Cikakken dawowa shugaban mafi sauri, kamar kudu ko dunƙule, a ƙasa da farfajiya na aikin |

Roƙo | Amfani da shi lokacin da farfajiyar kayan aiki ya zama mara daidaituwa ko kuma lokacin da aka ga dama da aka yi a cikin kwana banda digiri 90 | An yi amfani da shi lokacin da ake so bayyanar ko kuma ana so a ado don dalilai na aiki ko dalilai na aiki |

Farfajiya | Sau da yawa yana da finer mafi kyau, tare da haƙuri mai haƙuri a kan gama gari | Farfajiyar bangon bangon bangon ba shi da mahimmanci, amma ƙasa ƙasa tana buƙatar sassauƙa mai santsi don kyakkyawan wurin zama |

Maching | Ana buƙatar zaɓin kayan aikin da aka dace, yankan da ke yankan dabaru, da dabarun da ke tattare don cimma ingancin yanayin da ake so | Yawanci na bukatar zurfin yanke kuma na iya zama takamaiman kayan aiki |

Farfajiya ta gama aiki a cikin comperbores

Farfajiya shine muhimmiyar la'akari lokacin da kwatanta masu magance abubuwa. Dukansu nau'ikan ramuka suna buƙatar santsi, ko da farfajiya don tabbatar da zama da kyau da kuma jeri na masu haɗari. Koyaya, spotffores sau da yawa suna da finer farfajiya idan aka kwatanta da comperbores.

Babban dalilin tabo shine don samar da ɗakin kwana, mai santsi don kai mai saurin hutawa, tabbatar da madaidaiciyar matsa lamba kuma yana hana lalacewa ta gaba. A sakamakon haka, farfajiya na wani tabo ne mai mahimmanci kuma yawanci ana gudanar da shi don jure wa'aziyya ta hannu.

A cikin takaddama, farfajiya na bangon bangon bangon ba shi da mahimmanci, kamar yadda suke ba da farko don ɗaukar nauyin ɗaukar hoto. A kasan farfajiya na ƙirar, inda mafi daraja shugaban ya dogara, har yanzu yana buƙatar mafi sassauci mai santsi don ɗakunan wuri.

Hanyoyin da ake amfani da su da kayan aikin da aka yi amfani da su don ƙirƙirar spotfrefures da kuma masu ba da shawara na iya tasiri ga gama samun nasara. Zabin kayan aiki da ya dace, yankan sigogi, da kuma dabarun da ke da mahimmanci suna da mahimmanci don samun ingancin yanayin da ake so.

HUKUNCIN MULKI: A lokacin da za a yi amfani da shi

Zabi tsakanin tabo da kuma turare ya dogara da abubuwa da yawa da buƙatun aikin. Yi la'akari da jagororin masu zuwa yayin yanke shawara:

1.Faststener kai tsaye: Idan kana buƙatar kai mai ban dariya ya zama flush ko mai da aka yiwa ado ko dalilai na aiki, yi amfani da kanta. Idan vossment ba lallai ba ne, toptraple na iya isa.

2.Ssuurft yanayin: Lokacin da ma'amala da shimfidar wuri ko m sitates, santsi na laushi don fastenners, tabbatar da matsin lamba na tsari da matsa lamba.

3.Amsar da tsaurara: Yi la'akari da sararin samaniya don shigarwa na ginin. Countervores suna buƙatar ƙarin zurfin kuma bazai dace da wuraren motsa jiki ko sarari ba.

Alamar 4.FASSER: FASAHA KUDI KUDI KUDI DA KYAUTATA YAWAN ZUCIYA tsakanin TOMELFE DA KYAUTA. Tabbatar da lokacin hutu tare da takamaiman sifar kai mai sauri da girma.

5. Mutmanufturin tsayar: tantance damar sarrafa kayanka da kuma kayan aikin kayan aikinka. Counterbores yawanci suna buƙatar zurfin yanke-kukan kuma na iya zama takamaiman kayan aiki.

Ta hanyar kimanta waɗannan abubuwan kuma a daidaita su da bukatun aikinku, zaku iya yanke shawara tsakanin ta amfani da tabo mai ɗorewa.

Dabaru da kayan aiki don samfuri da ramuka masu ƙima

Bayani na sarrafawa: daga ramuka na matukai zuwa fasalolin gama gari

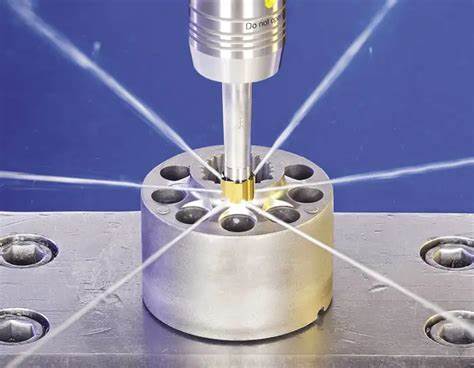

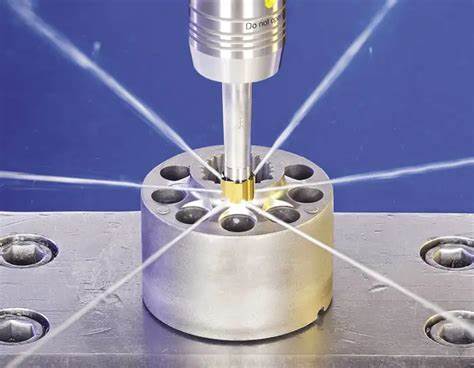

Kirkirar samfuri da ramuka masu sa ido sun ƙunshi tsarin gudanarwa da yawa. Mataki na farko shine ƙirƙirar rami mai matukin jirgi, wanda ya zama kamar cibiyar zuwa cibiyar don tabo. Yawancin matukin jirgi yawanci ana gutsura, gundura, ko milled zuwa diamita da ake buƙata da zurfi.

Da zarar an kirkiro rami na matukin jirgi, mataki na gaba shine in yi na'ura ko kuma ta hanyar. Ana yin wannan ta amfani da kayan aikin musamman waɗanda suka dace da diamita da ake so da zurfi na fasalin. Yana da mahimmanci don tabbatar da cewa kayan aiki ya yi daidai da ramin matukin jirgi don kula da ɗaukar hankali.

A ƙarshe, kayan aikin yana shiga cikin aikin kayan don ƙirƙirar potface ko kuma counterbore. To, kayan aikin da aka yi, barin santsi, lebur farfajiya ko lokacin hutu, dangane da fasalin da ake amfani da shi.

Kayan aiki da kayan aiki don Countsebore da Taboconing

Kayan aiki na musamman suna samuwa ga ayyukan da alama ta hanyar daidaitattun abubuwa. Waɗannan kayan aikin suna zuwa cikin geometries daban-daban da girma dabam don ɗaukar diamita daban-daban daban da zurfin.

Kayan aikin da aka yi kama da yawan shuke sama ko ƙarshen injin da suka dace da rami na farko. An tsara gefuna masu yankewa don ƙirƙirar rami mai lebur mai ɗorewa tare da bangon madaidaiciya. Wasu kayan aikin da ke tattare da su suna da zurfin zurfin zurfafa don ɗaukar abubuwa daban-daban na tsayi.

Kayan aiki, a gefe guda, suna da ɗan gajeren yanke tun lokacin da suke buƙatar ƙirƙirar lokacin hutu. Suna iya samun matukin jirgi ko jagora don tabbatar da ɗaukar hankali tare da ramin matukin gidan. Kayan aikin Spotface sau da yawa suna da ɗakin kwana ko dan kadan zagaye zagaye fuska don samar da ingantaccen wurin zama.

Baya ga kayan aikin ƙwararrun kayan aiki, daidaitattun mills da kuma sake yin masumaitawa don ƙirar da ke tabo. Zaɓin kayan aiki ya dogara da takamaiman buƙatun aikin, kamar girman ramin, zurfin, kuma a farfajiya ta ƙare.

Kalubale da mafita a cikin ramuka masu hawa da hasashe

Cikakkiyar CNC da Takaddun hasashe CNC ta gabatar da wasu matsaloli na musamman. Daya daga cikin manyan batutuwan yana ci gaba da ɗaukar hankali tsakanin ramin matukin jirgi da fasalin Machine. Duk wani kuskure na iya haifar da waje-cibiyar ko rami mai saukar ungulu, wanda zai iya haifar da abubuwan da suka faru.

Don shawo kan wannan kalubalen, yana da mahimmanci a yi amfani da kayan aikin da matukan jirgi wanda aka gina ko jagororin da suka dace da rami. Wannan yana taimakawa wajen kiyaye kayan aiki da aka ɗora a lokacin aikin Memining. Takaitaccen fasahohi da kuma dabarun masu amfani da shi ma yana da mahimmanci ga tabbatar da cewa aikin ya kasance mai tsayayye kuma ya canza a cikin aikin.

Wani kalubale yana cimma nasarar ƙarewa, musamman a cikin kayan da ke haifar da lalacewa ko ƙonawa. Ta amfani da kaifi, ingancin kayan aiki masu inganci tare da tsarin da ya dace na iya taimaka wajen rage girman waɗannan batutuwan. Ingantaccen Yankan Yanke da Ciyarwa, tare da amfani da coolant, kuma iya ba da gudummawa ga mafi kyawun ƙarewa.

Nasihu don zaɓar kayan aikin da ya dace don kowane aiki

Zabi kayan hannun dama don cakulan da tabo mai mahimmanci yana da mahimmanci don cimma sakamakon da ake so. Anan akwai wasu nasihu don kiyayewa:

1.Conider da girman ramin da zurfi: Zabi kayan aikin da suka dace da diamita da ake buƙata da zurfin fasalin. Don masu ba da izini, tabbatar cewa kayan aiki na iya ɗaukar tsayin tsayin daka.

2.Ku ga kayan aikin da aka gina gindin gidaje: kayan aiki tare da matukan jirgi ko jagora zasu iya taimakawa wajen kula da hankali da jeri tare da ramin matukin jirgi.

3.Cing da kayan aiki kayan aiki da shafi: Zaɓi Kayan aikin da aka yi daga manyan kayan inganci, kamar ƙarfe na sama, kuma tare da kayan kwalliya don kayan da aka dace.

4.Condering Putursations gama gari: An tsara wasu kayan aikin don samar da babban karewa fiye da wasu. Zabi kayan aiki tare da madaidaicin geometry da kuma shirye-shiryen gado don takamaiman bukatunku.

5. Nemo da kayan aikin na kayan aiki: nemi kayan aikin da zasu iya sarrafa kewayon girma da zurfi don haɓaka amfaninsu a cikin shago.

Tsarin ƙira da mafi kyawun ayyuka

A lokacin da ƙirar ƙirar da ke buƙatar matattarar ramuka ko wuraren shakatawa, akwai mafi kyawun ayyuka don kiyayewa:

1.Cirewa yana bayyana nau'in fasalin: Yi amfani da alamomin da suka dace da kuma sanya hannu don nuna ko rami yana da ƙuruciya ko sikelin. Wannan yana taimakawa don guje wa rikicewa yayin tsarin Multining.

2. provide cikakken girma: hada da diamita, zurfin, da kowane irin girma da suka dace don counterbore ko propfface. Ga masu ba da labari, saka hitin gaba na gaba don tabbatar da dacewa.

3. Duka kayan abu: Zabi mai daɗaɗɗun matattara da diamita waɗanda suka dace don kayan aikin da aka dace. Wasu abubuwa na iya buƙatar sifofi ko zurfi don guje wa maganganu kamar lalata ko ƙonewa.

4.Think game da bukatun Majalisar: Lokacin da tantance ramuka ko tabo yadda za a tattara shi kuma akwai wasu wurare ko kuma akwai wasu hanyoyin da suka dace.

5Amma gamsuwa na farfajiya: Idan ana buƙatar cin koli na farfajiya ko Fikakkiyar hanya, a tabbatar da bayyana wannan akan zane ko kuma a cikin takaddun ƙira.

Ta bin waɗannan ayyukan ƙira da kuma kyakkyawan tsari, injiniyoyi da masu zanen kaya na iya taimakawa wajen tabbatar da cewa ramuka da kuma samfuran ramuka da aka yi daidai da inganci.

Aikace-aikace da karatun karatun

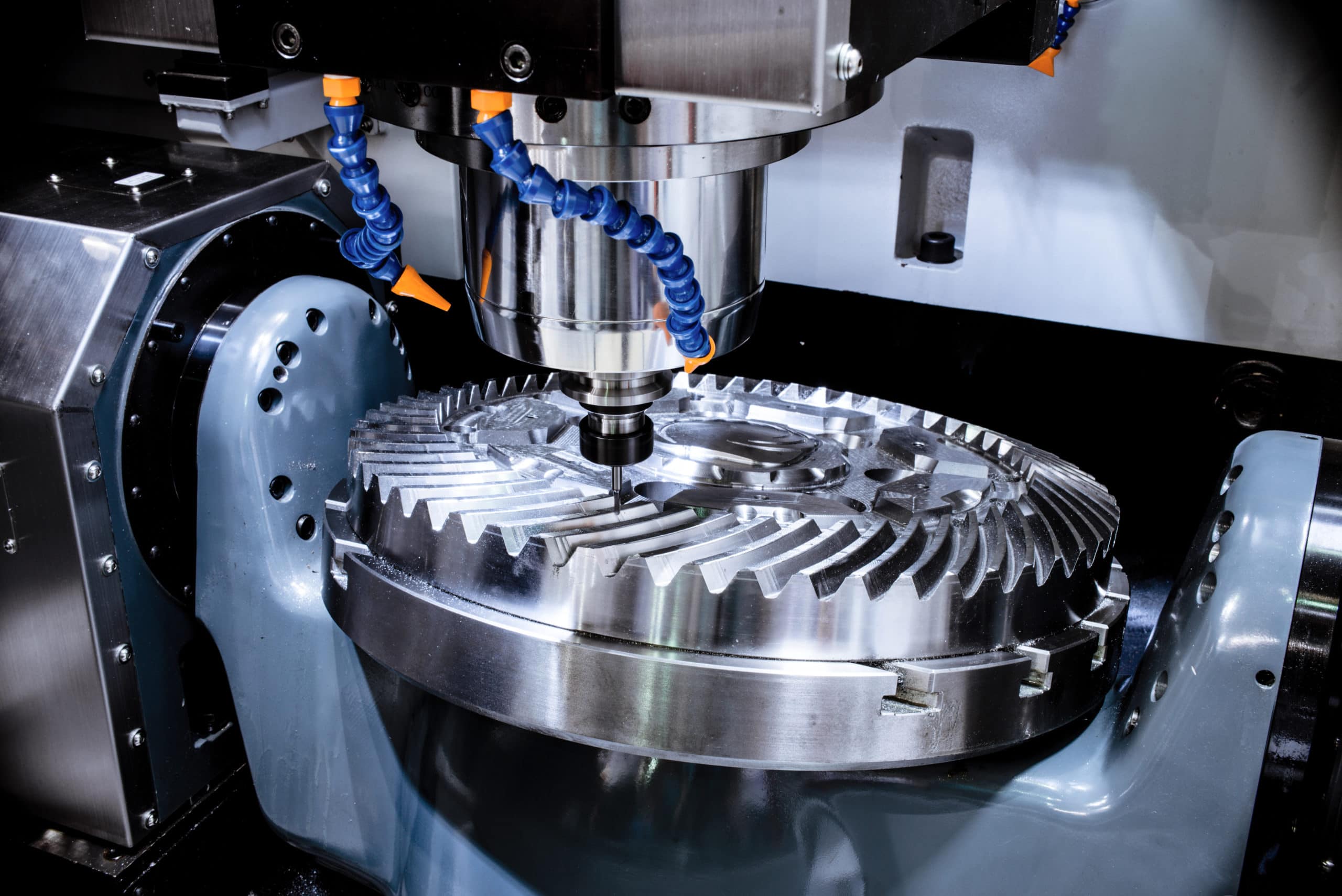

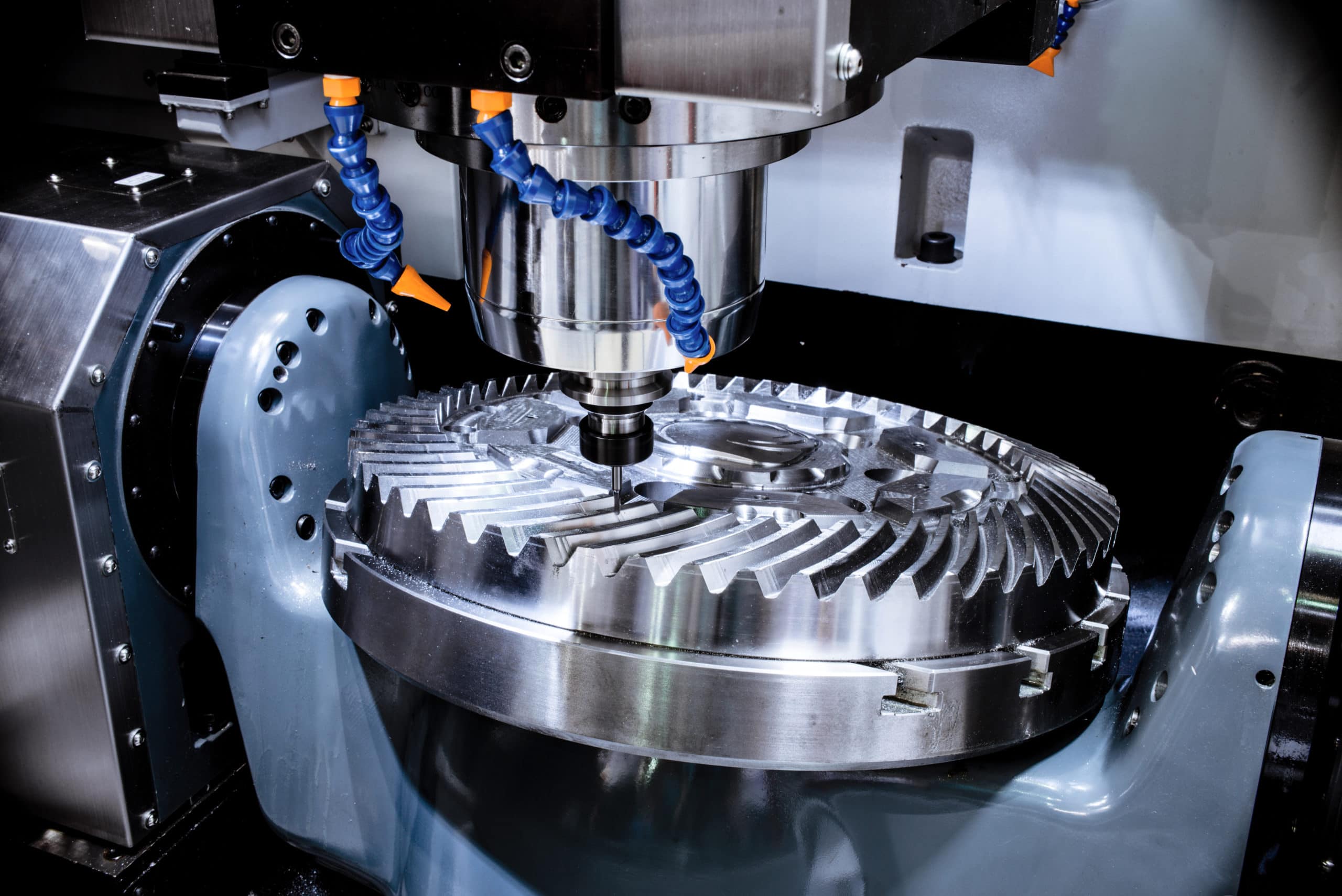

Aikace-aikacen Aer-aikace-aikace: Aerospace, Aertous, da ƙari

Fikakkiyar ramuka da ramuka masu ƙima suna nemo aikace-aikace a duk faɗin masana'antu, kowannensu da bukatunta na musamman da ƙalubale. A cikin masana'antar Aerospace, alal misali, wadannan fasali fasali suna da mahimmanci don ƙirƙirar haɗi mai tsaro da flush.

Masana'antar kayan aiki kuma sun yi matukar dogaro da ramuka da kuma ramuka masu ƙima don injunan shiga, dakatarwar dakatarwa, da sauran kayan aikin tsaftacewa. Waɗannan fasal din suna tabbatar da daidaituwa daidai, amintaccen sauri, da kuma tsabta, bayyanar ƙwararru a cikin samfurin ƙarshe.

Sauran masana'antu, irin su masana'antu na gab da kullun, injin ɗin, da kuma aikin katako, kuma suna amfani da ramuka masu yawa don aikace-aikace iri-iri. Daga kayan aikin kayan aikin don tsara kayan aikin injin, waɗannan fasali suna taka muhimmiyar rawa sosai wajen ƙirƙirar masu ƙarfi, daidai, da kuma gani da haɗi da aka gani.

Karatun Case: Spotffface da Counterbore a aikace

Don fi fahimtar mahimmancin tabo da ramuka, bari mu kalli karatun karatun duniya.

Karatun Nazarin 1: Majalisar Aerospace

Masana'antu na Aerospace yana fuskantar al'amura tare da Majalisar wani abu mai mahimmanci saboda mashahuran ra'ayi. Ta hanyar haɗe da ramuka na tabo a cikin ƙirar, sun sami damar ƙirƙirar ɗakin kwana, har ma suna zaune a farfajiya, suna tabbatar da jeri mai kyau da haɗin kai. Wannan canji mai sauƙi ya cire abubuwan da ke faruwa da inganta ingancin samfurin ƙarshe.

Karatun Nazarin 2: Aikin Injin Kayan Aiki

Kamfanin masana'antar mota yana neman jere tsarin samar da injin su kuma rage lokacin da aka kashe a kan wanda aka lalata a kan wanda aka lalata da tsaftacewa ramuka masu ƙyalƙyali. Ta hanyar aiwatar da ramuka na tursasawa a cikin zanen su, sun sami damar ƙirƙirar tsabta, bayyanar ruwa ga masu taimako yayin da suke rage buƙatar ƙarin matakan aiki. Wannan canjin ya haifar da mahimmancin lokaci da ajiyar kuɗi masu tsada a tsarin samar da su.

Karatun Karatun 3: Masana'antu na Littattafai

Wani masana'anta masana'anta yana fuskantar kalubale tare da bayyanar da samfuran samfuran su saboda fallasa shugabannin da suka fallasa shugabannin. Ta hanyar haɗa abubuwa masu ƙima a cikin ƙirar, suna iya ƙirƙirar sleok, bayyanar ruwa don cikakkun kaya da jin daɗin kayan aikinsu. Wannan ci gaba ya taimaka a bambance samfuran su a cikin kasuwa mai gasa da kuma inganta gamsuwa na abokin ciniki.

Karatun wadannan karatuttukan suna nuna fa'idodin masu tanti wanda ke nuna fa'idar da kuma ramuka masu ƙima na iya kawo masana'antu daban-daban da aikace-aikace. Ta hanyar fahimtar takamaiman bukatun kowane irin aiki, injiniyoyi da masu zanen kaya na iya haɗa waɗannan abubuwan don inganta ingancin samfurin, sarrafa layin Streetline, kuma haɓaka ƙwarewar mai amfani da ƙwararru.

Tukwici don zabar tsarin haƙƙin da kuka yi

A lokacin da yanke shawara tsakanin tabo da ramuka masu ƙima don aikinku, la'akari da waɗannan shawarwari:

1.evarewa ka'idojin aikinka. Yi la'akari da dalilai kamar karfin haɗin, bayyanar gani na ƙarshe, da kowane sarari ko taro ko taro.

2.Coniider da kayan amfani da aka yi amfani da su. Abubuwan daban-daban na iya buƙatar hanyoyin sarrafawa daban-daban ko fasalin girma don cimma sakamakon da ake so. Misali, kayan softer na iya buƙatar poprowal potwace ko zurfin m don guje wa ɓarna ko matsawa.

3.To cikin asusun samar da samarwa da tsarin lokaci. Zabi tsakanin wurin tabo da ramuka na iya haifar da lokacin samar da abubuwa da tsada. Don samar da girma-girma yana gudana, yana iya zama mafi inganci don amfani da ramuka na ƙira don rage buƙatar ƙarin matakan sarrafa bayan.

4.Consult tare da ƙwararrun machs ko injiniyoyi. A lokacin da cikin shakka, nemi shawara game da ƙwararru da suka sami gogewa tare da ramuka da ƙima a cikin irin aikace-aikace. Zasu iya samar da ma'anar fahimta da shawarwari dangane da gwaninta.

5.Cond sosai gwajin da kuma prototyy. Kafin kammala ƙirar ku, ƙirƙirar ƙirar ƙira da kuma yin gwaji sosai don tabbatar da cewa tsarin da aka zaɓa ya gana da duk bayanan da ake buƙata a aikace-aikacen ƙarshe.

Ƙarshe

A cikin wannan labarin, mun bincika mahimman bambance-bambance tsakanin misalan wuri da kuma matakan ƙididdiga, fasalin samfuran guda biyu masu mahimmanci a cikin masana'antar da suka tsara. Ta hanyar fahimtar halaye na musamman, hanyoyin sarrafawa, da aikace-aikace, ƙwararrun ƙwararru na iya yin yanke shawara na musamman lokacin zaɓi fasalin da suka dace don ayyukansu. Fikakkiyar ramuka da ramuka masu ƙima suna taka muhimmiyar rawa wajen tabbatar da daidaito, aminci, da kuma ƙarfin da aka tattara a cikin masana'antu daban-daban. Yayinda muke ci gaba da fitar da bidi'a a kera, rungumi ikon waɗannan karancin amma manyan fasali zasuyi matukar muhimmanci ga nasara a filin da muke yi a Filibmu ta Mazara.

Faqs

Tambaya: Menene bambance-bambance na farko tsakanin tabo da ramuka?

A: Takaddun ramuka marasa kyau ne, samar da wani lebur surface don ɗaukar fansa don zama ja. Ramunan da ke dauke da zurfi suna zurfi, ba da izinin shugabanci da aka dawo da shi a ƙasa. Footffes suna da siffar silili mai sauƙi, yayin da suke da bayanin martaba suna da bayanin martaba.

Tambaya. Ta yaya zan yanke shawara ko don amfani da rami mai ɗorewa ko kuma rami mai kauna don aikina?

A: Yi la'akari da takamaiman buƙatun aikace-aikacenku, kamar ƙarfin haɗin da bayyanar gani. Kimanta kayan da ake amfani da shi, kamar yadda wasu na iya buƙatar girman fasalin daban-daban. Tattaunawa tare da ƙwararrun mama ko injiniyoyi da kuma yin gwaji sosai da kuma prototying.

Tambaya: Za a iya ƙirƙirar ramuka da ramuka masu ƙima ta amfani da wannan kayan aikin guda?

A: Yayin da wasu kayan aikin, kamar ƙarshen Mills da kuma sake nazarin, ana iya amfani dashi don duka biyun, kayan aiki na musamman. Kayan aikin da aka lissafa sau da yawa suna da matukin matukin jirgi da zurfafa zurfafa, yayin da sanannun kayan aikin suna da gajere na yankan. Zaɓin kayan aiki ya dogara da takamaiman buƙatun aikin.

Tambaya: Waɗanne kursi ne na kowa don gujewa lokacin da ƙirar rami?

A: A bayyane yake saka nau'in fasalin ta amfani da alamomin da suka dace da kuma sanya hannu don guje wa rudani yayin injin. Bayar da cikakken girma, gami da diamita, zurfin, da kuma fastenner shugaban tsayi. Yi la'akari da kayan aikin da yawan jama'a lokacin da tantancewa da diamita.

Tambaya. Ta yaya ramuka masu hawa da tabo suna ba da gudummawa ga tsarin masana'antu?

A: Haske da ramuka da tabo suna tabbatar da jeri daidai, amintaccen sauri, da kuma kyakkyawan yanayin, ƙwararru ne a cikin samfurin ƙarshe. Zasu iya samarwa ta hanyar rage buƙatar ƙarin matakan sarrafa bayan aiki da rage haɗarin kurakuran Majalisar kurakurai. Waɗannan fasalin suna ba da gudummawa ga gaba ɗaya da kuma farashin sakamako na masana'antu.

Tambaya: Shin ana iya canza rami mai taurin kai zuwa rami mai tushe ko akasin haka?

A: Canza rami mai taurin kai zuwa rami mai yuwuwa yana yuwuwar yin rami zuwa zurfin zurfin. Koyaya, sauya tabtara zuwa gajiyar na iya zama mafi ƙalubale, kamar yadda yake buƙatar zurfafa rami. Zai fi kyau a tsara da na'ura madaidaiciya fasalin daga farkon.

Tambaya: Menene kurakurai na kowa don gujewa cikin matattarar da alama?

A: Tabbatar da daidaituwa daidai da ladabi tsakanin rami na matukin jirgi da fasalin da aka yi don guje wa cibiyar ko ramuka na angled. Yi amfani da kaifi, ingancin kayan aiki masu inganci tare da kwalliyar da suka dace da yankan sigogi don cimma nasarar karewar da ake so. Yi amfani da dabarun tsallakewa da masu amfani don kula da kwanciyar hankali na aiki a cikin tsarin sarrafa.

Tambaya: Ta yaya bukatun na farfajiya ya bambanta tsakanin ramuka da tubalin?

A: Haske na tabo sau da yawa suna buƙatar freiner farfajiya, kamar yadda manufarsu ta farko ita ce samar da ingantaccen wurin zama. Ramunan da ke ramuka na iya samun dan kadan ya gama karewa a kan bangaren kasashen, amma har yanzu surorin har yanzu yana buƙatar santsi. Ya kamata a tattauna takamaiman abubuwan da aka gama gama gari a cikin takardun ƙira.