Ɔltin we yu nid fɔ no bɔt di ol dɛn we gɛt trɛd: di kayn dɛn, di aplikeshɔn dɛn, di ɛp we go ɛp yu fɔ gayd yu

Di we aw yu de si di pikchɔ dɛn: 0

Aks fɔ aks kwɛstyɔn dɛn .

Threaded holes na impɔtant tin fɔ mek di mɔdan manufakchurin, we de wok as di fawndeshɔn fɔ assemble komponent dɛn sikrit wan, we de gi sikrit, adaptabl, ɛn durable fastening sɔlvishɔn dɛn we de sɔpɔt ɔl tu di mas prodakshɔn ɛn kɔstɔm fabrikeshɔn. Dis atikul go sho ɔl wetin yu nid fɔ no bɔt dis majik tin. Mek wi tek wan klos luk pan di ditel dem fo threaded hol dem!

Difinishɔn ɛn di kayn ol dɛn we dɛn dɔn trɛd .

Wetin na di ol dɛn we gɛt trɛd?

Ɔl dɛn we gɛt trɛd na silinda opin dɛn we dɛn mek fɔ aksept fastɛns lɛk skru ɔ bolt. Di insay pat pan dɛn ol dɛn ya gɛt ɛlikal rij—we dɛn kɔl trɛd—we kin miks wit ɛksternal trɛd dɛn na fastɛn. Dis strכkchכ de mek wan strכng, frikshכn-bεys kכnεkshכn, kip kכmכpכnt dεm sikyuכr fasten. Di ol dɛn we gɛt trɛd de ple impɔtant pat pan bɔku industri dɛn, lɛk ɔtomotiv, ilɛktroniks, ɛn aerospace, usay mɛkanikal stebiliti ɛn izi fɔ disassembly impɔtant.

Tayp dɛn fɔ di ol dɛn we gɛt trɛd .

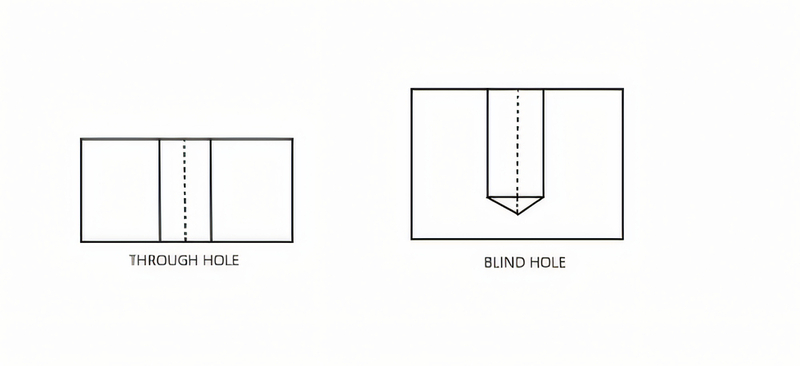

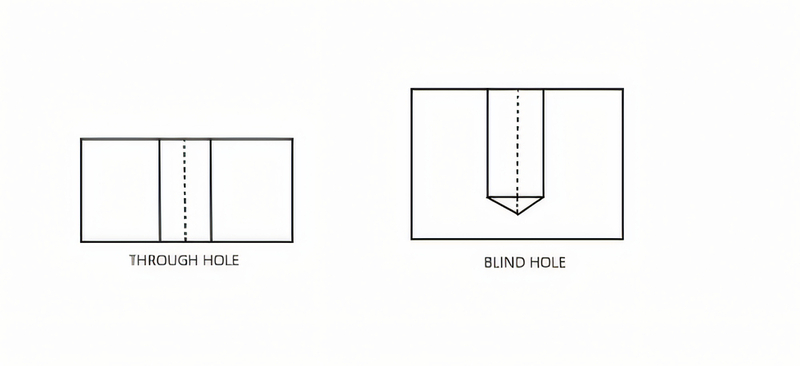

Tu praymari kayn ol dɛn de we dɛn kin trɛd bay we dɛn de yuz dɛn dip ɛn dizayn: tru ol ɛn blaynd ol dɛn . Fɔ wan kɔmprɛhɛnsif ɔvaviu fɔ difrɛn kayn ol dɛn na injinɛri, yu kin rifer to wi . Gayd pan difrɛn kayn ol dɛn ..

Tru ol dɛn : Dɛn ol dɛn ya de go ɔlsay na di matirial, we de alaw fɔ mek pɔsin fast fɔ pas frɔm wan say to di ɔda say. Dɛn kin kɔmɔn na aplikeshɔn usay di fastɛns fɔ go insay ɔl tu di say dɛn na di wokpies. Fɔ ɛgzampul, insay ɔtomotiv asɛmbli, tru ol dɛn de mek dɛn ebul fɔ mek bolt dɛn sikyuɔr wit nɛt na di ɔpɔzit say.

Blaynd ol : Nɔ lɛk tru ol, blaynd ol nɔ de ɛkstɛnd ɔlsay na di matirial. Di dip de kɔntrol so di fastɛns nɔ go kɔmɔt na di ɔda say. Blaynd ol dɛn kin gɛt flat ɔ kɔn-shaped bottom ɛn dɛn fayn fɔ aplikeshɔn usay aesthetics ɔ functionality de aks fɔ mek di fastener de ayd, lɛk insay prɛsishɔn ilɛktroniks ɔ mɛdikal divays dɛn. Fɔ no mɔ bɔt blaynd ol dɛn, chɛk wi Atikul bɔt blaynd ol dɛn na injinɛri ɛn mashin ..

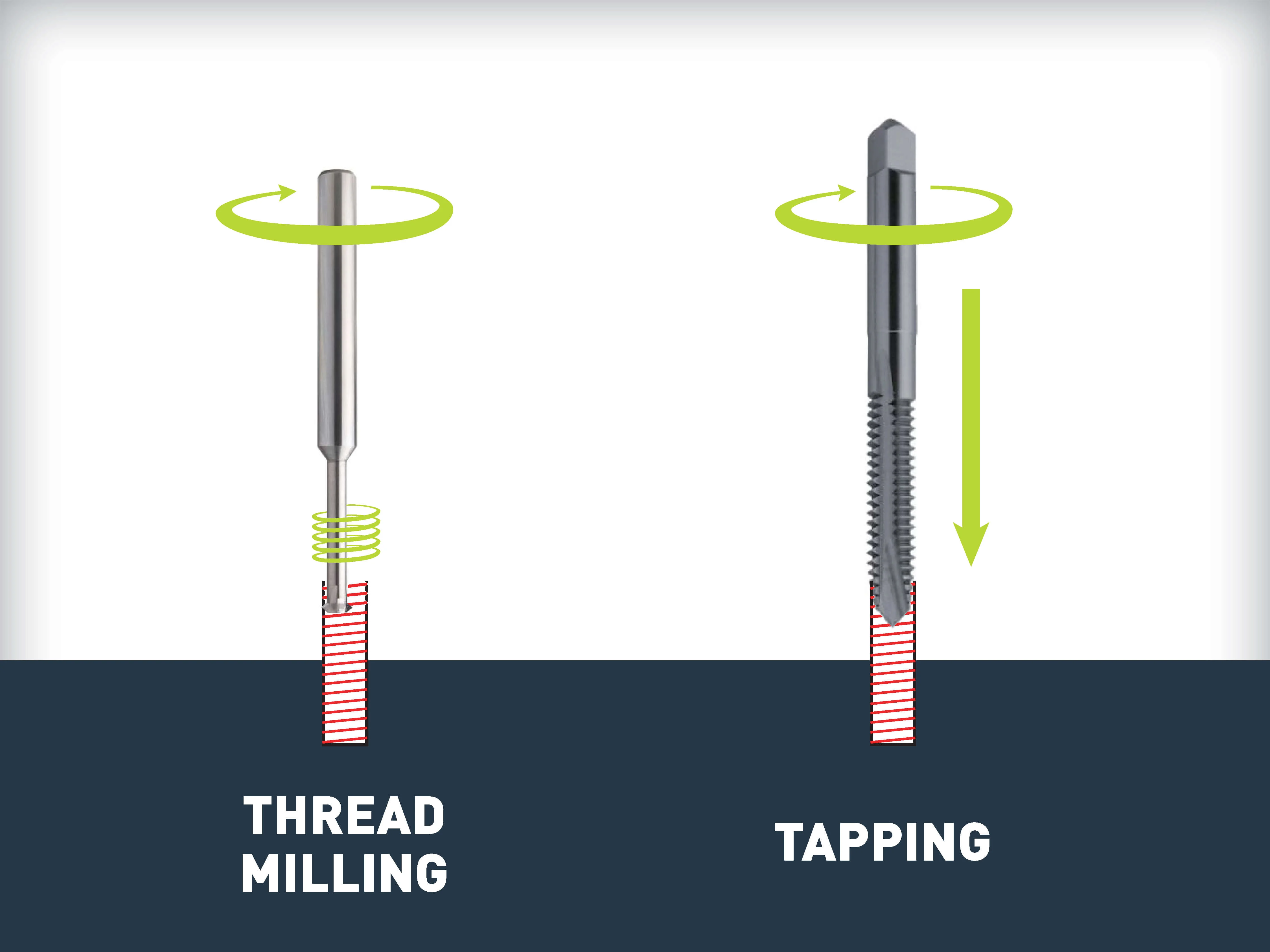

Fɔ mek dɛn ol dɛn ya we gɛt trɛd, di wan dɛn we de yuz mashin kin yuz difrɛn we dɛn fɔ yuz am. Fɔ tap ɛn mil na kɔmɔn we dɛn, bɔt dɛn kin yuz di we dɛn we dɛn nɔ de yuz, lɛk insɛt dɛn we dɛn dɔn trɛd, bak fɔ mek tin dɛn we soft ɔ we dɛn nid fɔ gɛt mɔ trɛnk. Dɛn prɔses ya kin involv bɔku tɛm . CNC prɛsishɔn mashin fɔ optimal akkuracy ɛn kɔnsistɛns.

Kɔmpia tebul: tru ol vs blaynd ol dɛn

| ficha | tru ol | blaynd ol dɛn |

| Dip | I de go ɔp tru di matirial . | pat pan dip, nɔ de go tru . |

| Yuz kes . | We Fastener nid fɔ pas tru ɔl tu di say dɛn . | Aesthetically hidden, fastener nɔ de kɔmɔt . |

| Di shep we de dɔŋ . | Opin na ɔl tu di say dɛn . | Tipikli flat ɔ kɔnik . |

Dɛn tu kayn dɛn ya kin gi dɛn bɔku bɔku tin dɛn, bɔt bɔku tɛm di sɛlɛkshɔn kin dipen pan di prɔjek in strɔkchɔral rikwaymɛnt dɛn, ɛstitik dɛn, ɔ matirial limiteshɔn dɛn.

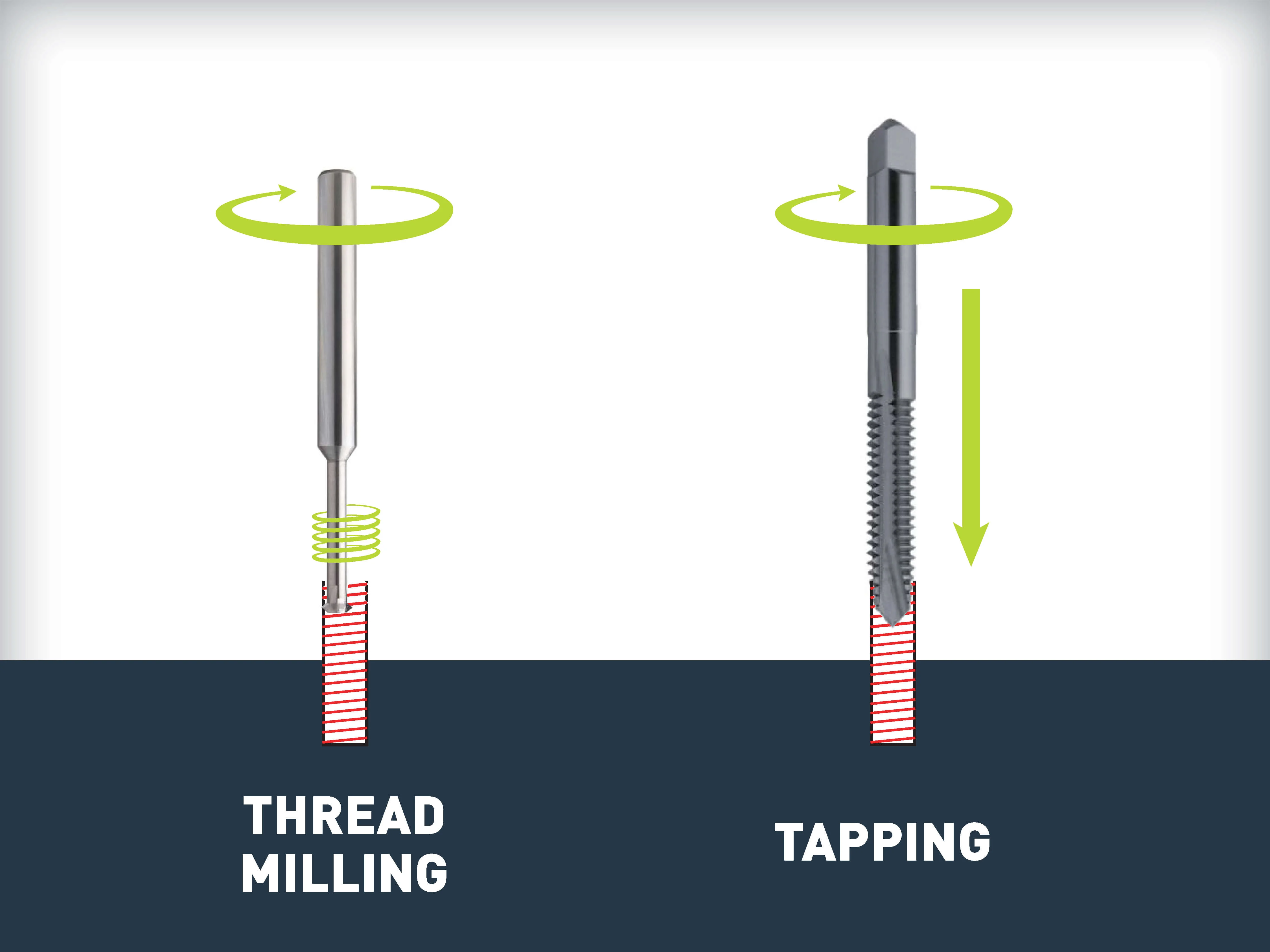

Threaded holes vs. tap ols .

Klarify di tɛminɔlɔji: Threading vs. tapping .

Bɔku tɛm, pipul dɛn kin kɔnfyus we dɛn de tɔk bɔt ol dɛn we gɛt trɛd ɛn tap. Pan ɔl we sɔntɛnde dɛn kin yuz dɛn wɔd ya fɔ chenj dɛnsɛf, dɛn kin rili tɔk bɔt difrɛn we dɛn ɛn aw tin kin kɔmɔt.

Threading:

I de mek ɛksternal trɛd dɛn pan rod, bolt, ɔ skru .

Involv fɔ kɔt hɛlikal grov dɛn rawnd di ɔda say na wan silinda ɔbjɛkt .

Tapping:

I de mek intanɛnt trɛd dɛn insay wan ol we dɛn dɔn drɔ bifo tɛm .

Fɔm threaded cavities in matirial dɛn lɛk mɛtal, wud, ɔ plastic

Difrɛns ɛn di we aw dɛn de du tin ɛn di we aw dɛn de du tin .

Di ol dɛn we gɛt trɛd:

Usually pre-formed during casting or molding .

Bɔku tɛm dɛn kin si am na pat dɛn we dɛn mek bɔku bɔku wan .

Gi kɔnsistɛns trɛd kwaliti .

I kin nid fɔ gɛt smɔl post-prɔsɛsin .

Tapped holes:

Krio bay we dɛn kɔt trɛd dɛn insay wan ol we dɔn de .

Ofa fleksibiliti fɔ kɔstɔm aplikeshɔn dɛn .

kin du na di sayt ɔ as nid de .

Rikways prɛsis tul ɛn skil .

| Aspect | threaded holes | Tapped holes |

| Fɔmeshɔn . | We dɛn de mek di tin dɛn we dɛn de mek . | Pɔst-drilin . |

| Ɔltɛm | Ay | Variable we de chenj chenj . |

| Kastomayshɔn . | Limitɛd . | I rili fleksibul . |

| Tuling . | Speshal mold dɛn . | Taps ɛn drɔl bit dɛn . |

| Pe | Lower fɔ ay volyum . | Lower fɔ smɔl batch dɛn . |

Di men tin dɛn we wi fɔ tink bɔt:

Di prɔpati dɛn we dɛn gɛt .

Di trɛd we yu nid fɔ gɛt trɛnk .

Prodakshɔn Volyum .

Di tin dɛn we dɛn fɔ du fɔ mek di tin dɛn we dɛn nid fɔ mek di Asɛmbli .

Kost-ɛfɛktiv .

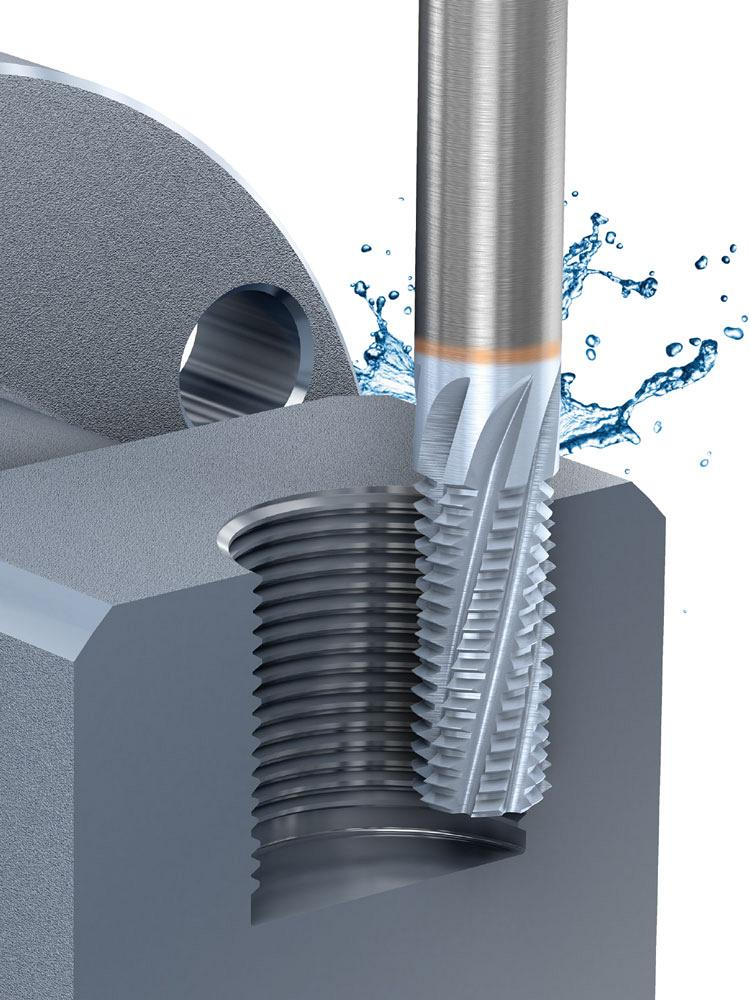

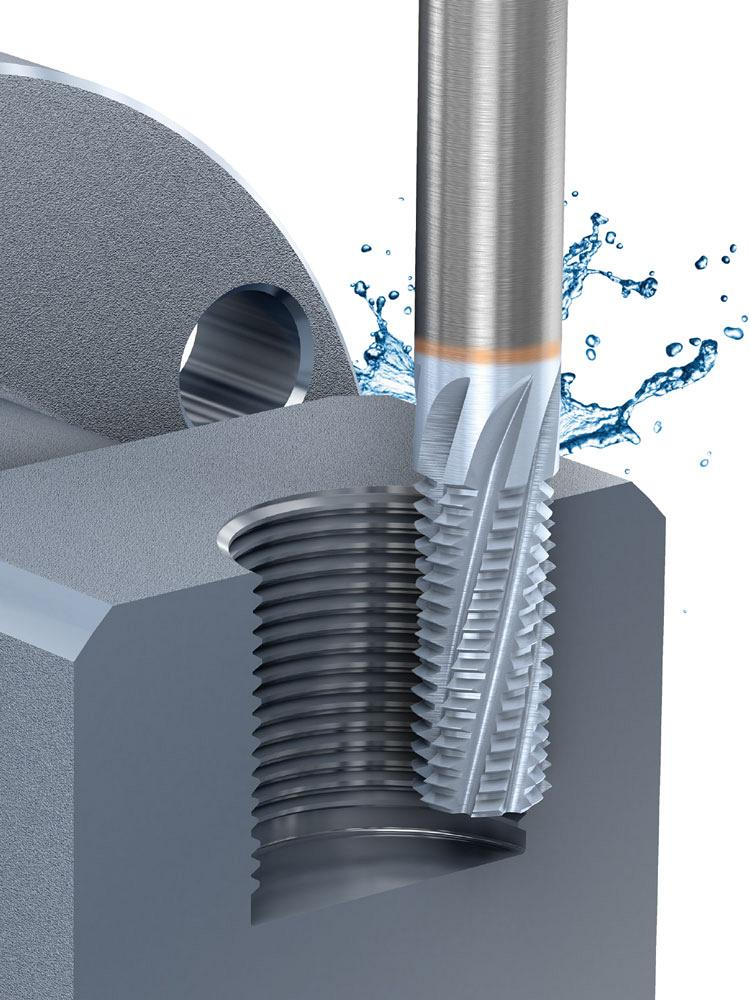

Di prɔses dɛn we de biɛn fɔ mek trɛd ol dɛn .

Fɔm, tap, ɛn trɛd: Wan kɔmparativ analisis fɔ di we dɛn fɔ du tin .

Fɔ mek ol dɛn we gɛt trɛd, gɛt fɔ du wit difrɛn tɛknik dɛn, ɛn ɛni wan pan dɛn fit fɔ difrɛn tin dɛn ɛn aplikeshɔn dɛn. Dɛn prɔses ya kin yuz bɔku tɛm . CNC prɛsishɔn mashin fɔ optimal akkuracy ɛn efyushɔn. Lɛ wi fɛn di men we dɛn fɔ du am:

Fɔm .

Yuz prɛshɔn to displeys matirial .

I de mek strɔng trɛd dɛn we nɔ de pul matirial .

Ideal fɔ soft mɛtal ɛn plastic .

Tapping fɔ tap .

Kɔt intanɛnt trɛd dɛn insay ol dɛn we dɛn dɔn drɔ bifo tɛm .

Ofa prɛsishɔn ɛn versatility .

I fayn fɔ bɔku bɔku tin dɛn fɔ yuz .

Threading we dɛn de trɛd .

Tipikli de rifer to fɔ mek ɛksternal trɛd dɛn .

kin aplay to intanɛnt ol dɛn na sɔm kɔntɛks dɛn .

Bɔku tɛm dɛn kin yuz am togɛda wit tapping .

| di we aw dɛn | nɔ | ebul fɔ du am: |

| Fɔm . | No matirial west, strɔng trɛd dɛn . | Limited to soft matirial dɛn . |

| Tapping fɔ tap . | Versatile, prɛsis . | kin wik matirial strɔkchɔ . |

| Threading we dɛn de trɛd . | Efishin fɔ ɛksternal trɛd dɛn . | Less kɔmɔn fɔ intanɛnt ol dɛn . |

Step-by-step gayd fɔ mek di ol dɛn we gɛt trɛd: izi fɔ fala stɛp dɛn

Krio threaded holes nor nid for bi daunting. Fɔ fala dɛn step ya fɔ mek yu gɛt sakrifays, we yu kin yuz fɔ difrɛn difrɛn tin dɛn . Di kayn CNC mashin dɛn : .

Dril di ol: Yuz drɔl smɔl smɔl smɔl pas di trɛd saiz we yu want. Dɛn kɔl dis di tap drɔl saiz.

Chamfer Di ol: Krio wan smɔl Chamfer na di ol ɛntrɛ yuz wan big drɔl bit ɔ wan kɔntasink tul. I de ɛp fɔ gayd di tap.

Lubrik di tap: Put di wata we de kɔt ɔ ɔyl na di tap. I de ridyus frikshɔn ɛn ɔt, ɛp di tap fɔ kɔt mɔ izi wan.

Start di tap: Put di tip fɔ di tap insay di chamfered ol. Put layt prɛshɔn ɛn tɔn di tap kloksayz smɔl smɔl.

Kɔntinyu fɔ tap: Kɔntinyu fɔ tɔn di tap. Afta ɛni af dɔn tɔn fɔ go bifo, rivɛns di tap wan kwata tɔn fɔ brok di chips.

Finish di ol: Kɔntinyu te di tap dɔn pas tru di wok ɔ rich di dip we yu want. Rivas di tap aut na di ol.

7.Klin di trɛd dɛn: Yuz kɔmprɛsd ɛya ɔ brɔsh fɔ pul ɛni chips ɔ dɔti na di trɛd dɛn we dɛn jɔs kɔt.

Pro Tips:

Yuz wan tap gayd fɔ stret trɛd dɛn .

Praktis pan skrap matirial fɔs .

Tek am slo fɔ avɔyd fɔ brok tap .

Di kayn tap dɛn we dɛn kin yuz na ol trɛdin .

Ovaviu fɔ Kɔmɔn Tap Tayp dɛn ɛn di we aw dɛn de yuz dɛn .

Bɔku kayn tap dɛn de we dɛn kin yuz na ol trɛdin, ɛn ɛni wan pan dɛn gɛt in yon kwaliti ɛn aplikeshɔn dɛn:

Tap dɛn we de tap:

Yu fɔ gɛt smɔl smɔl taper na di say we dɛn de kɔt

Ideal fɔ stat trɛd dɛn na blaynd ol ɔ taf matirial dɛn .

Distribute cutting force ova sɔm trɛd dɛn .

Plɔg tap dɛn:

Una gɛt wan shɔt taper we dɛn fala wit ful trɛd dɛn .

Yuz fɔ thread tru ol ɔ afta wan taper tap .

I fayn we di ol gɛt say fɔ kɔmɔt .

Di tap dɛn we de dɔŋ:

Una gɛt wan rili shɔt taper ɛn ful trɛd dɛn we dɔn lɛf smɔl fɔ lɛ wi rich di ɛnd .

Yuz fɔ thread klos to di bottom fɔ blaynd ol dɛn .

Rikways wan ol dip fɔ akɔmod di tap .

Spiral Point Taps: .

gɛt spiral flut we de push chips bifo di tap .

Ideal fɔ tru ol dɛn na matirial dɛn we prone to lɔng, stringi chips

Dɛn kin yuz am mɔ na CNC tap ɔpreshɔn dɛn .

Spiral flut tap dɛn:

gɛt spiral flut dɛn we de pul chips bak kɔmɔt na di ol .

Dɛn kin yuz am fɔ blaynd ol dɛn usay chip ɛvakyushɔn rili impɔtant .

Ɛp fɔ mek dɛn nɔ pak chip ɛn fɔ mek dɛn brok di tul dɛn .

| Tap Tayp | Taper lɔng | aplikeshɔn |

| Taper we yu go yuz . | Smɔl smɔl . | Start thread, blaynd ol, taf matirial |

| Plɔg | Shɔt | tru ol, afta taper tap . |

| Bottoming . | Na rili shɔt . | Threading klos to bottom of blind holes . |

| Spiral Point . | - | Tru ol, matirial wit stringi chips . |

| spiral flut . | - | Blaynd ol dɛn, chip ɛvakyushɔn . |

Fɔ pik di rayt tap fɔ sɔm patikyula matirial ɛn aplikeshɔn dɛn .

Fɔ pik di tap we fit dipen pan di matirial ɛn di kayn ol:

Sɔft matirial dɛn (aluminum, bras, plastic):

Yuz taper ɔ plɔg tap fɔ tru ol dɛn .

Spiral flute taps wok gud fɔ blaynd ol dɛn .

Dɛn kin advays fɔ mek dɛn kɔt spid ɛn kɔt kɔt kɔsa pitch dɛn .

Had matirial dɛn (stiɛl, stenlɛs stiɛl, taytaniɔm):

Start wit wan taper tap, den wan plɔg tap fɔ tru ol dɛn .

Yuz taper tap, dɔn wan tap we de dɔŋ fɔ blaynd ol dɛn .

Slower cutting speeds, fayn fayn pitch dɛn, ɛn robust lubrication nid fɔ de

Tru di ol dɛn:

Blaynd ol dɛn:

Start wit wan taper tap fɔ gayd di threading .

Fɔ fala wit wan bottoming tap to thread klos to di bottom

Spiral flute taps ɛp wit chip ɛvakyushɔn .

Tips we go ɛp fɔ mek di ol dɛn we gɛt trɛd pafɛkt .

Fɔ mek prɛsis, durable threaded ol dɛn nid fɔ pe atɛnshɔn to ditiɛl ɛn di rayt tɛknik dɛn. Na sɔm valyu tin dɛn fɔ ɛp yu fɔ gɛt di bɛst rizɔlt:

kɔmɔn mistek dɛn fɔ avɔyd .

Yuz di rɔng tap drɔl saiz:

Failing fɔ chamfer di ol ɛntrɛ:

Tapping tu kwik:

Nɔ yuz lɔbrik:

Inkris frikshɔn ɛn ɔt, we de mek di kwaliti nɔ fayn fɔ di trɛd .

Put di wata we de kɔt ɔ ɔyl we fit fɔ di tin we dɛn yuz

Fail fɔ klia chips:

Optimizing akkuracy ɛn durabiliti fɔ threaded ol dɛn .

Yuz di rayt tap fɔ di wok:

Tink bɔt di tin dɛn we dɛn nid, di kayn ol we dɛn fɔ gɛt, ɛn di tin dɛn we dɛn nid fɔ mek di trɛd .

Pik di rayt tap tayp ɛn saiz .

Start di tap stret:

Mentɛn kɔnsistɛns kɔt spid ɛn prɛshɔn:

Brek chips ɔltɛm:

Klin di trɛd dɛn fayn fayn wan:

Rimov debris we kin intafya wit fastener fit .

Yuz kɔmprɛsd ɛya, brɔsh, ɔ tin fɔ klin di trɛd .

Verifay se di kwaliti fɔ di trɛd:

Chek fɔ si if di sayz, di pitch, ɛn di fɔm kɔrɛkt wan .

Yuz thread gauges ɔ optik kɔmparatɔ fɔ krichɔl aplikeshɔn dɛn .

Fɔ no mɔ bɔt prɛsishɔn ɛn tolɛreshɔn, luk na wi gayd fɔ CNC mashin tolerances

| tip | benefit . |

| Yuz kɔrɛkt tap drɔl saiz . | AKƆRƐKT TRƐD SAYZ . |

| Chamfer hol entrance . | I izi fɔ tap Start . |

| Kontrol Tapping Speed . | ridyus ɔt ɛn wear . |

| Yuz lɔbrikeshɔn . | Impruv Thread Kwaliti . |

| Klia chips ɔltɛm . | Prevent chip pak ɛn brek . |

| Start Tap Straight . | Nɔ krɔs-thrɛd . |

| Mentɛn kɔnsistɛns spid ɛn prɛshɔn . | Optimal thread kwaliti ɛn tul layf . |

| Klin trɛd dɛn fayn fayn wan . | Mek shɔ se yu gɛt di rayt fastɛns fit fayn fayn wan . |

| Verifay fɔ di kwaliti fɔ di trɛd . | Mit di tin dɛn we yu nid fɔ du fɔ mek yu kɔrɛkt . |

Fɔ ajɔst di ays lɛvɛl fɔ prɛsishɔn na yu trɛd ol dɛn, tink bɔt fɔ yuz yuz . CNC prɛsishɔn mashin tɛknik dɛn.

Di impɔtants fɔ threaded ol dɛn na manufakchurin .

Threaded holes de ple wan impɔtant pat pan di mɔdan manufakchurin, we de gi sikyɔriti ɛn rili kɔnɛkshɔn fɔ difrɛn komponent ɛn asɛmbli dɛn.

Ki bɛnifit dɛn .

Versatility : I fayn fɔ bɔku bɔku aplikeshɔn dɛn akɔdin to di industri dɛn .

Strɔng : Ɔf robust ɛn durable kɔnɛkshɔn dɛn .

Prɛsishɔn : Ɛnable kɔrɛkt alaynɛshɔn ɛn pozishɔn fɔ pat dɛn .

Ease of Assembly : Fasilitayt kwik ɛn efishɔnal asɛmbli prɔses .

Riyuzabiliti : Alaw fɔ disassembly ɛn riassembly witout kɔmprɔmis intɛgriti .

Di ol dɛn we gɛt trɛd kin rili impɔtant we dɛn de mek tin dɛn, dɛn kin gɛt balans we gɛt trɛnk, prɛsishɔn, ɛn we dɛn kin yuz fɔ du bɔku tin dɛn. Dɛn rayt dizayn ɛn implimɛnt impɔtant fɔ mek shɔ se di prɔdak kwaliti, rilaybiliti, ɛn pefɔmɛns akɔdin to difrɛn industri dɛn.

FAQS bɔt trɛd ol dɛn .

Wetin na threaded hols we dɛn kin yuz fɔ?

Dɛn kin yuz ol dɛn we gɛt trɛd fɔ tay di kɔmpɔnɛnt dɛn fayn fayn wan togɛda bay we dɛn de yuz skru, bolt, ɔ ɔda tin dɛn we dɛn dɔn trɛd. Dɛn impɔtant na industri dɛn lɛk ɔtomotiv, aerospace, ilɛktroniks, ɛn kɔnstrɔkshɔn fɔ rili, nɔ-pɛrmanɛnt kɔnɛkshɔn.

Wetin na di difrɛns bitwin wan ol we gɛt trɛd ɛn wan ol we dɛn tap?

Wan ol we gɛt trɛd na ɛni ol we gɛt insay trɛd, we dɛn mek bay difrɛn we dɛn lɛk fɔ tap, mil, ɔ rɔl. Wan tap ol spɛshal wan de tɔk bɔt wan ol usay dɛn kin kɔt trɛd yuz tap, we kin mek i bi wan sɔbsɛt pan di ol dɛn we gɛt trɛd.

Aw a go pik bitwin blaynd ol dɛn ɛn tru ol dɛn?

Blaynd ol dɛn fayn we di fastɛns nɔ fɔ pas kɔmplit wan tru di matirial, bɔku tɛm na fɔ aesthetic ɔ spɛs-sɛvin rizin dɛn. Tru ol dɛn de alaw di fastɛns fɔ go ɔlsay na di wok, we dɛn kin lɛk fɔ strɔng, mɔ sikrit kɔnɛkshɔn dɛn.

Us matirial dɛn kin tap ɔ trɛd?

Bɔku pan di mɛtal dɛn (lɛk stɛl, aluminiɔm, ɛn bras), plastic, ɛn ivin wud dɛn kin tap ɔ trɛd. Bɔt, sɔft matirial kin nid spɛshal kia ɔ insay fɔ mek shɔ se di trɛd dɛn ol fayn fayn wan.

Wetin na di bɛst we fɔ mek trɛd ol dɛn?

Di bɛst we fɔ du am dipen pan di aplikeshɔn. Tapping na kɔst-ɛfɛktiv fɔ standad ol dɛn, thread rolling de strɔng di tin dɛn we de rawnd fɔ ay-stress aplikeshɔn dɛn, ɛn mil de gi prɛsishɔn fɔ kɔstɔm ɔ kɔmpleks prɔjek dɛn.

Aw a go ebul fɔ protɛkt trɛd strip?

Fɔ mek yu nɔ pul trɛd, mek shɔ se yu alaynɛt di rayt alaynɛshɔn, yuz di kɔrɛkt fastɛns saiz, nɔ mek yu tayt pasmak, ɛn put lɔbrikɛn we yu de thread. Fɔ ay-lod aplikeshɔn dɛn, tink bɔt fɔ yuz trɛd insɛt dɛn fɔ mek di trɛd dɛn strɔng.

Yu tink se dɛn go ebul fɔ mek di ol dɛn we dɔn pwɛl we dɔn pwɛl?

Yes, dɛn kin ripɛnt di ol dɛn we dɔn pwɛl we dɛn dɔn pwɛl bay we dɛn de yuz tɛknik dɛn lɛk ri-tap ɔ instɔl trɛd insɛt dɛn lɛk ɛli-kɔyl. Dɛn we ya de mek di trɛd dɛn kam bak ɛn mek di ol kɔntinyu fɔ gɛt trɛnk.