Polifatalamidi (PPA) ye tulonkɛfɛn ye min bɛ kɛ ka ɲɛsin ɛntɛrinɛti plastiki ma. Yala i delila k’i yɛrɛ ɲininka mun de b’a to plastiki minnu bɛ baara kɛ kosɛbɛ, olu nafa ka bon kosɛbɛ iziniw kɔnɔ wa? PPA ye poliyamidi ye min bɛ kɛ ni kristali ye, a bɛ kɛ ni aromatiki ye, a bɛ fanga ni funteni kunbɛncogo ɲuman di.

Nin sɛbɛn in kɔnɔ, aw bɛna fɛn kɛrɛnkɛrɛnnenw, baarakɛcogo, fɛn dilanni jateminɛw, fɛn dɔw sɛmɛntiya ani ka ɲɔgɔn sanga ni PPA plastiki ka ɛntɛrinɛti plastiki wɛrɛw ye, ka hakilina nafamaw di dilanbagaw ni fɛn dilannikɛlaw ma.

Polifatalamidi (PPA) ye mun ye?

PPA, walima polifutalimidi, o ye plastiki ye min bɛ baara kɛ kosɛbɛ. A bɛ poliyamidi aromatikiw ka denbaya kɔnɔ.

PPA bɛ dɔn a ka nafolo danmadɔw fɛ, i n’a fɔ:

kemikɛli kɛcogo ani a jɔcogo .

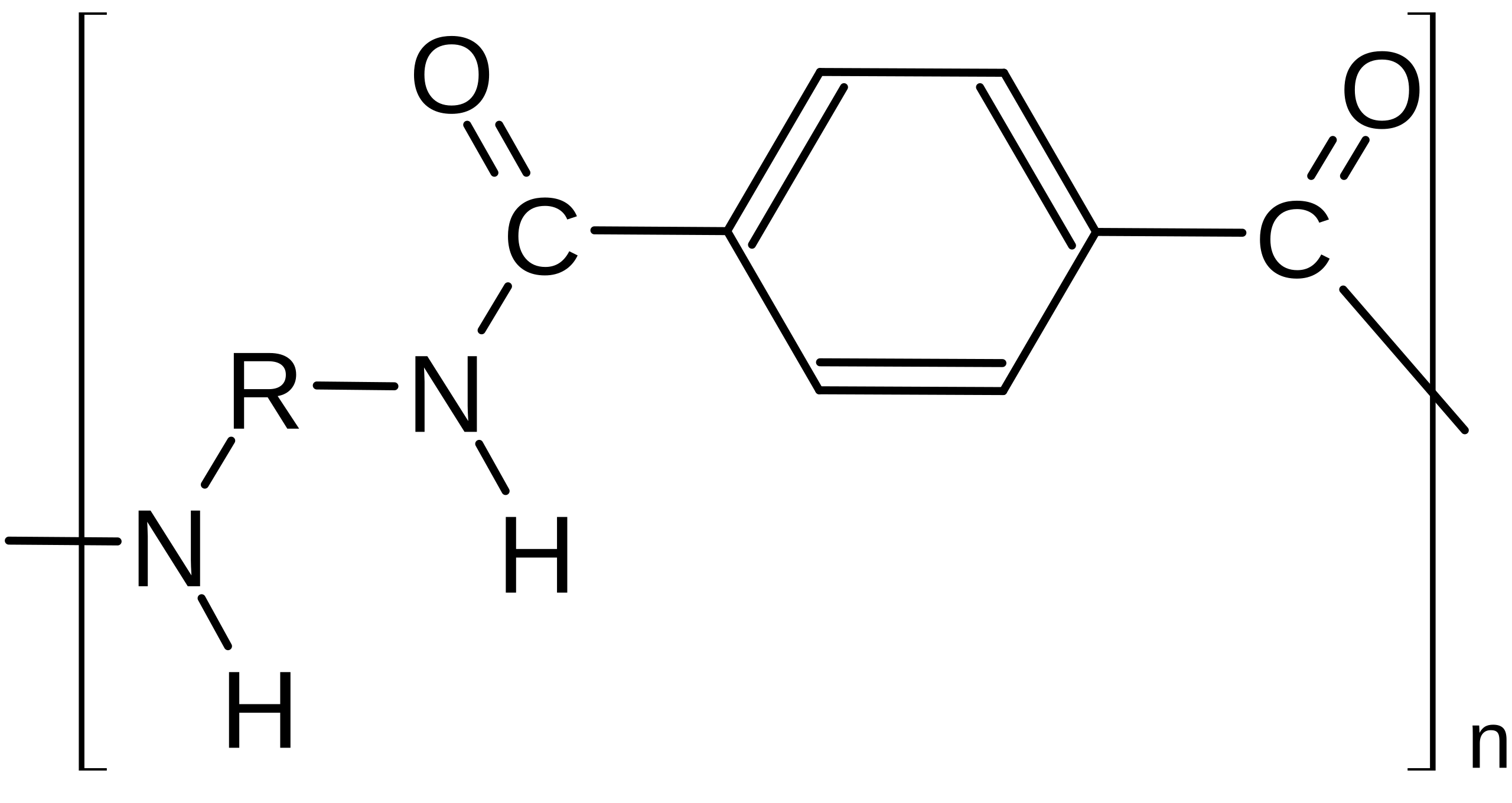

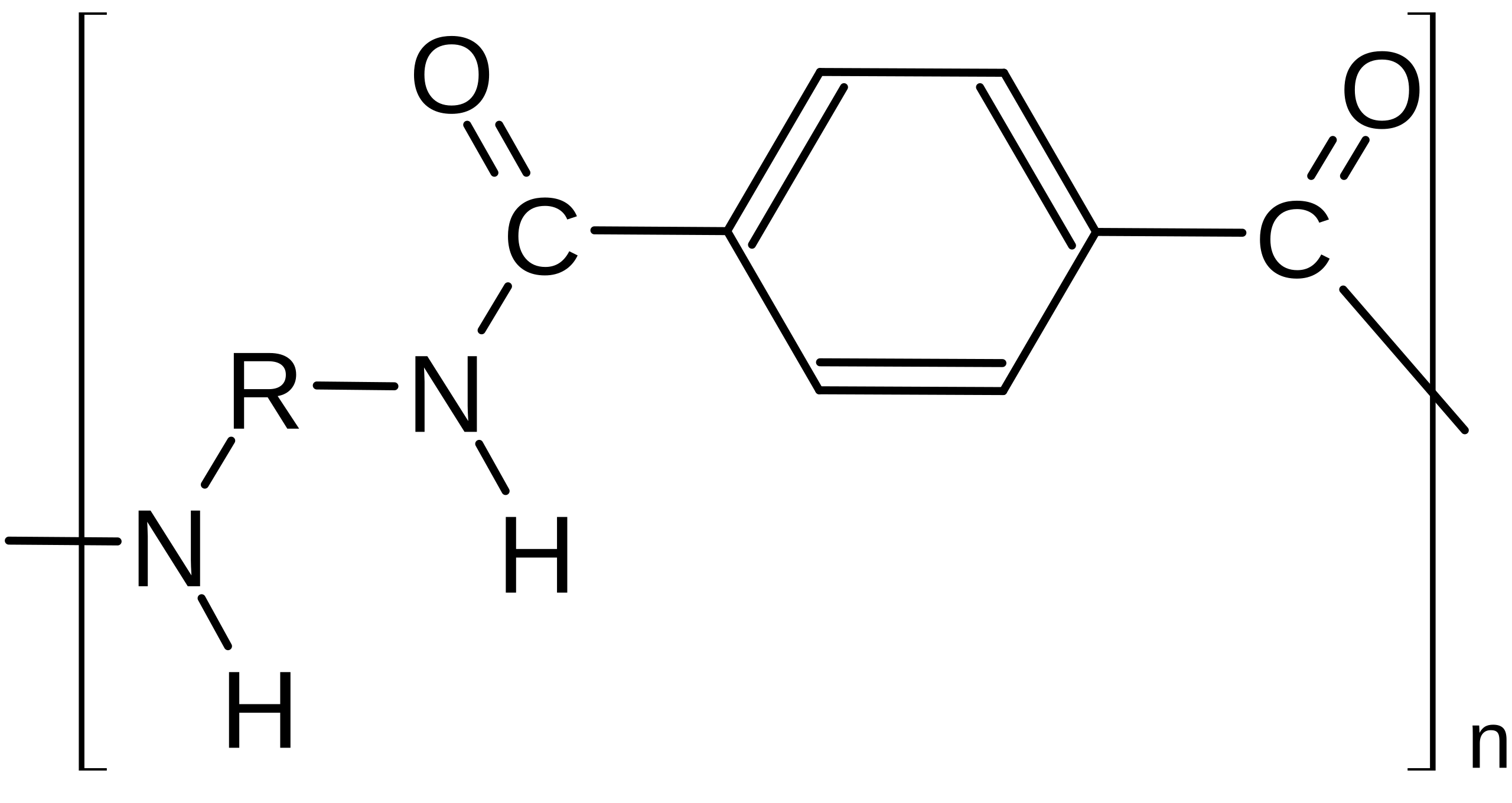

PPA ka kemikaliya cogoya ye aromatiki bololanɛgɛw ni amide kuluw ye. O kuluw bɛ ɲɔgɔn falen-falen ni alifati kuluw ye ani asidi Benzenedikaribɔkisiliki kuluw ye.

PPA ka CAS nimɔrɔ, n’o ye taamasiyɛn ye min ɲɔgɔn tɛ, o ye 27135-32-6 ye ..

PPA ka

| nafolo nafa | . |

| Point de melting . | Sanfɛla (>150°C) . |

| Glass transition température . | Sanfɛla (>150°C) . |

| Sumaya tiɲɛni funteni . | >280°C |

| Tensile fanga . | Jamanjan |

| gɛlɛya . | Jamanjan |

| notched impact fanga . | A ka bon ni plastiki ye min bɛ se ka suma ni ɲɔgɔn ye . |

| Coefficient de friction . | Fɛ́gɛn |

| Coefficient de coefficient de abrasion . | Fɛ́gɛn |

| Tendency creep . | Fɛ́gɛn |

| ji minɛcogo . | A ka dɔgɔn kosɛbɛ (0,1-0,3%) . |

| kemikɛli resistance . | A ka bon kosɛbɛ, hali ka se kemikɛli juguw ma . |

| resistance thermal . | Jamanjan |

| Kuran ka rezisti . | Jamanjan |

| resistance ka sɛgɛn . | Jamanjan |

| Surface resistance . | Kosɛbɛ sanfɛ . |

| Volume resistance . | Kosɛbɛ sanfɛ . |

| Tracking resistance . | Sanfɛ, a man gɛlɛn ni ji hakɛ ye . |

| Sɛgɛn resistance . | Ɲuman ɲuman |

| Dimensions sabatili . | A ka ɲi kosɛbɛ, a ka dɔgɔ . |

| Kristalini . | A bɛ kɛ sababu ye ka kemikɛli kunbɛn ani ka kɛ ni masinw ye cogo ɲuman na . |

| Corrosion resistance . | Ɲuman ɲuman |

| nɔrɔli Elastomers la . | Direct, sans ne mago bɛ bonding agents la . |

| Flammability . | Ba inherently flame retardant . |

| baarakɛ funteni . | A ka bon (ka se 350°C ma) |

A bɛ tali kɛ ɛntɛrinɛti plastiki wɛrɛw la .

Polifitalamidi (PPA) bɛ bɔ kɛnɛ kan ɛntɛrinɛti plastikiw cɛma k’a sababu kɛ a ka balansi kabakoma ye masin, funteni ani kemikɛli cogoyaw la. Nin ye PPA bɛ tali kɛ cogo min na ni ɛntɛrinɛti plastiki wɛrɛw ye minnu bɛ kɛ ka caya.

PPA ni Nylon ka 6/6.

Ni an y’a suma ni Nilon 6/6 ye, PPA bɛ fanga ni gɛlɛya fisaman di, o b’a to a bɛnnen don kosɛbɛ baarakɛcogo ɲumanw na. Ka fara o kan, PPA ka funteni bɛ se ka caya kosɛbɛ, o b’a to a bɛ se ka sigicogo dafalen mara funteni kɔrɔtalenw na, nilon 6/6 bɛna nɔgɔya walima ka tiɲɛ yɔrɔ minnu na.

| Propriété | PPA | Nilon 6/6 Bamako, Mali. |

| Barika | sanfɛ . | Ka lajigin |

| gɛlɛya . | A sanfɛ | A ka dɔgɔn ka gɛlɛya . |

| Sumaya kɛlɛli . | sanfɛ (ka se 280°C ma) | A bɛ se ka kɛ (ka se ~180°C ma) . |

PPA ni PA46 ye .

Ni a bɛ tali kɛ PA46 la, PPA bɛ funteni sabatili jira ka tɛmɛ. O bɛ PPA kɛ sugandili ɲuman ye baarakɛcogo la min bɛ kɛ ni funteni caman sɔrɔli ye waati jan kɔnɔ. Nka, PPA ni PA46 fila bɛɛ bɛ kemikɛli kunbɛncogo kelenw di, o b’a to u bɛ se ka baara kɛ ka ɲɛ sigidaw la minnu bɛ kɛ ni kemikɛli ye.

| Propriété | PPA | PA46 . |

| Sumaya min bɛ kɛ ni funteni ye . | sanfɛ . | Jamanjan |

| kemikɛli resistance . | Ɲɔgɔn | Ɲɔgɔn |

PPA ni PA6 ye ɲɔgɔn sɔrɔ.

PPA bɛ tɛmɛ PA6 kan masinko siratigɛ la, a bɛ fanga caman di, ka gɛlɛya, ani ka muɲu. Nka, PPA bɛ baarakɛ funteni caman de wajibiya, o bɛ se ka dɔ fara a dilanni gɛlɛya n’a musaka kan ni a bɛ tali kɛ PA6 la.

| Propriété | PPA | PA6 . |

| Mekaniki jogo . | A sanfɛ | Ka lajigin |

| baarakɛ funteni . | sanfɛ (~350°C) . | duguma (~260°C) . |

PPA ka fɛn caman b’a la .

Polifitalamidi (PPA) bɛ se ka labɛn walasa ka baara kɛcogo kɛrɛnkɛrɛnnenw ɲɛnabɔ ni fɛn caman b’a la. O ɲɛtaa ninnu b’a to a bɛ se ka kɛ fɛn ye min bɛ se ka kɛ fɛn caman ye.

Barikama ni filɛriw ye .

PPA bɛ se ka barika sɔrɔ ni gilasi walima minerali falenfɛnw ye walasa k’a ka masinw bonya. O fasaw bɛ gɛlɛya, fanga, ani sɛgɛn ni sɛgɛn kunbɛn kosɛbɛ. Baarakɛminɛn minnu bɛ nafa sɔrɔ o la, olu dɔw ye thermostat housings ani pompe wear rings ye, yɔrɔ minnu na a muɲuni ye key ye.

Impact modifiers .

Ni aw ye ɛlasɔmuw fara PPA kan, o bɛ dɔ fara a ka gɛlɛya kan, o b’a to a bɛ se ka kɛ sababu ye ka nɔ bila a la. Nin fɛn caman b’a la ka fɛn caman sɛmɛntiya mobili tiɲɛni yɔrɔw la, yɔrɔ min na lakana nafa ka bon kosɛbɛ. Elektroniki minɛnw so fana bɛ nafa sɔrɔ, bawo u ka kan ka kasaara ni sɛgɛnw muɲu.

Toughness (Gɛlɛya) min bɛ caya : o bɛ a to a bɛ se ka muɲu doni barikamaw kɔrɔ .

Aplikasi : Automotive Crash Parts, Electronic Housings .

Sumaya sabatilifɛnw .

Sumaya sabatilifɛnw bɛ fara a kan walasa PPA ka se ka funteni caman sɔrɔ waati jan kɔnɔ, k’a sɔrɔ a ma tiɲɛ. Nin fɛn caman b’a la ka fɛn caman sɛmɛntiya mobili ni izini yɔrɔw la minnu bɛ baara kɛ sigida funtenimaw na, i n’a fɔ mobili yɔrɔw walima masinw minnu bɛ sɔrɔ u jukɔrɔ izini baarakɛcogo la.

Flame retardants .

Flame Retardants nafa ka bon kosɛbɛ baarakɛyɔrɔw la, tasuma lakanani ye ɲɛtaa kunba ye yɔrɔ minnu na. O farankanw b’a to PPA fɛnw bɛ lakana sariya gɛlɛnw labato, k’u kɛ fɛn bɛnnenw ye ɛntɛrinɛti, mobili ani jɔli minɛnw na.

Tasuma lakanani ɲɛnabɔlen : Dan bɛ jenini ni sisi bɔli la .

Aplikasi : Elektroniki, Mobili yɔrɔw, So jɔli minɛnw .

PPA faralen ɲɔgɔn kan ni plastiki wɛrɛw ye .

PPA bɛ se ka fara ɲɔgɔn kan ni plastiki wɛrɛw ye walasa k’a jogo ɲɛ. O bɛ a ka baarakɛcogo caman bonya.

PPA faralen ɲɔgɔn kan ni polifenilɛni sulfure (PP) ye .

Ni PPA ni polifenilɛni sulfide (PPS) farala ɲɔgɔn kan, o nɔ ye fɛn ye min fanga ka bon ani min ka gɛlɛn. Nin ɲagami in fana bɛ kemikɛli ni funteni kunbɛncogo ɲuman di, o b’a to a dafalen don sigida gɛlɛnw na, yɔrɔ minnu na muɲuli nafa ka bon.

PPA min bɛ fara ɲɔgɔn kan ni nilon ye .

PPA ni nilon ɲagamini bɛ gɛlɛya bonya ani ka nɔ bila a la ka sɔrɔ ka dimension stabilité ɲuman mara. Nin faralen ɲɔgɔn kan, o ka ɲi kosɛbɛ baarakɛminɛnw na minnu ka kan ka balansi ni baarakɛcogo nɔgɔya.

Toughness and Impact resistance : dɔ bɛ fara a muɲuni kan sigidaw la minnu ka gɛlɛn kosɛbɛ .

Dimension Stabilité : A bɛ cogoya ni baara kɛcogo mara baara kɛtuma na .

Processability : A dilanni n’a dilanni ka nɔgɔn, o b’a to a bɛ se ka kɛ fɛn caman ye .

PPA faralen ɲɔgɔn kan ni poliyetilɛni terefitaliti ye (PET) .

Ni PPA farala ɲɔgɔn kan ni poliyetilɛni terefitalati (PET) ye, o ɲagaminen bɛ funteni kunbɛncogo ɲuman, masin fanga, ani hakɛ sabatili ɲuman fara ɲɔgɔn kan. Ka fara o kan, a bɛ kemikoro fanga di kosɛbɛ, o b’a to a ka ɲi kosɛbɛ baara kɛtaw la minnu bɛ se ka muɲu ani ka kɛ tiɲɛ ye.

Funteni kunbɛncogo : A bɛ funteni caman muɲu k’a sɔrɔ a ma tiɲɛni kɛ .

Mekaniki fanga : A barika ka bon ani a bɛ mɛn, a bɛnnen don fɛnw jɔcogo ma .

Dimension Stabilité et resistance chimique : Dannaya bɛ sɔrɔ sigidaw la minnu bɛ kɛ ni kemikɛli ye .

PPA baarakɛcogo .

Polifitalamidi (PPA) bɛ tɛmɛ izini suguya caman kan k’a sababu kɛ a ka funteni, a ka masina ani a ka kemikaliya ye.

Mobili industrie .

PPA bɛ baara kɛ kosɛbɛ mobili seko ni dɔnko siratigɛ la, kɛrɛnkɛrɛnnenya la, sigida minnu bɛ funteni caman na ani minnu bɛ kɛ ni kemikɛli ye.

Fuel Line Connectors : PPA ka funteni kunbɛncogo ani a ka kemikaliya sabatili b’a to a ka ɲi kosɛbɛ fɛnɲɛnamafagalanw dilancogo la.

thermostat housings : A bɛ masinw ka dafalenya mara hali ni funteni kɔrɔtalen don, o bɛ motɛri nɛnɛ dannamɔgɔ sabati.

Fiɲɛ nɛnɛma pɔnpew : PPA ka muɲuli n’a ka baarakɛcogo b’a to a bɛ se ka baara kɛ cogoya caman na.

| Mobili ka baarakɛcogo | nafa . |

| Connecteurs de ligne de terre . | Funteni ni kemikɛli ka se ka kɛ . |

| thermostat so . | A bɛ sigicogo mara temps sanfɛtaw la . |

| Fiɲɛ nɛnɛma pɔnpew . | A bɛ mɛn cogo gɛlɛnw na . |

Elektroniki baarakɛyɔrɔ .

PPA ka funteni ni kuran cogoyaw b’a kɛ fɛn dafalen ye ɛntɛrinɛti yɔrɔw la minnu bɛ se ka muɲu kosɛbɛ.

LED Mounts : A bɛ funteni min bɛ sɔrɔ LEDw fɛ, o ɲɛnabɔ ka sɔrɔ ka jɔli dɛmɛ barikama di.

Fila ni kabɛl lakanani : PPA bɛ insulasi ni lakana di sigida koɲɛw ma, ka dannaya kuntaalajan sabati.

Connecteurs : A bɛ to dannaya la sigidaw la, minnu nafa ka bon kosɛbɛ ɛntɛrinɛti minɛnw na.

| Elektroniki baarakɛcogo | nafa . |

| LED mounts . | A ka fisa ni thermal management ye . |

| Fila ni kabali lakanani . | Insulasi ni sigida lakanani . |

| Connecteurs . | sabatili bɛ kɛ cogo la min bɛ kɛ ni waati caman ye . |

Industriw ka baarakɛminɛnw .

Industriw sigidaw la, PPA bɛ yeelen bɔ n’a sɛgɛnbaliya ye ani a sabatili cogoya gɛlɛnw na.

Pompi sɛgɛnw : A ka sɔgɔsɔgɔninjɛ kunbɛncogo ani a bonya sabatili bɛ a to a ka baara kɛ ka ɲɛ waati kɔnɔ.

Mekaniki yɔrɔw : birikiw, girinw, ani busi minnu dilannen don ni PPA ye, olu bɛ masin fanga caman di ani ka sɛgɛn.

Yɔrɔ minnu bɛ se ka kɛ ni kemikɛli ye : PPA ka kemikaliya bɛ se ka kɛ sababu ye ka sigida gɛlɛnw sɔrɔ i n’a fɔ kemikɛlifɛnw.

| Industrie application | nafa . |

| Pompe wear rings . | Abrasion resistance, sabatili . |

| Mekaniki yɔrɔw . | Fanga ni sɛgɛnbaliya . |

| Yɔrɔ minnu bɛ se ka kɛ ni kemikɛli ye . | A bɛ se ka kɛ sababu ye ka kemikɛli gɛlɛya . |

Consumer Goods .

PPA fana bɛ sɔrɔ don o don fɛnw na, a bɛ muɲu ani ka baara kɛ.

Denso ni kunsigiw bɛ kɛ : PPA ka muɲuli ni a ka se ka furakɛli kɛ, o bɛ kɛ sababu ye ka baara kɛ ka mɛn mɔgɔ yɛrɛ ladonni furaw la.

Minɛnw yɔrɔw : A bɛ kɛ yɔrɔw la minnu bɛ se ka funteni sɔrɔ minɛnw ni forow la, ka fɛnw janya bonya.

Mɔgɔ yɛrɛ ladonni fɛnw : razɔri bɛ nafa sɔrɔ PPA ka muɲuli ni a ka ɲɛnajɛko la.

| Consumer Goods Application | Benefit . |

| Denw ka ɲinw/kungoriw bɛ kɛ ka fɛnw kɛ . | resistance chimique, durabilité . |

| Minɛnw yɔrɔw . | Sumaya kɛlɛli du kɔnɔfɛnw kama . |

| Mɔgɔ yɛrɛ ladonni fɛnw . | Fanga ni ɲɛnajɛko lawulili . |

Baarakɛcogo fɛɛrɛw .

PPA baarakɛcogo bɛ fɛɛrɛ kɛrɛnkɛrɛnnenw de wajibiya. A ka nafolo kɛrɛnkɛrɛnnenw bɛ ɲini ka baara kɛ koɲuman.

Pikirili Molidali .

Pikiriw dilanni ye PPA baarakɛcogo fɔlɔ ye. O fɛn in ka wuliyɔrɔ ka bon, o bɛ a wajibiya ka funteni caman sɔrɔ.

PPA ka baarakɛcogo funteni bɛ se ka se 350°C ma (662°F). O funteni caman bɛ a to a bɛ se ka wuli ka ɲɛ ani ka mɔli fa.

Nka, PPA ka sɔgɔsɔgɔninjɛ ka bon kosɛbɛ, o bɛ gɛlɛyaw jira. A bɛ se ka kɛ sababu ye ka mɔni fa gɛlɛya.

Baarakɛcogo paramɛtɛrɛw kɔlɔsili ɲuman nafa ka bon. Funteni, tansiyɔn ani pikiri teliya ka kan ka ɲɛ.

| Paramɛtiri | nafa danma . |

| Aw bɛ funteni wuli . | 330-350°C . |

| Mold température . | 140-180°C . |

| Pikiri tansiyɔn . | 100-150 MPa . |

| Pikiri teliya . | Ka bɛrɛbɛn |

Minɛn kɛrɛnkɛrɛnnenw bɛ se ka kɛ wajibi ye. A ka ca a la, a ka ca a la, a ka kan ka kɛ ko a ka kan ka kɛ ko a bɛ se ka kɛ ko a bɛ se ka kɛ.

masinw ni surface finishing .

PPA bɛ se ka kɛ masin ye ni fɛɛrɛw ye minnu bɛ kɛ ka kɛɲɛ ni sariya ye. Nka, a fanga ka bon ani a ka funteni kunbɛn.

Baarakɛminɛnw ka kan ka funteni caman muɲu minnu bɛ sɔrɔ masinw dilanni waati la. Karɔti baarakɛminɛnw bɛ kɛ ka caya u ka muɲuli kama.

Nɛnɛ kɛcogo ɲumanw nafa ka bon kosɛbɛ. U bɛ sumaya kojugu bali ani ka baarakɛminɛnw ɲɛnamaya mara.

| Masini baara | minnu bɛ kɛ ni baarakɛminɛnw ye . |

| Turning . | Carbide inserts . |

| Milling . | Carbide End Mills . |

| Drilling . | Carbide Drills . |

A ka c’a la, fɛnɲɛnamafagalanw bɛ baara kɛ ni fɛnɲɛnamafagalanw ye. U bɛ dɛmɛ don ka surface finiw ni jogo ɲumanw sɔrɔ.

Polishing bɛ se ka surface smoothness ɲɛ. A bɛ dɔ Fàra aesthetic appeal kan.

Annealing bɛ kɔnɔna degunw lajɔ. A bɛ dimension stabilité (hakɛ sabatili) ɲɛ.

Abrasive blasting bɛ se ka finiw dilan minnu bɛ kɛ ka ɲɛ walima minnu bɛ kɛ ni sɛbɛnni ye. A bɛ dilancogo sɛgɛsɛgɛli kɛ.

Lajɛ fɛɛrɛw .

PPA yɔrɔw bɛ se ka lajɛ ni fɛɛrɛ suguya caman ye. Sugandili bɛ bɔ baarakɛcogo ni dilancogo wajibiyalenw na.

Welding ye fɛɛrɛ ye min bɛ kɛ ka PPA yɔrɔw fara ɲɔgɔn kan. Ultrasonic ni laser welding bɛ kɛ ka caya.

Screwing ani riveting fana ye sugandiliw ye minnu bɛ se ka kɛ. U bɛ ɲɔgɔndan barikamaw di, minnu bɛ kɛ ni masin ye.

Lajɛ kɛcogo wɛrɛw ye snap-fitting ani adhesive bonding ye. U bɛ dilancogo sɛgɛsɛgɛli ni nɔgɔya di.

| Assemblée fɛɛrɛ | nafaw . |

| Welding . | Joli barikamaw, banbaliw . |

| Screwing . | Jɛɲɔgɔnya min bɛ bɔ, min bɛ se ka bɔ, o bɛ se ka bɔ . |

| riveting . | Simple, barikama masinw sirili . |

| Snap-fitting . | A lajɛ teliya la, nɔgɔya la . |

| Bonding adhesive . | versatile, a bɛ fara ɲɔgɔn kan minnu tɛ kelen ye . |

Lajɛ kɛcogo sugandili bɛ bɔ fɛn suguya caman na. Fɛn minnu bɛ bɛn ɲɔgɔn ma, fanga wajibiyalenw, ani fɛn dilanni nafama, olu ye jateminɛ jɔnjɔnw ye.

Dilan jateminɛw PPA yɔrɔw kan .

Ni aw ye PPA dilan ni PPA ye, o bɛ jateminɛ kɛ kosɛbɛ. Fɛn suguya caman bɛ nɔ bila PPA yɔrɔw ka baarakɛcogo n’u dilanni na.

structurel design optimisation .

A jɔcogo ɲuman nafa ka bon kosɛbɛ PPA yɔrɔw la. A bɛ baara kɛcogo ɲuman ni a ɲɛnamaya kɛcogo ɲuman sabati.

A ka kan ka kɛ fɛn ye min bɛ kɛ ka fɛnw janya, o ka kan ka kɛ dɔɔni dɔɔni. Yɛlɛma barikamaw bɛ se ka kɛ sababu ye ka degunw caya.

Ribbing ni boss design bɛ se ka gɛlɛya ni fanga bonya. U ka kan ka bonya ani ka u bila.

Shrinkage ni warpage ka kan ka kunbɛn. Siginidenw ni u bonya suguya wɛrɛw bɛ se ka kɛ ka dilancogo ladilanni kɛrɛnkɛrɛnnenw de wajibiya.

Draft angles ani radius transitions bɛ nɔgɔya ka tiɲɛni kɛ. U ka kan ka dafa yɔrɔ jateminɛ na.

| Design Element | Recommendation . |

| ƝƐFƆLI ƝƐFƆLIW . | dɔɔnindɔɔnin, aw kana fɛn caman Changements sur les changements . |

| Ribbing ani patɔrɔnw . | A hakɛ bɛnnen don ani a bɛ bila . |

| Shrinkage ani Warpage . | Kɔlɔsili kɛ cogoya ni bonya suguya wɛrɛw kama . |

| Angles de draft . | A bɛnnen don ka demolding nɔgɔya . |

| Radius transitions . | A bɛ se ka kɛ part geometry ye . |

Funteni ɲɛnabɔli ani funteni bɔli .

PPA yɔrɔw bɛ se ka funteni sɔrɔ walima ka u bila funteni na. Funteni maracogo ɲuman nafa ka bon.

Nɛnɛ siraw bɛ se ka funteni jɛnsɛn. U ka kan ka bila siratigɛ la.

Sumaya bonya ka kan ka jateminɛ. A bɛ se ka nɔ bila a yɔrɔ hakɛw la ani a ka bɛn.

Material Selection ani farankanw .

PPA kalasi ni farankanw sugandili nafa ka bon kosɛbɛ. A bɛ bɔ baarakɛcogo kɛrɛnkɛrɛnnenw na.

Barika minnu bɛ kɛ i n’a fɔ gilasi fiyɛw walima minɛnw bɛ se ka nafaw bonya. U bɛ fanga, gɛlɛya ani hakɛ sabatili ɲɛ.

Fɛn minnu bɛ fara a kan, olu bɛ se ka jogo kɛrɛnkɛrɛnnenw di. Tumu, UV sabatili, ani tasuma kunbɛnni ye misaliw ye minnu bɛ sɔrɔ tuma caman na.

| farankan | nafolo yiriwali . |

| tulumafɛnw . | Flow ni moule bɔli ɲɛnabɔlen . |

| UV stabilisateurs . | UV tiɲɛni kɛlɛli . |

| Flame retardants . | A ka tasuma bɛ se ka kɛ . |

Dimensions sabatili ni ji minɛcogo .

PPA ka ji minɛcogo ka dɔgɔn. Nka, dilancogo min bɛ kɛ ka ji hakɛ dɔgɔya, o nafa ka bon hali bi.

Datugulan ɲuman ni a lakanani bɛ se ka dɔ bɔ ji la ka taa a fɛ. U bɛ dɛmɛ don ka dimension stabilité mara.

dilan ni baarakɛcogo jateminɛw .

Designing for manufacturability ye fɛnba ye. A bɛ kɛ sababu ye ka fɛn dilanni kɛ ka ɲɛ ani ka musaka bɔ.

Draft angles ani fillets bɛ nɔgɔya ka molding ani ka ci. U ka kan ka don dilancogo la.

Baarakɛminɛnw dilanni ka kan ka kɛ PPA ka baarakɛ funteni caman ye. Nɛnɛ ni fiɲɛbɔlan bɛnnen don.

masinw ni surface finishing techniques .

PPA yɔrɔw bɛ se ka kɛ ni masinw ni surface fini ye. Fɛɛrɛw sugandili bɛ bɔ kɔlɔlɔ ɲininen na.

Masina paramɛtɛrɛw ka kan ka ɲɛnabɔ PPA kama. Baarakɛminɛnw sugandili ɲuman ni u nɛnɛni nafa ka bon kosɛbɛ.

Surface finishing techniques i n’a fɔ polishing walima abrasive blasting bɛ se ka aesthetics (ɲɛnajɛ) bonya. U bɛ se ka baarakɛcogo ɲumanw fana ɲɛ.

Ni aw ye PPA dilan ni PPA ye, o bɛ taabolo bɛɛjɛfanga de wajibiya. Jatebɔcogo dafalen, funteni marali, fɛnw sugandili, ani u dilanni nafa bɛɛ nafa ka bon.

Kuncɛli

Kuncɛli la, PPA plastiki bɛ bɔ kɛnɛ kan a ka funteni, a ka masina ani a ka kemikaliya cogoyaw la. A ka funteni ka bon kosɛbɛ ani a fanga b’a to a ka ɲi kosɛbɛ baarakɛcogo caman na. PPA ka fɛn caman kɛli bɛ yeelen bɔ iziniw kɔnɔ i n’a fɔ mobili, ɛntɛrinɛti, izini, ani fɛnw feereli fɛnw. A ka se ka baara kɛ cogo gɛlɛnw na, o b’a to a bɛ se ka da a kan fɛn caman bɛ se ka da min kan.

Ladilikanw: A bɛ se ka kɛ ko aw bɛ a fɛ ka a bɛɛ kɛ plastiki ye .