Poliyamidi, n’a bɛ fɔ a ma ko nilon, o bɛ yɔrɔ bɛɛ. K’a ta mobili yɔrɔw la ka taa a bila fɛnw na minnu bɛ kɛ ka fɛnw feere, a nafa tɛ ban. A sɔrɔla Wallace Carothers fɛ, Nilon ye fɛn caman sɛmɛntiya fɛnw dɔnniya la. Mun na a bɛ kɛ ka caya ten? A ka sɛgɛnbaliya bɛ mɔgɔ kabakoya, a jɔcogo ka nɔgɔn, ani a ka funteni sabatili ka bon, o b’a to a ka ɲi kosɛbɛ izini suguya caman ma.

Nin sɛbɛn in kɔnɔ, i bɛna u suguya caman dɔn, u ka nafolo kabakomaw, ani u ka baarakɛcogo caman. Aw ye a dɔn mun na PA plastikiw bɛ ka taa a fɛ ka kɛ tulonkɛfɛn ye bi fɛn dilanni na.

Poliyamidi (PA) plastiki ye mun ye?

Poliyamidi (PA) plastiki, n’a bɛ fɔ a ma tuma caman ko nilon, o ye sɛnɛfɛnw sɛnɛcogo ye min bɛ se ka kɛ fɛn caman ye. A bɛ dɔn a ka fanga danma, a ka muɲuli, ani a ka se ka sɛgɛn ni kemikaliw kɛlɛ. Walasa ka danfara minnu bɛ poliyamidi ni nilon cɛ, olu faamuya, aw bɛ se ka an ka barokun lajɛ . Danfara min bɛ poliyamidi ni nilon cɛ ..

kemikɛli kɛcogo ani a jɔcogo .

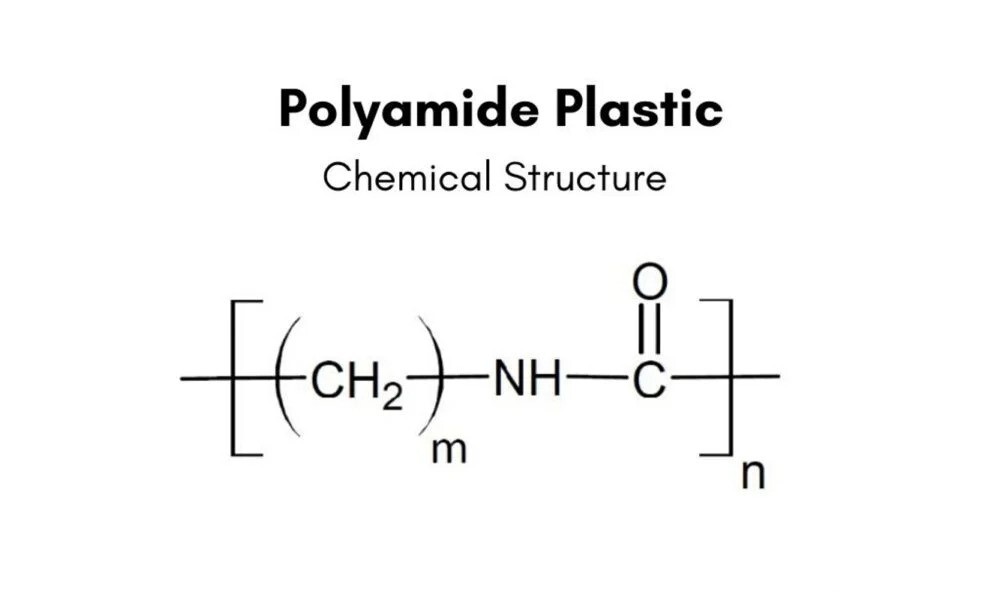

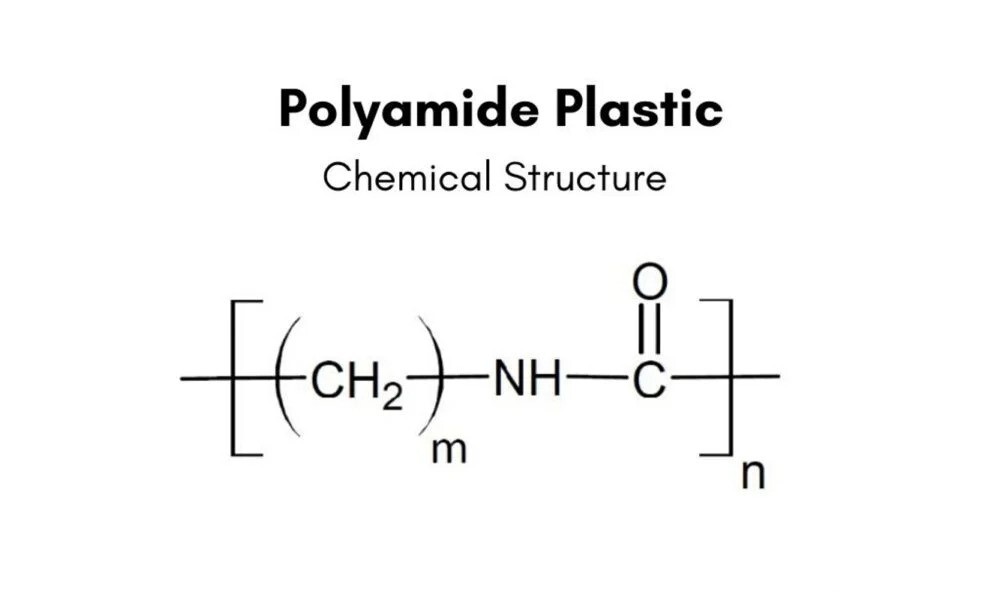

PA plastikiw bɛ dɔn ni amide (-conh-) jɛɲɔgɔnyaw ye u ka molekiyɔmu jɔcogo la. O jɛɲɔgɔnyaw bɛ idɔrɔzi jɛɲɔgɔnya barikamaw Kɛ polimɛri cakɛdaw ni ɲɔgɔn cɛ, k’a ka jogo kɛrɛnkɛrɛnnenw Di PA ma.

Poliyamidi dɔ jɔcogo jɔnjɔn bɛ i n’a fɔ nin:

-[NH-Co-R-NH-Co-R'-]-

Yan, r ni r' bɛ fɛnɲɛnamafagalan suguya caman jira, minnu bɛ PA suguya kɛrɛnkɛrɛnnen latigɛ.

Monomɛri minnu bɛ kɛ PA bɔli la .

PA plastikiw bɛ dilan ni monomɛri suguya wɛrɛw ye. Minnu ka ca ni tɔw bɛɛ ye, olu dɔw ye:

Caprolactam: A bɛ kɛ ka PA 6 dilan .

Asidi hexamethylenediamine ni adipiki: A bɛ kɛ PA 66 la .

Asidi 11-aminoundecanoïque: A bɛ kɛ PA 11 sɔrɔli la .

Laurolactam: A bɛ kɛ ka PA 12 dilan .

PA Numɛri kɛcogo faamuyali .

Yala i delila k’i yɛrɛ ɲininka o jatew kɔrɔ ye mun ye PA suguyaw la wa? An k'a tiɲɛ:

Jateden kelen (misali la, PA 6): A bɛ karɔbɔli atomu hakɛ jira monomɛri kɔnɔ .

Double number (misali la, PA 66): A bɛ karɔbɔli atomu jira monomɛri fila kelen-kelen bɛɛ la minnu bɛ kɛ .

Poliyamidi (PA) Plastiki ka baarakɛcogo fɛɛrɛw .

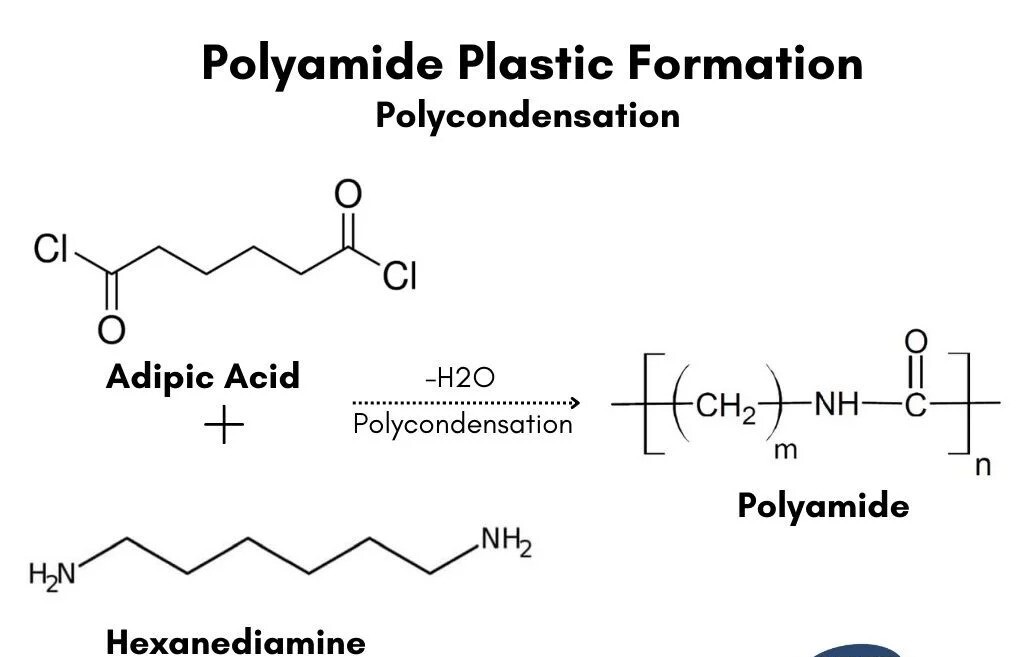

Poliyamidi (PA) plastikiw, walima nilonw, bɛ sɔrɔ polimeri kɛcogo wɛrɛw fɛ, u kelen-kelen bɛɛ bɛ nɔ bila u ka jogo n’u ka baarakɛcogo la. Fɛɛrɛ fila minnu bɛ kɛ tuma caman na, olu ye polimerizasiyɔn kondensasiyɔn ni ring-opening polimerizasiyɔn ye. An ka nin wale ninnu bɛ baara kɛ cogo min na, an k’o sɛgɛsɛgɛ.

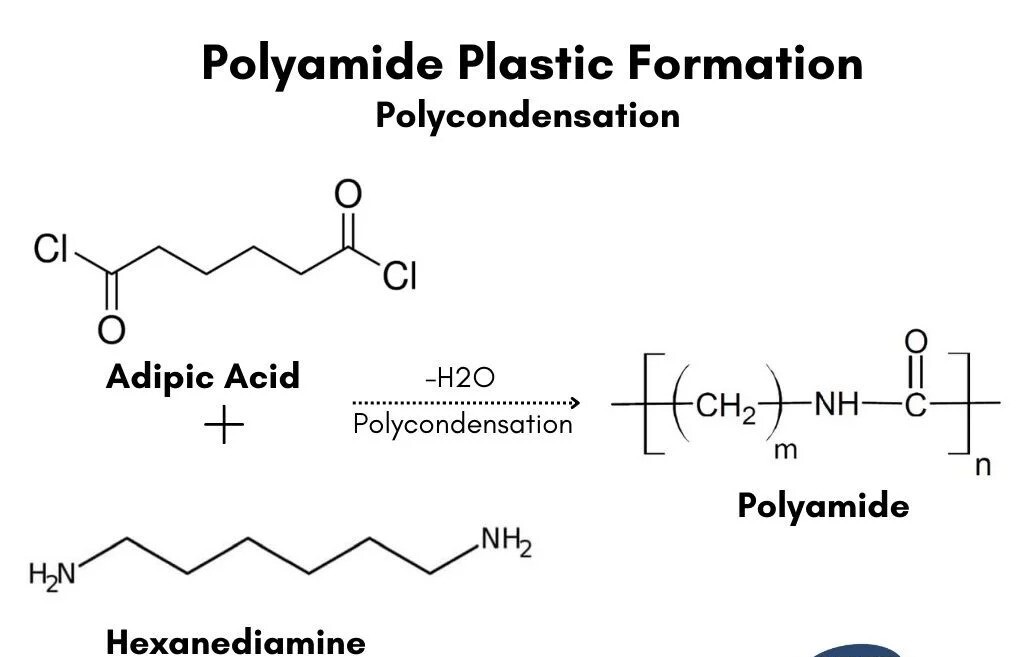

Polimerizasiyɔn kondensasiyɔn .

Nin fɛɛrɛ in bɛ i n’a fɔ kemikɛli dɔnkili jɛɲɔgɔn fila ni ɲɔgɔn cɛ: diacids ani diamines. U bɛ jaabi di cogoya kɛrɛnkɛrɛnnenw na, ka ji bɔnɛ o kɛcogo la. O kɔlɔlɔ ye? Cakɛda janw nilon polimɛriw.

A bɛ baara kɛ cogo min na, o filɛ nin ye:

Diacides ni diamines bɛ ɲagami yɔrɔw la minnu bɛ bɛn ɲɔgɔn ma.

Funteni bɛ kɛ, o bɛ kɛ sababu ye ka farikoloɲɛnajɛ kɛ.

Ji mɔlikuluw bɛ bɔ (jidɛsɛ).

Polimɛri cakɛdaw bɛ dilan ani ka bonya ka mɛn.

O waleyali bɛ taa ɲɛ fo cakɛda janya ɲininen ka se.

Nin fɛɛrɛ in misali ɲuman ye PA 66 sɔrɔli ye.A bɛ dilan ni hexamethylenediamine ni adipic acid faralen ye ɲɔgɔn kan.

Nafa jɔnjɔn minnu bɛ sɔrɔ polimerizasiyɔn kondensasiyɔn na:

Polimɛri min bɛ daminɛ ni bolo ye .

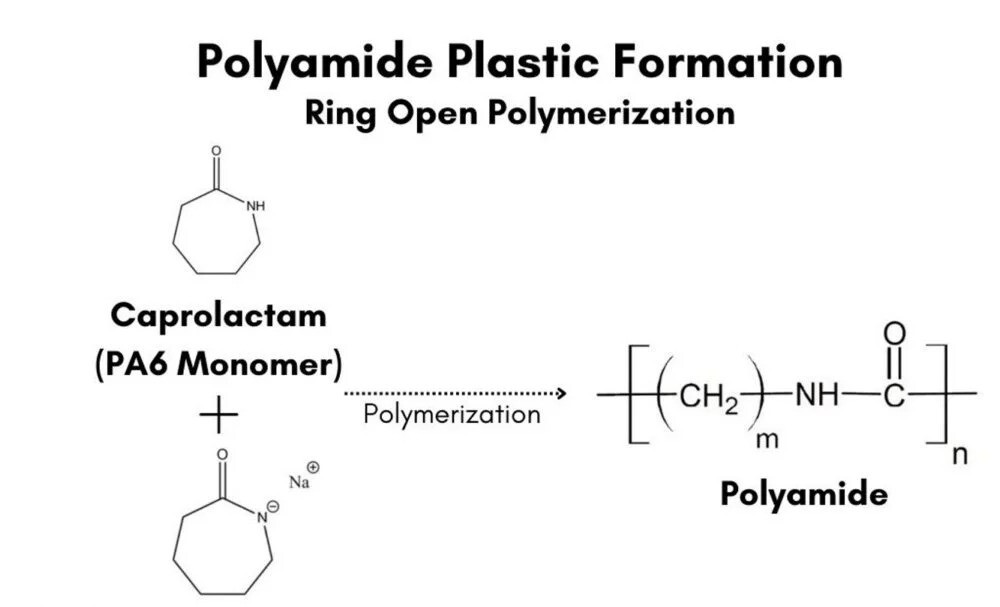

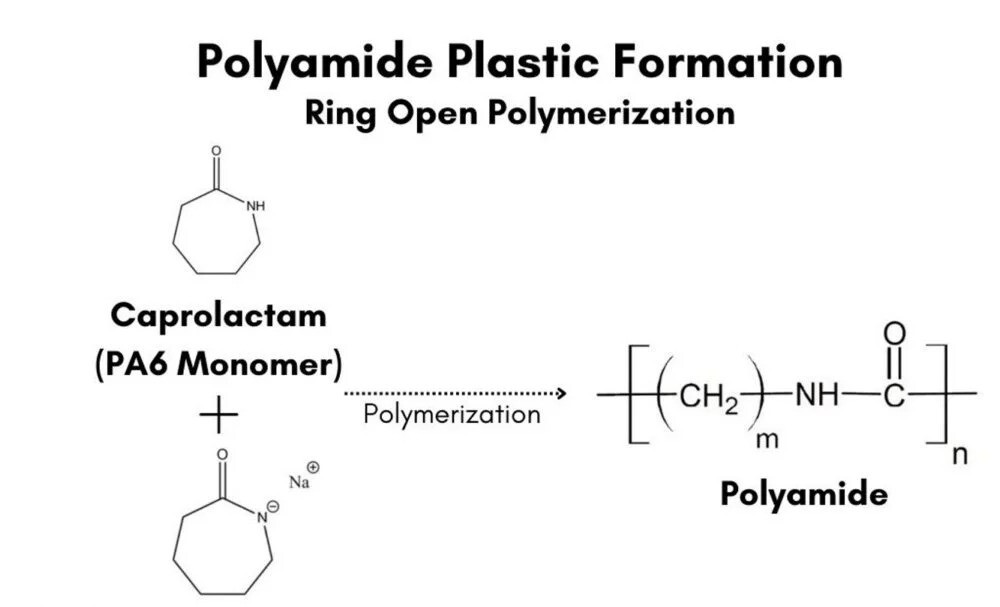

O fɛɛrɛ in bɛ i n’a fɔ ka molekiyɔmu sɛrɛkili dɔ zipi. A bɛ baara kɛ ni monomɛriw ye minnu bɛ se ka wuli, i n’a fɔ Caprolactam, walasa ka PA plastikiw dilan.

O kɛcogo bɛ tali kɛ:

Sumaya monomɛri sikliki (misali la, Caprolactam ka ɲɛsin PA 6 ma).

katalisita dɔ farali a kan walasa ka farikoloɲɛnajɛ teliya.

Kari ka ring structure da wuli.

bololanɛgɛ dafalenw sirili walasa ka polimɛri cakɛda janw dilan.

Polimerizasiyɔn min bɛ daminɛ ni ring ye, o nafa ka bon kosɛbɛ PA 6 ni PA 12 dabɔli la.

O fɛɛrɛ in nafa ye ninnu ye:

Fɛn laban saniyalen ka saniyaba .

Baara kɛcogo ɲuman ni fɛnɲɛnamafagalanw ye .

Se ka PA suguya kɛrɛnkɛrɛnnenw dilan .

O fɛɛrɛ fila bɛɛ fanga ɲɔgɔn tɛ u la. Sugandili bɛ bɔ PA suguya ɲininen na ani a kɛcogo laɲininen na.

Poliyamidi suguyaw (PA) Plastiki .

Poliyamidi (PA) plastiki bɛ sɔrɔ suguya caman na, u kelen-kelen bɛɛ bɛ jogo kɛrɛnkɛrɛnnenw di ka da u ka molekiyɔmuw cogoya kan. O suguya ninnu bɛ tila kɛrɛnkɛrɛnnenya la ka kɛ poliyamidi alifatikiw ye, minnu bɛ kɛ ni aromatiki ye, ani poliyamidi aromatikiw. An ka don suguya minnu na minnu ka ca kosɛbɛ.

Poliyamidi alifatikiw .

Olu de ye PA suguya ye min ka ca kosɛbɛ. U bɛ Dɔn u ka fɛn caman kɛcogo la ani u ka baarakɛcogo caman na.

PA 6 (Nylon 6) .

A dilannen don ni Caprolactam ye .

Toughness excellent ani abrasion resistance .

A bɛ kɛ ka caya finiko ni ɛntɛrinɛti plastikiw la .

PA 66 (Nylon 66) .

A bɛ sɔrɔ hexamethylenediamine ni asidi adipiki la .

A wulicogo ka bon ni PA 6 ye (255°C ni 223°C) .

A ka ɲi kosɛbɛ ka ɲɛsin funteni caman baarakɛcogo ma .

PA 11 (Nylon 11) .

PA 12 (Nylon 12) .

A dilannen don ni Laurolactam ye .

ji minɛcogo min ka dɔgɔn poliyamidiw cɛ .

A ka fisa ni dimensions (hakɛ) sabatili ye .

PA 6-10 (Nylon 6-10) .

A bɛ PA 6 ni PA 66 ka nafaw fara ɲɔgɔn kan .

ji minta dɔgɔyali ka tɛmɛ PA 6 walima PA 66 kan .

resistance chimique ɲuman .

PA 4-6 (Nylon 4-6) .

A ka ca a la, a bɛ se ka wuli poliyamidi alifatikiw cɛ (295°C) .

Sumaya ni masinko danfaralenw .

A ka ca a la, a bɛ kɛ ni baarakɛcogo caman ye .

Poliyamidi semi-aromatikiw (polyphthalamides, PPA) .

PPAw bɛ danfara min bɛ alifatiki ni poliyamidi aromatikiw cɛ, o cɛ. U bɛ nin fɛn ninnu di:

Funteni kunbɛncogo ɲɛnabɔlen .

Dimensions (hakɛ) sabatili ka fisa .

A bɛ se ka kɛ ko a bɛ se ka kɛ ko a bɛ se ka kɛ .

Poliyamidi aromatikiw (aramidiw) .

Nin poliyamidi minnu bɛ baara kɛ kosɛbɛ, olu bɛ waso:

fanga ni girinya hakɛ danfaralen .

Outstanding Heat Resistance .

Kimiya sabatili ɲumanba .

Aramidi minnu bɛ fɔ kosɛbɛ, olu ye Kevlar ani Nomex ye.

Nin ye fɛnw ye minnu bɛ se ka kɛ sababu ye ka fɛnw kɛ ɲɔgɔn na teliya la:

| PA suguya | sɔgɔli yɔrɔ (°C) | ji minɛcogo | kemikɛli resistance . |

| PA 6 . | 223 | Jamanjan | Duman |

| PA 66 . | 255 | Jamanjan | Duman |

| PA 11 . | 190 | Fɛ́gɛn | Ɲuman ɲuman |

| PA 12 . | 178 | A ka dɔgɔ kosɛbɛ . | Ɲuman ɲuman |

| PPA . | 310+ . | Fɛ́gɛn | A kaɲi kɔsɛbɛ |

| Aramidw . | 500+ . | A ka dɔgɔ kosɛbɛ . | Ɲuman ɲuman |

Poliyamidi (PA) ka

| jogo plastiki | alifatiki poliyamidi | semi-aromatiki poliyamidi | aromatikiw |

| Aw bɛ resistance don . | sanfɛ, kɛrɛnkɛrɛnnenya la PA 66 ani PA 6 la. | A ka bon ni alifatiki PAS ye. | A ka ɲi kosɛbɛ cogo juguw la. |

| Sumaya min bɛ kɛ ni funteni ye . | A ka ɲi, fo ka se 150°C ma (PA 66). | A ka fisa, a bɛ se 200°C ma. | A ka ca a la, a bɛ se ka kɛ 500°C ye. |

| Barika | Koɲuman, bɛ se ka bonya ni fasaw ye. | A ka bon ni alifatiki PAS ye. | A ka bon kosɛbɛ, a bɛ baara kɛ ni a ye baarakɛcogo caman na. |

| Toughness . | A ka ɲi kosɛbɛ, PA 11 ani PA 12 bɛ se ka wuli. | A ka ɲi, a ka gɛlɛn kosɛbɛ. | A ka dɔgɔ, fo ni a b’a sɛmɛntiya. |

| Impact fanga . | sanfɛ, kɛrɛnkɛrɛnnenya la PA 6 ani PA 11. | A ka ɲi, a ka dɔgɔn dɔɔni ka tɛmɛ alifatiki PAS kan. | A ka dɔgɔ, fo ni a b’a sɛmɛntiya. |

| Friction . | A ka dɔgɔ, a ka ɲi kosɛbɛ sliding applications. | A ka dɔgɔ kosɛbɛ, a ka ɲi kosɛbɛ sɛgɛn sigidaw la. | A ka dɔgɔ, a ka fisa ni degun ye. |

| kemikɛli resistance . | A ka ɲi, kɛrɛnkɛrɛnnenya la PA 11 ani PA 12 la. | A ka fisa ni Alifatiki PAS ye. | A ka ɲi kosɛbɛ, a bɛ se ka a kɛlɛ kosɛbɛ. |

| ji minɛcogo . | A ka ca PA 6/66 la, a ka dɔgɔn PA 11/12 la. | A ka dɔgɔn, a bɛ sabati nɛnɛ na. | A ka dɔgɔ kosɛbɛ, a bɛ se ka kɛlɛ kosɛbɛ. |

| Kuranko insulasi . | A ka ɲi kosɛbɛ, a bɛ baara kɛ kosɛbɛ. | A ka ɲi, a bɛ jigin dɔɔni. | A ka ɲi kosɛbɛ, a bɛ baara kɛ ni sigida ye min bɛ baara kɛ kosɛbɛ. |

| Mekaniki damping . | A ka ɲi, kɛrɛnkɛrɛnnenya la PA 6 ani PA 11. | A bɛ kɛ cogo dafalen na, a bɛnnen don baarakɛcogo ma. | Faantan, fo ni fɛn dɔ b’a la. |

| Sliding Properties . | A ka ɲi, kɛrɛnkɛrɛnnenya la PA 6 ani PA 66 la. | A ka ɲi kosɛbɛ, a ka ɲi kosɛbɛ fɛnw lamagacogo la. | exceptionnel under stress. |

| Sumaya kɛlɛli . | fo ka se 150°C ma (PA 66), sanfɛ ni fɛn caman b’a la. | A ka fisa, a bɛ se 200°C ma. | A ka ca a la, fo ka se 500°C ma. |

| UV resistance . | Low, PA 12 mago bɛ fɛn caman caman caman caman caman caman caman caman caman caman caman caman caman caman caman caman caman caman caman caman caman caman caman caman caman caman caman caman. | A ka ca, a ka fisa ni Alifatiki PAS ye. | A ka dɔgɔ, a mago bɛ farankanw kan. |

| Flame retardant . | bɛ se ka ladilan walasa ka sariya labato. | Naturalement ka tɛmɛ tasuma kan. | Tasuma-fanga-ko-kɛlɛba. |

| Dimensions sabatili . | A ka teli ka ji minɛ, a bɛ sabati PA 11/12 kɔnɔ. | Superior, dɔgɔman min bɛ ji minɛ. | A ka ɲi kosɛbɛ, a sabatilen don kosɛbɛ. |

| Abrasion resistance . | sanfɛ, kɛrɛnkɛrɛnnenya la PA 66 ani PA 6 la. | A ka fisa ni alifatiki kalasi ye. | exceptionnel, idéal pour le friction haute. |

| Sɛgɛn resistance . | A ka ɲi baarakɛcogo barikamaw la. | Superior, kɛrɛnkɛrɛnnenya la degunw kɔrɔ. | A ka bon, a bɛ baara kɛ ni a ye waati jan kɔnɔ, a bɛ kɛ ni degunba ye. |

Yɛlɛma donna poliyamidi la .

Poliyamidi (PA) plastikiw bɛ se ka ladilan walasa k’u ka nafaw yiriwa baara kɛrɛnkɛrɛnnenw kama. An ka fɛn dɔw lajɛ minnu bɛ kɛ ka caya.

Glass fibre barika bonya .

Glass fibres bɛ fara a kan walasa ka PA plastikiw fanga, u gɛlɛya ani u hakɛ sabatili ɲɛ. Nin fɛn caman b’a la ka fɛn caman sɛmɛntiya mobili ni izini baara la, yɔrɔ minnu na, a muɲuni ka caya, o nafa ka bon.

| Nafa sɔrɔli | nafa . |

| Barika | Dɔ farala doni-ta-seko kan . |

| gɛlɛya . | rigidité entrepré . |

| Dimensions sabatili . | Dɔgɔyali dɔgɔyali ni warping . |

Karɔbɔni fiyɛri barika bonya .

Ni aw ye fibre carbones fara a kan, o bɛ poliyamidiw ka masinw ni u ka funteni jiginni sabati. O ye yɔrɔ ɲuman ye yɔrɔw la minnu bɛ baara kɛ kosɛbɛ, minnu bɛ sɔrɔ masinw ka degun walima funteni na, i n’a fɔ aerospace yɔrɔw.

| Nafa sɔrɔli | nafa . |

| Mekaniki fanga . | Deformation ka se ka a yɛrɛ tanga ka ɲɛ . |

| Sumaya min bɛ kɛ ni funteni ye . | Funteni bɔli ka fisa . |

tulumafɛnw .

tulumafɛnw bɛ dɔ bɔ ɲɔgɔnkanu na ani ka sɛgɛnbaliya kunbɛn baarakɛcogo la i n’a fɔ birikiw ni girinw. Ni PA plastikiw bɛ se ka baara kɛ ka ɲɛ ani ka ɲɛnamaya janya.

| Nafa sɔrɔli | nafa . |

| Friction reduction . | A ka kan ka kɛ ni sɛgɛn ye . |

| Baarakɛcogo nɔgɔman . | Dɔ farala baarakɛcogo ɲuman kan ani a yɔrɔ dɔw la . |

UV stabilisateurs .

UV sabatilifɛnw bɛ poliyamidiw ka muɲuli janya kɛnɛma sigidaw la, u kɛtɔ k’u tanga tiɲɛni ultraviolet ma. O nafa ka bon kɛnɛyako la i n’a fɔ mobili kɛnɛma walima kɛnɛma minɛnw.

| Nafa sɔrɔli | nafa . |

| UV resistance . | Kɛnɛya sabatili kuntaalajan . |

| Dɔgɔyali dɔgɔyali . | Baara kɛcogo ɲuman tile yeelen jirali kɔrɔ . |

Flame retardants .

Flame Retardants b’a to poliyamidiw bɛ tasuma lakanani sariyaw dafa kuran ni mobili siratigɛ la. O bεε bεε bε PA bεn ka baara kε sigidaw la, tasuma bε bεn yɔrɔ minnu na.

| Nafa sɔrɔli | nafa . |

| Tasuma resistance . | A ka fisa yɔrɔw la minnu ka suma walima tasuma bɛ se ka sɔrɔ yɔrɔ minnu na . |

| Ka bɛn a ma | A bɛ bɛn industry tasuma lakanani sariyaw ma . |

Impact modifiers .

Impact modifiers bɛ dɔ fara poliyamidiw ka gɛlɛya kan, o b’a to u bɛ se ka u yɛrɛ tanga karili ma degun barikamaw kɔrɔ. O fɛn caman b’a la ka fɛn caman sɛmɛntiya baarakɛyɔrɔw la, yɔrɔ minnu na yɔrɔw bɛ se ka nɔ bila siɲɛ caman na, i n’a fɔ farikoloɲɛnajɛ minɛnw walima izini masinw.

| Nafa sɔrɔli | nafa . |

| Toughness dɔ bɛ ka caya . | A bɛ se ka kɛ ka a yɛrɛ tanga ka ɲɛ ani ka a kari . |

| A bɛ se ka muɲu . | Ɲɛnamaya janya sigidaw la minnu bɛ fanga la . |

Baarakɛcogo fɛɛrɛw poliyamidi (PA) plastiki la .

Poliyamidi (PA) plastiki bɛ se ka baara kɛ ni fɛɛrɛ suguya caman ye, u kelen-kelen bɛɛ bɛ bɛn baarakɛcogo wɛrɛw ma. An ka baarakɛcogo kunbabaw sɛgɛsɛgɛ.

Pikirili Molidali .

Pikiriw dilanni bɛ kɛ ka caya PA yɔrɔw dilanni na k’a sababu kɛ a bolicogo ɲuman ye ani a dilanni. O kɛcogo bɛ a ɲini ka funteni, ja ani nɔgɔ cogoya kɔlɔsi kosɛbɛ.

Funteni : PA 6 bɛ funteni hakɛ 240-270°C de wajibiya, ka sɔrɔ PA 66 mago bɛ 270-300°C la.

Jala : Jali ɲuman nafa ka bon walasa ka ji hakɛ dɔgɔya ka tɛmɛ 0,2% kan. Nɔgɔ bɛ se ka kɛ sababu ye ka fiɲɛw sɔrɔ i n’a fɔ splay marks ani ka dɔ bɔ masinw na.

Mold temperature : Mold température ideal bɛ daminɛ 55-80°C la, ka kɛɲɛ ni PA suguya ni a yɔrɔ dilanni ye.

| PA suguya | bɛ funteni | jalen wajibiya | mɔli funteni . |

| PA 6 . | 240-270°C . | < 0,2% ji . | 55-80°C . |

| PA 66 . | 270-300°C . | < 0,2% ji . | 60-80°C . |

Walasa ka kunnafoni wɛrɛw sɔrɔ pikiri kɛcogo paramɛtiriw kan, aw bɛ se ka an ka barokun sɔrɔ . Taabolo paramɛtiriw ka ɲɛsin pikiri kɛcogo ma min bɛ mɔgɔ dɛmɛ.

Extrusion

Extrusion ye fɛɛrɛ wɛrɛ ye min bɛ kɛ PA baarakɛcogo la, kɛrɛnkɛrɛnnenya la walasa ka siginidenw kɛ minnu bɛ to senna i n’a fɔ tubabukan, pipew, ani filimuw. Nin fɛɛrɛ in bɛ cogoya kɛrɛnkɛrɛnnenw de wajibiya poliyamidi suguya caman na. Walasa ka danfara minnu bɛ bɔli ni pikiri kɛli cɛ, olu faamuya, aw bɛ se ka an ka danfara jira . Pikiri fiyɛ molding vs extrusion blow moulding ..

Vis design : Vis de three-serie avec ratio L/D ye 20-30 ye, o ka ɲi PA bɔli ma.

Funteni : Bɔli funteni ka kan ka kɛ 240-270°C cɛ PA 6 ni 270-290°C la PA 66 la.

| paramètre (Extrusion paramètre) | sigicogo ladilikan . |

| Screw L/D ratio . | 20-30 . |

| PA 6 Baarakɛcogo funteni . | 240-270°C . |

| PA 66 Baarakɛcogo funteni . | 270-290°C . |

3D Printing

Selective laser sintering (SLS) ye 3D sɛbɛnni fɛɛrɛ ye min bɛ fɔ kosɛbɛ poliyamidiw kama. A bɛ baara Kɛ ni laser ye ka sinter powdered PA materials layer par layer, ka yɔrɔ gɛlɛnw ni yɔrɔ tigitigiw Dabɔ. SLS ka ɲi kosɛbɛ prototyping ni low-volume sɔrɔli la bawo a bɛ mouli mago bɔ. Walasa ka kunnafoni wɛrɛw sɔrɔ 3D sɛbɛnni kan ani a bɛ tali kɛ cogo min na ni laadala fɛn dilanni fɛɛrɛw ye, aw ye an ka barokun lajɛ . ye 3D sɛbɛnni ye min bɛ pikiri kɛ pikiri kɛli la ..

Nafaw : SLS bɛ sira di dilancogo gɛlɛnw dabɔli ma, ka fɛnw tiɲɛni dɔgɔya, wa a bɛ se ka wuli kosɛbɛ ka kɛɲɛ ni ladamucogo ye.

Aplikasi : A bɛ kɛ ka caya mobili, aerospace, ani furakɛli baarakɛyɔrɔw la walasa ka prototyping teliya ani ka baara kɛ.

| 3D Printing Method Nafaw | . |

| Selective laser sintering (SLS) . | Haute précision, no molds wajibiyalen don . |

Walasa ka kunnafoni wɛrɛw sɔrɔ prototyping technologies rapides kan, aw bɛ se ka an ka barokun sɔrɔ . Rapid Prototype ka fɛn dilanni fɛɛrɛ nafama ye mun ye.

Poliyamidi (PA) furaw farikoloma .

Poliyamidi (PA) furaw bɛ sɔrɔ farikolo suguya caman na. Foroko kelen-kelen bɛɛ n’a ka jogo ni a ka baarakɛcogo kɛrɛnkɛrɛnnenw don. An ka PA cogoya ni a bonya danfaralenw sɛgɛsɛgɛ:

Pellets .

Pellets ye PA suguya ye min ka ca .

U ye fɛn misɛnninw ye minnu bɛ kɛ silinda ye, walima minnu bɛ kɛ i n’a fɔ disiki .

A ka ca a la, a bɛ kɛ ni 2-5mm ye a cɛmancɛ la .

U bɛ kɛ fɔlɔ pikiri kɛcogo la .

muguw .

PA muguw bɛ ni fɛnɲɛnamafagalan finmanw ye, minnu bɛ daminɛ ni 10-200 microns ye .

U bɛ Kɛ baara suguya caman na, i n’a fɔ:

Granules .

Granules ka bon dɔɔni ka tɛmɛ peleti kan .

U janya ye milimɛtɛrɛ 4-8 ye .

Granules ka nɔgɔn ka balo extrusion machines la ni i ye a suma ni muguw ye .

U bɛ fɛnw bolicogo ɲɛ ka taa a fɛ baara kɛtuma na .

Siginiden solide

PA bɛ se ka kɛ masin ye ka kɛ cogoya gɛlɛn suguya caman ye .

Sɛbɛn minnu bɛ sɔrɔ tuma caman na, olu ye berew, platiw ani yɔrɔw ye minnu dilannen don ka kɛɲɛ ni mɔgɔw sago ye .

O siginidenw dabɔra ka bɔ PA stock materials .

U bɛ fɛn caman di baarakɛcogo kɛrɛnkɛrɛnnenw ni u dilanni na .

| na . | kɛ cogo min | bɛ |

| Pellets . | 2-5mm diamètre . | Pikirili Molidali . |

| muguw . | 10-200 microns . | Molding rotational, coating poudre, SLS 3D imprimante . |

| Granules . | 4-8mm diamètre . | Extrusion processus . |

| Solides . | Laadalata suguya caman . | Masina yɔrɔw ani a dilanni kɛrɛnkɛrɛnnenw . |

Poliyamidi (PA) plastiki baarakɛcogo .

Poliyamidi (PA) plastiki ye fɛn caman ye, o b’a to a nafa ka bon izini suguya caman kɔnɔ. A fanga, a ka kemikaliya, ani a ka muɲuli bɛ nafa di sigida caman na minnu ka gɛlɛn.

Mobili industrie .

Mobiliko siratigɛ la, poliyamidiw bɛ kɛ ka ɲɛsin fɛn caman ma minnu nafa ka bon. Motɛri yɔrɔw, fɛnɲɛnamafagalanw, ani kuran fɛnw bɛ u jigi da PA plastiki kan k’a sababu kɛ a ka funteni kunbɛncogo, a fanga ani a muɲuni ye.

| Aplikasi | nafa jɔnjɔnw . |

| Motɛri yɔrɔw . | Sumaya kɛlɛli, fanga . |

| Esans Sitiw . | kemikɛli resistance, low permeability . |

| Kuran insulateurs . | Kuran insulasi, funteni sabatili . |

Industriw ka baarakɛminɛnw .

Industriw ka sigidaw Aw ye nafa sɔrɔ poliyamidi ka sɛgɛnbaliya la ani a ka sɛgɛnbaliya la. Bearings, gears, valves, ani seals minnu dilannen don ni PA ye, olu bɛ mɛn, u bɛ dɔ bɔ ɲɔgɔn na, wa u bɛ baara kɛ ka ɲɛ sigidaw la minnu bɛ degunba lase u ma.

| Aplikasi | nafa jɔnjɔnw . |

| birikiw ni girinw . | Aw bɛ resistance don, friction dɔgɔman . |

| Valves ani sigilanw . | kemikɛli ni masinw ka rezisti . |

Consumer Goods .

K’a ta farikoloɲɛnajɛ minɛnw na ka se don o don du kɔnɔfɛnw ma, poliyamidi bɛ kɛ ka caya a ka gɛlɛya n’a ka fɛn caman sɛgɛsɛgɛli la. Fɛn minnu bɛ i n’a fɔ tenis-minɛnw ani dumunikɛminɛnw, olu bɛ nafa sɔrɔ PA ka muɲuli n’a baara nɔgɔya la.

| Aplikasi | nafa jɔnjɔnw . |

| Spor minɛnw . | Toughness, flexibilité . |

| du kɔnɔfɛnw . | Durability, nɔgɔya ka moulding . |

Kuran ni elekitoroniki .

Elektroniki la, poliyamidiw nafa ka bon u ka kuran sɛgɛsɛgɛli kɛcogo la. U bɛ Kɛ ɲɔgɔndanw na, switchw la, ani dakunw na yɔrɔ minnu na insulasi ni funteni bɛ Se ka Sɔ̀rɔ kosɛbɛ.

| Aplikasi | nafa jɔnjɔnw . |

| Connecteurs ani switchw . | Kuranko insulasi, funteni kunbɛncogo . |

| A bɛ kɛ cogo min na . | Fanga, kemikali ka resistance . |

Dumuniko industriyali .

Poliyamidi minnu bɛ sɔrɔ dumuni na, olu farati tɛ dumuni na, wa u bɛ kɛ ka u kɛ fɛnw ye minnu bɛ kɛ ka fɛnw ta, ka fɛnw lase u ma, ani ka u kɛ masinw ye. O fɛnw bɛ se ka kɛ sababu ye ka kemikɛli kɛcogo ɲuman sɔrɔ ani ka ji minɛcogo dɔgɔya.

| Aplikasi | nafa jɔnjɔnw . |

| Dumuni-kalanso pake | kemikɛli resistance, safe ka sɔrɔ ka ɲɔgɔn sɔrɔ . |

| , o bɛ kɛ sababu ye ka fɛnw lase . | Durabilité, resistance de ménomité . |

Poliyamidi (PA) plastiki ni fɛn wɛrɛw sumalen .

Poliyamidi (PA) plastiki bɛ bɔ kɛnɛ kan a ka fanga, a ka se ka fɛnw sɛgɛsɛgɛ, ani a ka kemikaliyaw faralen ɲɔgɔn kan cogo kɛrɛnkɛrɛnnen na. A bɛ tali kɛ fɛn wɛrɛw la cogo min na, o filɛ nin ye.

PA Plastique vs. Polyester .

Poliyamidi ni poliyesitɛri fila bɛɛ ye polimɛriw ye minnu dilannen don, nka danfara jɔnjɔnw b’u la. PA bɛ fanga ni sɔgɔli kɛcogo ɲuman di, ka sɔrɔ poliyesitɛri bɛ se ka sɛgɛn ni ka dɔgɔya. PA fana bɛ ji caman minɛ ka tɛmɛ poliyesitɛri kan, o bɛ nɔ bila a hakɛ sabatili la sigida nɔgɔlenw na.

| Poliyamidi | (PA) | Poliyesitɛri . |

| Barika | sanfɛ . | Ka bɛrɛbɛn |

| Impact resistance . | Ɲuman ɲuman | Ka lajigin |

| ji minɛcogo . | Jamanjan | Fɛ́gɛn |

| Stretch resistance . | Ka lajigin | sanfɛ . |

PA plastiki ni poliporopilini (PP) .

PA bɛ ni masinw ye ka ɲɛ ni a bɛ tali kɛ poliporopilini (PP) la, i n’a fɔ fanga ka bon ani a bɛ sɛgɛn. Nka, PP bɛ se ka kɛ ni kemikɛli ye ka tɛmɛ, kɛrɛnkɛrɛnnenya la asidi ni alkaliw kan. PA bɛ funteni kunbɛn ka tɛmɛ, ka sɔrɔ PP bɛ dɔn a ka se ka wuli ka bɔ a nɔ na ani ka a girinya nɔgɔya.

| Poliyamidi | (PA) | Poliporopilini (PP) . |

| Barika | sanfɛ . | Ka lajigin |

| kemikɛli resistance . | A ka ɲi, nka a barika ka dɔgɔ asidiw ma . | Ɲuman ɲuman |

| Sumaya kɛlɛli . | sanfɛ . | Ka lajigin |

| Flexibilité . | Ka lajigin | sanfɛ . |

PA Plastiki vs. poliyetilɛni (PE)

Poliyamidi bɛ fanga ni funteni caman di ni poliyetilɛni (PE) ye. PE bɛ se ka wuli ka bɔ a nɔ na ani a ka ji bɛ se ka kɛ a la ka ɲɛ, o b’a to a ka ɲi kosɛbɛ pakew dilanni na. PA kɔni, a ka fisa ni baara ye min bɛ kɛ ni masinw ka muɲuli ye ani funteni kunbɛncogo. Walasa ka danfara minnu bɛ PE suguyaw ni ɲɔgɔn cɛ, olu faamuya, aw bɛ se ka an ka barokun lajɛ . Danfara minnu bɛ HDPE ni LDPE cɛ ..

| Propriété | Polyamide (PA) | Poliyetilɛni (PE) . |

| Barika | sanfɛ . | Ka lajigin |

| Sumaya kɛlɛli . | sanfɛ . | Ka lajigin |

| Flexibilité . | Ka lajigin | sanfɛ . |

| Ji kɛlɛli . | Ka lajigin | Ɲuman ɲuman |

PA Plastiki vs. nɛgɛw (Aluminum, nɛgɛ) .

Hali ni nɛgɛw i n’a fɔ aliminiyɔmu ni nɛgɛw barika ka bon kosɛbɛ, PA plastiki ka nɔgɔn kosɛbɛ wa a dilanni ka nɔgɔn. PA bɛ se ka sɔgɔsɔgɔ, wa a tɛ kɛ ni nɛgɛw ladonni ye minnu bɛ kɛ sigidaw la minnu bɛ sɔgɔsɔgɔ. Nɛgɛw bɛnnen don kosɛbɛ baarakɛcogo ma minnu bɛ fanga jugu ni doni tacogo de wajibiya, ka sɔrɔ PA ka fisa ni girinya dɔgɔyali ye ani ka dɔ fara fɛnw sɛgɛsɛgɛli kan. Walasa ka nɛgɛ suguya wɛrɛw suma ɲɔgɔn na, aw bɛ se ka an ka barokun sɔrɔ . Titanium vs aluminiyɔmu nafama.

| Polyamide | (PA) | Aluminiyɔmu | nɛgɛ . |

| Barika | Ka lajigin | Jamanjan | Kosɛbɛ sanfɛ . |

| Girinya | A ka dɔgɔ (a ka nɔgɔn) . | Ka bɛrɛbɛn | Jamanjan |

| Corrosion resistance . | Ɲuman ɲuman | Duman | Faantan |

| Flexibilité . | sanfɛ . | Ka lajigin | Ka lajigin |

Walasa ka kunnafoni wɛrɛw sɔrɔ nɛgɛmafɛnw n’u nafaw kan, aw bɛ se ka an ka gafe lajɛ . Nɛgɛ suguya wɛrɛw ..

Kuncɛli

Poliyamidi (PA) plastikiw bɛ se ka kɛ fɛn caman ye, u bɛ fanga di u ma, u bɛ funteni kunbɛn, ani u bɛ se ka muɲu. O jogo ninnu b’a to u nafa ka bon bi ɛntɛrinɛti ni fɛn dilanni na. A kɛra mobili ye, ɛntɛrinɛti, walima izini baarakɛcogo la, PA plastikiw bɛ baara kɛcogo ɲuman di.

Ni aw bɛ PA suguya dɔ sugandi, aw bɛ jateminɛ kɛrɛnkɛrɛnnenw jateminɛ i n’a fɔ fanga, fɛn caman sɛgɛsɛgɛli, ani sigida kɛlɛli. PA kalasi kelen-kelen bɛɛ bɛ nafa kɛrɛnkɛrɛnnenw di baarakɛcogo wɛrɛw ma, ka baara in kɛcogo ɲuman sabati.

Ladilikanw: A bɛ se ka kɛ ko aw bɛ a fɛ ka a bɛɛ kɛ plastiki ye .