Polibutilɛni terefitalati (PBT) bɛ yɔrɔ bɛɛ, k’a ta aw ka mobili la ka taa a bila ɛntɛrinɛti la. Nka, o ye mun ye tigitigi? Nin semi-crystalline engineering thermoplastic ye poliyesitɛri denbaya ta ye ani a bɛ balansi di fanga ni muɲuli ma.

Nin sɛbɛn in kɔnɔ, an bɛna PBT kɛ fɛn ye min bɛ kɛ fɛn kɛrɛnkɛrɛnnen ye, a ka nafaw, a baarakɛcogo, ani a bɛ kɛ cogo min na iziniw kɔnɔ i n’a fɔ mobili ni ɛntɛrinɛti.

Polibutilɛni terefitaliti (PBT) ye mun ye?

Polibutilɛni terefitalati (PBT) ye sɛnɛfɛnw ye minnu bɛ sɔrɔ poliyesitɛri denbaya kɔnɔ. A bɛ dɔn a fanga, a ka se ka fɛnw sɛgɛsɛgɛ, ani a bɛ se ka a yɛrɛ tanga kemikɛli ma. O nafolo ninnu kosɔn, PBT bɛ baara kɛ kosɛbɛ mobili, ɛntɛrinɛti ani izini baarakɛcogo la.

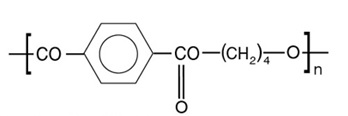

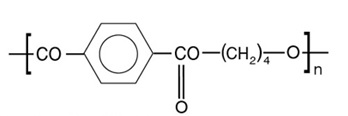

PBT ka kemikaliya ni a jɔcogo .

PBT ka kemikaliya sigicogo jiralen don ni formula (C12H12O4)N ye. Polimɛri bɛ kɛ cakɛda janw ye minnu bɛ sɔrɔ ɛsitɛri sirili fɛ. O siriw bɛ fɛn di fɛn ma min bɛ se ka muɲu ani ka funteni kunbɛn, o de b’a to a ka ɲi sigida gɛlɛnw ma. A ka semi-crystalline structure bɛ dimension stabilité di, o kɔrɔ ye ko a bɛ a cogoya mara hali degun kɔrɔ.

Polibutilɛni terefatati ka molekiyɔmuw ka baarakɛcogo .

A yɔrɔ kolomaw ye:

1,4-butanediol (BDO) : A bɛ fɛn caman fara a kan ani ka dɛmɛ don a la ni a bɛ se ka a yɛrɛ tanga.

Asidi terefitaliki (TPA) walima dimetilɛ tɔrɔsi (DMT) : o bɛ gɛlɛya ni sigicogo dafalen di.

PBT ka sinti .

PBT sɔrɔli bɛ tali kɛ polikɔndansiyɔn na dimetilɛ tɔrɔsi (DMT) walima asidi terefitaliki (TPA) ni 1,4-butanediol (BDO) cɛ ..

Fɛn minnu bɛ kɛ ni fɛnɲɛnamafagalanw ye:

Sinsin bɛ daminɛ ni ɛsitɛri ye, BDO bɛ min kɛ ni DMT walima TPA ye. Ni aw bɛ DMT kɛ, mɛtanɔli bɛ dilan i n’a fɔ a kɔfɛfɛn. Ni TPA ye, ji bɛ bɔ. Nin wale in bɛ BDO tɛmɛnen bɔ, o bɛ na ni polimɛri cakɛda janw sɔrɔli ye kondensasiyɔn walew fɛ.

kemikorow ka ɲɔgɔndanw: .

DMT ka jaabi:

TPA ka jaabi:

O wale ninnu bɛ Kɛ funteni caman na, a ka c’a la 230°C ni 250°C cɛ , ani yɔrɔ la min bɛ Weele ko vacuum. Katalisita fana bɛ se ka kɛ ka farikoloɲɛnajɛ teliya ani ka molekiyɔmu girinya caman sɔrɔ.

| Reaction type | by-product | reaction condition . |

| DMT ni BDO ye . | Methanol . | 230-250°C, Vacuum . |

| TPA ni BDO . | Ji | 230-250°C, Vacuum . |

Nin polikɔnzasiyɔn kɛcogo in ye fɛnba ye min bɛ kɛ ka polimɛri cakɛdaw dilan minnu bɛ to senna, minnu bɛ se ka funteni kɛlɛ, minnu bɛ PBT ɲɛfɔ.

PBT ye poliyesitɛri denbaya kɔnɔmɔgɔ ye .

I n’a fɔ poliyesitɛri, PBT bɛ ɲɔgɔn bɔ ni poliyesitɛri tɔw ye i n’a fɔ . Terefitaliti poliɛtilɛni (PET) . Nka, a b’a yɛrɛ Bɔ a ka kristalɛ hakɛ teliya la ani a ka baarakɛ-minɛnw funteni dɔgɔyali fɛ. O b’a to a bɛ kɛ cogoya gɛlɛnw na nɔgɔya la. Ni an ye a suma ni poliyesitɛri tɔw ye, PBT ka masinw ka fisa ani a ka kemikaliya ka ɲi, o b’a to a dafalen don yɔrɔw la minnu bɛ tuluw, fɛnɲɛnamafagalanw ani funteni caman sɔrɔ.

PBT ka nafaw .

PBT bɛ nafolomafɛnw faralen ɲɔgɔn kan, minnu bɛ kɛ sababu ye ka baara suguya caman kɛ, olu faralen ɲɔgɔn kan. An ka a jogo jɔnjɔnw lajɛ kosɛbɛ.

| Propriété suguya | Property | details . |

| Farikolo yɔrɔw . | Hakɛ | 1,31 g/cm³ |

| Dantigɛli min bɛ kɛ oksizɛni na . | 25% . |

| ji minɛcogo (lɛrɛ 24) . | 0,08%-0,1% . |

| Dimensions sabatili . | Ɲuman ɲuman |

| UV resistance . | Duman |

| Mekaniki jogo . | Tensile fanga . | 40-50 MPa . |

| Modulus flexural . | 2-4 GPA . |

| Elongation ka break . | 5-300% . |

| resistance creep . | A ka ca ni funteni kɔrɔtalenw ye . |

| thermal properties . | Funteni-yɔrɔ-ko- funteni (HDT) . | 115-150°C (a bɛ 0,46 MPa); 50-85°C (a bɛ 1,8 MPa la) . |

| Max ka baara kɛcogo funteni . | 80-140°C . |

| Tasuma resistance . | A bɛ sɔrɔ ka kɛɲɛ ni tasuma ye min bɛ se ka tasuma kɛlɛ . |

| Coefficient de expansion thermal . | 6-10 x 10⁻⁵/°C . |

| Kuranko nafaw . | Dielektriki fanga . | 15-30 kV/mm . |

| Dielektriki basigilen @ 1 kHz . | 2,9-4. |

| Volume resistivity . | 14-17 x 10⊃1;⁵ ohm.cm . |

| kemikɛli resistance . | A bɛ se ka kɛ sababu ye ka kemikɛli kɛ . | Asidi minnu bɛ dilan, alikɔliw, hidrɔkarbonw, furajiw, tuluw . |

| UV ni nɔgɔ kɛlɛli . | Jamanjan |

| A bɛ se ka kɛ ka fɛnɲɛnamafagalanw kɛlɛ, tuluw . | Ɲuman ɲuman |

Farikolo yɔrɔw .

PBT bɛ dimension stabilité ɲuman di, hali sigida cogoya caman na. A ji bɛ dɔgɔya, a ka c’a la, a bɛ 0,1% lamini sanga 24 kɔnɔ.

O ji minta dɔgɔyali bɛ kɛ sababu ye k’a muɲu funteni degunw ni kemikɛli sigida gɛlɛnw na. PBT bɛ se k’a cogoya n’a baarakɛcogo mara ko gɛlɛnw na.

Mekaniki jogo .

PBT bɛ a yɛrɛ bonya ni fanga caman ye, a ka gɛlɛn, ani a ka gɛlɛya. Nin ye hakɛ jiralan dɔw ye:

| nafolo | nafa . |

| Tensile fanga . | 50-60 MPa . |

| Modulus flexural . | 2,3-2,8 GPA . |

| Elongation ka break . | 50-300% . |

PBT fana bɛ fanga ɲuman jira min bɛ se ka nɔ bila a la. A bɛ se ka doni barikamaw muɲu k’a sɔrɔ a ma kari walima ka kari.

Fɛn wɛrɛ min nafa ka bon, o ye a ka resistance creep ye. PBT bɛ se k’a cogoya mara degun basigilen na, hali ni a funteni ka bon.

thermal properties .

PBT ka funteni hakɛ ka ca (HDT) ni a bɛ tali kɛ ɛntɛrinɛti plastiki caman wɛrɛw la. Misali la, ni 1,8 MPa doni ye, a ka HDT bɛ 60°C lamini na, k’a sɔrɔ Poliporopilini ta ye 50°C dɔrɔn ye.

A fana bɛ ni funteni hakɛ caman ye, o b’a jira ko a bɛ se ka jogo mara funteni kɔrɔtalenw na. PBT bɛ se ka funteni-taama kuntaala surunw muɲu ani ka funteni sɔrɔ waati jan kɔnɔ, k’a sɔrɔ a ma tiɲɛniba kɛ.

Kuranko nafaw .

PBT bɛ kuran caman di ani dielektriki fanga. O jogo ninnu b’a to a ka ɲi kosɛbɛ kuran yɔrɔw la minnu bɛ se ka u tanga.

A bɛ a yɛrɛ tanga bɔli ma, a bɛ bɔn, ani a bɛ se ka kuran ciriw tiɲɛ. PBT ka dielektriki bɔnɛ dɔgɔyali fana b’a to a bɛnnen don ɛntɛrinɛti baarakɛcogo caman ma.

kemikɛli resistance .

PBT bɛ a jira ko a bɛ se ka kɛ fura suguya caman ye, i n’a fɔ:

O kemikaliya kɛlɛli bɛ PBT kɛ yɔrɔ ye min bɛ bɛn yɔrɔw ma minnu bɛ sɔrɔ fɛnɲɛnamafagalanw, gaziw ani tuluw la. A bɛ se k’a ka dafalenya mara sigidaw la minnu bɛ kɛ ni kemikɛli ye.

PBT fana bɛ UV resistance ɲuman di, ka tiɲɛni bali ka bɔ tile yeelen na. A nɔgɔ kɛlɛli bɛ dɔ fara a ka muɲuli n’a ka ɲɛnajɛko kan.

PBT suguyaw ni fɛn caman b’a la .

PBT kalasi minnu ma fa .

PBT hakɛ minnu ma fa, olu ye fɛn suguya jɔnjɔn ye min tɛ fara a kan. U bɛ balansi di nafolo ma min bɛnnen don baara caman ma.

O kala ninnu bɛ na ni fɛn caman ye minnu bɛ se ka wuli ka bɔ u nɔ na, o bɛ kɛ sababu ye ka pikiri kɛcogo caman kɛ ani ka fɛnw bɔ kɛnɛ kan.

Fibre de fibre verre PBT .

Glass fibre reinforced PBT ye fɛn ye min bɛ fɛn caman sɛmɛntiya. Glass fibres farali bɛ fɛn in ka masina cogoyaw bonya kosɛbɛ.

Tensile strength, flexural modulus, ani compression strength bɛ se ka bonya ni siɲɛ 2 ye ka se siɲɛ 3 ma ni i ye a suma ni jatedenw ye minnu ma fa. O bɛ kɛ sababu ye ka gilasi fibre barikama PBT kɛ fɛn ɲuman ye ka ɲɛsin baarakɛcogo ma.

Fiɲɛ hakɛ bɛ se ka ɲɔgɔn ta, a ka c’a la, a bɛ daminɛ 10% na ka se 50% ma. Fibre hakɛ caman sɔrɔli bɛ na ni fanga ni gɛlɛya ye ka tɛmɛ nka a bɛ dɔ bɔ ductility la.

PBT min falen bɛ minɛnw na .

Minɛriw falenfɛnw, i n’a fɔ talki ni kalisiyɔmu karɔbɔni, olu bɛ se ka fara PBT kan. O fasaw bɛ dimensions (hakɛ sabatili) sabati ani ka dɔ bɔ a dɔgɔyali la mouling (muli) waati la.

PBT hakɛ minnu falen don fɛnɲɛnamafagalanw na, olu bɛ dɔ fara u gɛlɛyali kan ani u ka funteni kunbɛncogo kan ni i ye u suma ni jatew ye minnu ma fa. Nka, a nɔfɛko fanga bɛ se ka dɔgɔya dɔɔnin.

PBT min bɛ kɛ ka tasuma don a la .

Flame-retardant PBT nafa ka bon kosɛbɛ baarakɛcogo la ni tasuma lakanani sariya gɛlɛnw ye. Tasuma-fanga-minɛn suguya caman bɛ Se ka Kɛ, u kelen-kelen bɛɛ n’u nafa n’u dɛsɛw.

Tasuma-fagalan minnu bɛ kɛ ni halojeni ye, i n’a fɔ fɛnɲɛnamafagalanw, olu bɛ se ka kɛ nka u bɛ se ka kɛ sigida haminankow ye. Fɛn wɛrɛ minnu tɛ ni halojeni ye, i n’a fɔ fosiporozɛni, olu bɛ ka bonya.

Tasuma-fagalan sugandili tɛ tasumako dɔrɔn de minɛ, nka a bɛ nɔ wɛrɛw fana de minɛ i n’a fɔ masin fanga, funteni kunbɛncogo, ani kuran sɔgɔli.

PBT min bɛ se ka fɛn caman sɛmɛntiya .

Impact modification bɛ kɛ ka PBT ka gɛlɛya ni a ka ductility ɲɛ. A ka ca a la, a bɛ se ka kɛ ko fɛn minnu bɛ se ka kɛ, olu ye elastomɛriw ye, i n’a fɔ:

O bεε bε bεn ni bεnkansεbεn ye PBT matiriyali kɔnɔ. U bɛ fanga Minɛ 'sènbɔli waati la, ka kari daminɛni ni a jɛnsɛnni bali.

A nɔfɛta fanga bɛ se ka bonya kosɛbɛ, kɛrɛnkɛrɛnnenya la funteni dɔgɔyali la. Nka, modulu ni funteni bɛ se ka tiɲɛ dɔɔnin.

Yɛlɛma wɛrɛw .

PBT bɛ se ka fɛn caman wɛrɛw kɛ walasa ka sariya kɛrɛnkɛrɛnnenw dafa:

UV sabatilifɛnw bɛ se ka fara a kan walasa ka tile yeelen ni waati kɛcogo ɲɛ.

tulumafɛnw, i n’a fɔ PTFE walima silikoni, olu bɛ se ka don a kɔnɔ walasa ka dɔ bɔ ɲɔgɔn na ani ka u sɛgɛn.

Dumuni-kalan PBT bɛ sɔrɔ ka kɛ dumuni ni minfɛnw ye.

Antistatic agents bɛ se ka kɛ ka charges statiques jɛnsɛn ɛntɛrinɛti kan.

Kulɛriw ni ɲɛgɛnɛsiraw bɛ se ka fara a kan ka ɲɛsin ɲɛnajɛko ma.

Tablo min bɛ duguma, o bɛ fɛn caman sɛmɛntiya fɛn wɛrɛw la minnu bɛ se ka fɛn caman sɛmɛntiya PBT nafaw kan:

| Yɛlɛma | fanga | gɛlɛya | bɛ nɔ bila | funteni kunbɛncogo la | Dimensional Stabilité |

| Fibre de verre . | ↑ | ↑ | ↓ . | ↑ | ↑ |

| Minerali filɛri . | ↑ | ↑ | ↓ . | ↑ | ↑ |

| Flame retardant . | ↓ . | ↓ . | ↓ . | ↓ . | ↓ . |

| Impact modifier . | ↓ . | ↓ . | ↑ | ↓ . | ↓ . |

Baarakɛcogo fɛɛrɛw PBT .

PBT ye fɛn ye min bɛ se ka baara kɛ ni fɛɛrɛ suguya caman ye. An ka fɛɛrɛw sɛgɛsɛgɛ minnu ka ca kosɛbɛ ani u ka paramɛtiri jɔnjɔnw.

Pikiri molding

Pikiri kɛli ye fɛɛrɛ ye min bɛ kɛ ka caya PBT baarakɛcogo la. o fɛn bɛ sumaya fo ka se funteni ma min bɛ cɛ 230°C ni 270°C . O kɔfɛ, a bɛ pikiri kɛ bɔgɔ la min bɛ mara 40-80°C la tansiyɔnba kɔrɔ (a ka c’a la 100-140 MPa ). ɲɛnabɔ Ka baarakɛcogo paramɛtɛrɛw —i n’a fɔ funteni ni pikiri tansiyɔn —a bɛ yɔrɔ ɲuman sabati ani ka fiɲɛw dɔgɔya i n’a fɔ . Warping walima . Sink marks ..

| paramètre | range optimale . |

| Aw bɛ funteni wuli . | 230-270°C . |

| Mold température . | 40-80°C . |

| Pikiri tansiyɔn . | 100-140 MPa . |

Extrusion .

Extrusion ye fɛɛrɛ wɛrɛ ye min bɛ kɛ ka caya ka ɲɛsin fɛnw dilanni ma minnu ma dafa i n’a fɔ sɛbɛnw, berew, ani profiles. Extrusion waati la, PBT bɛ wuli ka fanga sɔrɔ die fɛ, ni funteni hakɛ bɛ kɔlɔsi cɛ 230°C ni 250°C . Ni aw bɛ ɲuman mara, juru teliya ni nɛnɛ hakɛ o nafa ka bon hakɛ tiɲɛni na.

| Extrusion paramètre | nafa ɲuman . |

| Aw bɛ funteni wuli . | 230-250°C . |

| Vis Speed . | A ladilanna ka da a bɔli kan . |

Blow Molding .

Fiɲɛbɔlan bɛ kɛ ka yɔrɔw dilan minnu kɔnɔna bɛ kɛ fɛn ye i n’a fɔ buteliw walima minɛnw. O kɛcogo in na, PBT bɛ Bɔ tubabukan na, n’o bɛ Weele ko Parisson, o kɔ fiɲɛ bɛ Fiyɛ a kɔnɔ ka Kɛ cogoya ye. Funteni ni fiɲɛ tansiyɔn bɛ jɔyɔrɔba ta walasa ka fɛn dɔ sɔrɔ min bɛ kɛ ka ɲɛ, min bɛ kɛ cogo kelen na.

| Paramɛtiri | baarakɛcogo . |

| Aw bɛ funteni wuli . | 230-250°C . |

| Fiɲɛ tansiyɔn . | Optimisé pour les parts hollows . |

Molding compression .

compression molding ye PBT bilali ye moule sumayalen na ani ka a degun ni degun ye. O fɛɛrɛ in bɛ kɛ ka caya yɔrɔbaw walima yɔrɔbaw la . A ka ɲi kosɛbɛ baarakɛcogo la min bɛ fɛn barikamaw ɲini, minnu bɛ mɛn, minnu mago bɛ cogoya tigitigi marali la.

PBT compression mouling baarakɛcogo misali ye:

Funteni hakɛ: 230°C fo 250°C .

Moli funteni hakɛ: 150°C fo 180°C .

Degun min bɛ kɛ ka fɛnw labɛn: 10 ka se 50 MPa ma .

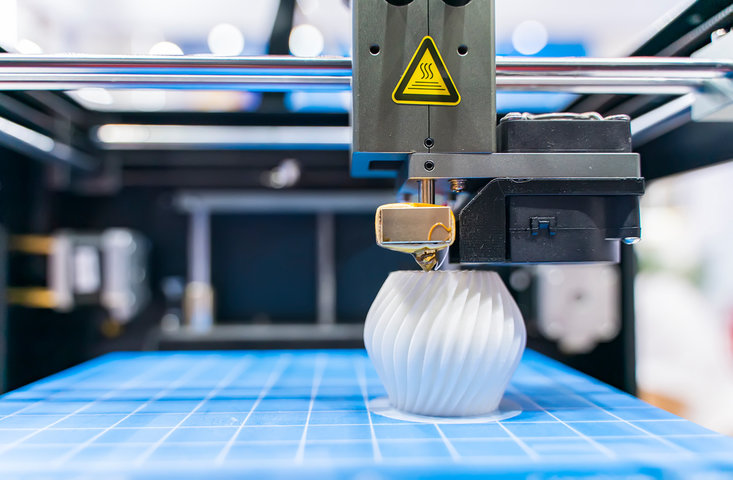

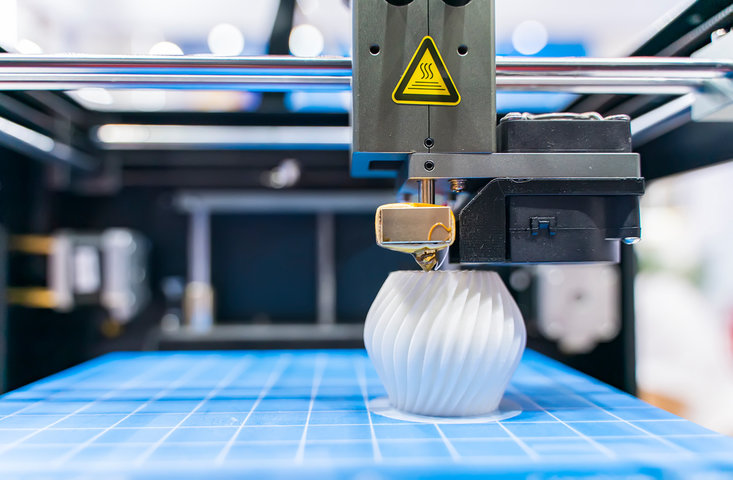

3D sɛbɛnni ni PBT ye .

Hali ni a man ca, PBT bɛ se ka baara kɛ ni 3D sɛbɛnni fɛɛrɛw ye i n’a fɔ fused filament fabrication (FFF) walima selective laser sintering (SLS). A bɛnnen don ka yɔrɔ gɛlɛnw dilan, yɔrɔ minnu bɛ mɛn, fanga ka bon minnu na. Sɛbɛnni kɛcogo ɲumanw i n’a fɔ extrusion temperature ani print speed, o bɛ layɛrɛw nɔgɔya ani ka nɔrɔli barikamaw kɛ.

| 3D Printing parameter | effect sur qualité . |

| Extrusion température . | A bɛ nɔ bila layer bonding . |

| sɛbɛnni teliya . | Contrès de précision . |

PBT ka baarakɛcogo .

PBT bɛ baara sɔrɔ izini caman na k’a sababu kɛ a ka nafolo ɲumanw ye. An ka baara kɛyɔrɔ jɔnjɔn dɔw sɛgɛsɛgɛ.

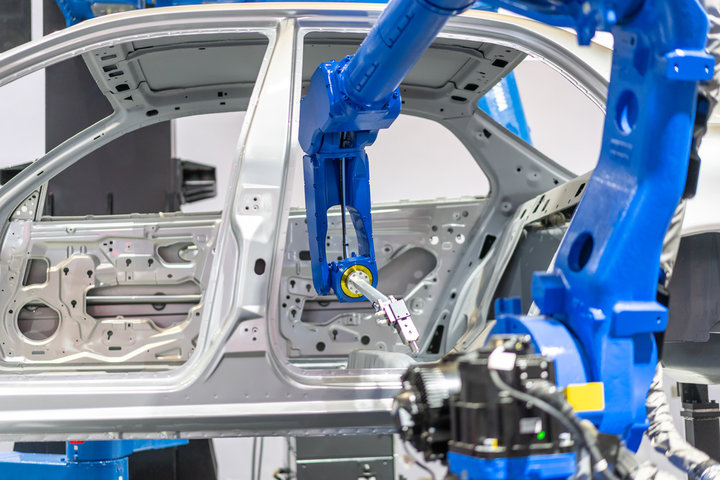

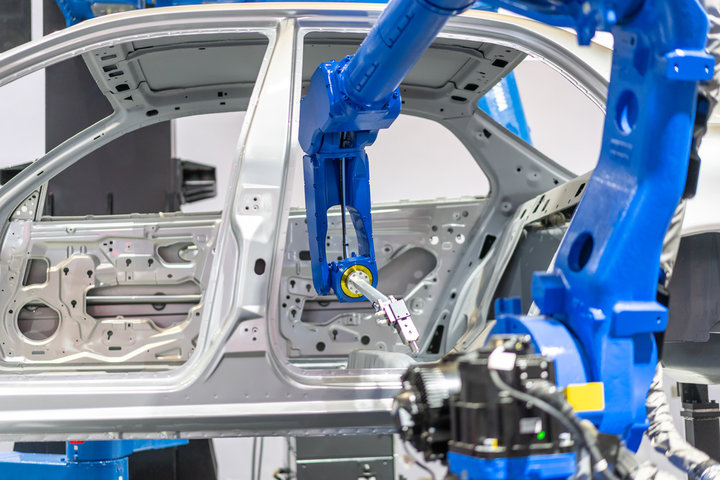

Mobili industrie .

PBT bɛ baara kɛ kosɛbɛ mobili baara la k’a sababu kɛ a bɛ mɛn, a bɛ se ka funteni kunbɛn, ani a bɛ se ka a yɛrɛ tanga. a ka ɲi kosɛbɛ yɔrɔw la i n' a fɔ bumpers , body panels , motor parts , ani transmission components . Misali la, PBT bɛ sɔrɔ ka caya Window Motor Shells , Gearboxes , ani Radiator Windows , a bɛ baara kɛcogo ɲuman di yɔrɔ minnu na sigida gɛlɛnw na.

| Mobili yɔrɔ | PBT baarakɛcogo . |

| Bumpers . | Impact resistance ani flexibilité . |

| Motɛri yɔrɔw . | Kuran insulasi ni a muɲuni . |

| Transmission components . | Tumuw kɛlɛli kemikaliya . |

Elektroniki ni kuran minɛnw .

la Elektroniki seko ni dɔnko siratigɛ , PBT nafa ka bon a ka kuran lakanani nafaw la. A bɛ kɛ kafoɲɔgɔnyaw la , minnu bɛ nɛnɛ , ani transformateur , ka lakana ni muɲuli sabati. PBT fana ye fɛn ye min bɛ fɔ mɔgɔw fɛ ɛntɛrinɛti kan ani so kɔnɔ minɛnw na i n’a fɔ frigow ni finiko masinw, a bɛ masin fanga ni funteni sabatili fila bɛɛ di yɔrɔ min na.

| Electronic component | PBT baarakɛcogo . |

| Connecteurs . | Kuranko insulasi . |

| Fans de cool . | Sumaya kɛlɛli . |

| Transformateurs ani Relais . | So min bɛ mɛn, o bɛ funteni mara . |

Consumer Goods .

na fɛnw feereli fɛnw , PBT bɛ sɔrɔ ka caya du kɔnɔ fɛnw na i n' a fɔ vacuum cleaner components ani kafe dilanni yɔrɔw . A fanga n' a muɲuni fana b' a kɛ sugandili ɲuman ye farikoloɲɛnajɛfɛnw na , i n' a fɔ Skate Soles ani Power Drill Housings ..

Furakɛcogo minɛnw .

PBT ka biyocompatibilité ani chimique resistance b' a to a bɛnnen don furakɛli minɛnw ma . A ka teli ka kɛ opereli minɛnw na , kolotugudaw la , ani furakɛli minɛnw minnu bɛ fɛn tigitigiw, minnu bɛ mɛn, ani minnu saniyalen don. Ni ji minta dɔgɔyara, o bɛ a to dannaya kuntaalajan furakɛli sigidaw la.

| furakɛli minɛn | PBT jɔyɔrɔ . |

| Opereli minɛnw . | A bɛ se ka muɲu ani a bɛ se ka kɛ biocompatibilité ye . |

| Orthopedic Implants . | kemikorow ka se ka u ka banaw kunbɛn ani ka u sabati . |

Plomberie ani ji minɛcogo .

la Plomberie ni fluid minɛcogo , PBT bɛ kɛ ka valves , fittings , ani pompe impellers . A bɛ se ka kemikorow kɛlɛ, ka ji minɛ ka dɔgɔn, ani ka a muɲu kosɛbɛ, o b’a to a dafalen don fɛnw na minnu bɛ ji, tulu ani saniya furaw la.

| Plomberie component | PBT baarakɛcogo . |

| Valves ani fittings . | kemikɛli resistance . |

| Pompe Impellers . | A bɛ mɛn ji la ji la . |

Industrie masinw

PBT jɔyɔrɔ ka bon kosɛbɛ izini masinw na , a bɛ kɛ yɔrɔ min na ka birikiw , dilan , ka girinw , ani wuluwuluw . O yɔrɔw bɛ nafa sɔrɔ PBT ka sɛgɛnbaliya la , , ani masin fanga ka bon ..

| ka izini yɔrɔ | PBT baarakɛcogo . |

| birikiw ni girinw . | Aw bɛ resistance don, friction dɔgɔman . |

| Rollers ani Cams . | muɲuli ni tiɲɛni . |

Dumunifɛnw dilanni minɛnw .

PBT bɛ kɛ dumuniw na ka da a kan a bɛ labato FDA sariyaw . A ka ca a la a bɛ sɔrɔ conveyor belts , food processing blades , ani masin wɛrɛw la minnu bɛ dumuni minɛ. PBT ka se ka ji ni saniya furaw kɛlɛ, o b’a to a ka ɲi dumuni saniyalanw ni dannakow la.

| Dumuniko yɔrɔ | PBT baarakɛcogo . |

| , o bɛ kɛ sababu ye ka fɛnw lase . | FDA ka sariya labatoli, ji kɛlɛli . |

| Dumunifɛnw dilanni bɔgɔlanw . | A bɛ mɛn ani a bɛ saniya . |

PBT nafaw ni a dɛsɛw .

I n’a fɔ fɛn o fɛn, PBT fanga n’a dan bɛ a la.

Nafaw .

PBT bɛ nafa jɔnjɔn caman di izini caman kɔnɔ, o b’a to a bɛ kɛ sugandili ye min ka di kosɛbɛ baarakɛcogo ɲumanw na.

Mekaniki jogo ɲumanw ani hakɛ sabatili

PBT bɛ waso fanga , gɛlɛyaba la , ani gɛlɛya , o b’a to a bɛ mɛn masinw ka degun kɔrɔ. A bɛ dimension stabilité mara , hali sigida cogoya caman na, a bɛ a to yɔrɔw ka u cogoya mara.

PBT min bɛ kɛ ni kemikɛli ye ani min bɛ se ka sɛgɛn,

bɛ se ka furakisɛ suguya caman kɛlɛ, i n’a fɔ furajiw , o , ani tuluw . A sɛgɛnbaliya b’a to a bɛnnen don yɔrɔ lamagannenw ma i n’a fɔ girinw, yɔrɔ min na, sɔgɔli dɔgɔyali nafa ka bon.

kuran insulasi ɲuman

Nin polimɛri in bɛ tɛmɛ kuran kan , ni dielektriki fanga ka bon ani dielektriki bɔnɛ ka dɔgɔn . A bɛ fanga bɔli bali ani a bɛ kɛ ka caya ɛntɛrinɛti ni kuran yɔrɔw la.

ji minta dɔgɔyali ani UV resistance

ni ji minɛcogo ka dɔgɔn , PBT b’a ka masina jogo mara sigidaw la minnu falen don nɛnɛ na. A fana bɛ UV fiɲɛ kɛlɛ , o b’a to a ka ɲi kɛnɛyako la k’a sɔrɔ a ma tiɲɛ kosɛbɛ waati kɔnɔ.

Nafa minnu bɛ sɔrɔ .

Hali ni fanga caman bɛ PBT la, dan dɔw fana b’a la minnu ka kan ka jateminɛ.

min bɛ kɛ ka nɔgɔ bɔ, o bɛ

PBT mɔni dɔgɔyaliba jira baara kɛtuma na, o b’a to a ka gɛlɛn ka hakɛ tiɲɛni mara yɔrɔ gɛlɛnw na. Molidi fɛɛrɛ tigitigiw de ka kan walasa ka dɔ bɔ a dɔgɔyali la.

,

PBT ka dɛsɛ nafama dɔ ye a ka sɛgɛsɛgɛli ye jilafɛnw na . Ni aw ye sɔrɔ ka mɛn ji ni ji funteni , o bɛ se ka o fɛn tiɲɛ waati kɔnɔ, ka dan sigi a kɛli la sigidaw la minnu bɛ ji bɔ.

A ka teli ka kɛ warping ni notch sensitivity

ye ka da diferential shrinkage , PBT ka teli ka warping , kɛrɛnkɛrɛnnenya la yɔrɔbaw walima yɔrɔ gɛlɛnw na. Ka fara o kan, PBT min tɛ barika sɔrɔ, o bɛ notch sensitivity jira , o b’a to a bɛ se ka kariw sɔrɔ minnu bɛ tali kɛ degun na.

Funteni hakɛ dɔgɔyali (HDT)

ni a bɛ tali kɛ ɛntɛrinɛti plastiki tɔw la, PBT bɛ ni HDT dɔgɔman ye , o kɔrɔ ye ko a bɛ se ka kɛ a man ɲi funteni caman sɔrɔli la ni barikalan walima hakɛ kɛrɛnkɛrɛnnenw tɛ.

| Nafa | minnu bɛ sɔrɔ . |

| Mekaniki jogo ɲumanw . | Moule shrinkage haute . |

| Dimension (hakɛ) ka sabatili . | Sensibilité de l’hydrolyse . |

| kemikɛli ɲuman ani a doncogo . | A ka teli ka kɛ warping ni notch sensitivity ye . |

| Kuran insulasi min bɛ se ka da a kan . | funteni jiginni funteni dɔgɔyali ni tɔw ye . |

| ji minta ka dɔgɔn ani UV resistance . |

|

Kuncɛli

Polibutilɛni terefitalati (PBT) bɛ bɔ kɛnɛ kan a ka masina fanga , kɛlɛli la , ani a hakɛ sabatili . A ka fɛn caman kɛli b’a to a nafa ka bon kosɛbɛ iziniw kɔnɔ i n’a fɔ mobili, ɛntɛrinɛti ani furakɛli minɛnw. PBT ka nafaw, a ka baarakɛcogo, ani a ka baarakɛcogo faamuyali nafa ka bon kosɛbɛ walasa ka fɛn ɲumanw sugandi ani ka fɛnw dilanni ɲuman sabati.

Ladilikanw: A bɛ se ka kɛ ko aw bɛ a fɛ ka a bɛɛ kɛ plastiki ye .