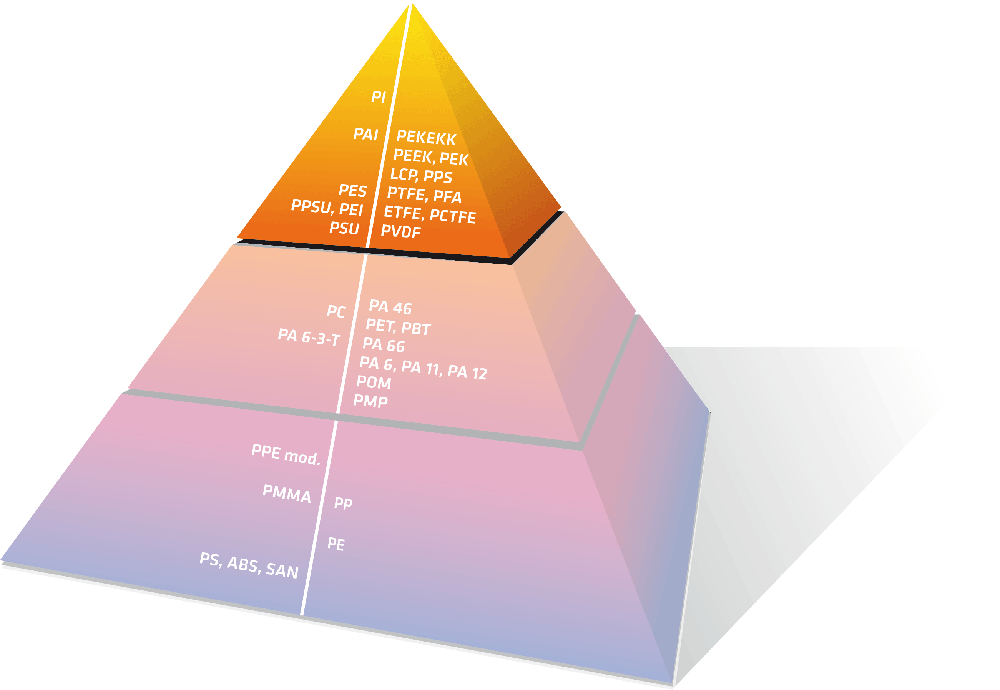

Mun de b’a to Peek plastiki bɛ kɛ fɛn ye min ɲɔgɔn tɛ? Ni iziniw bɛ ka fɛn barikamaw, minnu bɛ se ka funteni kɛlɛ, olu bɛ ka wuli ka bɔ kɛnɛ kan. Polyetheretherketone (Peek) ye ɛntɛrinɛti plastiki ye min bɛ taa ɲɛ, a dabɔra san 1980 waatiw la, a lakodɔnnen don a ka baara kɛcogo ɲuman fɛ cogoya juguw kɔnɔ.

Nin sɛbɛn in kɔnɔ, i bɛna a dɔn Peek ye min ye, a ka nafolo, ani mun na a nafa ka bon kosɛbɛ izini caman kɔnɔ. An bɛna a jogo kɛrɛnkɛrɛnnenw sɛgɛsɛgɛ ani mun na a ye sugandili ɲuman ye aerospace, furakɛli, ani mobili baarakɛcogo la.

Peek plastiki ye mun ye?

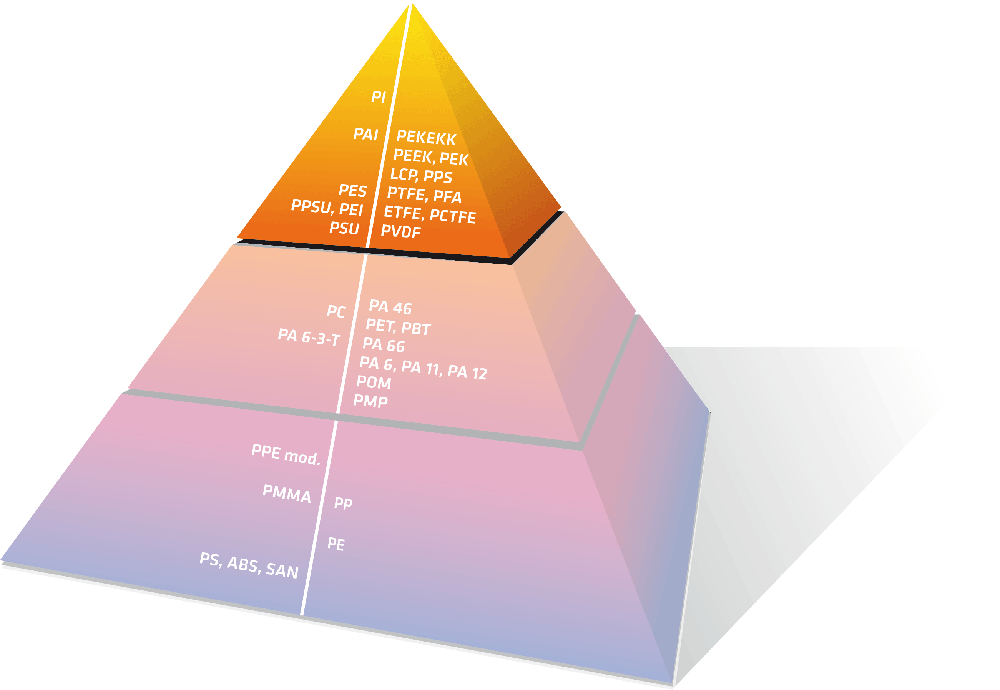

Peek, walima poliyetɛri etɛri ketone, o ye ɛntɛrinɛti plastiki ye min bɛ baara kɛ kosɛbɛ. A bɛ dɔn a ka nafolo danmadɔw n’a ka fɛn caman kɛli fɛ izini suguya caman kɔnɔ. Walasa ka kunnafoni wɛrɛw sɔrɔ Peek bɛ baara kɛ cogo min na fɛn dilanni na, aw bɛ se ka an ka gafe lajɛ . Peek pikiri kɛcogo ..

kemikɛli kɛcogo ani a jɔcogo .

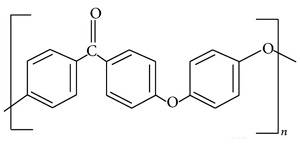

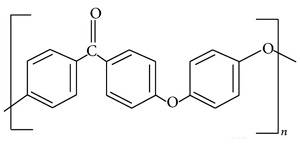

Peek ka molekiyɔmu jɔcogo bɛ Kɛ ni etɛri kulu fla ni keton kulu kelen-kelenw ye. O labɛn kɛrɛnkɛrɛnnen bɛ a ka jogo kabakomaw di mɔgɔw ma.

Peek ka kemikaliya formula ye C19H14O3 ye. A ka CAS nimɔrɔ ye 29658-26-2 ye.

Peek ka sinti .

Peek dilanni bɛ taabolo damadɔw de la:

Monomɛri labɛnni:

Monomɛri jɔnjɔnw: 4,4’-difluorobenzophenone ani hydroquinone .

hydroquinone bɛ furakɛ ni basigi barikama ye i n’a fɔ karɔbɔni natɔmu .

Polimerizasiyɔn kɛcogo:

A bɛ sɔrɔ funteni caman na (300°C lamini na) .

A bɛ kɛ aprote solvant polaire kɔnɔ (misali la, diphelyl sulfone) .

A bɛ tali kɛ nucléophile aromatique substitution .

Isolation ani saniya:

O kɛcogo in bɛ na ni peek ka polimɛri kɔkolo gɛlɛn gɛlɛn ye. O de y'a To Peek bɛ Se ka funteni muɲu fo ka Se 240°C ma. o nafolo ninnu faamuyali nafa ka bon kosɛbɛ ni aw bɛ jateminɛ kɛ . Pikiri molding tolerances ka ɲɛsin peek yɔrɔw ma .

Peek cogoyaw .

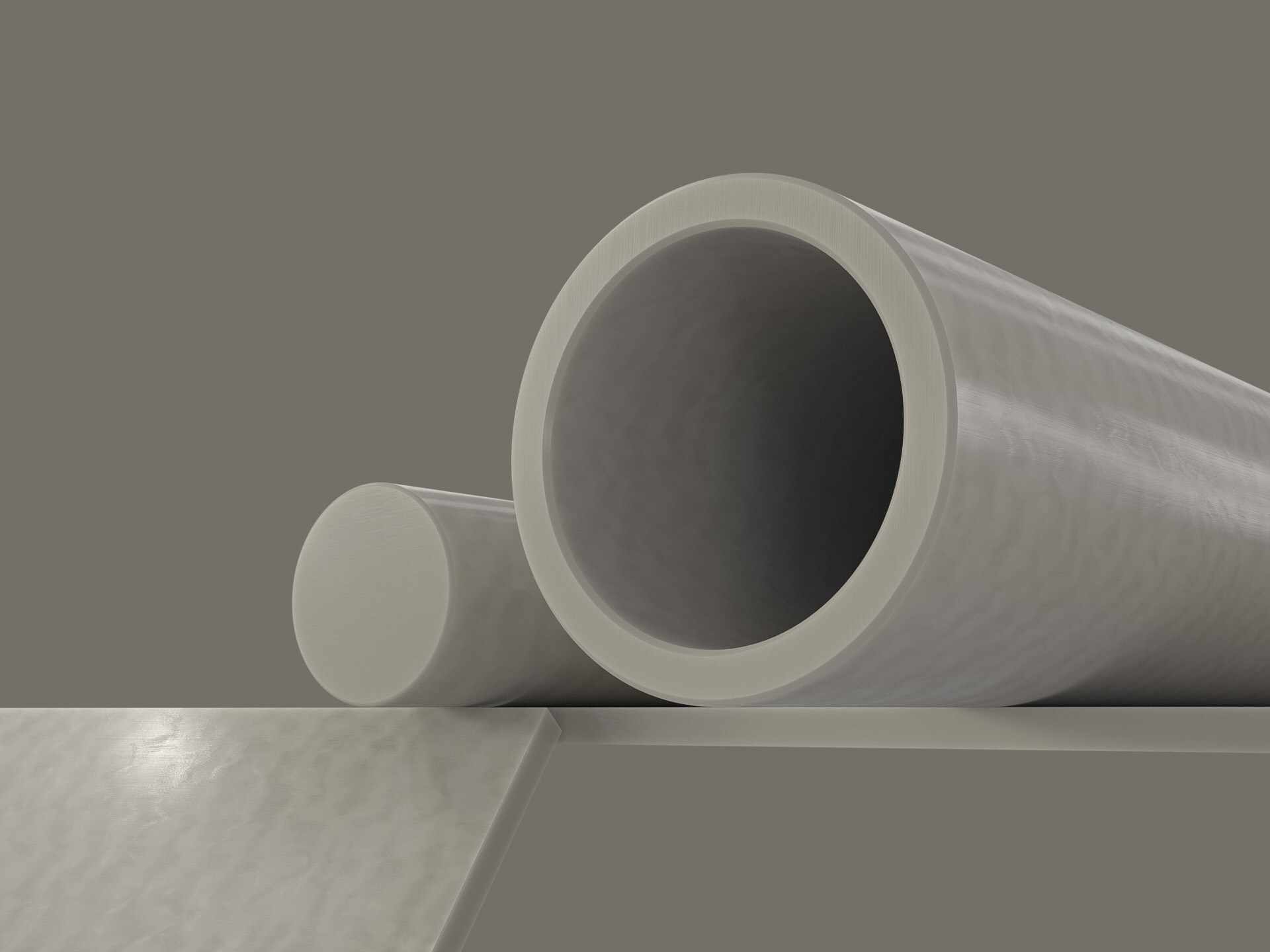

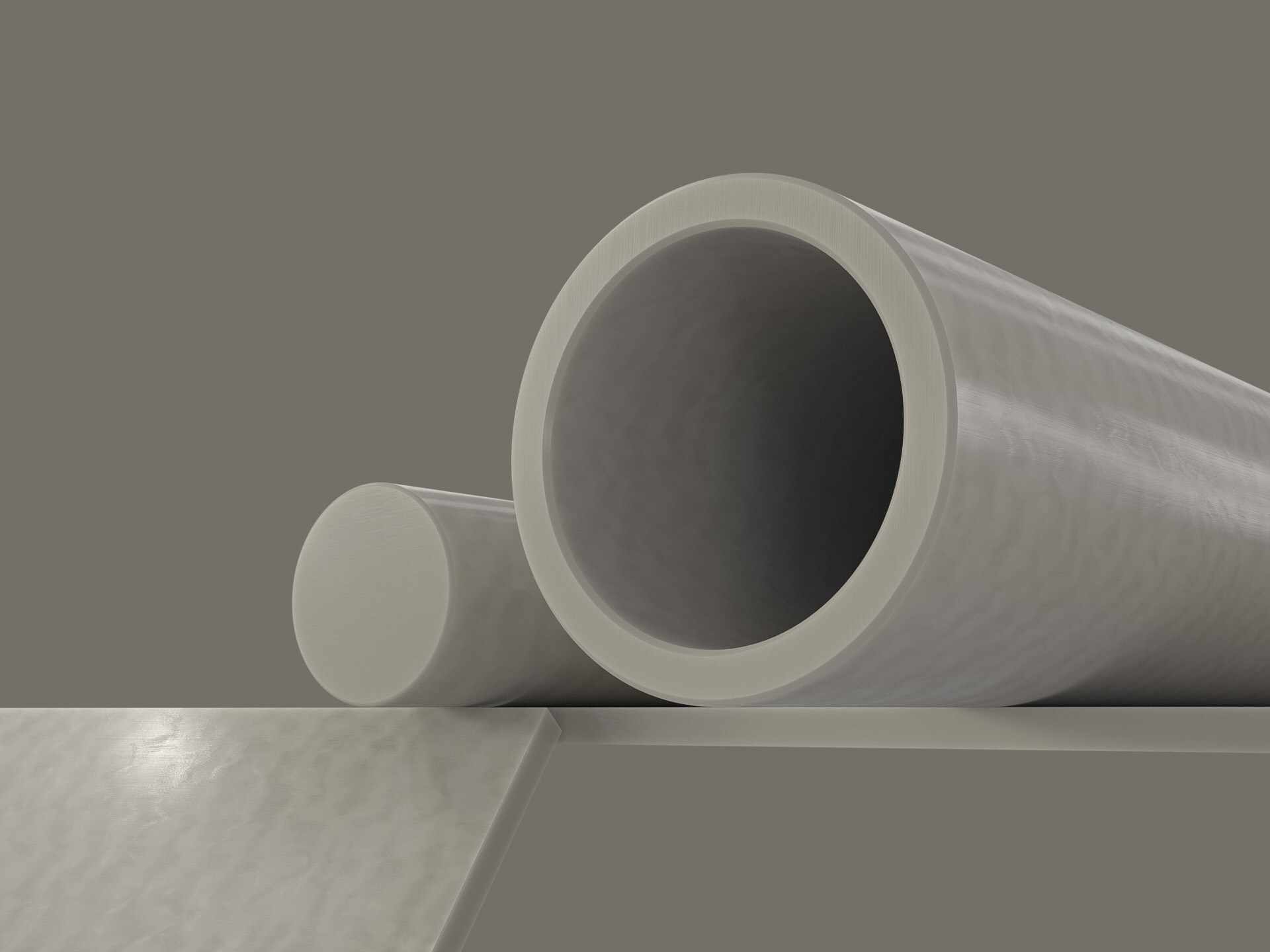

Peek bɛ sɔrɔ cogoya caman na walasa a ka bɛn fɛn dilanni taabolo suguya caman ma:

| sɛbɛn | ɲɛfɔli . |

| Pellets . | Granules misɛnw, minnu bɛ kɛ kelen ye pikiri kɛli kama . |

| mugu . | Fɛn finmanw ka ɲɛsin compression molding ma, 3D sɛbɛnni . |

| Rods . | Stock cogoyaw ka ɲɛsin masinw ma minnu bɛ kɛ ka kɛɲɛ ni mɔgɔw sago ye . |

| Granules . | I n’a fɔ peletiw, minnu bɛ kɛ ka kɛɲɛ ni fɛn caman ye . |

Formulaire kelen-kelen bɛɛ bɛ nafa kɛrɛnkɛrɛnnenw di baara kɛrɛnkɛrɛnnenw ma. Formulaire ɲuman sugandili nafa ka bon kosɛbɛ walasa ka baara kɛcogo ɲuman ni baara kɛcogo ɲuman sɔrɔ.

Peek Plastic ka jogo ɲumanw .

Peek bɛ waso ni nafolo faralen ɲɔgɔn kan cogo kɛrɛnkɛrɛnnen na. U b' a kɛ a bɛnnen don .

Farikolo yɔrɔw .

Peek farikolo cogoyaw b’a to a bɛ bɔ kɛnɛ kan ɛntɛrinɛti plastikiw cɛma:

density: 1,26 - 1,32 g/cm³

A yecogo: Opaque, Beige Kulɛri .

Kristali: Semi-Crystalline structure .

A kristalɛ bɛ se ka ji suguya caman kɛlɛ cogo ɲuman na. O kɛcogo fana bɛ Peek ka sɛgɛn baarakɛcogo n’a hakɛ sabatili bonya.

Mekaniki jogo .

Peek bɛ a yɛrɛ bonya ni masin fanga kabakoma ye:

Tensile fanga: 90-100 MPa .

Modulu tensile: 3,5 - 3,9 GPA .

Flexural fanga: 170 MPa .

Modulu flexural: 4,1 GPA .

A bɛ se ka kɛ ko a bɛ se ka kɛ (Izod notched): 80-94 J/M .

O jogo ninnu bɛ To u cogo la hali ni funteni kɔrɔtalen don. Peek ka gɛlɛya n'a ka fanga b'a kɛ fɛn ɲuman ye min bɛ kɛ ka baara ɲini, o bɛ tali kɛ plastiki wɛrɛw la minnu bɛ baara kɛ kosɛbɛ i n'a fɔ . ultem (PEI) ..

thermal properties .

Peek ka funteni cogoya ye danfara ye:

A bɛ se ka wuli yɔrɔ min na (TM): 343°C .

Glass transition température (TG): 143°C .

Funteni funteni hakɛ (HDT): 152°C ni 1,8 MPa ye .

Sumayako: 0,25 W/(M·K)

Coefficient de expansion sumayalen: 47 μm/(m·k) .

O nafolo ninnu b’a to Peek ka se ka baara kɛcogo sabati sigidaw la minnu ka bon kosɛbɛ, o min nafa ka bon kosɛbɛ . Plastiki pikiri kɛcogo ..

Plastiki min bɛ funteni kunbɛn kosɛbɛ: Peek .

kemikɛli nafaw .

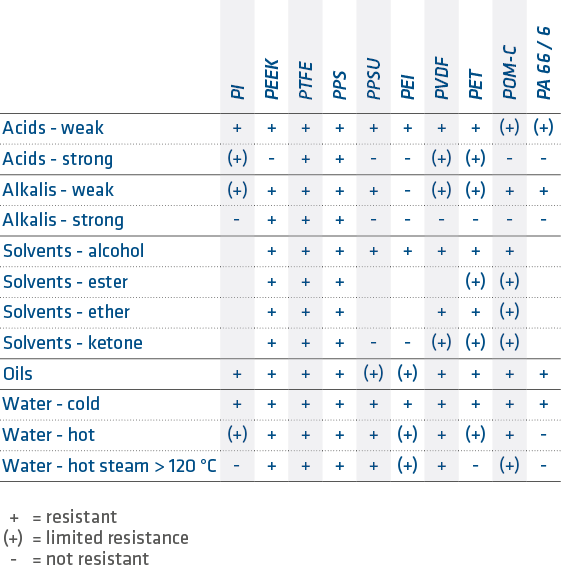

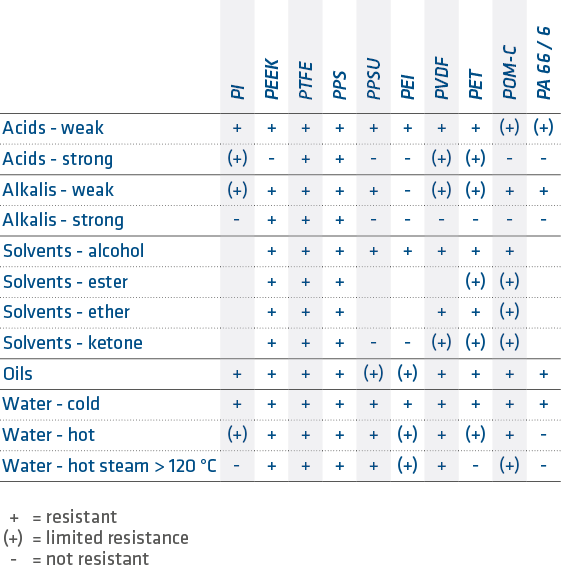

Peek bɛ kemikɛli kɛcogo ɲuman jira:

A bɛ se ka kɛ fura fanba ye minnu bɛ sɔrɔ fɛnɲɛnamaw ni fɛnɲɛnamafagalanw na .

Jiko gɛlɛya ɲumanba (ni waji, ji, kɔgɔji) .

Radiation resistance ka bon .

A bɛ to a sabatilen na kemikɛli sigida gɛlɛnw na. O bɛ Peek kɛ fɛn ɲuman ye baarakɛcogo nɔgɔlenw na.

peek chimique resistance .

Kuranko nafaw .

Peek ka kuran cogoya ye ko ye min ka kan ka kɔlɔsi:

Dielektriki fanga: 20 kV/mm .

Volume resistivité: 16 x 10^15 Ω·cm

Surface Resistivity: 10^13 Ω .

O jogo ninnu b’a to u ɲɛ bɛ kɛ fɛn ye min bɛ se ka kɛ fɛn ye min ka ɲi kosɛbɛ funteni hakɛ caman na.

Nafamafɛn wɛrɛw .

Peek bɛ nafa wɛrɛw di:

Aw bɛ se ka a don: coefficient de friction (0,25 dynamique) .

Biocompatibilité: A bɛnnen don furakɛlifɛnw ni minɛnw ma .

Flame Retardancy: V0 Rating (Ul 94) ka jigin ka se 1,45 mm ma .

A ka ji minta dɔgɔyali (0,5% sanga 24 kɔnɔ) bɛ kɛ sababu ye ka dimension (hakilila) sabatili kɛ. Peek ka saniya bangenen b’a to a bɛnnen don so saniyalen sigidaw ma. O nafolo ninnu b’a to u bɛ se ka kɛ sugandili ɲuman ye baara caman na ni i ye a suma ni fɛn dilanni fɛɛrɛ tɔw ye i n’a fɔ . Die casting ..

Peek plastiki baarakɛcogo .

Aerospace .

Aerospace kɔnɔ, Peek bɛ baarakɛcogo ɲuman ni dannaya di. Aplikasi minnu bɛ sɔrɔ tuma caman na, olu ye:

Peek fanga, a sabatili ani a girinya dɔgɔyali nafa ka bon kosɛbɛ aerospace kɔnɔ.

Mobili .

Peek bɛ se ka cogoya gɛlɛnw muɲu mobili sigidaw la:

A ka kemikaliya ni a ka funteni bɛ se ka kɛ sugandili ye min bɛ se ka da a kan.

Furakɛli

Peek ye biological ye ani a bɛ se ka sɛnɛ. A bɛ kɛ ka caya furakɛli la:

Peek bɛ banabagatɔw lakanani ni u ka minɛnw ka ɲɛnamaya janya.

Elektroniki .

Elektroniki la, Peek bɛ insulasi ni sabatili ɲuman di:

Peek b’a ka nafaw mara cogoya juguw la.

tulu & gazi .

Peek bɛ petoroli ni gazi sigidaw gɛlɛyaw muɲu:

A bɛ baara kɛcogo dafalen di juguya cogoyaw la.

Dumuniko ɲɛnabɔli .

Dumuniko la, Peek bɛ saniya ni sɛgɛnbaliya di:

Peek bɛ dumuniw lakanani ni u minɛnw sabatili sabati.

Peek plastiki kalasi .

Peek bɛ sɔrɔ kalasi suguya caman na. U kelen-kelen bɛɛ bɛ nafolo kɛrɛnkɛrɛnnenw di minnu dabɔra baara kɛrɛnkɛrɛnnenw kama.

Unfilled (Virgin) Peek .

Unfilled peek ye a cogo saniyalen ye. A bɛ:

A ka ɲi kosɛbɛ baarakɛminɛnw na minnu bɛ saniya ni saniya ɲini, i n’a fɔ semikɔndukiriw dilanni ani furakɛli minɛnw.

Fibre de fibre verre resorteur .

Glass fibre barika bonya bɛ Peek ka nafaw bonya:

fanga ni gɛlɛya bɛ bonya (modulu la fo ka se 10 gPa ma) .

Sumaya sabatili ka bon (HDT fo ka se 315°C ma)

Dimensions (hakɛ) sabatili ka fisa .

Sumayabana dɔgɔyali (CLTE jiginnen fo 1,1 ppm/°C) .

Kalansenw bɛ sɔrɔ 30% gilasi fibre. U ka ɲi kosɛbɛ jɔli baara la mobili, aerospace ani izini minɛnw na.

fibre de carbone en reinforcée peek .

Fibre carbone bɛ Peek ka baara kɛ ka se hakɛ bɛɛ la:

Fanga ni gɛlɛya min ka bon (Tensile fanga fo ka se 300 MPa ma)

Sɛgɛn kɛlɛli ɲumanba .

Superior don resistance .

Funteni sɛnɛcogo ka dɔgɔn (CLTE ka dɔgɔn fo 0,2 ppm/°C)

Kulɛri nɛrɛma .

Kalanso minnu bɛ ni 30% ye, olu ka ca. U bɛ kɛ sigidaw la minnu ka gɛlɛn kosɛbɛ, i n’a fɔ aerospace structures ani mobili yɔrɔw minnu bɛ baara kɛ kosɛbɛ.

Bearing Grade Peek .

Bearing grades bɛ labɛn ka kɛɲɛ ni sɛgɛn ni friction applications ye:

A bɛ dɔgɔya coefficient de friction (ni 0,10 ye) .

A ka ca a la, a bɛ se ka sɛgɛn (ka se 10x ma ka tɛmɛ Virgin Peek kan)

Sumayako ɲɛnabɔli (fo ka se 2x ma) .

Aw bɛ tulumafɛnw fara a kan (PTFE, graphite) .

U ka ɲi busiw, birikiw, ani sigilanw ma izini minɛnw, pɔnpew ani valvew kɔnɔ. Peek bearing grades ka tɛmɛ laadala nɛgɛ ni plastiki fɛnw kan.

FDA ka kalandenw ka kalan ni u ka furakɛli .

Peek kalasi dɔw bɛ FDA ka sariya gɛlɛnw dafa:

Dumuniw ka ɲɔgɔn sɔrɔli sariya labatoli (FDA 21 CFR 177.2415)

Biocompatibilité (ISO 10993, USP Classe VI)

sterilisation resistance (Autoclave, Gamma, Eto)

Kulɛriw minnu bɛ sɔrɔ u yɛrɛ la walima minnu bɛ kɛ furakɛli ye .

U bɛ kɛ dumunikɛminɛnw na, opereli minɛnw na, ani furakɛli minɛnw na minnu bɛ don u kɔnɔ. Lakanali ni saniya bɛ sabati baarakɛcogo la min ka gɛlɛn kosɛbɛ.

| Grade | Properties | applications . |

| A ma fa . | Saniya, Toughness . | Semiconducteur, Dɔgɔtɔrɔso |

| Fibre de verre (30%) . | Fanga, sabatili . | Mobili, Aerospace, Industrie |

| Fibre carbone (30%) . | Baara kɛcogo ɲuman . | Aerospace, mobili sanfɛla . |

| Muɲuli | Friction dɔgɔman & wear . | Busiw, sigilanw, birikiw . |

| FDA ka sariyaw . | Dumuni ni furakɛli lakanani . | Opereli baarakɛminɛnw, fɛnw dontaw, dumuniw dilanni . |

Yɛlɛma ni fɛn caman b’a la ka fɛn caman sɛmɛntiya.

Peek bɛ se ka ladilan walasa k’a ka nafaw yiriwa. Fura ni furakɛli suguya caman bɛ kɛ. U bɛ peek tailor ka baara kɛrɛnkɛrɛnnenw kɛ.

Filɛlikɛlaw ni barikalanw .

Filɛliw ni barikalanw bɛ Peek ka masinw ni funteni cogoyaw ɲɛ:

Filɛli suguya ni a hakɛ bɛ sugandi ka kɛɲɛ ni ɲinini wajibiyalenw ye.

Annealing and stress relieving .

Annealing and stress relieving optimize peek ka nafaw:

Annealing .

A bɛ dɔ fara kristalini kan .

A bɛ dimension sabatili bonya .

A bɛ kemikɛli ka se ka a yɛrɛ tanga .

Degun ka lafiya .

A bɛ dɔ bɔ kɔnɔna degunw na .

A bɛ WarPage ni Distorsion dɔgɔya .

A bɛ masinw ni tigɛcogo ɲɛ .

O furakɛli ninnu bɛ kɛ tuma caman na yɔrɔw la minnu dilannen don ni masinw ye walima minnu bɛ dilan.

Fura minnu bɛ kɛ ka fɛnw fara ɲɔgɔn kan .

Furakɛcogo faralenw bɛ Peek ka baara kɛcogo janya sigida gɛlɛnw na:

UV stabilisateurs .

Aw bɛ aw yɛrɛ tanga degradation ultraviolet ma .

Aw bɛ masinw ka nafaw mara kɛnɛma .

Baarakɛwaati janya tile yeelen na .

Flame retardants .

Tasuma kɛlɛli fanga bonya .

Aw bɛ dɔ bɔ sisi ni gazi bagajiw la .

Aw bɛ se ka tasumafagalanw sariyaw dafa .

U b’a to Peek ka baara kɛ ni a ye baarakɛcogo caman na.

| Modification | Effect | Baarakɛcogo . |

| Fibre de verre . | Fanga, sabatili . | Structure, Automotive . |

| Fibre carbone . | Baara kɛcogo ɲuman . | Aerospace, don yɔrɔw . |

| tulumafɛnw . | Friction dɔgɔman & wear . | birikiw, girinw, sigilanw . |

| Annealing . | Kristali, sabatili . | Yɔrɔ minnu ka ɲi, olu ye kemikɛli ye . |

| Degun ka lafiya . | Warpage min bɛ dɔgɔya . | Machine & formulaires yɔrɔw . |

| UV stabilisateurs . | Kɛnɛma muɲuli . | Kɛnɛma yɔrɔw . |

| Flame retardants . | Tasuma lakanani . | Transportation, Electronics |

Baarakɛcogo fɛɛrɛw ka ɲɛsin peek plastiki ma .

Peek bɛ se ka baara kɛ ni fɛɛrɛ suguya caman ye. U kelen-kelen bɛɛ n’a ka jateminɛw don. An ka fɛɛrɛ jɔnjɔnw sɛgɛsɛgɛ.

Pikirili Molidali .

Pikiriw dilanni ka teli ka kɛ walasa ka a yɔrɔw lajɛ minnu ka gɛlɛn:

Setup bɛnnen nafa ka bon kosɛbɛ yɔrɔw la minnu ka ɲi. Minɛn kɛrɛnkɛrɛnnenw ka kan ka Kɛ k'a sababu Kɛ funteni caman ye.

Extrusion .

Extrusion bɛ peek profiles continues dilan:

Profiles, Films, Tubes .

berew, sɛbɛnw, ani ladamucogo .

Filɛri finmanw ni membranes .

Tubuw minnu tɛ se ka kɛ ani minnu barika ka bon .

Fɔli jateminɛw .

nɛnɛba min bɛ sɔrɔ kristalɛni na .

Jibolisiraw walima nɛnɛbɔlanw .

Annealing ka ɲɛsin dimension sabatili ma .

Nɛnɛ hakɛ bɛ nɔ bila fɛn labanw na. A ka kan ka kɛ ka ɲɛ fɛn kelen-kelen bɛɛ la.

3D sɛbɛnni .

3D Printing bɛ dilancogo hɔrɔnya di peek yɔrɔw ma:

Peek ye gɛlɛya sɔrɔ 3D sɛbɛnni na. Nka a bɛ se ka kɛ sababu ye ka yɔrɔw kɛ minnu ɲɔgɔn tɛ, minnu bɛ baara kɛ kosɛbɛ.

Machining .

Peek bɛ se ka kɛ masin ye i n’a fɔ nɛgɛw:

turning , milling, drilling .

CNC ka minɛnw standard .

Baarakɛminɛn minnu bɛ kɛ ni nɛgɛ ye, minnu bɛ se ka kɛ fɛn ɲumanw ye .

Setup rigide ani baara kɛcogo .

Baarakɛminɛnw sugandili ani u doncogo koɲɛw .

Fɛɛrɛ ɲumanw bɛ sɔrɔ . Tolerances sirilenw . Baarakɛminɛnw doncogo bɛ se ka kɛ nafama ye ka da a kan a bɛ se ka a yɛrɛ minɛ.

Fɛɛrɛ wɛrɛw .

Peek bɛ se ka baara kɛ cogo wɛrɛw la:

Molding compression .

Casting .

Welding .

O fɛɛrɛw bɛ Peek ka baarakɛcogo suganditaw bonya. U bɛ Kɛ baara kɛrɛnkɛrɛnnenw ni wajibiw kama.

| Fɛɛrɛ | Baarakɛcogo misali | jɔnjɔnw |

| Pikirili Molidali . | Yɔrɔ gɛlɛnw, hakɛ caman . | Funteni caman, Mold Design . |

| Extrusion . | Profiles, Films, Tubes . | Cooling, Dimensional Contrôle . |

| 3D sɛbɛnni . | Personnalisés, prototypes . | Warping, layer bonding . |

| Machining . | Yɔrɔ minnu ka ɲi, olu hakɛ ka dɔgɔ . | Baarakɛminɛnw doncogo, chip control . |

| Molding compression . | Siginiden nɔgɔmanw, yɔrɔ minnu ka bon . | Premouage, degun . |

| Casting . | prototypes, runs misɛnw . | Matériel de moule, shrinkage . |

| Welding . | Jɛmukan, Lajɛba . | Surface labɛnni, paramɛtɛrɛw . |

Walasa ka faamuyali dafalen sɔrɔ plastiki baaracogo fɛɛrɛw kan, minnu bɛ kɛ Peek kama, aw bɛ se ka an ka gafe ɲɛ 10nan lajɛ . Plastiki pikiri kɛcogo ..

Dilancogo jateminɛw bɛ kɛ peek yɔrɔw kan .

Kogow janya ani u jateminɛcogo .

Kogo janya bɛ nɔ bila fanga la, a gɛlɛyali la, ani a dilanni na:

Aw bɛ a laɲini ka kɛ kelen ye (± 0,025 in/0,64 mm) .

Aw bɛ aw yɛrɛ tanga tilayɔrɔw ma minnu ka bon (>0,16 in/4 mm) walasa ka u bali . Sinsin taamasiyɛnw ni yɔrɔ lakolonw .

Aw bɛ kɔkiliw ni kɔkiliw kɛ ka barika don a la, ni a janya ye 50-60% ye kogoba la .

Design ka ɲɛsin . Angles draft (1-2°) walasa ka bɔli nɔgɔya ani ka tiɲɛni bali .

Geometry ɲuman bɛ fɛnw baaracogo ɲɛ ani a bɛ mɔli facogo n’a bɔli nɔgɔya. Aw bɛ baara kɛ ni coring ni hollowing ye walasa ka tilayɔrɔw dɔgɔya ani ka fɛnw tacogo dɔgɔya.

Shrinkage ani Warpage Control .

Peek bɛ dɔgɔya kosɛbɛ (1-2%) nɛnɛ waati la, o bɛ se ka kɛ sababu ye ka Warpage sɔrɔ:

Aw bɛ kogo janya kelen kɛ walasa ka nɛnɛ ni dɔgɔyali sabati hali .

Aw bɛ dɔgɔyali makɔnɔnen don mɔbili dilanni na (1,5% ye daminɛ ɲuman ye)

Balannako Gating and Filling Walasa ka jibɔ ni tansiyɔn tilali kelen sɔrɔ .

Aw bɛ nɛnɛ hakɛ ni funteni hakɛ kɔlɔsi walasa ka danfara dɔgɔyali dɔgɔya .

Warpage bɛ Kɛ k'a sababu Kɛ diferential shrinkage ye a yɔrɔw dakunw ni ɲɔgɔn cɛ. A bɛ se ka dɔgɔya ni dilancogo ɲuman ye (misali la, simetriki jateminɛ) ani baarakɛcogo (misali la, nɛnɛ dɔɔni dɔɔni).

Krecɛnya ni sɛgɛn kɛlɛli .

Peek bɛ ni creep ni sɛgɛn kɛlɛli ɲumanba ye, nka a bɛ se ka bonya ka taa a fɛ ni dilancogo ye:

Aw bɛ aw yɛrɛ tanga nkɔni ni notiw ma, minnu bɛ se ka degun camanba lase mɔgɔ ma ani ka faraw daminɛ .

Aw bɛ radii caman kɛ (>0,06 in/1,5 mm) ani filɛtiw walasa ka degunw tila ɲɔgɔn na cogo kelen na .

Orient Reinforcement fibres ka ɲɛsin degunba ma walasa ka fanga bonya kosɛbɛ .

Kɔrɔsili degun hakɛw ni wotoro boli walasa ka to fɛn in ka muɲuli dan kɔnɔ .

Ka doni ta waati jan kɔnɔ, o nafa ka bon kosɛbɛ walasa ka se ka baara kɛ cogo la min bɛ se ka da a kan a yɔrɔ bɛɛ la. Aw bɛ baara kɛ ni sɔgɔli ni fɛnw dalajɛli ye yɔrɔw la minnu ka gɛlɛn kosɛbɛ walasa ka fanga ni gɛlɛya sabati.

wear and friction optimization .

Peek bɛ ni sɛgɛnlafiɲɛbɔ ni ɲɔgɔndan nafama ye, min bɛ se ka ɲɛnabɔ ni dilancogo ye:

Aw bɛ baara kɛ ni yɔrɔ nɔgɔlenw ye minnu bɛ sɔgɔ (RA <0.8 μm) walasa ka dɔ bɔ sɔgɔsɔgɔninjɛ ni sɛgɛn na .

Aw bɛ aw yɛrɛ tanga abrasive ma ni yɔrɔ gɛlɛnw walima yɔrɔ gɛlɛnw ye, o bɛ se ka sɛgɛn teliya .

Aw bɛ tulumafɛnw don a kɔnɔ i n’a fɔ tulumafɛnw, jimarayɔrɔw, walima yɛrɛlafililan faralenw .

A’ ye furuɲɔgɔnya minɛn bɛnnenw sugandi (misali la, nɛgɛ, seramiki) ka da Tribologique wajibiyalenw kan .

A dilanni bɛnnen bɛ sɛgɛn ni ɲɔgɔndan dɔgɔya, ka yɔrɔw lamagatɔw ka baarakɛwaati janya i n’a fɔ birikiw, girinw ani sigilanw. Aw bɛ a lajɛ ka baara kɛ ni Peek ka biriki kɛrɛnkɛrɛnnenw ye minnu bɛ kɛ ka baara kɛ ni fɛn caman ye.

Dimensions sabatili ni tiɲɛni .

Peek bɛ dimension stabilité ɲuman di ka da a ka ji minɛcogo dɔgɔyali kan ani gilasi jiginni funteni ka bon. Tiɲɛni bɛ se ka kɛ ni dilancogo ni baarakɛcogo ɲuman ye:

Aw bɛ tolerances sirilenw kɛ (±0,002 IN/0.05 mm) walasa ka hakɛw ni u bɛnnenw sɔrɔ .

Aw bɛ a to a ka dɔgɔya kelen na (1,5%) a dilanni na walasa a ka fɛn caman Changements de mélding kɔfɛ .

Aw bɛ gating ni ejection kɛ ka fɛn tiɲɛni ni degun tolenw dɔgɔya .

Aw ye jateminɛ kɛ annealing la min bɛ kɛ ka mɔgɔw dɛmɛ ka degunw lajɔ ani ka sabatili ɲɛ .

Yɔrɔ tigitigiw, minnu bɛ sabati, olu nafa ka bon baara nafamaw la i n’a fɔ aerospace, furakɛli ani ɛntɛrinɛti. U bɛ a to baara kɛcogo basigilen, a lajɛli nɔgɔya, ani a ka dannaya kuntaalajan.

| Design aspect | key considerations | nafaw . |

| Kogo ka bon . | Uniform (±0,025 in), aw bɛ aw yɛrɛ tanga >0,16 in ma, kɔkiliw 50-60% . | Fanga, modulabilité, sink minimum . |

| Shrinkage ani Warpage . | Balance Gating, 1,5% allowance, dɔɔnin dɔɔnin. | Dimensional accuracy, minimal distorsion . |

| Creep ani sɛgɛn . | Radii >0.06 IN, Fibre Orientation, Contrôle de stress . | dannaya kuntaalajan , fanga ka bon . |

| wear and friction . | Surfaces smooths (RA <0.8 μm), tulumafɛnw, fɛnw fila-fila . | Baarakɛwaati janyalen, friction low . |

| Dimensions sabatili . | Tolerances ±0.002 IN, A ka kan ka dɔgɔya cogo kelen na, annealing . | Precision, consistance, nɔgɔya lajɛ . |

Peek ni plastiki wɛrɛw suma ɲɔgɔn na .

Peek ye thermoplastiques ye minnu bɛ se ka baara kɛ kosɛbɛ. Nka a bɛ se ka suma ni fɛn wɛrɛw ye minnu bɛ taa ɲɛ? An ka a lajɛ ka ɲɛ.

| Propriété | Peek | PEI | PPS | PTFE | PI . |

| Max. service temp. (°C) | 260 | 170 | 240 | 260 | 400 |

| Tensile fanga (MPa) . | 100 | 105 | 80 | 25 | 150 |

| Modulu flexural (GPA) . | 4.1 | 3.3 | 4.0 | 0.5 | 3.5 |

| IZOD impact notched (KJ/M⊃2;) . | 7 | 6 | 3 | 2 | 4 |

| kemikɛli resistance . | Ɲuman ɲuman | Ɲuman ɲuman | Ɲuman ɲuman | Kabakoma | Duman |

| Aw bɛ resistance don . | Ɲuman ɲuman | Duman | Duman | Fisa | Duman |

| Coefficient de Friction . | 0,10-0,25 . | 0,20-0,35 . | 0,15-0,30 ye . | 0,05-0,10 ye . | 0,10-0,25 . |

| ji minɛcogo (%) . | 0.5 | 1.2 | 0.05 | <0,01 . | 1.5 |

Peek ni Pei (ultem) .

PEI (polyetherimide) , min bɛ dɔn ni tɔgɔ ye ko Ultem, o ye polimɛri wɛrɛ ye min bɛ baara kɛ kosɛbɛ:

Peek fanga ka bon, a ka gɛlɛn, ani a ka funteni sabatili ka bon .

Peek tensile fanga: 100 MPa, PEI: 105 MPa

Module de flexural peek: 4,1 GPA, PEI: 3,3 GPA .

Peek Glass Transition Temperature (TG): 143°C, PEI: 217°C

Peek b’a ka masinw mara ni funteni caman ye (260°C ni 170°C baarakɛcogo basigilen)

PEI bɛ ni dimension stabilité ɲuman ye, a bɛ ji minɛ ka dɔgɔn, ani a ka dielektriki fanga ka bon .

u fila bɛɛ bɛ ni kemikɛli kunbɛncogo ɲuman ye ani tasuma kunbɛncogo danma .

Peek ka tɛmɛ PEI kan funteni jugumanba la ani masin doni na. PEI ye sugandili ɲuman ye jɔli ni kuran baara la.

Peek ni PPS .

PPS (polyphenylene sulfide) ye fɛn ye min bɛ se ka kɛ fɛn ye min bɛ se ka kɛ fɛn ye min bɛ se ka kɛ fɛn ye min bɛ se ka kɛ fɛn ye min bɛ se ka kɛ fɛn ye min bɛ se ka kɛ fɛn ye.

Peek fanga ka bon, a bɛ se ka a yɛrɛ minɛ, ani a bɛ se ka sɛgɛn .

Peek tensile fanga: 100 MPa, PPS: 80 MPa

peek notched izod impact fanga: 7 kJ/m², PPS: 3 kj/m²

PPS ka kemikaliya ka fisa, kɛrɛnkɛrɛnnenya la asidi barikamaw, basiw, ani furajiw .

Peek sɔngɔ ka gɛlɛn nka a bɛ masinw ka baarakɛcogo ɲuman ni funteni sabatili di .

PPS ka nɔgɔn ka baara kɛ ni a ye (a bɛ jigin yɔrɔ min na) wa a ka ji minɛcogo ka dɔgɔn .

Peek ye sugandili ɲuman ye ka ɲɛsin masinw ni tribolozi baarakɛcogo ma. PPS bɛnnen don sigidaw ma minnu bɛ kɛ ni kemikɛli ye ani porozɛw musaka minnu bɛ musaka caman bɔ.

Peek ni PTFE ye .

PTFE (polytetrafluoroethylene), min bɛ dɔn ni tɔgɔ ye ko Teflon, o ye fluoropolimɛri ye min ɲɔgɔn tɛ:

Peek fanga ka bon kosɛbɛ, a ka gɛlɛn, wa a bɛ se ka sɛgɛn .

Peek tensile fanga: 100 MPa, PTFE: 25 MPa

Module de flexural peek: 4,1 GPA, PTFE: 0,5 GPA .

PTFE ye coefficient de friction (0,05-0,10) ani a ka fisa ni fɛn bɛɛ ye minnu tɛ fɛn ye .

Peek bɛ se ka funteni caman muɲu fiɲɛ na (260°C ni 260°C baara kɛli ka taa a fɛ)

PTFE ye kemikaliya ye ka tɛmɛ ani a bɛ se ka fura bɛɛ kɛlɛ a bɛ se ka kɛ .

Peek bɛnnen don kosɛbɛ fɛnw jɔcogo, doni-ta-baaraw ani doncogo la. PTFE ka fisa ni baarakɛcogo ye min bɛ kɛ ni fɛn ye min tɛ fɛn caman kɛ, min tɛ fɛn ye, ani min tɛ kɛ ni fɛn ye min tɛ kɛ ni fɛn ye.

Peek ni poliimidiw (PI) .

Polimidi (PI) ye denbaya ye min kɔnɔ, polimɛriw bɛ yen minnu bɛ funteni caman bɔ, minnu bɛ baara kɛ kosɛbɛ:

Peek ka gɛlɛya ka bon, a ka fanga ka bon, ani a ka sɛgɛn .

Peek elongation ka lafiɲɛbɔ: 50%, PI: 10-30%

peek notched izod impact fanga: 7 kJ/m², PI: 3-5 kJ/m²

PI dɔw, i n’a fɔ PMR-15 ani BPDA-PPD, olu bɛ se ka funteni hakɛ camanba muɲu (ka se 400°C ma) .

Peek ka nɔgɔn ka baara kɛ (thermoplastic vs. thermoset) wa a bɛ se ka kɛ ni kemikɛli ye ka ɲɛ .

PIw bɛ kɛ ka caya i n’a fɔ finimuguw, filimuw, fiɲɛw, ani fɛnɲɛnamafagalanw .

Peek ye sugandili ɲuman ye min bɛ kɛ ka ɲɛsin baarakɛcogo ni tribolozi baarakɛcogo caman ma. PIw bɛ kɛ ni funteni hakɛ caman sɔrɔli mago bɛ a la, a ka ca a la, aerospace ni elekitoroniki la.

Hali n’o sangaɲɔgɔnma in bɛ tali kɛ plastiki la min bɛ se ka baara kɛ kosɛbɛ, a ka kan ka kɔlɔsi ko baara dɔw la, o fɛnw bɛ se ka ɲɔgɔn sɔrɔ ni nɛgɛ barikamaw ye. Misali la, aerospace baarakɛcogo la, ɛntɛrinɛti injiniyɛriw bɛ se ka sugandi peek ni aluminiyɔmu nɛgɛw cɛ minnu fanga ka bon i n’a fɔ . 6061 ani 7075 aluminiyɔmu ..

Walasa ka baarakɛcogo caman sɔrɔ, ɛntɛrinɛti injiniyɛriw bɛ se ka jateminɛ kɛ plastikiw la minnu ka ca i n’a fɔ . ABS (Acrylonitrile Butadiene Styren .

Sigida ni sabatili fanw ka ɲɛsin Peek ma .

Peek ka se ka segin a cogo kɔrɔ la .

Peek ye thermoplastique ye min bɛ se ka segin ka kɛ fɛn wɛrɛ ye:

A bɛ se ka wuli ka segin a kan siɲɛ caman .

Segin-ka-bɔnyew ye masinw ni kemikaliw lasegincogo ye .

Peek recyclé bɛ a ka fɛn fɔlɔw fanba mara .

A bɛ se ka ɲagami ni peek walima polimɛri wɛrɛw ye .

Recycling Peek bɛ dɛmɛ ka tiɲɛniw dɔgɔya ani ka nafolo mara. O ye fɛn nafamaba ye fɛn dilanni na.

Kuwame ka baarakɛcogo ɲuman sɔrɔli .

Peek dilanni bɛ fanga sɔrɔ kosɛbɛ:

A bɛ baara kɛ ni fɛɛrɛ ye min tɛ furaji ye (polimerizasiyɔn min bɛ funteni wuli kosɛbɛ) .

O bɛ dɔ bɔ mago la min bɛ se ka kɛ sababu ye ka fanga sɔrɔ solvant (solvant) sɔrɔli la .

Fɛn minnu bɛ kɛ , olu bɛ sabati , wa u man kan ka ta kɛrɛnkɛrɛnnenya la .

Peek ka baarakɛcogo ɲuman bɛ sira di dilancogo nɔgɔmanw ma minnu bɛ baara kɛ ka ɲɛ .

O kow bɛ kɛ sababu ye ka fanga dɔgɔya ani ka fɛnɲɛnamafagalanw bɔ. U bɛ mɔgɔ ɲɛnafin kɛ sugandili ye min bɛ sigida lakana.

Ɲɛnamaya kɛcogo jateminɛ .

Ɲɛnamaya kɛcogo jateminɛ (LCA) kalanw y’a jira ko Peek ka sabatili nafaw:

Peek yɔrɔw bɛ baara kɛ waati jan kɔnɔ, ka dɔ bɔ u nɔnabila magow la .

U bɛ se ka nɛgɛmafɛnw bila u nɔ na minnu ka gɛlɛn, ka dɔ bɔ sɛnɛfɛnw na .

Peek ka funteni hakɛ caman sɔrɔli bɛ se ka kɛ sababu ye ka taabolo ɲumanw sɔrɔ .

A ka kemikaliya bɛ dɔ bɔ a la ko a ka kan ka kɛ ka fɛnw lakana .

A ka ɲɛnamaya bɛɛ kɔnɔ, Peek bɛ nafa sɔrɔ sigida la. A bɛ dɛmɛ don nafolo sɔrɔcogo ɲuman na ani ka dɔ bɔ fɛnɲɛnamafagalanw bɔli la.

| Aspect | nafa . |

| Segin-ka-bɔnyew . | Nɔgɔ dɔgɔyali, nafolo maralenw . |

| Kuwame ka baarakɛcogo ɲuman . | Dɔgɔyali ni fɛnɲɛnamafagalanw bɔli . |

| Ɲɛnamaya kɛcogo ɲuman . | Baarakɛwaati jan, dilancogo ɲumanw . |

Farankan

Peek Plastic bɛ jogo kɛrɛnkɛrɛnnenw di ɲɔgɔn ma, i n’a fɔ fanga caman, funteni kɛlɛli, ani kemikaliya. O nafolo ninnu b’a to Peek bɛ se ka baara kɛ baara caman na iziniw kɔnɔ i n’a fɔ aerospace, furakɛli, ani mobili. Peek ka jatew, a ka baarakɛcogo ani a ka dilancogo jateminɛw faamuyali fɛ, ɛntɛrinɛti injiniyɛriw bɛ se k’a seko bɛɛ kɛ.

Ladilikanw: A bɛ se ka kɛ ko aw bɛ a fɛ ka a bɛɛ kɛ plastiki ye .