Polyphthalamide (PPA) na gem-chenja insay injinɛri plastic. Yu dɔn ɛva tink bɔt wetin mek plastic dɛn we gɛt ay pafɔmɛnshɔn rili impɔtant na di industri dɛn? PPA na sɛmi-kristalayn, aromat polyamide we de gi supia trɛnk ɛn ɔt rɛsistɛns.

Insay dis post, yu go lan yunik prɔpati, aplikeshɔn, manufakchurin kɔnsidareshɔn, modifyeshɔn ɛn kɔmpiashɔn wit ɔda injinɛri plastic dɛn fɔ PPA plastic, we de gi valyu insayt to dizayna ɛn manifakta dɛn.

Wetin na polyphthalamide (PPA)?

PPA, ɔ Polyphthalalamide, na plastic matirial we gɛt ay pafɔmɛnshɔn. I de na di famili fɔ sɛmi-kristalin aromat poliamid dɛn.

PPA na pipul dɛn we sabi fɔ in spɛshal prɔpati dɛn, we inklud:

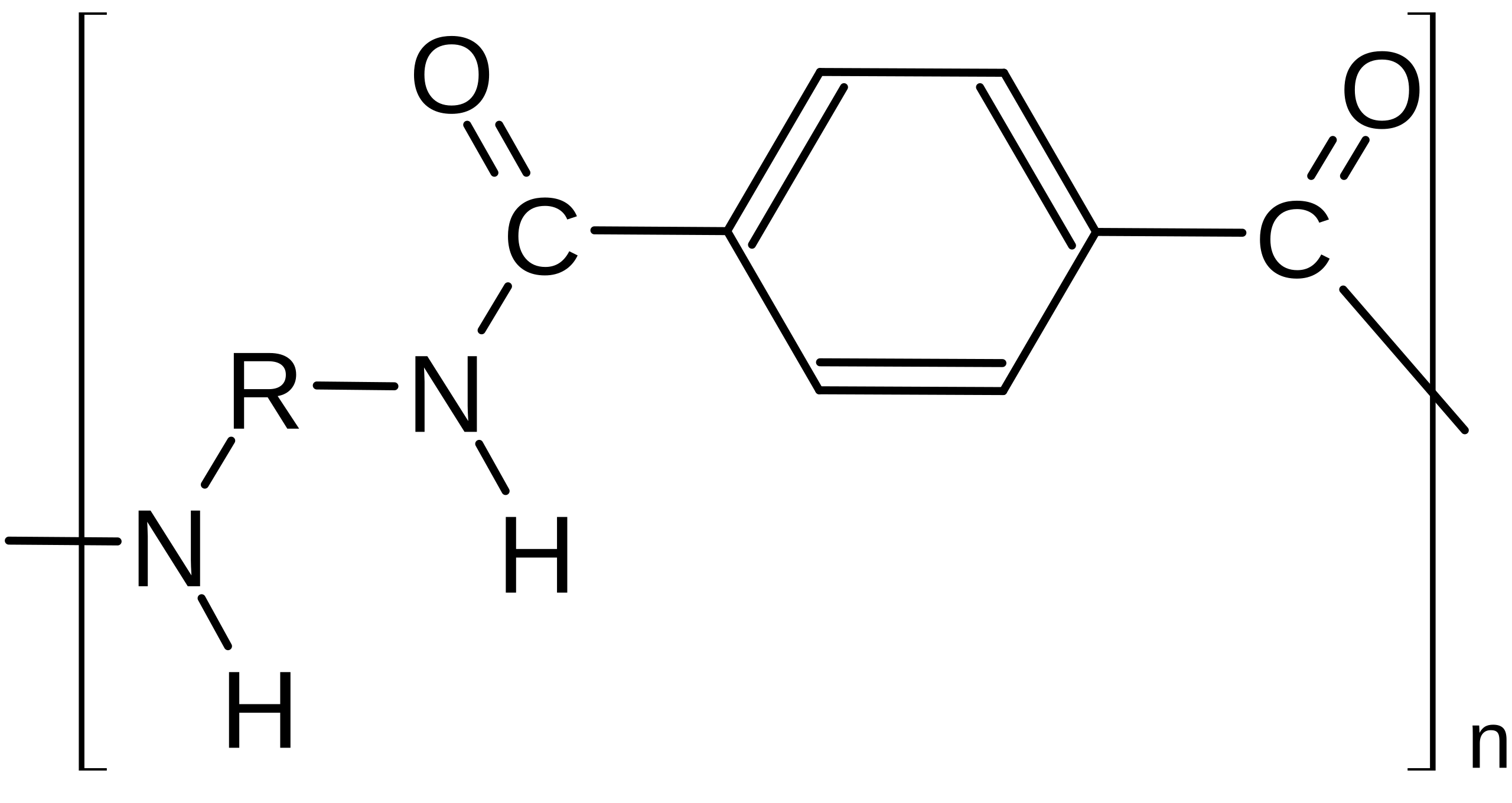

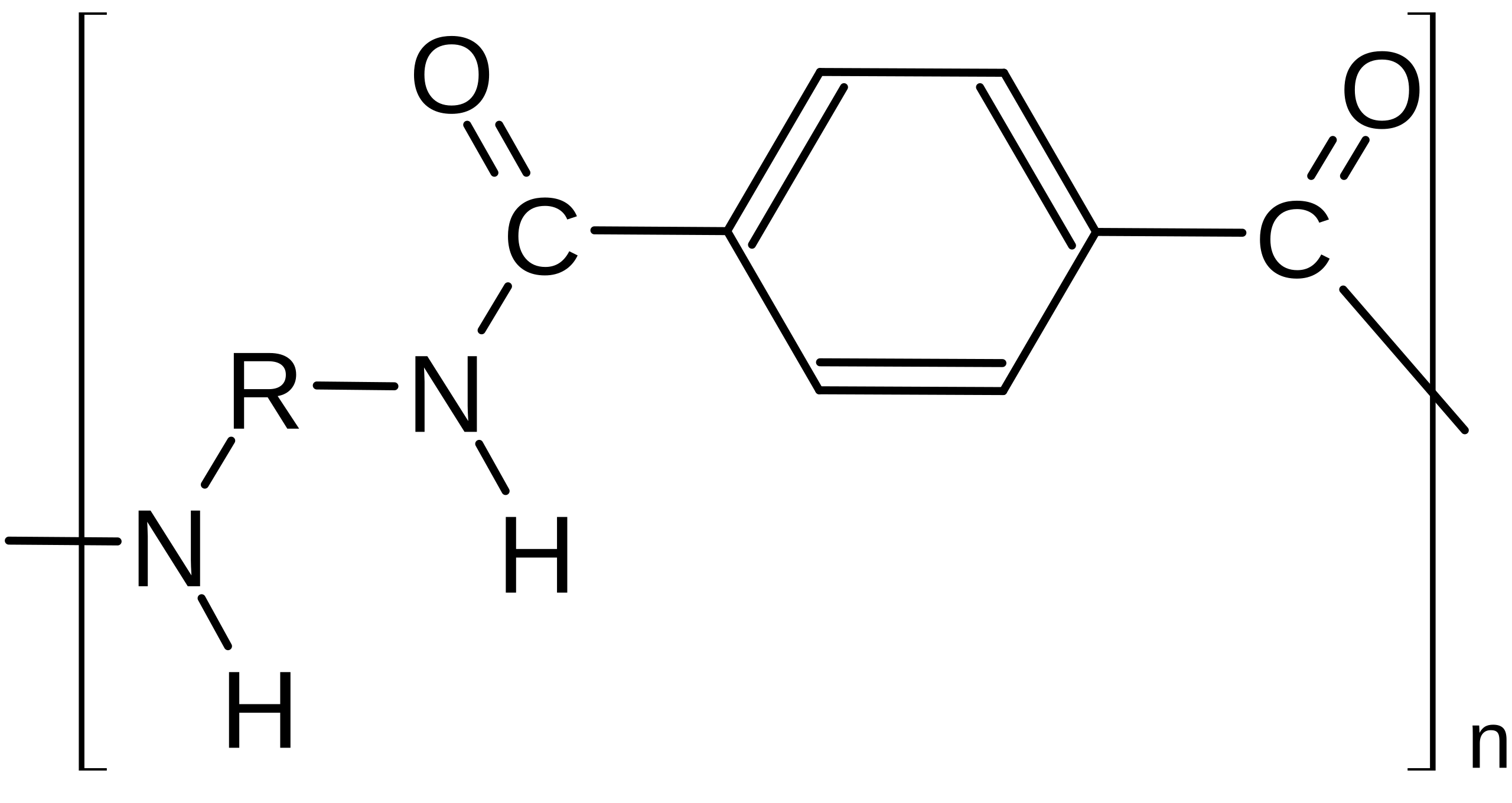

Kεmikכl kכmכshכn εn strכkchכ .

Di kemikal strכkchכ fכ PPA kכnsis fכ aromatכk ring dεm εn amid grup dεm. dis grup dεm de כltεm bכnd to alifatik grup dεm εn bεnzεdikכbכksilik asid grup dεm.

PPA in CAS nɔmba, we na wan spɛshal aydentifaya, na 27135-32-6..

Prɔpati dɛn fɔ PPA

| prɔpati | valyu . |

| Point we de mɛlt . | ay (>150°C) |

| Glas transishɔn tɛmpracha . | ay (>150°C) |

| Di tɛmpracha fɔ di ɔt distɔshɔn . | >280°C na wan wan wan wan wan wan wan wan wan wan wan wan wan wan wan wan wan |

| Tensile Strɔng . | Ay |

| Stifnɛs . | Ay |

| Notched impakt trɛnk . | ay pas plastic dɛn we dɛn kin kɔmpia . |

| Frikshɔn kɔfishin . | Lo |

| Abrasion Coefficient . | Lo |

| Krio tendency . | Lo |

| Mostɔ absɔpshɔn . | rili smɔl (0.1-0.3%) |

| Kεmikכl rεsistεns . | rili ay, ivin to agresiv kemikal dɛn . |

| Termral resistans . | Ay |

| Ilektrikal resistans . | Ay |

| Resistance to Wear . | Ay |

| Surface resistans . | Na rili ay . |

| Volyum resistans . | Na rili ay . |

| Tracking resistans . | Ay, i nɔ izi fɔ mek di wata we de insay di wata nɔ bɔku . |

| Fatigue resistans . | Wɛl dɔn |

| Dimenshɔnal stebiliti . | Eksɛlɛnt, lɔw wɔpej |

| kristaliniti . | Kɔntribyut to kemikal rɛsistɛns ɛn fayn fayn mɛkanikal prɔpati dɛn . |

| Koroshɔn rɛsistɛns . | Wɛl dɔn |

| Adhesion to elastomers . | Dairekt, witout nid fɔ bonding agents . |

| Flamabiliti fɔ mek yu bɔdi bɔn . | Nɔto inhɛrɛntly flame retardant . |

| Di Tɛmpratura fɔ di Prɔsɛsin . | ay (i go rich 350°C) |

Kɔmpia wit ɔda ɛnjinɛri plastic dɛn .

Polyphthalamide (PPA) tinap bitwin injinɛri plastic bikɔs ɔf in impreshɔnal balans fɔ mɛkanikal, tɛmral, ɛn kemikal prɔpati. Na dis na aw PPA kɔmpia to ɔda kɔmɔn wan dɛn we dɛn kin yuz ɛnjɛnɛri plastic.

PPA vs. Naylon 6/6.

We yu kɔmpia am wit naylon 6/6, PPA de gi supia trɛnk ɛn stiffnɛs, we de mek i bɛtɛ fɔ ay-pafɔmɛnshɔn aplikeshɔn dɛn. Apat frɔm dat, PPA gɛt bɔku ay ɔt rɛsistɛns, we de alaw am fɔ mentɛn strɔkchɔral intɛgriti na ɛlevɛt tɛmpracha usay naylon 6/6 go sof ɔ difɔm.

| Property | PPA | Naylon 6/6. |

| Trɛnk | Di wan dɛn we ay pas ɔl . | Ridyus |

| Stifnɛs . | Big pas | Less stiff . |

| Di wan dɛn we de fɛt fɔ mek di ples wam . | I ay pas dat (i go rich 280°C) | Modaret (we go rich ~180°C) |

PPA vs. PA46.

We dɛn kɔmpia am wit PA46, PPA de sho ay tɛmral stebiliti. Dis de mek PPA bi beta choice in aplikeshon we involv prolong exposure to high temperecha. כl tu di PPA εn PA46 de gi di sem kayn lεvεl dεm fכ kεmikכl rεsistεns, we de alaw dεm fכ du fayn fayn wan na kεmikכl agrεsiv envayroment.

| Property | PPA | PA46. |

| Tɛmral stebiliti . | Di wan dɛn we ay pas ɔl . | Ay |

| Kεmikכl rεsistεns . | Fiba | Fiba |

PPA vs. PA6.

PPA pas PA6 we i kam pan mɛkanikal prɔpati, we de gi big trɛnk, stiffnɛs, ɛn we go de fɔ lɔng tɛm. Bɔt, PPA nid fɔ gɛt ay prɔsesin tɛmpracha, we kin mek di kɔmplisiti ɛn di kɔst fɔ mek tin dɛn go ɔp we yu kɔmpia am wit PA6.

| Property | PPA | PA6. |

| Mekanikal prɔpati dɛn . | Big pas | Ridyus |

| Di Tɛmpratura fɔ di Prɔsɛsin . | Di wan we ay pas ɔl (~350°C) | di wan we smɔl (~260°C) |

Modifyin dɛn fɔ PPA .

Polyphthalamide (PPA) kin tayl fɔ mit spɛshal pefɔmɛns nid dɛn tru difrɛn modifyeshɔn dɛn. Dɛn ɛnhansmɛnt ya de mek am ivin mɔ versatile in dimand aplikeshɔn dɛn.

Riinfɔsmɛnt wit filɛs .

PPA kin riinfɔs wit glas ɔ minral filɛs fɔ bɔst in mɛkanikal prɔpati dɛn. Dɛn filla ya kin rili ɛp fɔ mek di stiff, trɛnk, ɛn nɔ ebul fɔ wɛr ɛn te. Aplikeshɔn dɛn we de bɛnifit frɔm dis inklud tɛmostayt haus ɛn pɔmp wear ring, usay fɔ de fɔ lɔng tɛm na di men tin.

Impekt modifya dɛn .

Ad elastomers to PPA de inkrisayz in toughness, we de mek am mo resilient to impact. Dis modifyeshɔn rili yusful fɔ ɔtomotiv krash kɔmpɔnɛnt dɛn, usay sef impɔtant. Ilɛktronik divays haus dɛnsɛf de bɛnifit, as dɛn nid fɔ bia wit aksidɛntal drɔp ɛn shɔk.

Inkris Toughness : I de mek shɔ se i de te ɔnda dinamik lod dɛn .

Aplikeshɔn dɛn : Ɔtomotiv Krash Pat dɛn, Ilɛktronik Hausin dɛn

Di wan dɛn we de mek di ples wam .

Dɛn ad ɔt stebyulayza fɔ alaw PPA fɔ bia wit di lɔng tɛm we dɛn de ɛksplɔz to ay tɛmpracha we nɔ gɛt digrɛdeshɔn. Dis modifyeshɔn impɔtant fɔ ɔtomotiv ɛn industrial kɔmpɔnɛnt dɛn we de wok na hot ɛnvayrɔmɛnt, lɛk ɔnda-di-hud motoka pat ɔ mashin insay industrial prɔses.

Di wan dɛn we nɔ gɛt faya fɔ mek dɛn nɔ gɛt faya .

Flame retardants na impɔtant tin fɔ aplikeshɔn usay faya sef na di tɔp prayoritɛd. Dɛn aditiv dɛn ya de mek shɔ se PPA matirial dɛn mit strɛng sef standad, we de mek dɛn fayn fɔ yuz insay ilɛktroniks, ɔtomotiv, ɛn kɔnstrɔkshɔn matirial.

Impɔtant Faya Sef : Limit kɔmbɔshɔn ɛn smok ɛmishin .

Aplikeshɔn dɛn : Ilɛktronik, Ɔtomotiv Pat dɛn, Bildin Matirial dɛn

Kompawnd PPA wit ɔda plastic dɛn .

PPA kin kɔmpawnd wit ɔda plastic fɔ mek in prɔpati dɛn bɛtɛ. Dis de mek in arenjmɛnt fɔ aplikeshɔn dɛn bɔku.

PPA we dɛn kɔmpawnd wit polyphenylene sulfide (PPS) .

We dɛn jɔyn PPA wit polyphenylene sulfide (PPS), di rizɔlt na matirial we gɛt ay trɛnk ɛn stiffnɛs. Dis blend de gi yu bak fayn fayn kemikal ɛn ɔt rɛsistɛns, we de mek i pafɛkt fɔ harsh ɛnvayrɔmɛnt usay fɔ durabiliti impɔtant.

PPA we dɛn kɔmpawnd wit naylon .

Blɛnd PPA wit naylon de ɛp fɔ mek di taf ɛn impak rɛsistɛns we de mek i kɔntinyu fɔ gɛt gud dimɛnshɔnal stebiliti. Dis kɔmbaynshɔn na fayn tin fɔ aplikeshɔn dɛn we nid fɔ balans fɔ durabiliti ɛn izi fɔ prosɛs.

Toughness and Impact Resistance : Inkris durability in ay-stress envairomɛnt dɛn .

Dimensional stabiliti : de mentɛn shep ɛn pefɔmɛns we yu de yuz am

ProcessAbility : I izi fɔ mol ɛn fɔm, mek i bi mɔ versatile

PPA we dɛn kɔmpawnd wit polyethylene terephthalate (PET)

We PPA kɔmpawnd wit polyethylene terephthalate (PET), di blɛnd de kam togɛda fayn fayn ɔt rɛsistɛns, mɛkanikal trɛnk, ɛn dimɛnshɔnal stebiliti. Apat frɔm dat, i de gi strɔng kemikal rɛsistɛns, we de mek i fayn fɔ aplikeshɔn dɛn we nid ɔl tu di tɛm we dɛn go de ɛn di prɛsishɔn.

Heat Resistance : I de bia wit ay tempɔret we nɔ gɛt dɛgradishɔn .

Mekanikal Strɔng : Strɔng ɛn Durable, I fayn fɔ strɔkchɔ kɔmpɔnɛnt dɛn

Dimenshonal stebiliti en kemikal resistans : Riliable in kemikal agresiv envairoment

Aplikeshɔn dɛn fɔ PPA .

Polyphthalamide (PPA) excels in difrɛn industri dɛn bikɔs ɔf in ɛksɛpshɔn tɛmal, mɛkanikal, ɛn kemikal prɔpati dɛn.

Ɔtomotiv Indastri .

PPA de yuz bɔku bɔku wan na di ɔtomotiv sɛktɔ, mɔ na ay-tɛmpracha ɛn kemikal dimand ɛnvayrɔmɛnt.

Fiul Layn Kɔnɛkta : PPA in ɔt rɛsistɛns ɛn kemikal stebiliti de mek am fayn fɔ fiul delivri sistem.

Thermostat Housings : I de mentɛn mɛkanikal intɛgriti ivin na ɛlevɛt tɛmpracha, ɛn mek shɔ se di injin kol we pɔsin kin abop pan.

Air Coolant Pumps : PPA in durabiliti ɛn pefɔmɛns alaw am fɔ wok ɔnda di dimand kɔndishɔn.

| Otomotiv Aplikeshɔn | Bɛnifit . |

| Fiul Layn Kɔnɛkta dɛn . | Hɛt ɛn kemikal rɛsistɛns . |

| Tɛmostayt Hausin dɛn . | Mentɛn strɔkchɔ na ay temps . |

| Air Coolant Pumps . | Durable ɔnda taf kɔndishɔn dɛn . |

Ilɛktronik Indastri .

PPA in tɛmral ɛn ilɛktrik prɔpati dɛn de mek am pafɛkt matirial fɔ ilɛktronik kɔmpɔnɛnt dɛn we nid ay durabiliti.

LED mounts : I de handle di hot we LED dɛn de jenarayz we i de gi strɔng strɔkchɔral sɔpɔt.

Waya ɛn Kebul Protɛkshɔn : PPA de gi insuleshɔn ɛn protɛkshɔn frɔm di tin dɛn we de apin na di envayrɔmɛnt, fɔ mek shɔ se dɛn rili abop pan di tin dɛn we de apin fɔ lɔng tɛm.

Kɔnɛkta : I stil de we pɔsin kin abop pan na say dɛn we gɛt ay tɛmpracha, we rili impɔtant fɔ ilɛktronik divays dɛn.

| Ilɛktroniks aplikeshɔn | bɛnifit . |

| LED mawnt dɛn . | Eksɛlɛnt Tɛmral Manejmɛnt . |

| Waya ɛn Kebul Protɛkshɔn . | Insuleshɔn ɛn Envayrɔmɛnt Sefty . |

| Kɔnɛkta dɛn . | Stebiliti in ay-temp kɔndishɔn dɛn . |

Indastrial Aplikeshɔn dɛn .

Insay industrial ɛnvayrɔmɛnt, PPA de shayn wit in wear resistans ɛn stebiliti ɔnda harsh kɔndishɔn.

Pɔmp Wear Rings : In abrasion resistans ɛn dimɛnshɔnal stebiliti de mek shɔ se dɛn de wok fayn fayn wan ova tɛm.

Mechanical Components : Bearings, gia, ɛn bushings we dɛn mek wit PPA de gi ay mɛkanikal trɛnk ɛn wear resistans.

Di pat dɛn we nɔ de kɔmɔt na di kemikal : Di kemikal we de mek di PPA nɔ gɛt kemikal de mek i fayn fɔ di say dɛn we dɛn kin yuz fɔ mek tin dɛn we nɔ fayn lɛk di plant dɛn we dɛn kin yuz fɔ mek kemikal.

| Indastrial Aplikeshɔn | bɛnifit . |

| Pɔmp Wear Ring dɛn . | Abrasion resistans, stebiliti . |

| Mekanikal komponent dɛn . | Strɔng ɛn Wear Resistance . |

| Di pat dɛn we nɔ de kemikal . | I ebul fɔ bia wit di bad bad tin dɛn we dɛn kin yuz fɔ mek di kemikal dɛn we dɛn kin yuz fɔ mek kemikal dɛn . |

Di guds dɛn we dɛn de yuz fɔ bay tin dɛn .

PPA de bak insay ɛvride kɔshɔma prɔdak dɛm, we de gi fɔ lɔng tɛm ɛn pefɔmɛns.

Tut brɔsh ɛn iabrɔsh bristl : PPA in durabiliti ɛn resistans to kemikal dɛn de mek shɔ se i de wok fɔ lɔng tɛm na pɔsin in yon kia prɔdak dɛm.

Aplayans Komponent : Dɛn kin yuz am na pat dɛn we nɔ de ɔt fɔ dishwash ɛn ɔvin, we de ɛp fɔ mek di prɔdak lɔng.

Personal Care Items : Razor handle ɛn kɔsmɛtik pak de bɛnifit frɔm PPA in durabiliti ɛn aesthetic apil.

| Kɔnsuma Guds Aplikeshɔn | Bɛnifit . |

| Tutbrɔsh/Hairbrush Bristles . | Kεmikכl rεsistεns, durabiliti . |

| Di Kɔmpɔnɛnt dɛn fɔ di Aplayans . | Hɛt rɛsistɛns fɔ tin dɛn we dɛn kin yuz na os . |

| Di tin dɛn we pɔsin fɔ du fɔ kia fɔ insɛf . | Strɔng ɛn aesthetic apil . |

Teknik fɔ prosɛs .

Fɔ prosɛs PPA nid spɛshal tɛknik dɛn. I spɛshal prɔpati dɛn de aks fɔ tek tɛm handle.

Moldin fɔ injɛkshɔn .

Injɛkshɔn moldin na di men we fɔ prosɛs PPA. Di matirial in ay mɛlt pɔynt nid fɔ mek di tɛmpracha go ɔp.

Tipik prɔsesin tɛmpracha fɔ PPA kin rich 350°C (662°F). Dɛn ay tɛmpracha ya de mek shɔ se dɛn de flɔ fayn fayn wan ɛn dɛn de ful-ɔp di mol.

Bɔt, PPA in ay mɛlt viskɔsiti de prɛzɛnt chalenj dɛn. I kin mek i nɔ izi fɔ ful-ɔp di mold.

Fɔ tek tɛm kɔntrol di prɔsesin paramita dɛn impɔtant. Tempracha, prɛshɔn, ɛn injɛkshɔn spid fɔ ɔptimayz.

| Paramita | Tipik Valyu . |

| Melt tempɔret . | 330-350 ° C |

| Mold tempɔret . | 140-180 ° C . |

| Injɛkshɔn prɛshɔn . | 100-150 MPA |

| Injɛkshɔn spid . | Soba |

I kin nid fɔ gɛt spɛshal ikwipmɛnt dɛn. Bɔku tɛm, dɛn kin nid fɔ gɛt mold ɛn barɛl dɛn we nɔ de chenj we nɔ de chenj.

Machining ɛn di say we dɛn de dɔn di wɔl .

PPA kin bi mashin yuz standad teknik. Bɔt, in ay trɛnk ɛn ɔt rɛsistɛns de poz chalenj.

Tul dɛn fɔ tinap fɔ di ay tɛmpracha we dɛn de mek we dɛn de mek mashin. Bɔku tɛm dɛn kin yuz kabayd tul dɛn fɔ mek dɛn go de fɔ lɔng tɛm.

Di rayt we fɔ mek di ples kol na impɔtant tin. Dɛn kin mek dɛn nɔ ɔt pasmak ɛn mek dɛn kɔntinyu fɔ liv dɛn layf.

| Machining Opareshɔn | Rikɔmɛnd Tul dɛn . |

| Fɔ tɔn . | Carbide insert dɛn . |

| Milin fɔ mil . | Carbide end mils . |

| Drilling . | Dril dɛn we dɛn kin yuz fɔ du kabayd . |

Bɔku tɛm, dɛn kin yuz di prɔses dɛn we dɛn kin du afta dɛn dɔn mek di mode. Dɛn kin ɛp fɔ ajɔst di sɔfays finish ɛn prɔpati dɛn we dɛn want.

Polishing kin mek di say we dɛn de mek di grɔn fayn fayn wan. I de mek di aesthetic apil bɛtɛ.

Annealing de rilivu di strɛs dɛn we de insay. I de improve dimenshonal stebiliti.

Abrasive blasting kin mek mat ɔ tɛkstɔr finish. I de gi dizayn fleksibiliti.

Teknik dɛn fɔ Asɛmbli .

PPA komponent dɛn kin assembled yuz difrɛn we dɛn. Di choice dipen pan di aplikeshɔn ɛn dizayn rikwaymɛnt dɛn.

Welding na wan kɔmɔn tɛknik fɔ jɔyn PPA pat dɛn. Bɔku tɛm dɛn kin yuz ɔltrasɔnik ɛn layz wɛldin.

Skru ɛn rivetin na bak viable opshɔn dɛn. Dɛn de gi strɔng, mɛkanikal kɔnɛkshɔn.

Ɔda asɛmbli we dɛn kin yuz na snap-fit ɛn adhesive bonding. Dɛn de gi dizayn fleksibiliti ɛn simpul tin dɛn.

| Di we aw di asɛmbli de wok | fayn fayn wan di bɛnifit dɛn we i gɛt . |

| Welding na na na na na na na na na na na na na na na na na na na . | Strɔng, pɔrmanent jɔyn dɛn . |

| Skrut fɔ skru . | Rimovable, Mechanical Kɔnɛkshɔn . |

| Rivɛtin . | Simpul, strɔng mɛkanikal fastɛns . |

| Snap-fit | Kwik, izi asɛmbli . |

| Adhesive bonding we de adhesive . | Versatile, jɔyn difrɛn matirial dɛn . |

Di we aw dɛn kin pik di we aw dɛn kin pik pipul dɛn kin dipen pan difrɛn tin dɛn. Di tin dɛn we dɛn nid fɔ du, di tin dɛn we dɛn nid fɔ du fɔ mek dɛn gɛt trɛnk, ɛn di we aw dɛn de mek di tin dɛn we dɛn de mek na di men tin dɛn we dɛn fɔ tink bɔt.

Dizayn kɔnsidareshɔn fɔ PPA kɔmpɔnɛnt dɛn .

Fɔ disayn wit PPA nid fɔ tek tɛm tink bɔt. Difrɛn tin dɛn de inflɔws di pefɔmɛns ɛn manufakchurabiliti fɔ PPA kɔmpɔnɛnt dɛn.

Structural dizain optimizayshɔn .

Prɔpa strɔkchɔral dizayn impɔtant fɔ PPA pat dɛn. I de mek shɔ se i de wok fayn ɛn i go liv lɔng.

Tiknes transishɔn fɔ bi smɔl smɔl. Wantɛm wantɛm, chenj kin mek yu gɛt strɛs kɔnsɛntreshɔn.

Ribbing ɛn boss dizayn kin mek di rigid ɛn trɛnk bɛtɛ. Dɛn fɔ gɛt di rayt sayz ɛn dɛn fɔ put dɛn.

Shrinkage ɛn wɔpej fɔ kɔntrol. Difrɛn shep ɛn saiz dɛn kin nid fɔ gɛt patikyula dizayn ajɔstmɛnt dɛn.

Draft angles ɛn radius transishɔn dɛn de mek am izi fɔ pwɛl. Dɛn fɔ bi adekwayt fɔ di pat jɔyometri.

| Dizayn Ɛlimɛnt | Rikɔmɛndishɔn . |

| Tiknɛs transishɔn dɛn . | Smɔl smɔl, avɔyd fɔ chenj wantɛm wantɛm . |

| Ribbing ɛn bɔs dɛn . | Di rayt sayz ɛn di ples we dɛn put am . |

| Shrinkage ɛn wɔpej . | Kontrol fɔ difrɛn shep ɛn saiz dɛn . |

| Draft angul dɛn . | Adequate fɔ mek i izi fɔ pwɛl . |

| Radius transishɔn dɛn . | Naf fɔ pat jɔyometri . |

Hɛt mɛnejɛmɛnt ɛn tɛmal dissipeshɔn .

PPA komponent dɛn kin jenarayz ɔ dɛn kin ɛkspos to ɔt. I impɔtant fɔ mek dɛn ebul fɔ kɔntrol di ɔt fayn fayn wan.

Di chanɛl dɛn we de mek pɔsin kol kin ɛp fɔ mek di ɔt nɔ wam. Dɛn fɔ put dɛn na stratejik wan.

Dɛn fɔ tink bɔt fɔ mek di tɛmal ɛkspɛnshɔn go bifo. I kin afɛkt pat dimɛnshɔn ɛn fit.

Material selekshɔn ɛn aditiv dɛn .

Di choice fɔ PPA gred ɛn aditiv dɛn rili impɔtant. I dipen pan di patikyula aplikeshɔn rikwaymɛnt dɛn.

Riinfɔsmɛnt lɛk glas fayba ɔ minral kin ɛp fɔ mek di prɔpati dɛn go bifo. Dɛn kin impruv trɛnk, stiffnɛs, ɛn dimɛnshɔnal stebiliti.

Aditiv kin gi sɔm patikyula prɔpati dɛn. Lubrikeshɔn, UV stebiliti, ɛn flame retardans na kɔmɔn ɛgzampul dɛn.

| Aditiv | prɔpati ɛnhansmɛnt . |

| Lubrikɛnt dɛn . | Impɔtant flɔ ɛn mold rilis . |

| UV stɛbyulayza dɛn . | Resistance to UV digradishɔn . |

| Di wan dɛn we nɔ gɛt faya fɔ mek dɛn nɔ gɛt faya . | Ridyus Flamabiliti . |

Dimensional stebiliti ɛn mɔstɔ absɔpshɔn .

PPA gɛt lɔw mɔstɔ absɔpshɔn. Bɔt fɔ disayn fɔ smɔl mɔstɔ sɛnsitiviti stil impɔtant.

If yu sial ɛn protɛkt di kɔtin fayn fayn wan, dat kin mek yu nɔ it bɔku bɔku wata. Dɛn de ɛp fɔ mek di dimɛnshɔnal stebiliti kɔntinyu fɔ de.

Manufacturability ɛn prɔsesin kɔnsidareshɔn dɛn .

Disain fɔ manufakchurabiliti na di men tin. I de mek shɔ se dɛn de prodyuz fayn fayn wan ɛn i nɔ de tek bɔku mɔni.

Draft angul ɛn filɛt dɛn de mek am izi fɔ mek dɛn mol ɛn pwɛl. Dɛn fɔ put dɛn insay di dizayn.

Tooling Design fɔ akɔn fɔ PPA in ay prɔsesin tɛmpracha. Fɔ mek yu kol fayn fayn wan ɛn fɔ mek yu bɔdi kol fayn fayn wan na impɔtant tin.

Machining ɛn Surface Finishing Techniques .

PPA komponent kin nid mashin ɛn surface finishing. Di we aw dɛn kin pik di tɛknik dɛn kin dipen pan di tin we dɛn want fɔ apin.

Machining paramita dɛn fɔ optimize fɔ PPA. Di rayt tul sɛlɛkshɔn ɛn kol na impɔtant tin.

Surface finishing techniques lɛk polishing ɔ abrasive blasting kin mek aesthetics bɛtɛ. Dɛn kin ɛp bak fɔ mek di prɔpati dɛn we dɛn de yuz fɔ wok fayn bak.

Disain wit PPA nid fɔ gɛt ɔlistik we. Structural integriti, heat management, material selection, ɛn manufacturability ɔl impɔtant.

Dɔn

Fɔ dɔn, PPA plastic tinap fɔ in supia tɛmral, mɛkanikal, ɛn kemikal prɔpati dɛn. I ay ɔt rɛsistɛns ɛn trɛnk de mek am fayn fɔ diman aplikeshɔn dɛn. PPA in versatility de shayn akɔdin to industri dɛn lɛk ɔtomotiv, ilɛktroniks, industrial, ɛn kɔshɔma guds. Di ebul we i ebul fɔ pefɔm ɔnda tranga kɔndishɔn de mek i bi wan rilibul chuk fɔ bɔku prɔdak dɛn.

Tips: Yu maybe intres to di ol plastics