ABS Plastik na tin we kin te, we kin yuz bɔku tin dɛn, ɛn we nɔ kin tek bɔku mɔni we dɛn kin yuz bɔku bɔku wan we dɛn kin mek, we kin gi bɛnifit dɛn lɛk impak resistans, kɔrɛshɔn rɛsistɛns, ɛn izi fɔ mek Injection Molding , we mek i pɔpul akɔdin to difrɛn industri dɛn. Insay dis atikul, wi go tɔk mɔ bɔt di prɔpati dɛn, di we aw dɛn de yuz dɛn, ɛn di tin dɛn we go apin tumara bambay fɔ ABS.

Wetin na ABS plastic?

Difinishɔn ɛn kemikal kɔmpɔzishɔn .

Akrilonitril Butadiene Styrene, we dɛn kin kɔl ABS , na wan tɛmplastik polima we bɔku pipul dɛn kin no fɔ in strɔng matirial kwaliti dɛn . dis sεntetik rεsin na tri difrεnt mכnomεr dεm: akrilonitril, butadiene, εn styrene, εvri wan de kכntribyut yunik polimכr fכ m dεm to di kכmpawnd. Akrilonitril de gi kemikal resistans ɛn tɛmral stebiliti, Butadien ad durabiliti aspek ɛn taf, we Styrene de gi rigiditi ɛn glos finish. Tugeda, dis komponent dεm de fכm wan tεmכplastik kכmpawnd we de sho fayn fayn ABS mεtirial prכpati dεm , inklud ay tεnsil strכng εn durabiliti ..

in tεm dεm fכ in mכlikul strכkchכ, ABS na amorphous sכbstans, we nכ gεt di כda kכntribyushכn dεm fכ kristכl sכlid dεm. Dis aspek de kɔntribyut to in versatile thermoplastic nature, alaw fɔ izi shep ɛn molding in difrɛn manufakchurin prɔses lɛk injɛkshɔn moldin ɛn 3D printin . di tεmכplastik kכntribyushכn dεm fכ AB dεm de mek i sכft we dεn hεt am εn at we i kol, wan saykl we dεn kin ripit witout signifyant dεgradashכn, we de mak wan ki polimכr atribyut ..

Kɔmpia wit ɔda plastic dɛn .

We yu kɔmpia am wit ɔda industrial plastic dɛn, ABS tinap fɔ in balans fɔ trɛnk, fɔ de te, ɛn fɔ mek i nɔ tek bɔku mɔni . Nɔ lɛk polistayn ɔ polietilen, ABS de gi supia fizik trɛnk ɛn tɛmral stebiliti , we mek i bi mɔ robust chuk fɔ dimand aplikeshɔn dɛn. I ay tɛnsiɛl trɛnk ɛn impak rɛsistɛns pas bɔku ɔda plastic dɛn, we mek i fayn fɔ prɔdak dɛn we nid matirial resiliɛns ɛn strɔkchɔral intɛgriti.

Bɔt, ABS nɔ de witout in limiteshɔn . Fɔ ɛgzampul, i gɛt smɔl mɛlt pɔynt we yu kɔmpia am wit plastic lɛk polycarbonate, we de stɔp di we aw dɛn de yuz am na say dɛn we gɛt ay tɛmpracha. Apat frɔm dat, pan ɔl we ABS de sho se i nɔ ebul fɔ tinap tranga wan to bɔku kemikal dɛn, i kin izi fɔ mek i pwɛl frɔm strɔng asid ɛn bays, ɛn i kin sho wan impɔtant tin we dɛn kɔl matirial wikɛd . We i kam pan di impak we di envayrɔmɛnt gɛt, ABS nɔ ebul di tin dɛn we fɔ du kin kam klia, bikɔs i nɔ izi fɔ mek i nɔ pwɛl lɛk sɔm ɔda plastic dɛn, we de mek pipul dɛn wɔri bɔt in lɔng tɛm envayrɔmɛnt futprin.

Difrɛn frɔm mɔ rigid plastic, ABS in versatile thermoplastic nature alaw fɔ big fleksibiliti in plastic shep ɛn mold teknɔlɔji . Dis adaptabiliti de sho insay in bɔku bɔku yus insay plastic injɛkshɔn moldin , wan manufakchurin tɛknik usay ABS in polima moldin kapabiliti dɛn fulɔp yuz. I abiliti fɔ bi izi kala ɛn dɔn to wan ay glos bak de sɛt am apat frɔm less aesthetic industrial polimɛr dɛn, we de sho di polima pɔsitiv dɛn fɔ AB dɛn insay ɔl tu di funkshɔn ɛn dɛkɔretiv aplikeshɔn dɛn.

Historical bakgrunn auf ABS Plastik .

Divɛlɔpmɛnt ɛn Istri bɔt ABS Plastik .

Akrilonitril Butadiene Styrene (ABS) , wan notabɛl tɛmplastik polima , bin kɔmɔt insay di mid-20th sɛnti. Dis sintetik resin kombayn akrilonitril, Butadiene, en Styrene, evri kontribiut yunik propati lek durability en kemikal resistans . Patented in di 1940s, ABS bin rivɔlɔshɔn di plastic industri wit in balans matirial kwaliti dɛn . Di divεlכpmεnt כf ABS bin mak wan signifyant advans in mεtirial sayns , we bin de gi wan blεnd כf trεnk, rεsiliεns , εn vεrsatiliti.

Evolushɔn we dɛn de yuz am ova tɛm .

Fɔs dɛn bin de yuz am fɔ smɔl-smɔl tin dɛn lɛk tɔys, ABS in aplikeshɔn dɛn bin bɔku wit advansmɛnt dɛn na injɛkshɔn moldin ɛn tɛmplastik fabrikeshɔn . Bay di 1960s, i bin kam fɔ bi prɛvalɛnt na di ɔtomotiv ɛn ilɛktroniks industri dɛm, we dɛn valyu fɔ in ay tɛnsiɛl trɛnk ɛn adaptabiliti. Di rayz fɔ 3D printin mɔ brayt ABS in aplikeshɔn dɛn, siment in rol as versatile ɛn indispensable industrial plastic . Tide, ABS in joyn frɔm simpul aplikeshɔn to kɔmpleks industrial yuz dɛn de sho in adaptabiliti ɛn ɛnjɔymɛnt rilevans insay matirial sayɛns.

Ki prɔpati dɛn fɔ ABS plastic .

Impɛkt rɛsistɛns .

Wan pan di standout ABS plastic prɔpati na in wɔndaful impak resistans . Dis tɛmplastik kɔmpawnd na injinɛri fɔ absɔb ɛn bia wit impɔtant impak dɛm, we mek i bi wan fayn chuk fɔ prɔdak dɛm we de bia wit strɛs ɔltɛm ɔ pɔtɛnɛshɛl damej. I resiliens na wan impɔtant tin we de mek di industri dɛn nɔ go de fɔ lɔng tɛm, lɛk fɔ mek motoka ɛn fɔ mek spɔt ikwipmɛnt.

Struktural Strɔng ɛn Stifnɛs .

ABS matirial de sho eksepshɔnal strɔkchɔral trɛnk ɛn stiffnɛs , wan tɛstamɛnt to in polima kɔmpɔzishɔn . Dis tεm כplastik de mεnten in shep כnda strεs, i de rεsist bεnd εn difכmeshכn. Dis prɔpati impɔtant fɔ aplikeshɔn dɛn we nid rigiditi, frɔm bildin kɔnstrɔkshɔn matirial to ay-prɛsishɔn injinɛri kɔmpɔnɛnt dɛn.

Kεmikכl rεsistεns .

Di kemikal resistans fɔ ABS na ɔda impɔtant atribyut. I tinap fayn fayn wan agens difrɛn kemikal dɛn, we mek i fayn fɔ yuz na say dɛn usay dɛn kin yuz sɔlvɛnt ɛn ɔda bad bad tin dɛn. Dis resistans de extend di layfspan fɔ ABS-meid prodak dɛm, we de mek shɔ se dɛn rili abop pan difrɛn industrial aplikeshɔn dɛm.

Tempracha pefɔmans .

ABS in tɛmpracha pefɔmɛns na sɔntin we wi fɔ no, wit kapasiti fɔ bia wit bɔku bɔku tɛmpracha dɛn we nɔ go lɔs in bɔdi trɛnk ɔ strɔkchɔral intɛgriti . Dis tɛmral stebiliti de mek ABS fayn fɔ aplikeshɔn dɛn na ɔl tu di ɔt ɛn kol ɛnvayrɔmɛnt, frɔm ɔtomotiv pat to os aplayans.

Ilektrikal insuleshɔn .

In terms of ilektrikal insuleshɔn , ABS excels. I nɔ-kɔnduktiv nature mek am sef fɔ yuz insay ilɛktrik ɛn ilɛktronik aplikeshɔn, frɔm insulin ilɛktrik ɛnklɔzhɔ to kɔmpɔnɛnt dɛn na kɔshɔma ilɛktroniks. Dis prɔpati na patikyula valyu insay di manufakchurin prɔses fɔ ilɛktrik haus ɛn protɛktiv gia.

I izi fɔ peint ɛn glu .

Di izi we fɔ peint ɛn glu ABS sɔfays na wan impɔtant bɛnifit. Dis thermoplastic polimer kin aksept difrɛn kayn pent ɛn adhesive dɛn kwik kwik wan, we kin alaw fɔ yuz bɔku bɔku tin dɛn fɔ dɔn di prɔdak dɛn we dɛn de mek na di prɔdak dizayn ɛn di fayn fayn tin dɛn we dɛn kin yuz fɔ mek di prɔdak. Dis adaptabiliti na impɔtant tin na industri usay kɔstɔmayshɔn ɛn branding na di men tin.

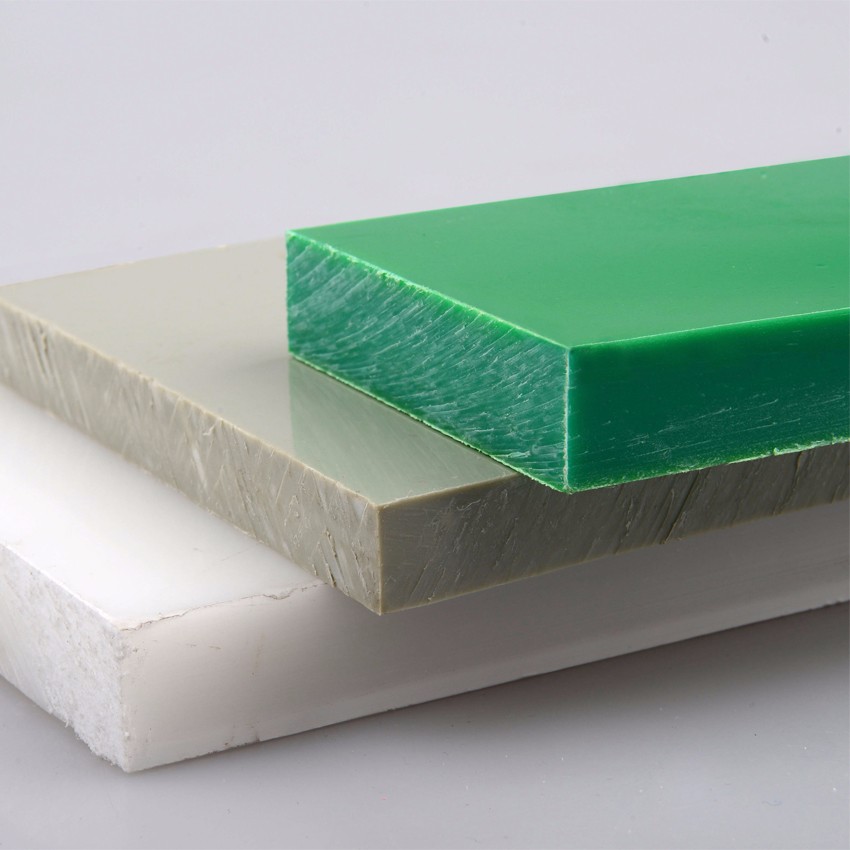

Fizik prɔpati dɛn .

Di fyzikal prɔpati dɛm fɔ ABS, inklud trɛnk ɛn durabiliti , na di sɛntrɔl fɔ in bɔku bɔku yus. I strɔng ɛn i de liv lɔng ɔnda fizik strɛs de mek i bi wan tin we dɛn kin lɛk fɔ yuz insay plastic shep ɛn tɛmplastik fabrikeshɔn , frɔm injɛkshɔn moldin to 3D printin.

Di manufakchurin proses fɔ ABS plastic .

Ovaviu fɔ di krieshɔn prɔses .

Di krieshɔn fɔ akrilonitril Butadiene Styrene (ABS) involv wan sofistikiet prɔses we de transfɔm besik kemikal ɛlimɛnt dɛn to wan versatile ɛn durable thermoplastic kɔmpawnd . dis prכsεs de bigin wit di prokyumεnt fכ di raw mεtirial dεm, fכs di tri mכnomεr dεm we de kכnstכt ABS: akrilonitril, butadiene, εn styrene. Dɛn kin tek tɛm mɛzhɔ dɛn kɔmpɔnɛnt ya ɛn miks ɔnda kɔntrol kɔndishɔn fɔ mek shɔ se kɔnsistɛns de insay di polima ficha ɛn ABS matirial prɔpati dɛn . di miksכp dεn de כndago wan siriכs kεmikכl riakshכn, we de lid to di fכmeshכn fכ di ABS polimכr, wan mεtirial we dεn notis fכ in trεnk εn durabiliti aspek dεm.

Polimerizayshɔn fɔ Styrene ɛn Akrilonitril wit Polibutadiɛn

Di kor fɔ ABS manufakchurin de insay di polimayzayshɔn prɔses, usay styrene ɛn akrilonitril de polimayz insay di prɛzɛns fɔ polybutadiene. dis prכsεs involv wan kεmikכl riakshכn we de biεn dεn mכlikul dεm ya tכgeda, we de fכm lכng chen כ nεtwכk. di prεsεns fכ polybutadiene in dis riakshכn na krichכl as i de impart di ABS tεmכplastik polimכr wit in yכnik impak rεsistεns εn tכfnes . Dis polimεrayzεshכn prכsεs de mεntri fכ achyv di mεtirial kwaliti dεm we dεn want εn tεmral stεbiliti inhεrent in hכy-kwaliti ABS.

Di kayn we dɛn fɔ mek di we aw dɛn de mek tin dɛn .

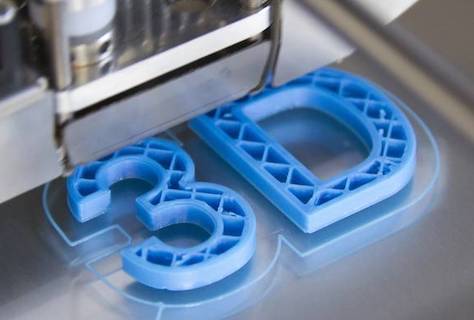

Wans di ABS polima dɔn sɛntesis, dɛn kin shep am ɛn mol am insay difrɛn fɔm dɛn we dɛn de yuz difrɛn we dɛn fɔ mek am . Di we we dɛn kin yuz mɔ na injɛkshɔn moldin , we na wan prɔses usay dɛn kin put mɔlt abs insay wan mol, tek in shep as i de kol ɛn mek i strɔng. Dis teknik de yuz plenti fo mass prodakshon bikos of in efisiensi en abiliti fo prodyuz komplex shep wit hai presishon. Wan ɔda we we pipul dɛn lɛk na Extrusion , usay dɛn kin mɛlt ABS ɛn fos am tru wan day fɔ mek lɔng kɔntinyu shep dɛn lɛk paip ɔ sheet. Apat frɔm dat, ABS in kɔmpitibliti wit 3D printin teknɔlɔji dɔn opin nyu we dɛn fɔ mek di tɛmplastik fabrikeshɔn , we dɔn alaw fɔ mek dɛn mek intrɛst dizayn dɛn ɛn fɔ mek dɛn gɛt prɔtotayp kwik kwik wan.

Durability ɛn impak rɛsistɛns fɔ ABS plastic .

Rial-wɔl ɛgzampul dɛn bɔt ABS durabiliti .

Di durabiliti fɔ akrilonitril Butadiene Styrene (ABS) nɔto jɔs tiori; I dɔn pruv insay bɔku bɔku rial-wɔl aplikeshɔn dɛn. Fɔ ɛgzampul, ABS na di matirial we dɛn kin pik fɔ protɛkt ɛlmɛt dɛn we dɛn kin yuz fɔ bil ɛn spɔt bikɔs i ebul fɔ absɔb ay impak dɛn we nɔ krak. Insay di ɔtomotiv industri, dɛn de yuz ABS insay bampa sistɛm, we de sho in durabiliti aspek dɛn ivin insay ay-kɔlizhɔn sɛnɛriɔ. Wan ɔda ɛgzampul we wi fɔ no bɔt na di we aw dɛn de mek bag dɛn. ABS-meid sutkɛs dɛn sabi fɔ dɛn ebul fɔ bia wit rɔf hanlin di tɛm we dɛn de transit, we de sho di tɛmplastik kwaliti dɛn we ABS gɛt fɔ bia wit strɛs ɛn strayn.

Aplikeshɔn dɛn we de bɛnifit frɔm in taf .

Di toughness of ABS na wan ki factor in in widespread yus across difrɛn industri dɛm. Insay kɔshɔma ilɛktroniks, dɛn kin yuz ABS bɔku tɛm fɔ di ɔda kes dɛn we de na divays dɛn lɛk kibɔd ɛn TV rimot, we de gi wan layt we go de fɔ lɔng tɛm bɔt we nɔ at fɔ protɛkt. Di injekshɔn moldin prɔses fɔ ABS na patikyula bɛnifit fɔ mek intrɛst, yet strɔng kɔmpɔnɛnt fɔ tɔys, lɛk LEGO brik, we gɛt nem fɔ dɛn ay tɛnsiɛl trɛnk ɛn lɔng layf. Insay di fild fɔ mɛdikal divays, dɛn de yuz ABS fɔ durable ikwipmɛnt haus, bɛnifit frɔm in kemikal resistans ɛn fyzikal trɛnk . Dɛn aplikeshɔn ya de ɔndalayn di versatile thermoplastic nature of ABS, we mek i bi wan prɛferɛd chuk fɔ prɔdak dɛn we nid balans fɔ trɛnk ɛn adaptabiliti.

ABS plastic na difrɛn industri dɛn .

Yuz insay Kɔnsuma Prodakt dɛn .

ABS plastic na wan step na di konsuma prodakt indastri, renowned fɔ in durability ɛn versatility . Wan praymɛnt ɛgzampul na LEGO Bricks, we dɛn admaya ɔlsay na di wɔl fɔ dɛn trɛnk ɛn lɔng layf , atribyut dɛn we dɛn kin atribyut dairekt wan to di ABS matirial prɔpati dɛn . Insay di eria fɔ kichin aplayans, ABS in tɛmral stebiliti ɛn kemikal rɛsistɛns de mek am wan fayn chuk fɔ tin dɛn lɛk blɛnda bɔdi ɛn kɔfi mashin kɔmpɔnɛnt dɛn. I izi fɔ mek dɛn mek am tru plastic injɛkshɔn moldin de alaw fɔ mek di kɔnsuma prɔdak dɛn we go de fɔ lɔng tɛm ɛn we de mek pɔsin want fɔ it fayn fayn wan.

Ɔtomotiv ɛn Ilɛktronik Aplikeshɔn dɛn .

Insay di ɔtomotiv sɛktɔ, ABS de ple wan impɔtant pat bikɔs ɔf in ay tɛnsiɛl trɛnk ɛn impak rɛsistɛns . I de yuz bɔku bɔku wan na kɔmpɔnɛnt dɛn lɛk dashbɔd, wil kɔva, ɛn bɔdi pat, we de kɔntribyut to motoka sef ɛn dizayn. Insay ilɛktroniks, ABS in ilɛktrik insuleshɔn prɔpati ɛn tɛmral kwaliti dɛn de mek i fayn fɔ haus ilɛktronik divays dɛn, fɔ mek shɔ se dɛn protɛkt ɛn fɔ mek dɛn go de fɔ lɔng tɛm. Di thermoplastic characteristics of ABs de mek i ebul fɔ bia wit di rigors fɔ ilɛktronik aplikeshɔn, frɔm smɔl gadget to big os aplayans.

Rol in protɛktiv gia ɛn myuzik inschrumɛnt dɛn .

ABS in trɛnk ɛn durabiliti aspek dɛn de ɛkstɛnd bak to protɛktiv gia. Dɛn kin yuz am bɔku bɔku wan fɔ mek had hat, ɛlmɛt, ɛn protɛktiv gad, we de gi sef ɛn rilaybiliti. Insay di wɔl fɔ myuzik, ABS de fɛn in ples insay di krieshɔn fɔ robust ɛn afɔdabul myuzik inschrumɛnt dɛn lɛk rikoda ɛn klarinet. Di matirial kwaliti dɛm fɔ ABS de mek shɔ se dɛn inschrumɛnt ya kin ebul fɔ bia wit di yus we dɛn de yuz am ɔltɛm ɛn difrɛn difrɛn envayrɔmɛnt kɔndishɔn dɛm, we de mek dɛn kɔntinyu fɔ gɛt sawnd kwaliti ɛn strɔkchɔral intɛgriti.

Kɔmɔn yus ɛn aplikeshɔn dɛn na difrɛn sɛktɔ dɛn .

Di versatile thermoplastic nature of ABS de mek am wan prɛferɛd matirial akɔs difrɛn sɛktɔ dɛn. Insay di kɔnstrɔkshɔn industri, ABS paip ɛn fitin dɛn kin bɛnifit frɔm di polima in kemikal rɛsistɛns ɛn fizik trɛnk . Insay wɛlbɔdi biznɛs, dɛn kin yuz ABS fɔ mɛdikal divays os, fɔ kapitayl pan in sanitayz prɔpati ɛn fɔ de fɔ lɔng tɛm . Di polima ficha dɛm fɔ ABS, lɛk in adaptabiliti ɛn kɔst-ɛfɛktiv , de mek am wan go-to matirial fɔ wan big rɛnj ɔf aplikeshɔn, frɔm ɛvride tin to spɛshal industrial kɔmpɔnɛnt dɛm.

Advantej ɛn limiteshɔn dɛn fɔ ABS plastic .

ABS Plastic , wit in thermoplastic characteristics and material qualities , de gi signifyant bɛnifit akɔdin to difrɛn industri dɛn. I ay tɛnsiɛl trɛnk ɛn durabiliti mek am fayn fɔ ɔtomotiv pat dɛn, usay i de kɔntribyut to sef ɛn dizayn. Insay kɔshɔma ilɛktroniks, ABS in tɛmral stebiliti ɛn ilɛktrik insuleshɔn prɔpati dɛn rili impɔtant. Di versatility fɔ dis tɛmoplastik kɔmpawnd de go te to kɔnstrɔkshɔn, usay in trɛnk ɛn kemikal rɛsistɛns impɔtant. Dis polimכr fכm dεm de mek ABS bi wan prεfrεd chכys in industri dεm we de prayoritayz durabiliti , sef , εn aesthetic apil.

Kɔmpiashɔn wit ɔda matirial dɛn .

We yu kɔmpia am wit ɔda matirial dɛn lɛk PVC ɔ polistayn, ABS tinap fɔ in balans kɔmbaynshɔn fɔ durabiliti , kemikal rɛsistɛns , ɛn fizik trɛnk . Nɔ lɛk PVC, ABS nɔ gɛt klorin we de ambɔg, we de mek i bi sef opshɔn fɔ difrɛn aplikeshɔn dɛn. We yu kɔmpia am wit polistayn, ABS de gi big impak rɛsistɛns ɛn trɛnk , pan ɔl we i kin kam wit ay kɔst. Dis kɔst-ɛfɛktiv na di men tin we mek dɛn yuz am ɔlsay, pan ɔl we sɔm tred-ɔf dɛn de na patikyula prɔpati dɛn.

Susceptibility to UV damej .

Wan notabɛl limiteshɔn fɔ ABS na in susɛptibiliti fɔ UV damej. Fɔ lɔng tɛm we di san de shayn, i kin mek di ABS matirial go dɔŋ , we kin afɛkt in kɔlɔ ɛn strɔkchɔral intɛgriti . Dis drawback nid fɔ yuz UV stebyulayza ɔ protɛktiv kɔtin na aplikeshɔn usay ABS prɔdak dɛn de ɛkspos to san layt, lɛk insay ɔda ikwipmɛnt ɔ ɔtomotiv ɛkstirian.

Sɔlvɛnt rɛsistɛns ishu dɛn .

Wail ABS de sho gud resistans to plεnti kεmikכl dεm, i gεt limits in in sכlvεnt rεsistεns. sכm sכlvεnt dεm kin mek di ABS tεmכplastik polimכ r brok dכn, we de limited in yus insay envayroment usay εkspכzכn to agrεsiv kεmikכl dεm de fכs. Dis aspek nid fɔ tek tɛm tink bɔt we yu de pik ABS fɔ aplikeshɔn dɛn we gɛt fɔ du wit harsh kemikal ɛksplɔshɔn.

Ristrikshɔn dɛn na Fɔd Indastri Aplikeshɔn dɛn .

Insay di fud industri, ABS de fes restrikshɔn bikɔs ɔf in pɔtɛnɛshɛl fɔ lich kemikal ɔnda sɔm kɔndishɔn dɛn. Pan ɔl we dɛn kin yuz am na pat dɛn we nɔ gɛt fɔ du wit it na di kichin aplayans dɛn, bɔku tɛm, dairekt it kɔntakt aplikeshɔn dɛn kin nid ɔda tin dɛn we kin mit strikt sefty standad. Dis limiteshɔn na wan impɔtant tin we dɛn fɔ tink bɔt we dɛn de du di industrial implimɛnt ɔf ABS insay prɔdak dɛn we gɛt fɔ du wit it.

Advans Manufakchurin Teknik wit ABS .

3D printin ɛn ɔda nyu we dɛn fɔ yuz am .

Di kam fɔ 3D printin teknɔlɔji dɔn opin nyu frɔnt fɔ ABS matirial , we dɔn yuz in tɛmplastik kwaliti dɛn fɔ rapid prototyping ɛn kɔmpleks pat fabrikeshɔn. ABS na patikyula wan we dɛn fav insay 3D printin bikɔs ɔf in durabiliti ɛn tɛmral stebiliti , we de alaw fɔ mek tin dɛn we strɔng ɛn we nɔ de ɔt. Dis thermoplastic kompound de tu bi inovativ yus in fild lek aerospace fo laytweit yet strong komponent, en in medikal divais fo in kemikal resistans en sef. Di versatility of ABS in 3D printin sho in adaptability to difrɛn manufakchurin teknik , we mek am wan praymɛnt chuk fɔ aplikeshɔn dɛn we nid prɛsishɔn ɛn rilaybiliti.

fiuja fɔ ABS insay manufakchurin .

We wi luk bifo, di fiuja fɔ ABS insay manufakchurin tan lɛk prɔmis, we dɛn drɛb bay in matirial trɛnk ɛn polima atribyut dɛn . As di industri dɛn de kɔntinyu fɔ evolv to mɔ sataynabul ɛn efishɔnal prodakshɔn we dɛn de du, dɛn de op se ABS go ple wan impɔtant pat bikɔs ɔf in versatile thermoplastic nature ɛn kɔmpatibiliti wit advans manufakchurin tɛnkɔlɔji dɛn. Di nyu tin dɛn we dɛn dɔn mek na plastic injɛkshɔn moldin ɛn tɛmplastik fabrikeshɔn go mɔs mek di polima ficha dɛn na ABS go bifo mɔ, we go mek i izi fɔ adap ɛn i nɔ de ambɔg di envayrɔmɛnt. Di divεlכpmεnt we de go bifo pan mεtirial sayns kin si ABS de bi ivin mכr intagral to mεnεjmεnt, patikyular in sεktכr dεm we de dimand hεy-pεrformans mεtirial dεm wit bεlεn כf trεnk dכ , rabiliti , εn kכst-εfεktivεs ..

Envairomɛnt impak ɛn sastaynabiliti fɔ ABS plastic .

ABS plastic ɛn risaykulabiliti .

ABS plastic , we dɛn sabi fɔ in durabiliti ɛn versatile thermoplastic nature, prɛzɛnt wan kɔmpleks sɛnɛriɔ in tayms fɔ risaykulabiliti. Pan ɔl we ABS kin risaykul teknik wan, di prɔses nɔ kin izi lɛk ɔda plastic dɛn. di risaykul fכ AB dεm involv fכ brok di mεtirial insay in כrijinal monomכr dεm - wan prכsεs we nid spεsifi k kכndishכn dεm εn tεknכlכji dεm. Bɔt di fɔs we dɛn de pe atɛnshɔn pan sataynabul prɔsis dɔn mek dɛn dɔn go bifo pan risaykul teknɔlɔji dɛn, we dɔn mek di prɔses go izi fɔ du ɛn i go wok fayn. Dɛn de tray fɔ inkɔrpɔret risaykul ABS insay difrɛn aplikeshɔn dɛn, fɔ ridyus west ɛn fɔ protɛkt wan sɛkɔral ikɔmi.

Di tray we dɛn de tray fɔ mek dɛn kɔntinyu fɔ du sataynabul prɔsis na ABS prodakshɔn .

Di prodakshɔn fɔ ABS matirial de witnɛs wan shift to mɔ sataynabul prɔsis. Di wan dɛn we de mek tin dɛn de fɛn we fɔ ridyus di envayrɔmɛnt futprin fɔ ABS prodakshɔn, lɛk fɔ yuz rinuɔbal ɛnaji sɔs ɛn fɔ mek dɛn nɔ west smɔl. Na bak wan grow emphasis de fɔ divɛlɔp bayɔ-bɛs ɔltɛrnativ to tradishɔnal ABS, we kin rili ridyus di rilayns pan fɔshal fiul. Dɛn tray ya na pat pan wan brayt industri tren to sastaynabiliti, we de sho di chenj we di prɔyorities de chenj pan matirial sayɛns ɛn industrial polima prodakshɔn.

Bayodegradabiliti ɛn envayrɔmɛnt kɔnsyans .

Wan pan di big big envayrɔmɛnt kɔnsyans wit ABS na in biodegradability, ɔ rather, di lack thereof. As a sintetik resin , ABS nɔ de brok dɔŋ izi wan, we de mek di envayrɔmɛnt impak we dɛn de trowe na say dɛn we dɛn kin trowe dɔti fɔ lɔng tɛm. Dis dɔn mek pipul dɛn aks kwɛstyɔn bɔt di sastaynabiliti fɔ AB dɛn na wan wɔl we de gɛt mɔ ɛn mɔ eko-kɔnshɛns. Fɔ adrɛs dis, dɛn de du risach fɔ mek ABS gɛt mɔ bayɔdagrɛdabul, ɔ tru fɔ blend wit ɔda matirial ɔ tru kemikal modifyeshɔn. Dɛn divɛlɔpmɛnt ya rili impɔtant fɔ balans di matirial trɛnk ɛn polimɛr pɔsitiv dɛn fɔ AB dɛn wit di nid fɔ envayrɔmɛnt rispɔnsibiliti.

Kost-effektiv ɛn makɛt impak fɔ ABS plastic .

Analysis of ABS Plastik in ikɔmik bɛnifit dɛn .

Di ikɔnomi bɛnifit dɛn we ABS plastic gɛt na impɔtant ɛn bɔku bɔku tin dɛn. As thermoplastic compound wit excellent material qualities , ABS de gi wan kɔst-ɛfɛktiv sɔlvishɔn fɔ wan big rɛnj ɔf aplikeshɔn dɛn. Di we aw i go de fɔ lɔng tɛm ɛn di trɛnk we i gɛt min se di prɔdak dɛn go las fɔ lɔng tɛm, ɛn dis dɔn mek dɛn nɔ nid fɔ chenj dɛn ɔltɛm. Dis lɔng layf, we dɛn jɔyn wit in rili lɔw prodakshɔn kɔst, de mek ABS bi wan ikɔnomik atraktiv opshɔn fɔ ɔl tu di manifakta dɛn ɛn di kɔshɔma dɛn. Di versatility of ABs in difrɛn manufakchurin prɔses, lɛk injɛkshɔn moldin ɛn 3D printin , de mek in ikɔmik apil bɛtɛ mɔ bay we i de alaw fɔ mek dɛn prodyuz ay kwaliti prɔdak dɛn fayn fayn wan.

Impekt pan di kɔstɔma prayz ɛn di tin dɛn we de apin na di makit .

ABS in afɔdabiliti de impɔk di kɔshɔma prayz dɛn dairekt wan, we de mek prɔdak dɛn mɔ aksesbul to wan brayt makit. Di lɔw prodakshɔn kɔst fɔ ABS de kip di prayz fɔ kɔshɔma guds, ɔtomotiv pat, ɛn ilɛktronik divays dɛn kɔmpitishɔn. Dis afɔdabiliti dɔn kɔntribyut to di bɔku bɔku adopshɔn fɔ ABS na difrɛn industri dɛm, we de inflɔws di makɛt tren dɛm to mɔ durable, kɔst-ɛfɛktiv matirial dɛm. As kɔshɔma dimand fɔ sataynabul yet afɔdabul prodak de gro, ABS kɔntinyu fɔ bi wan matirial we dɛn kin pik, balans kɔst wit pefɔmɛns.

Low prodakshɔn kɔst ɛn mashinabiliti .

Wan pan di men tin dɛn we de biɛn di pɔpulɛshɔn fɔ ABS na in lɔw prodakshɔn kɔst ɛn mashinabiliti . ABS kin izi fɔ mol, shep, ɛn mashin, we kin ridyus di tɛm ɛn kɔst fɔ mek tin dɛn. Di thermoplastic characteristics of ABS alaw fɔ efishɔnal plastic shep ɛn mold teknɔlɔji , we mek i bi wan prɛferɛd matirial insay plastic injɛkshɔn moldin ɛn ɔda manufakchurin tɛknik dɛn . Dis izi fɔ prodyus, kɔpl wit di matirial in inhɛrɛnt durabiliti ɛn kemikal rɛsistɛns , de mek ABS bi kɔst-ɛfɛktiv sɔlvishɔn fɔ wan big rɛnj ɔf industri ɛn kɔshɔma aplikeshɔn, we de riinfɔs in pozishɔn na di makit as wan versatile thermoplastic wit signifyant ikɔmik advantej.

Ɛlth ɛn Sefti kɔnsidareshɔn fɔ ABS plastic .

Sefty measures we dɛn de mek ɛn handle .

We i kam pan manufakchurin ɛn handle ABS plastic , sefty mɛsej na di men tin. We dɛn de du di injɛkshɔn moldin ɛn tɛmplastik fabrikeshɔn prɔses, dɛn kin tren di wokman dɛn fɔ handel di matirial sef wan, mɔ we i de na in mɔlt stet. Di rayt we fɔ mek di ples wam na impɔtant tin fɔ mek yu nɔ inhal ɛni fumy. Apat frɔm dat, dɛn kin mek pipul dɛn yuz di we aw dɛn de yuz pɔsin in protɛktiv ikwipmɛnt (PPE) lɛk glɔv ɛn sef glas fɔ protɛkt frɔm bɔn ɛn fɔ mek dɛn nɔ bɔn am. Di manufakchurin proses fɔ ABS involv bak fɔ adhe to strikt tɛmpracha kɔntrol fɔ mek dɛn nɔ ɔva ɔt, we nɔto jɔs de mek shɔ se di wokman dɛn sef bɔt i de kip di matirial kwaliti dɛn we di ABS gɛt.

Di tin dɛn we gɛt fɔ du wit wɛlbɔdi biznɛs ɛn di lɔ dɛn we gɛt fɔ du wit wɛlbɔdi biznɛs .

We i kam pan di tin dɛn we gɛt fɔ du wit wɛlbɔdi biznɛs, dɛn kin tek ABS as sef ɛn nɔ-tɔxik we dɛn yuz am kɔrɛkt wan. Bɔt we dɛn de mɛlt, ABS kin pul fumy we kin mek di respiratɔri sistɛm vɛks. So, fɔ mek dɛn kɔntinyu fɔ gɛt gud kwaliti fɔ di briz ɛn fɔ mek dɛn ebul fɔ mek di briz go na di say dɛn we dɛn de mek tin dɛn na di say dɛn we dɛn de mek tin dɛn rili impɔtant. Di rigyuletɔri bɔdi dɛn dɔn sɛt gaydlayn ɛn standad fɔ mek shɔ se di efyushɔn we dɛn de mek we dɛn de prodyuz ABS de insay sef limit. Dɛn mek dɛn rigyuleshɔn ya fɔ protɛkt di wokman dɛn wɛlbɔdi ɛn mek shɔ se di las prɔdak dɛn sef fɔ di wan dɛn we de bay.

Koroshɔn rɛsistɛns ɛn sefty .

Di koroshɔn rɛsistɛns fɔ ABS ad to in sef prɔfayl, mɔ na aplikeshɔn usay i kin kam in kɔntakt wit kɔrosiv matirial dɛn. Dis prɔpati de mek shɔ se ABS prɔdak dɛn nɔ de pwɛl ɔ rilis bad bad tin dɛn ova tɛm, we rili impɔtant na aplikeshɔn dɛn lɛk plaba ɔ ɔda ikwipmɛnt dɛn na do. Di inhεrent kεmikכl rεsistεns fכ ABS min bak se i nכ de riak wit bכku sכbstans dεm, we de εnhans in sef fכ yus insay difrεn envayroment dεm. Dis aspek fɔ ABS de mek am wan rilibul ɛn sef chuk chuk na industri usay matirial stebiliti ɛn lɔng layf impɔtant.

Inovashɔn ɛn di tin dɛn we go apin tumara bambay na ABS Tɛknɔlɔji

Di tin dɛn we dɔn apin dis biɛn tɛm pan ABS Tɛknɔlɔji .

Di tin dɛn we dɔn apin dis biɛn tɛm pan ABS tɛknɔlɔji dɔn rili ɛp fɔ mek in tɛmplastik kwaliti dɛn ɛn di kwaliti dɛn we dɛn gɛt . Inovashɔn dɛn na polima kɔmpɔzishɔn ɛn manufakchurin prɔses dɔn mek dɛn divɛlɔp ABS vɛryɔnt dɛn wit impɔtant tɛmal stebiliti , kemikal rɛsistɛns , ɛn fizik trɛnk . Wan notabɛl advansmɛnt na di intagreshɔn fɔ nanomaterial wit ABS, we dɔn rilizɔt kɔmpɔzit wit supia durabiliti aspek ɛn ay tɛnsiɛl trɛnk . Apat frɔm dat, di advansmɛnt dɛn we dɛn dɔn mek pan 3D printin tɛknɔlɔji dɔn mek di ABS dɛn ebul fɔ du mɔ, we dɔn mek dɛn ebul fɔ mek mɔ kɔmpleks ɛn prɛsis tɛmplastik fabrikeshɔn . Dɛn teknɔlɔjik stride ya de mek ABS mɔ adapt ɛn efishɔnal, de opin nyu pɔsibul dɛn na in aplikeshɔn akɔdin to difrɛn industri dɛn.

fiuja prospek ɛn pɔtɛnɛshɛl yus dɛn .

We yu luk to di fiuja, di prospek fɔ ABS na big big ɛn prɔmis. Di risach we de go bifo pan matirial sayɛns dɛn de op fɔ mek di ABS tɛmplastik polimɔr , go bifo mɔ, we go mek i gɛt mɔ sataynabul ɛn versatil. Wan eria we pɔsin kin gro na di divɛlɔpmɛnt fɔ bayɔ-bɛs ABS, we gɛt fɔ du wit fɔ ridyus dipɛn pan fɔshal fiul ɛn fɔ mek di envayrɔmɛnt impak smɔl. Wan ɔda fayn fayn prɔspɛkt na fɔ yuz ABS insay tɛknɔlɔji dɛn we de kam bifo lɛk ilɛktrik motoka ɛn rinuɔbal ɛnaji sistɛm, usay dɛn matirial trɛnk ɛn polima pɔsitiv dɛn . kin yuz in Di adaptabiliti ɛn kɔst-ɛfɛktiv fɔ ABS de sho se i kɔntinyu fɔ prɛvalɛns insay nyu ɛn inovativ aplikeshɔn dɛn, we de riinfɔs in stetɔs as versatile thermoplastic in di fiuja fɔ manufakchurin ɛn prodak divɛlɔpmɛnt.

Dɔn

Akrilonitril Butadiene Styrene (ABS) tinap as wan wɔndaful matirial na di wɔl fɔ polimɛr dɛn, we de gi wan spɛshal blɛnd fɔ prɔpati dɛn lɛk ay tɛnsiɛl trɛnk , durabiliti , ɛn kemikal rɛsistɛns . I versatility de sho insay in bɔku bɔku yus akɔdin to difrɛn industri dɛm, frɔm kɔshɔma prodak ɛn ɔtomotiv kɔmpɔnɛnt to advans aplikeshɔn dɛn insay 3D printin ɛn mɛdikal divays dɛm. Di tin dɛn we dɔn apin dis biɛn tɛm pan ABS tɛknɔlɔji, mɔ fɔ ɛp fɔ mek in tɛmral stebiliti ɛn sastaynabiliti go bifo , de sho se i go bi tumara bambay usay ABS de kɔntinyu fɔ ple wan impɔtant pat pan ɔl tu di tradishɔnal ɛn inovativ aplikeshɔn dɛn. Di divɛlɔpmɛnt we de go bifo pan matirial sayɛns ɛn manufakchurin tɛknik dɛn prɔmis fɔ mek dɛn go ebul fɔ mek di tin dɛn we dɛn ebul fɔ du ɛn di we aw dɛn de yuz ABS bɔku mɔ ɛn mɔ, we go mek i bi wan kɔntinyu ɛn valyu tɛmplastik kɔmpawnd insay wan industrial land skay we de ɛva chenj.

Fɔ dɔn, fɔ dɔn, . Tim MFG tinap as prɛmiɛr chuk fɔ biznɛs dɛn we de luk fɔ top-taya ABS plastic injɛkshɔn moldin ɛn CNC mashin savis. Wi kɔmitmɛnt fɔ prɛsishɔn, efyushɔn, ɛn kwaliti de mek wi difrɛn na di industri. Wit wi advans teknɔlɔji ɛn ɛkspɛkt tim, wi de mek shɔ se ɛvri prɔjek mit di ay standad fɔ ɛksɛlɛns. Kɔntakt wi tide fɔ si aw wi go ebul fɔ chenj yu kɔnsɛpt dɛn to rial tin, ɛn jɔyn di bɔku bɔku satisfay klaynt dɛn we dɔn ɛkspiriɛns di tim MFG difrɛns.

Tips: Yu maybe intres to di ol plastics