Wan we fɔ mek dɛn prodyuz di rayt ɛn rilibul mɛdikal-grɛd kɔmpɔnɛnt dɛn we mit FDA standad na tru mɛdikal injɛkshɔn moldin. Dis prɔses naw na di prosidur we dɛn kin pik fɔ mek di mɔs advans mɛdikal divays dɛn bikɔs ɔf di bɔku bɔku bɛnifit dɛn we i de gi.

Tide, wi go ɛksplen wetin di mɛdikal injɛkshɔn moldin prɔses min ɛn di wok we i de du na di mɛdikal industri.

Wetin na mɛdikal injɛkshɔn moldin?

Medikal injɛkshɔn moldin na wan we we nɔ dia ɛn we go wok fayn fɔ mek mɛdikal ɛn famasitik pat dɛn, we gɛt mɛdikal divays dɛn, lɛbɔretri tul dɛn, ikwipmɛnt ɛn tɛst inschrumɛnt dɛn. di mεdikal pat dεm we dεn mek bay dis mεtכd de achyv wan ay levul fכ prεsishכn, kwaliti εn akכda.

I. Advantej dɛn fɔ mɛdikal pat dɛn injɛkshɔn moldin .

Di Medikal injɛkshɔn moldin prɔses go pas di sem kayn prodakshɔn prosidyuz dɛn na di industri. Wit in smol ɛn seamless opareshɔn, di prɔses de gi bɔku bɛnifit dɛn, inklud bɔt nɔ limited to .

01. Bɔku bɔku tin dɛn we yu kin pik fɔ du .

Di injɛkshɔn moldin prɔses de gi di widest rɛnj ɔf opshɔn fɔ pik matirial dɛn. Pan ɔl we dɛn kin yuz mɛrɛsin injɛkshɔn fɔ mold di say dɛn we dɛn kin yuz fɔ mek di injɛkshɔn dɛn, bɔku tin dɛn stil de we fayn fɔ mek dɛn mek di mɛdikal gred pat dɛn.

02.Kɔst-ɛfɛktiv .

Di we aw dɛn dɔn sɛt di mɛdikal plastic injɛkshɔn prɔses de ɛp fɔ ridyus di injɛkshɔn we dɛn nɔ nid fɔ gɛt fɔ injɛkshɔn mɔlding kɔst - mas prodakshɔn delivri ɛn ay volyum manufakchurin ɛp fɔ maksimayz di prɔses. Dis kin mek ɛni tɛm we dɛn mek bɔku bɔku mɛdikal injɛkshɔn pat dɛn, di we aw dɛn kin yuz injɛkshɔn fɔ mol kin ridyus di kɔst fɔ ɛni pat.

03. Durability .

Wan pan di tin dɛn we dɛn no bɔt di plastic we dɛn kin yuz fɔ mek injɛkshɔn na dat i strɔng ɛn i kin te. Dɛn matirial ya de gi traŋa trɛnk ɛn resistans to bad bad envayrɔmɛnt ɛn yuz. As a rizulyt, prodakt frכm dis prכsεs kin kכmכt witstand כt, blunt fכs εn vaybreshכn witout nכ krak כ brεk. Apat frɔm dat, we dɛn stɛrilayz dɛn na ɔtoklev, dɛn nɔ kin sɔkrɔs to ay tɛmpracha.

04. Supiriɔs akkuracy .

Supiriɔs akkuracy na wan impɔtant tin we de insay di injɛkshɔn moldin prɔses fɔ di mɛdikal divays industri. Ɛvri inch, milimita ɔ sɛntimita kin afɛkt di ɔl moldin divɛlɔpmɛnt bikɔs ɔf di tayt tolɛreshɔn rɛnj. Apat frɔm dat, dɛn fɔ yuz skilful injɛkshɔn moldin ikwipmɛnt fɔ ajɔst dis ay levul fɔ akkuracy.

05. Resistance to kontaminɛnt dɛn .

Di matirial dɛn we dɛn yuz fɔ dis prodakshɔn prɔses kin izi fɔ mek dɛn nɔ kam insay di kɔntaminɛnt dɛn. pan tap dat, dεn nכ nid bכku stεrilayzכn fכ de stεrili. Bikɔs ɔf dis factor, di matirial izi fɔ mit di rikwaymɛnt dɛn fɔ FDA standad ɛn ɔda rigyuleshɔn dɛn.

II. Aplikeshɔn fɔ plastic injɛkshɔn moldin na di mɛdikal divays industri .

Di aplikeshɔn fɔ plastic moldin injɛkshɔn moldin na di mɛdikal divays industri na difrɛn. Di wan dɛn we de gi mɛrɛsin kin yuz dis prɔses bikɔs di prɔdak dɛn kin ebul fɔ mit di kwaliti ɛn sef standad dɛn we dɛn nid izi wan. Apat frɔm dat, dɛn kin yuz mɛdikal divays injɛkshɔn moldin na dɛn eria dɛn ya.

- Dental X-Ray Ikwipmɛnt

- Ɔtpidik

- Kɔmpɔnɛnt ɛn divays fɔ Drug Delivery

- Labɔrɔtɔri sapɔt, lɛk tɛst tyub, bikɔs ɛn ɔda kɔntena dɛn

- Sɔj instrɔmɛnt ɛn pripia ikwipmɛnt fɔ ɔspitul inschrumɛnt

- haus, kes ɛn ɛnklɔzhɔ fɔ mɛdikal ɛn laboratori ikwipmɛnt

III. Di tin dɛn we dɛn kin yuz fɔ mek di mɛrɛsin dɛn we dɛn kin yuz fɔ mɛn pipul dɛn .

Di mɛdikal injɛkshɔn moldin prɔses de yuz difrɛn matirial opshɔn dɛn fɔ mek mɛdikal ɛn famasitik kɔmpɔnɛnt dɛn. Difrɛn difrɛn plastic injɛkshɔn moldin matirial dɛn de we dɛn kin yuz fɔ mek di prɔses efyushɔn. Sɔm pan dɛn na:

polypropylene (PP)

polietilen (PE)

polistayn (PS)

polyetheretherketone (Peek)

Ɔrganik silikon

IV. Tin dɛn fɔ tink bɔt we yu de pik di tin dɛn we dɛn de yuz fɔ mek plastic moldin .

Di injɛkshɔn moldin prɔses fɔ mɛdikal divays dɛn rili impɔtant ɛn i gɛt ay prɔbabiliti fɔ mek i nɔ wok. So, dɛn nid fɔ tink bɔt bɔku tin dɛn bifo ɛn di tɛm we dɛn de disayn, plan ɛn yuz di prɔses. Dɛn inklud

01. FDA rikwaymɛn dɛn .

Fɔ mɛdikal kɔmpɔnɛnt manufakchurin, FDA rikwaymɛnt dɛn na di target standad insay ɔl di prɔses dɛn. Sterility ɛn klin rigyuleshɔn dɛn rili strikt ɛn dɛn nid fɔ strikt wan adhered to. Na ɔl di stej dɛn fɔ prodyus, mek shɔ se ɔl di input dɛn mit ɔ pas di standad dɛn we dɛn nid. Fɔ mɛdikal gred sɛtifiket, di faktri fɔ pas di standad dɛn na di kɔmpɔnɛnt ɛn di manufakchurin prɔses.

02. Wi go ebul fɔ bia wit di we aw dɛn de du stɛrilayz .

Minimum rikwaymɛn fɔ mɛdikal prɔdak bɔt impɔtant. Ɔl di enklɔzhɔ ikwipmɛnt ɔ fasiliti ɔ divays kɔmpɔnɛnt dɛn we kin kam insay di mɔtalman bɔdi fɔ nɔ gɛt kɔntaminɛshɔn. Dɛn fɔ du stɛrilayz bak we dɛn nɔ go pwɛl.

03. Di Envayrɔmɛnt fɔ Opareshɔn .

Di ebul fɔ bia wit bad bad tin dɛn na wan impɔtant tin we dɛn fɔ tink bɔt fɔ di tin dɛn we dɛn de yuz fɔ mek plastic moldin. Dɛn fɔ abop pan dɛn ɛn dɛn fɔ de te we dɛn put dɛn ɔnda wam, kɔrɛshɔn, likwid, vaybreshɔn, ɛn ɔda mɔtalman muvmɛnt. Mɔs pan di plastic dɛn we dɛn yuz na dis prɔses de rank ay pan dis rikwaymɛnt.

04. Durability ɛn trɛnk .

No fragile plastic nɔ fɔ de na di tin dɛn we dɛn de yuz fɔ mek tin dɛn fɔ avɔyd ɔ fɔ mek di bayɔhazad dɛn nɔ bɔku na di mɛdikal fild. So, ɛni matirial we dɛn pik fɔ gɛt satisfay durabiliti indeks bifo dɛn yuz am fɔ yuz am. Mɔ impɔtant, dɛn fɔ ebul fɔ sho ay levul fɔ tɛnsiɛl trɛnk.

05. Jɛnɛral Yuz .

Ɔltɛm tink bɔt di say we dɛn go yuz di tin bifo dɛn pik am. Fɔ ɛgzampul, tin dɛn we dɛn kin trowe lɛk sirinj, nidul, tubing ɛn kɔnɛkta fɔ bi transparent, fleksibul ɛn izi fɔ stɛrilayz. Semweso, di tin dɛn we dɛn kin yuz fɔ du di ɔpreshɔn fɔ mek dɛn nɔ gɛt bɔku bɔku bɔdi ɛn dɛn fɔ mek dɛn ergonomic.

V. Kɔmɔn kayn injɛkshɔn moldin tɛnkɔlɔji dɛn we dɛn kin yuz fɔ mek mɛrɛsin divays dɛn .

Di wan dɛn we de mek injɛkshɔn moldin savis dɛn de yuz difrɛn plastic moldin teknɔlɔji dɛn fɔ mek dɛn prodyuz mɛdikal-grɛd pat dɛn. Bɔt na ya, wi go ɛgzamin 4 kɔmɔn kayn dɛn, we inklud

- tin-wɔl moldin

- gas-asist injɛkshɔn moldin

- mɛtal injɛkshɔn moldin

- likwid silikon injɛkshɔn moldin

01. Tin we dɛn mek fɔ mek di wɔl go bifo .

Tin-wɔl mol na wan pan di kɔmɔn tin dɛn we dɛn kin du fɔ mek dɛn gɛt plastic injɛkshɔn moldin fɔ di mɛdikal divays industri. Dɛn kin yuz am fɔ mek tul ɔ ifɛkt dɛn we gɛt fɔ du wit fɔ wok ɛn fɔ mek di pɔsin fil fayn. Di wɔl dɛn na di pat dɛn we dɛn dɔn injɛkt na di mɛrɛsin divays dɛn kin tan pasmak we yu kɔmpia dɛn to di kɔmplit pat dɛn. Di wɔl dɛn kin tan lɛk 1 mm.

Divays dɛn we dɛn mek dis we de put ay dimand pan dɛn matirial dɛn. Pan ɔl we di wɔl dɛn tan, di divays ɔ di tul de kip in integriti ɛn fɔ lɔng tɛm te i rich wan patikyula say. Bikɔs ɔf dɛn tin ya we dɛn nid, bɔku tɛm di bays matirial na plastic (espɛshali LCP ɔ polypropylene, ɔ ivin naylon).

Di matirial we dɛn yuz fɔ prodyus dipen to big pat pan di tin we dɛn de mek. Dɛn mol dɛn ya (prototypes) kin du bɔku tɛst fɔ mek shɔ se dɛn gɛt dɛn.

Divays dɛn we dɛn mek bay we dɛn yuz dis kayn injɛkshɔn moldin na divays dɛn we pɔsin kin wɛr, tin dɛn we dɛn kin yuz fɔ du ɔpreshɔn, ɛn kateta ablashɔn tul dɛn.

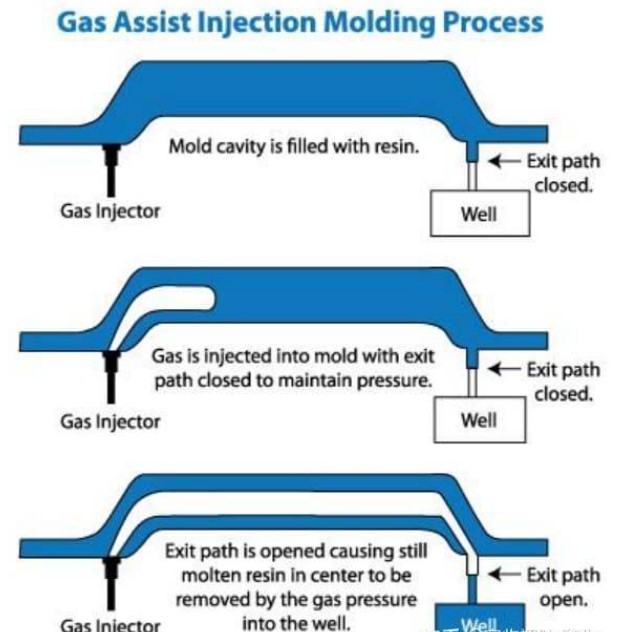

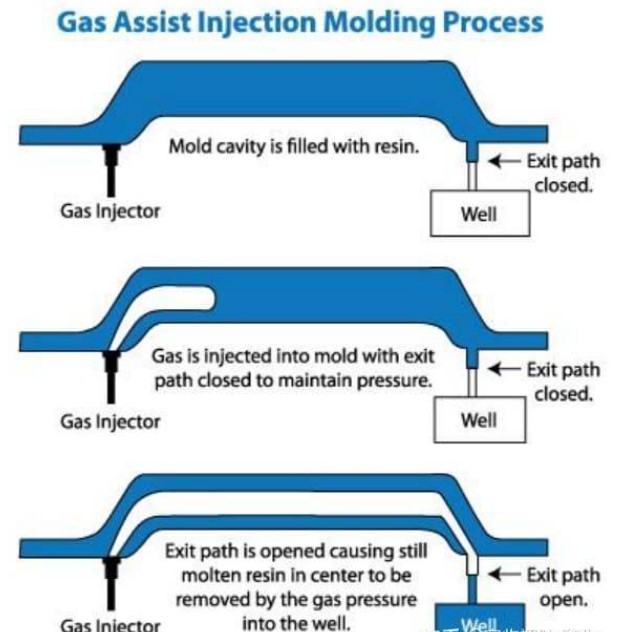

02. Gas assisted injekshɔn moldin .

Dis na wan mɔ kɔmpleks kayn moldin. We dɛn de du kɔvɛnshɔnal mol, tik pat dɛn kin dray ɔ mɛn sloslo pas di wɔl dɛn we de tinap. Di rizin fɔ dis na bikɔs nɔto inof prɛshɔn de fɔ pak di rɛsin fayn fayn wan ɛn mek i yunifom.

As a rizulyt, di resin end op lukin misshapen, unsightly en wiker in structure pas aw i shud bicos of shrink maks. Gas-asisted injection molding na di sɔlv fɔ dis prɔblɛm insay plastic injɛkshɔn moldin fɔ mɛdikal pat dɛn.

Di prɔses involv fɔ pas gas tru chanɛl dɛn we dɛn bil insay di mol. Di gas (naytrɔjen) de pas na di midul pan dɛn tik pat dɛn ya. Apat frɔm dat, dis de mek di prɛshɔn we dɛn nid fɔ pres di rɛsin fayn fayn wan agens di mol, we de rilizɔt wan smol, strɔkchɔral saund pat wit ziro shrinkage.

Di gas-asisted injection molding method nɔ fayn fɔ mek tul dɛn wit shap kɔna dɛn na di dizayn bikɔs di gas prɛshɔn go go dɔŋ if i nɔ flɔ insay wan stret layn. Bɔt dis kayn tin kin fayn fɔ mek dɛn mek kɔmpleks pat dɛn.

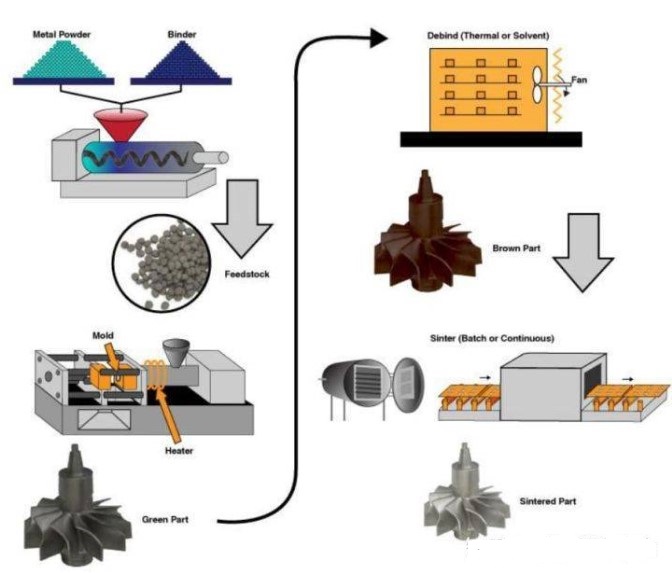

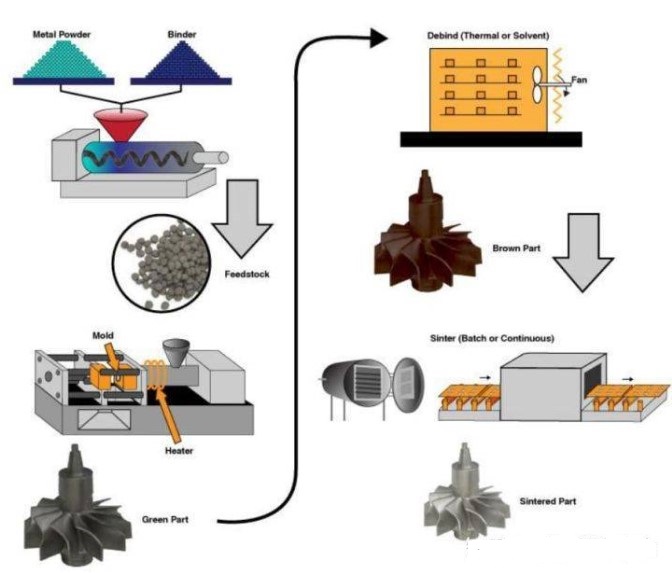

03. Moldin fɔ injɛkshɔn we dɛn mek wit mɛtal .

Di yus fɔ mɛtal dɛn na mɛdikal divays manufakchurin na teknɔlɔji we wi nɔ go ebul fɔ ignore. Di rizin fɔ dis na bikɔs mɛtal divays dɛn de ple impɔtant pat we dɛn nid fɔ gɛt ay density, smɔl saiz ɛn mobiliti. Dis nɔ de ambɔg di bɔku bɔku tin dɛn we dɛn kin yuz ɛn bɛnifit dɛn we dɛn kin gɛt frɔm tradishɔnal 3D printin, mɛrɛsin plastic moldin, ɔ gas-asist moldin.

Tipikli, atomization teknɔlɔji de prodyuz wan pauda miksɔp frɔm di mɛtal we dɛn want. Dɛn kin mek dis paoda insay pellets (feedstock) we gɛt wan binder fɔ mek i izi fɔ mol.

Afta dɛn dɔn injekt, dɛn kin pul di binder bay difrɛn we dɛn, lɛk sɔlvɛnt, katalaytik prɔses, ɔt ɔvin, ɔ ivin wan kɔmbaynshɔn pan dɛn we ya. Dis kin dɔn lɛf 100% density injɛkshɔn mold pat.

04. Likid silikon injekshɔn moldin .

Sɔm mɛrɛsin dɛn, lɛk tubing ɛn breathing mask, nɔ kin izi fɔ mek dɛn kɔntinyu fɔ yuz dɛn di rayt we. So, likid silikon injɛkshɔn moldin kin bi di wan we fit pas ɔl fɔ mek dɛn kayn divays dɛn de.

Di stringent we dɛn nid fɔ dis prɔses nid fɔ gɛt sanitayz prodakshɔn ɛnvayrɔmɛnt. Dis envairomɛnt de mek shɔ se dɛn nɔ put ɛni ambiɛnt ɛya, dɔst ɔ mɔstɔ pan di mol ɔ miksɔp as i de mek i strɔng. Di tin we tan lɛk rɔba we dis prɔses de mek, nɔ de ambɔg di kemikal dɛn.

Silikon nɔ de riak wit bayolojikal tisu, we de mek i fayn fɔ mek dɛn put am sef wan. Bɔt dis injɛkshɔn moldin prɔses nid bɔku stɛp dɛn. I dipen bak pan di prɔpati dɛn we dɛn want fɔ di silikon prodak we kɔmɔt frɔm am.

Dɔn

Team Rapid MFG Co., Ltd dɔn de du plastic injɛkshɔn moldin savis fɔ bɔku ia. Wi de handle evritin from . Plastik mold dizayn ɛn manufakchurin to moldin , peint, ɛn asɛmbli.