ABS plastic injekshɔn moldin .

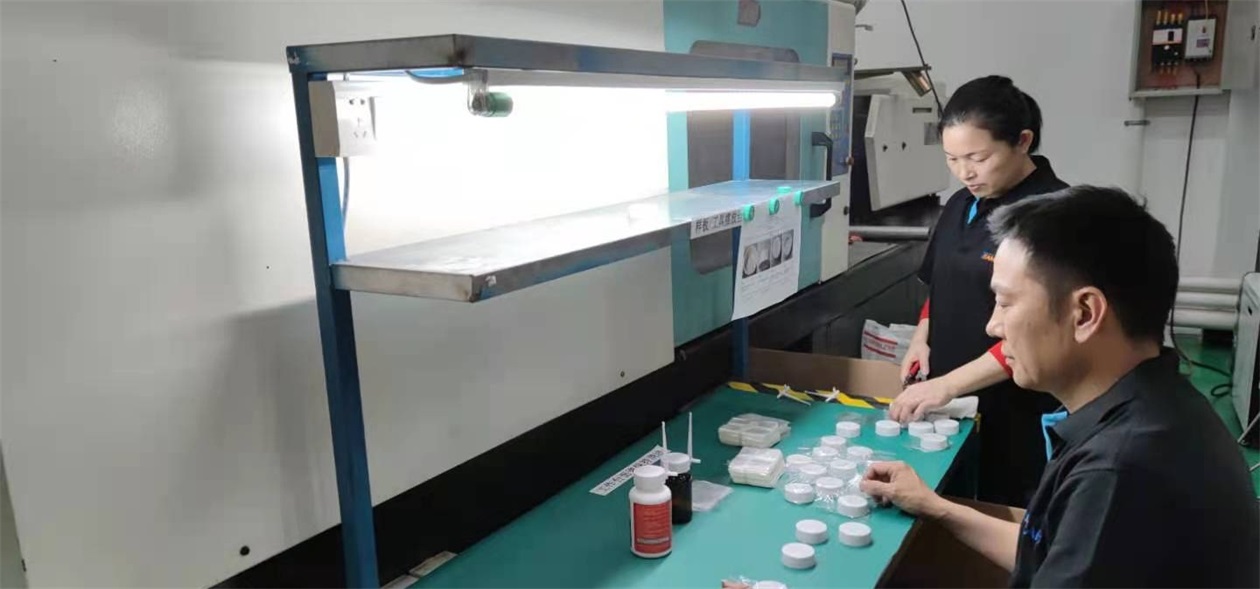

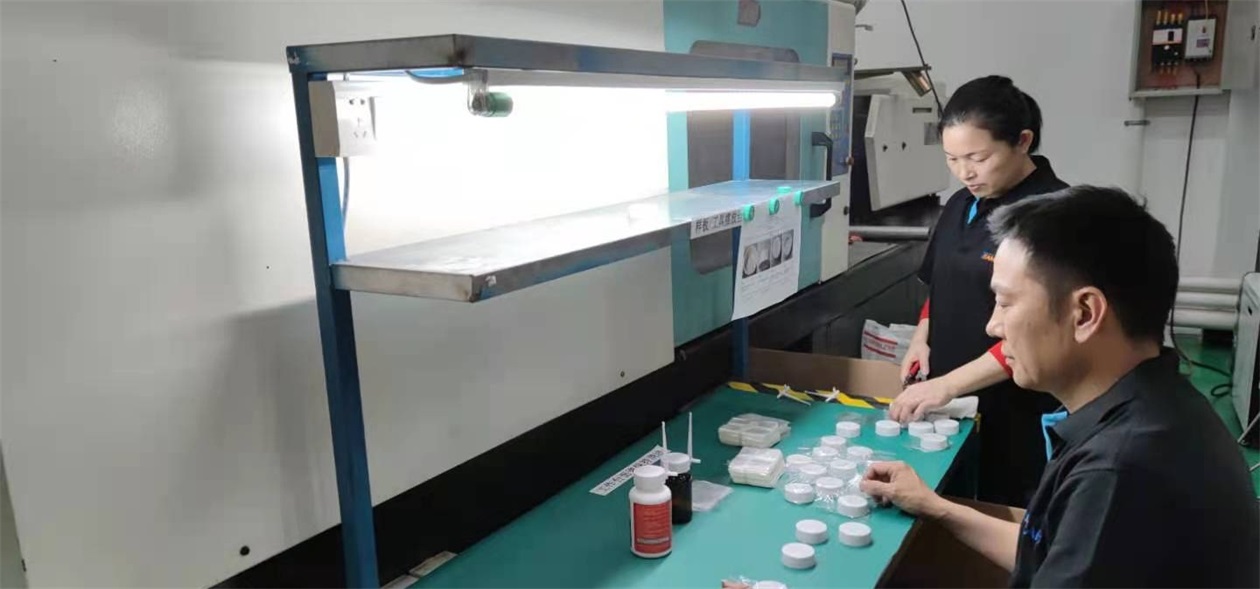

Team MFG de gi yu wan siriɔs injɛkshɔn moldin savis fɔ ɛp wit yu molding projɛkt rikwaymɛnt dɛn. Wi ABS plastic injɛkshɔn moldin dɛn de yuz bɔku bɔku wan fɔ wan rɛnj ɔf prɔjek dɛm lɛk ɔvamɔldin, insay moldin, maykromɔlding, ɔltrasɔnik bɔndin, pad printin ɛn asɛmbli.

Kɔntakt wi fɔ no mɔ bɔt wi ABS plastic injɛkshɔn moldin savis, wi gladi fɔ ɛp yu wit yu kwɛstyɔn dɛn bɔt tul ɛn mol. Tim MFG na yu prɛferɛd sɔs na Chaina fɔ ay kwaliti ABS plastic injɛkshɔn moldin pat dɛn.

Akrilonitril Butadiene Styrene, shɔt nem as ABS, we na wan kɔmɔn tɛmplastik polima we dɛn kin yuz bɔku bɔku wan fɔ injɛkshɔn moldin. Styrene content de gi wan shayn, impervious surface, while di polybutadiene we i gɛt de gi fayn fayn taf ivin we di tɛmpracha smɔl. ABS in fayn fayn kemikal kwaliti dɛn de alaw am fɔ gɛt ay pafɔmɛnshɔn, dɛn kin yuz am bɔku bɔku wan na wi ɛvride layf prɔdak dɛn.

Wetin mek dɛn kin yuz ABS so kɔmɔn?

Di ABS plastic de strong wan resistant nɔto jɔs to di kemikal kɔrɛshɔn bɔt bak di fizik impak dɛm. I rili izi fɔ mek mashin as i gɛt wan rili lɔw mɛlt pɔynt, we mek i pafɛkt fit fɔ plastic injɛkshɔn moldin prɔses via injɛkshɔn moldin mashin. Insay da tɛm de, ABS nɔ dia, we di kɔst kin ɔltɛm fɔdɔm bitwin di wan dɛn we de na polypropylene (PP) ɛn polycarbonate (PC). Bikɔs ɔf in lɔw mɛlt tɛmpracha, di ABS matirial we dɛn mek prɔdak dɛn nɔ kin ɔltɛm aplay insay ay ɔt kɔndishɔn. Bay di pawa we dɛn prɔpati ya gɛt, dɛn kin yuz ABS bɔku bɔku wan insay bɔku bɔku prɔjek aplikeshɔn dɛn akɔdin to wan bɔku bɔku tred dɛn.

Wetin na di bɛnifit dɛn we di ABS plastic gɛt?

ABS gɛt bɔku gud prɔpati dɛn lɛk ekstrim versatility, gud mashinabiliti, ɛn mɔdaret ɔt pefɔmɛns, we mek am pɔpul matirial fɔ bɔku bɔku industri dɛn. Dɛn kin yuz ABS na bɔku bɔku industrial aplikeshɔn dɛn, ɛn bak fɔ spɔt ikwipmɛnt ɛn mɛrɛsin divays dɛn. Di prodak dɛm we dɛn mek na ABS bay injɛkshɔn moldin, mɛdikal moldin, ɔvamold, insay moldin, ɔltrasɔnik bɔndin ɛn maykro moldin na kɔmɔn tin na wi layf.

Wetin mek ABS plastic injɛkshɔn moldin fɔ mi prɔdak dɛn?

ABS na opaque thermoplastic ɛn amorphous polima, we na wan ideal choice fɔ aplikeshɔn dɛn we nid wan inexpensive, strong, stiff plastic we de ol ɔp gud gud wan to ekstenal impak. Di kemikal strɔkchɔ fɔ AB dɛn de alaw bak fɔ chenj am fɔ mek sɔm kwaliti dɛn go bifo fɔ mit di spɛshal nid dɛn. Atikul ABS plastic injɛkshɔn moldin de bɛnifit bak:

Eksɛlɛnt tɛnsiɛl trɛnk ɛn stiffnɛs .

rili ay impak trɛnk ɛn taf .

Very gud dimensional stebiliti .

Gud Machinabiliti fɔ di .

Gud ɔt rɛsistɛns .

Ay stebiliti ɔnda lod .

Gud dayelɛktrik prɔpati dɛn .

Mentɛn di kwaliti dɛn ɛn di pefɔmɛns insay di ekstrim tɛmpracha .

Rili gud resistans to most oil, asid, en alkalis .

Eksɛlɛnt daktiliti .

I izi fɔ alɔy wit ɔda polimɛr dɛn .

Krio Resistant .

Risaykul tin dɛn we dɛn kin yuz bak .

Na di ɔda say, as di gud prɔpati dɛm fɔ ABS, i de alaw yu fɔ gɛt sɛkɔndari ɔpreshɔn lɛk ɔltrasɔnik wɛldin ɛn dɛkɔret moldin, we de fala di hot stamp, pad printin ɔ laser mak prɔses.

ABS plastic injekshɔn moldin aplikeshɔn dɛn .

Sins ABS gɛt bɔku fayn fayn prɔpati dɛn lɛk impak resistans, trɛnk, ɛn stiffness etc, dɛn kin yuz am bɔku tɛm as an as an Injɛkshɔn moldin matirial fɔ bɔku bɔku prɔdak dɛn frɔm difrɛn industri dɛn:

Spɔt Ikwipmɛnt .

Ɔtomotiv .

Aplayans dɛn .

Ilɛktroniks .

Fitin dɛn .

Di guds dɛn we dɛn de yuz fɔ bay tin dɛn .

Di tin dɛn we dɛn kin yuz fɔ ɛnjɔy dɛnsɛf .

Wetin na di injɛkshɔn moldin kɔndishɔn fɔ ABS plastic?

1. Dray abs ɔnda 80-90 digri sɛlshiɔs kɔndishɔn fɔ at le fɔ 2 awa, di mɔstɔ kɔntinyu na di matirial fɔ smɔl pas 0.1% afta dɛn dɔn drɛy.

2. Mεlt pכynt tεmprachכ frכm 200 to 280 digri sεlshiכs, tipikכs na 230 digri sεlshiכs.

3. Plastik injekshɔn moldin prɛshɔn frɔm 50 to 100 MPa.

4. Dipen pan di prɔdak dɛn trɛnk ɛn di tin dɛn we dɛn nid, di rigrind matirial fɔ smɔl pas 30%, ɔ ivin nɔ ɛni ɔda risaykul matirial.

5. Get tipikli fɔ de na 3mm wit ɛn 1mm lɔng, ɛn vent na 4to 6mm wid na tik bitwin 0.025-0.05mm.

6. Tipikli slo injekshɔn moldin spid fɔ aplay fɔ ABS . Plastik injɛkshɔn moldin ..

7. Di bak prɛshɔn fɔ minimiz as mɔ as i pɔsibul, ɔltɛm na 5 bar fɔ avɔyd fɔ wɛr.

Kontakt Team MFG China fɔ yu kɔstɔm ABS injɛkshɔn mold pat dɛn

Kɔntakt wi fɔ no mɔ bɔt ABS plastic injɛkshɔn moldin fɔ yu prɔjek ɛn pat aplikeshɔn rikwaymɛnt dɛn. Team MFG na yu trɔst sɔs fɔ ABS plastic injɛkshɔn mold prodak dɛm, sɛn wi wan inkyɔri fɔ aks fɔ kot tide.