Have you ever wondered why some injection-molded parts come out smooth and perfect, while others have unsightly blemishes or get stuck in the mold? The answer lies in draft angles – a critical aspect of injection mold design that can make or break your product's quality.In this post, you'll learn ab

Read More

Have you ever wondered how plastic products pop out of molds perfectly shaped? Ejector pins play a crucial role. These small components ensure the efficient release of molded parts in injection molding.In this post, you’ll learn what ejector pins are, why they’re essential, and how they fit into the

Read More

A bad CNC machine shop doesn't just cost you money. It costs you time — and sometimes an entire production run. The quote looked great. The lead time seemed reasonable. Then parts show up out of spec, or worse, they don't show up at all.This guide breaks down what actually matters when choosing a CN

Read More

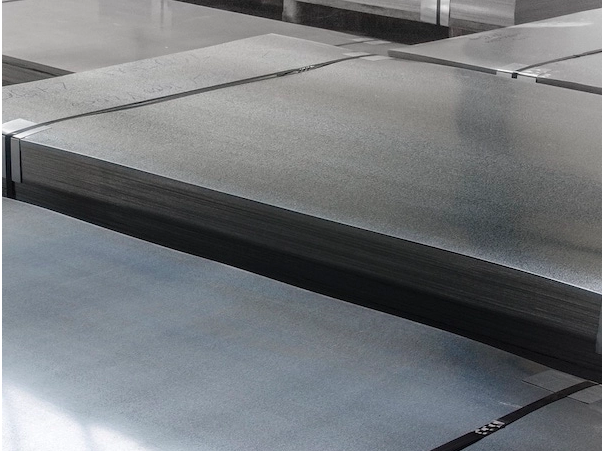

There are various types of sheet metals you can use in fabrication. Construction, aerospace, automotive, and medical industries use different sheet metal varieties to complete their production goals. With today's manufacturing technology, you can use sheet metals to create various products with utmo

Read More

Here's a question that trips up even seasoned engineers: Is Delrin just acetal with better marketing? The short answer: yes and no. The long answer could save you thousands in material costs and machining headaches. When you're spec'ing parts for CNC machining, injection molding, or rapid prototypin

Read More

Bronze eats carbide tools for breakfast. Yet most machine shops still treat it like brass or copper—then wonder why their surface finish looks like sandpaper and tooling costs explode. The truth? Bronze machining follows its own rules, and breaking them costs you time, money, and quality.Whether you

Read More

ULTEM, with its PEI-grade plastic materials, gives you a lot of flexibility in your CNC machining production. This high-quality premium thermoplastic material can give you the ease of machinability, lots of high-grade plastic properties, and strength and durability you will need to create long-term

Read More

Ever wondered how complex car bumpers are made? Reaction Injection Molding (RIM) is the answer. It's a game-changer in many industries.In this post, you'll learn about RIM's process, materials, and benefits. Discover why RIM is crucial for creating lightweight and durable parts.What is Reaction Inje

Read More