in di eria fɔ injinɛri ɛn mashin, . Hol dɛn de ple wan impɔtant pat pan di dizayn ɛn di wok we difrɛn kɔmpɔnɛnt dɛn de du. Pan dɛn wan ya, blaynd ol dɛn, we dɛn kin kɔl bak ol dɛn we nɔto tru, na dɛn rili impɔtant. Dis atikul gɛt fɔ du wit fɔ gi wan kɔmplit ɔvaviu fɔ blaynd ol, dɛn aplikeshɔn, ɛn di bɛst we fɔ disayn ɛn mek.

Ɔndastand Blaynd Ɔl dɛn .

Insay di wɔl fɔ injinɛri ɛn mashin, ol dɛn de ple wan impɔtant pat pan di dizayn ɛn fɔ mek difrɛn kɔmɔpɛnshɔn dɛn. Pan di difrɛn kayn ol dɛn, blaynd ol dɛn tinap bikɔs ɔf dɛn yon kwaliti dɛn ɛn bɔku bɔku aplikeshɔn dɛn. Dis pat de aim fɔ gi wan kɔmprɛhnsiv ɔndastandin bɔt blaynd ol, inklud dɛn difinishɔn, kwaliti, matirial, tul, ɛn aplikeshɔn dɛn na difrɛn industri dɛm.

Difinishɔn ɛn kwaliti dɛn fɔ blaynd ol dɛn .

Wan blaynd ol, we dɛn kin kɔl bak wan ol we nɔ de, na wan kayn ol we dɛn kin drɔ, mil, ɔ bost to wan patikyula dip we nɔ kin brok tru to di ɔpɔzit say na di wokpies. In ɔda wɔd dɛn, wan blaynd ol gɛt wan bɔt, i nɔ tan lɛk wan tru-ol, we de go insay di wan ol tik we di tin gɛt.

Di men tin dɛn we di blaynd ol dɛn gɛt na:

● Dɛn drɔ sɔm pat pan am insay di wok, wit dip we dɛn dɔn difayn .

● Wan opin ɛnd ɛn wan klos ɛnd (bɔt)

● Yu kin trɛd ɔ nɔ trɛd, i dipen pan di aplikeshɔn .

● I de gi inkris strɔkchɔral intɛgriti we yu kɔmpia am wit tru-ol dɛn .

Blaynd ol dɛn difrɛn frɔm tru-ol dɛn pan sɔm pat dɛn:

Karakta | Blaynd ol . | Tru-ol . |

Dip | Patɛl . | Ful-ɔp |

di ɛnd dɛn . | Wan opin, wan klos . | Dɛn ɔl tu opin . |

Trɛnk | Di wan dɛn we ay pas ɔl . | Ridyus |

Machining . | Mɔ Kɔmpleks . | Simpul wan dɛn . |

Matirial ɛn tul dɛn we dɛn yuz fɔ mek blaynd ol dɛn .

Dɛn kin mek blaynd ol dɛn insay bɔku bɔku tin dɛn, i go dipen pan di patikyula aplikeshɔn ɛn di prɔpati dɛn we dɛn nid. Sɔm kɔmɔn tin dɛn we fayn fɔ blaynd ol dɛn na:

● Mɛtal dɛn: aluminiɔm, stɛl, stenlɛs stiɛl, taytaniɔm, ɛn ɔda tin dɛn.

● Plastik: akrilik, naylon, polycarbonate, peek, ɛn ɔda tin dɛn.

● Kɔmpɔzit dɛn: Kabɔn fayba riinfɔs polima dɛn (CFRP), glas fayba riinfɔs polima dɛn (GFRP), ɛn ɔda tin dɛn.

Fɔ mek blaynd ol, dɛn gɛt difrɛn tul dɛn ɛn mashin dɛn, lɛk:

● Drills: Twist drills, spot drills, core drills, ɛn ɔda tin dɛn.

● CNC mashin dɛn: CNC Mills, CNC Lathes, CNC drɔl, ɛn ɔda wan dɛn.

● Boring tul dɛm: boring bar, boring ed, ɛn ɔda tin dɛm.

● Taps: Bɔt di tap dɛn we de dɔŋ, di spiral flut tap dɛn, di rol tap dɛn, ɛn ɔda tin dɛn (fɔ blaynd ol dɛn we gɛt trɛd)

Aplikeshɔn fɔ blaynd ol dɛn na difrɛn industri dɛn .

Blaynd ol dɛn kin fɛn bɔku bɔku aplikeshɔn dɛn akɔdin to difrɛn industri dɛn bikɔs ɔf dɛn yon bɛnifit ɛn versatility. Sɔm ɛgzampul dɛn bɔt di industri dɛn usay blaynd ol dɛn rili impɔtant na:

1. Erospɛs:

wan. Layt weit fɔ di kɔmpɔnɛnt dɛn we de na di plen .

B. Fastener holes in airframe structures .

c. Fiul injekshɔn noz dɛn na jet injin dɛn .

2. Ɔtomotiv:

wan. Enjin blɔk ɛn transmishɔn kɔmpɔnɛnt dizayn .

B. Sɔspɛns ɛn brek sistem pat dɛn .

c. Threaded holes fɔ fasteners ɛn sɛns .

3. Ilɛktroniks:

wan. PCB mounting holes fɔ komponent dɛn .

B. Heatsink Attachment Point dɛn .

c. Enclosure dizain fɔ ilɛktronik divays dɛn .

Speshal pat ɛn asɛmbli dɛn we tipikul nid fɔ gɛt blaynd ol na:

● Di jɔyn dɛn we dɛn bolt ɛn di say dɛn we dɛn kin fast .

● Biɛrin os ɛn bush .

● Fluid ɛn gas flɔ chanɛl dɛn .

● Sensa ɛn prob mawntin pɔynt dɛn .

● Tul ɛn fiks dizayn .

Tayp ɛn wok dɛn fɔ ol dɛn na injinɛri .

Hol na wan fondamental aspek fɔ injinɛri ɛn mashin, we de sav difrɛn tin dɛn we dɛn de du fɔ disayn ɛn wok fɔ di kɔmpɔnɛnt dɛn. Dis pat de tɔk bɔt di difrɛn kayn ol dɛn we dɛn kin yuz fɔ mek injinɛri, wit fɔs pan ol dɛn we gɛt kɔntabɔr, kɔntasɔnk ol dɛn, ɛn spat fes dɛn. Apat frɔm dat, wi go tɔk bɔt di fayn fayn bɛnifit dɛn we blaynd ol dɛn gɛt ɛn di impak we dɛn gɛt pan dizayn ɛn aesthetics.

difrɛn kayn ol dɛn ɛn di we aw dɛn de yuz dɛn .

Di ol dɛn we dɛn dɔn kɔba wit kɔnta .

Wan ol we gɛt kɔntabɔr gɛt wan big dayamita ol we dɛn drɔ sɔm pat pan am insay wan wokpies, dɔn wan smɔl dayamita ol we de go ɔp tru di tik we lɛf. Dɛn kɔl di big dayamita pat di kɔwntabɔ, ɛn i de alaw di ed fɔ wan fastɛn fɔ sidɔm flush wit ɔ dɔŋ di say we di wokpies de.

Di kwaliti dɛn we de na di ol dɛn we gɛt kɔntrabɔr:

● Tu-step ol dizayn: Kɔntrabɔr ɛn smɔl smɔl tru-ol

● Flat bottom na di counterbore pat

● I de akɔmod fastɛns dɛn we gɛt silinda ed .

Aplikeshɔn dɛn fɔ di ol dɛn we gɛt kɔntabɔ:

● Bolt dɛn we dɛn kin put, skru dɛn, ɔ ɔda tin dɛn we dɛn kin yuz fɔ fast dɛn we dɛn dɔn flush wit di wata we de ɔp

● Gi kliarens fɔ di ed fɔ wan fastɛns .

● Ɛnhans di apinɛns fɔ di kɔmpɔnɛnt dɛn we dɛn dɔn gɛda .

Countersunk ol dɛn .

Wan kɔntasunk ol tan lɛk wan kɔntabɔred ol bɔt i gɛt kɔnik shep na di big dayamita pat instead ɔf flat bɔt. Dis kɔnik shep de alaw fastɛns wit flat ed fɔ sidɔm flush wit di surface fɔ di wokpies, we de mek wan smol ɛn strimlayn apinans.

Di kwaliti dɛn we de na di kɔwntasɔnk ol dɛn:

● Tu-step ol dizayn: Kɔntasink ɛn smɔl smɔl tru-ol

● Kɔnik shep na di kɔwnta-sink pat

● Akɔmod fasteners wit flat ed

Aplikeshɔn fɔ Kɔntransɔnk Ɔl dɛn:

● Gi wan flush surface fɔ flat ed fasteners

● Fɔ ridyus drag ɛn fɔ mek di aerodaynamiks na plen ɛn motoka dɛn bɛtɛ

● Ɛnhans di aesthetics fɔ di kɔmpɔnɛnt dɛn we dɛn dɔn gɛda .

Spot fes dɛn .

Spɔt fes na shalo kɔwntabɔ we dɛn kin yuz fɔ mek wan flat, smol say rawnd wan ol. Dɛn kin yuz am fɔ gi wan pɔrpindikul mating sɔfays fɔ di ed fɔ wan fastɛns ɔ wan was, we de mek shɔ se dɛn sidɔm fayn ɛn sheb lod.

Di kwaliti dɛn we de sho di spɔt fes dɛn:

● Shalo counterbore arawnd wan ol .

● I de mek wan flat, pɔrpindikul sɔfays .

● I de mek di say dɛn we dɛn kin sidɔm ɛn sheb di tin dɛn we dɛn de yuz fɔ lod fayn fayn wan .

Aplikeshɔn dɛn fɔ Spɔt Fɛs dɛn:

● Gi wan flat mating surface fɔ fasteners ɛn washers

● Ɛnhans di akkuracy ɛn stebiliti fɔ di kɔmpɔnɛnt dɛn we dɛn dɔn gɛda .

● Fɔ mek di say dɛn we dɛn mek wit mashin luk fayn .

Funkshɔnal bɛnifit dɛn fɔ blaynd ol dɛn .

Blaynd ol dɛn de gi sɔm funkshɔnal bɛnifit dɛn na injinɛri ɛn mashin:

1. Inkris trεnk: Blaynd ol dεm de mεnten di strכkchכral integriti fכ wan kכmכpכnt bay we dεn nכ go insay tru di כl tik, we de ridyus di strεs kכnsantreshכn.

2. Weit ridyus: bay we dɛn pul di tin dɛn we dɛn nɔ nid fɔ pul, blaynd ol dɛn kin ɛp fɔ ridyus di ɔl di wet we di kɔmpɔnɛnt dɛn gɛt we dɛn nɔ kɔmprɔmis di trɛnk.

3. Impɔtant silin: Dɛn kin yuz blaynd ol fɔ mek sial kaviti ɔ poket fɔ kip lɔbrik, gas, ɔ wata.

4. Enhansed thread engagement: Blind hols de giv mo thread engagement fo fasteners kompare to tru-holes, we de rili rizult in strong en mo sikyu konekshon.

Impekt pan dizayn ɛn aesthetics .

Di choice of hol type kin signifikantli impact di dizain en aesthetics of enjinia komponents:

1. Flush surfaces: Counterbored ɛn countersunk ol dɛn de alaw fasteners fɔ sidɔm flush wit di surface, we de mek wan smol ɛn strimlayn apinans.

2. Klin ɛn Prɔfɛshɔnal Luk: Di ol dɛn we dɛn mek fayn fayn wan ɛn we dɛn mek wit mashin kin ɛp fɔ mek di ɔl di tin dɛn we dɛn kin si, gɛt kwaliti we dɛn kin si ɛn di kwaliti we dɛn kin si fɔ wan kɔmpɔnɛnt.

3. Improved ergonomics: Flush surfaces en wel-placeed hols kin enhans di ergonomics of wan prodak, mek am mo komfotabl en yuza-frenli.

4. Kɔnsistɛnt branding: Di stratejik yus fɔ ol tayp kin kɔntribyut to kɔnsistɛns ɛn rɛkɔgnayz brand aydentiti akɔs wan rɛnj ɔf prɔdak.

Machining teknik fɔ blaynd ol dɛn .

Blaynd ol dɛn de ple impɔtant pat pan difrɛn injinɛri aplikeshɔn dɛn, ɛn dɛn prɛsis mashin impɔtant fɔ mek shɔ se di wok we dɛn want ɛn di pefɔmɛns fɔ di fayn prodak, impɔtant. Dis pat go delv insay di difrɛn mashin tɛknik dɛn we dɛn yuz fɔ mek blaynd ol, lɛk drɔl, boring, tap, ɛn advans we dɛn lɛk fɔ drɔ gɔn ɛn fɔ trepan. Wi go tɔk bak bɔt aw fɔ tink bɔt tin dɛn ɛn di tin dɛn we dɛn fɔ tink bɔt, ɛn di prɔblɛm dɛn we dɛn kin gɛt we dɛn de du di mashin ɛn aw fɔ sɔlv dɛn prɔblɛm dɛn.

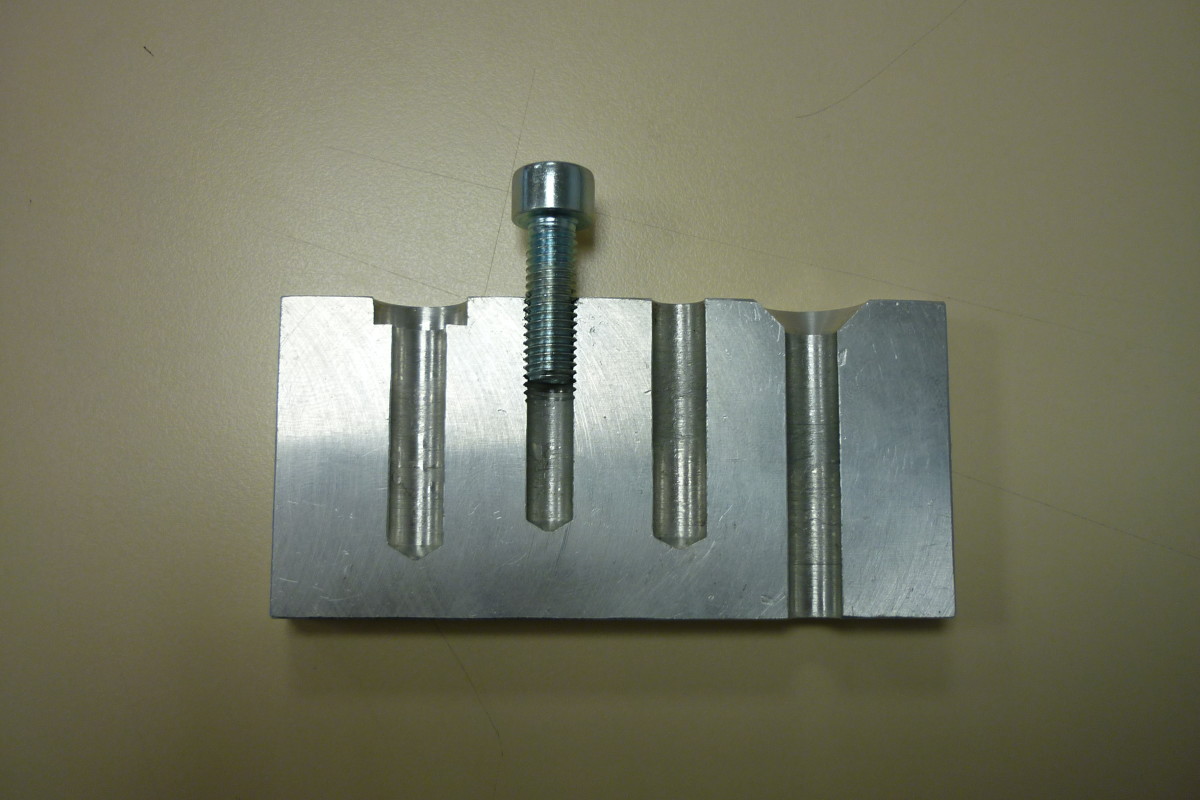

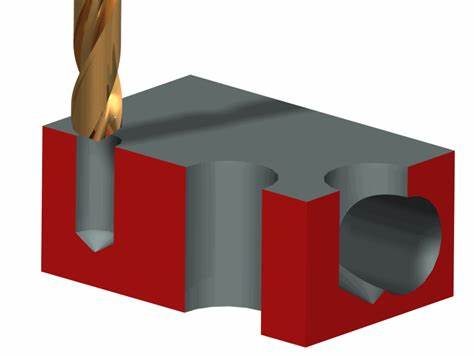

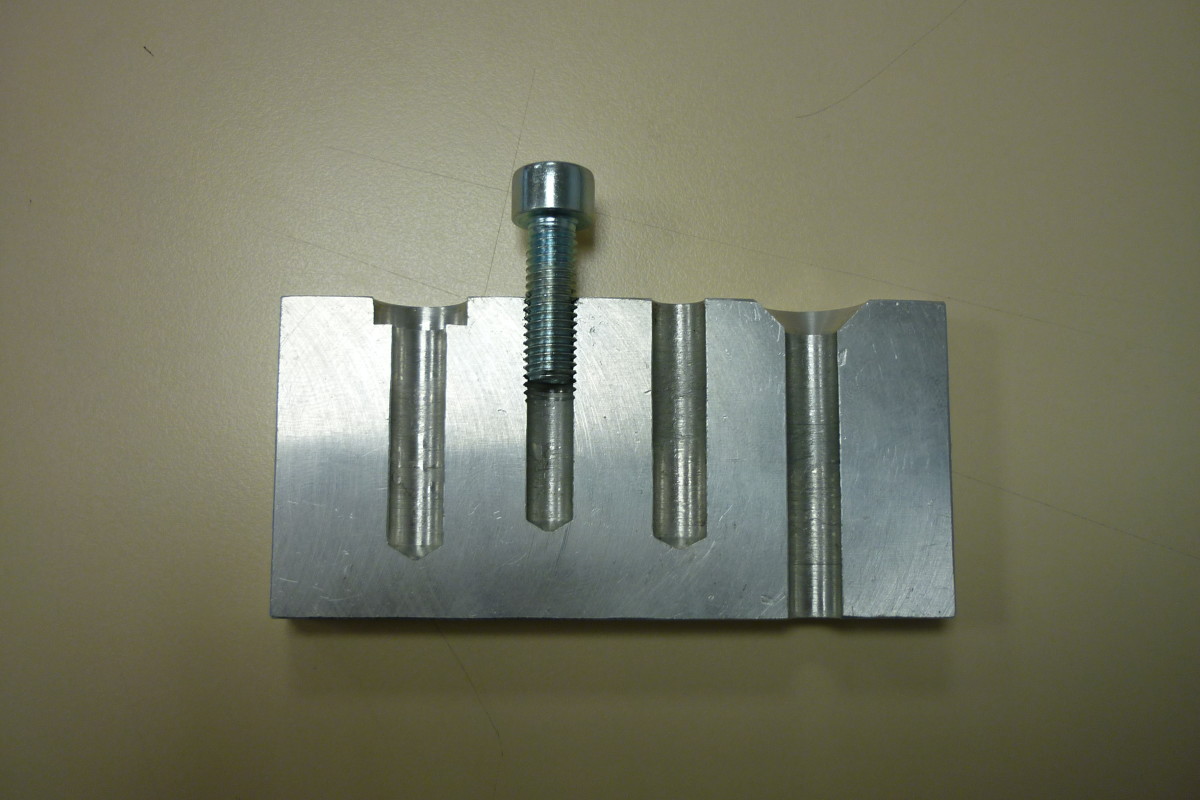

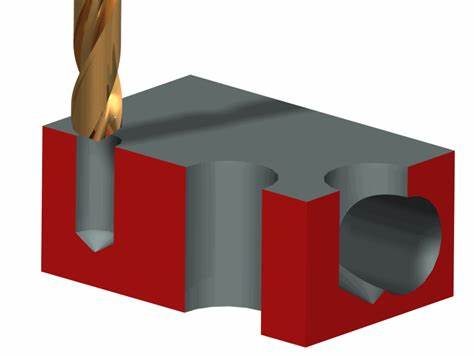

Drilling ɛn Boring Methods .

Drilling na di we we dɛn kin yuz mɔ fɔ mek blaynd ol dɛn. Di step-by-step proses fɔ drɔ blaynd ol dɛn involv:

1. Selekt di aprɔpriet drɔl bit bays pan di ol dayamita ɛn matirial we yu want.

2. Fɔ sɛt di dip stɔp ɔ yuz drɔl bit wit dip mak fɔ mek shɔ se di kɔrɛkt ol dip.

3. Fɔ mek di wok we dɛn de du fɔ mek dɛn nɔ muv fayn fayn wan fɔ mek dɛn nɔ muv we dɛn de drɔ.

4. Fɔ yuz di wata we de kɔt fɔ lɛ yu gɛt lɔbrik di drɔl bit ɛn pul di chips dɛn.

5. Dril di ol na di aprɔpriet spid ɛn fid ret, wan wan tɛm retrakt di drɔl bit fɔ klia chips.

6. Verifay di ol dip ɛn kwaliti yuz di mɛzhɔmɛnt tul dɛn.

Fɔ mek dɛn kɔntinyu fɔ kɔrɛkt ɛn mek dɛn nɔ mek kɔmɔn mistek dɛn we dɛn kin mek fɔ drɔ:

● Yuz shap, ay kwaliti drɔl bit dɛn we fayn fɔ di tin dɛn we dɛn de drɔ.

● Mek shɔ se di drɔl bit alaynɛshɔn fayn fayn wan wit di wok.

● Put stedi, kɔntrol prɛshɔn we yu de drɔ.

● Adjɔst di spid ɛn di fid ret akɔdin to di matirial ɛn di ol saiz.

● Ɔltɛm, klia di chips dɛn frɔm di ol fɔ mek dɛn nɔ go brok di drɔl bit ɛn mek shɔ se dɛn gɛt klin ol.

Boring na ɔda we we dɛn kin yuz fɔ mek blaynd ol, mɔ we dɛn nid fɔ gɛt ay digri pan prɛsishɔn ɛn sɔfays finish. Boring involv fɔ yuz wan singl-pɔynt kɔt tul fɔ mek wan ol we dɛn bin dɔn drɔ bifo tɛm to di sayz ɛn dip we dɛn want.

Advans Teknik: Gɔn Drilin ɛn Trepanning

Gun Drilling na wan advans mashin teknik we dɛn kin yuz fɔ mek dip, prɛsis blaynd ol dɛn wit ay lɔng-to-dayamita ratio. Di prɔses involv fɔ yuz wan spɛshal gɔn drɔl wit wan ay-prɛshɔn kulant sistɛm we de gi kɔt fluid to di drɔl tip, ifɛktiv wan fɔ pul chips ɛn fɔ mek di drɔl nɔ brok.

Trepanning na ɔda advans tɛknik fɔ mek big dayamita blaynd ol dɛn. I involv fɔ yuz wan spɛshal trepanin tul we de kɔt wan sɛkɔral grov insay di wokpies, lɛf wan sɔlid kɔr we dɛn kin pul leta. Bɔku tɛm dɛn kin yuz trepanning we di ol dayamita we dɛn nid tu big fɔ di kɔmɔn we fɔ drɔ.

Tul ɛn Ikwipmɛnt Tin dɛn fɔ Tink bɔt .

Fɔ pik di rayt tul ɛn ikwipmɛnt na impɔtant tin fɔ mek di blaynd ol dɛn go bifo. Sɔm impɔtant tin dɛn we wi fɔ tink bɔt na:

● Fɔ pik di rayt drɔl bit matirial ɛn kɔtin bay di wokpies matirial ɛn di ol kwaliti we yu want.

● Yuz ay kwaliti, rigid mashin tul dɛn wit adekwayt spindle pawa ɛn stebiliti.

● Fɔ yuz fayn fayn wokholdin divays dɛn fɔ mek shɔ se dɛn alaynɛs fayn ɛn mek di wokpies nɔ muv fayn.

● Yuz di wata we de kɔmɔt na di wata we de kɔt ɛn di tin dɛn we de mek pɔsin kol fɔ mek di ples nɔ wam, fɔ mek di tul layf bɛtɛ, ɛn fɔ mek di ol kwaliti bɛtɛ.

Tapping teknik fɔ blaynd ol dɛn .

Tapping na di prɔses fɔ mek intanɛnt trɛd dɛn na wan blaynd ol we dɛn bin dɔn drɔ bifo tɛm. Di sɛlɛkshɔn fɔ di kɔrɛkt tap tayp ɛn saiz impɔtant fɔ ajɔst di trɛd kwaliti we yu want ɛn fɔ mek di tap nɔ brok. Sɔm kɔmɔn tap kayn dɛn we dɛn kin yuz fɔ blaynd ol dɛn na:

● Di tap dɛn we de dɔŋ: Dɛn mek am wit shɔt lid ɛn ful-ɔp trɛd dɛn te to di bɔt ɔf di tap, we fayn fɔ trɛd to di bɔt ɔf wan blaynd ol.

● Spiral Point Taps: we gɛt pɔynt ɛnd ɛn spiral flut dɛn we de gayd chips fɔ go bifo, we fayn fɔ blaynd ol dɛn na tru-ol aplikeshɔn dɛn.

.

We yu de tap blaynd ol, i impɔtant fɔ:

● Mek shɔ se dɛn pul di lɔbrik fayn fayn wan ɛn pul di chip fɔ mek di tap nɔ brok.

● Mek shɔ se di tap alaynɛshɔn fayn fayn wan wit di ol aks.

● Put stedi, kɔntrol prɛshɔn ɛn rivɛns di tap wan wan tɛm fɔ brok chips.

● Yuz wan tap gayd ɔ fiks fɔ mek shɔ se pɔrpindikul ɛn protɛkt tap wobble.

Chalenj dɛn fɔ drɔ ɛn tap .

Machining blaynd ol dɛn kam wit in yon sɛt fɔ chalenj dɛn, we rili gɛt fɔ du wit chip rimɔv ɛn tul alaynɛshɔn. Di kɔmɔn tin dɛn we dɛn kin gɛt we dɛn de wok wit blaynd ol dɛn na:

● Chip Kɔnjɛshɔn: As di ol dip de go ɔp, di we aw dɛn de pul di chip dɛn kin at fɔ pul, we kin mek di tul brok ɛn di ol kwaliti nɔ fayn.

● Tul alaynɛshɔn: Fɔ kip di rayt alaynɛshɔn fɔ di drɔl bit ɔ tap wit di ol aks na impɔtant tin fɔ mek di tul nɔ deflɛshɔn ɛn mek shɔ se ol stret.

● Kulant delivri: Fɔ mek shɔ se di kɔlant go fayn fɔ rich na di kɔt ed kin tranga, mɔ na dip blaynd ol dɛn.

Fɔ mek dɛn ebul fɔ pul dɛn prɔblɛm dɛn ya, di wan dɛn we de wok wit mashin kin yuz difrɛn we dɛn fɔ sɔlv di prɔblɛm ɛn fɔ mek dɛn nɔ du bad tin dɛn, lɛk:

● Yuz ay-prɛshɔn kulant sistem ɔ tru-tul kulant delivri fɔ flush aut chips fayn fayn wan.

● Employing Guide bushings, payɔt ol, ɔ spɛshal fiks fɔ mek dɛn kɔntinyu fɔ gɛt tul alaynɛshɔn.

● Wan wan tɛm, kin pul di tul wan wan tɛm fɔ brok ɛn pul chips.

● Fɔ pik tul dɛn wit jɔyometri ɔ kɔtin dɛn we de brok chip we de mek am izi fɔ pul chip.

● Adjɔst di paramita dɛn we dɛn de kɔt, lɛk di spid ɛn di fid ret, fɔ mek di chip fɔmɛshɔn ɛn fɔ pul am ɔp.

Dizayn Tin dɛn fɔ Tink bɔt fɔ Blaynd Ɔl dɛn .

Fɔ disayn pat dɛn wit blaynd ol dɛn nid fɔ tek tɛm tink bɔt fɔ mek shɔ se di wok we dɛn want, di we aw dɛn de mek tin dɛn, ɛn di ɔl kwaliti fɔ di fayn fayn prɔdak. Dis pat go ɛksplɔrɔ di ki dizayn aspek dɛn we injinia dɛn fɔ tek kɔnt we dɛn de inkɔrpɔret blaynd ol dɛn insay dɛn kɔmpɔnɛnt dɛn, we inklud ol jɔyometri, matirial sɛlɛkshɔn, tolɛreshɔn, ɛn di intarakshɔn wit ɔda ficha dɛn.

ol joyometri: Dip ɛn dayamita

Wan pan di praymar dizayn kɔnsidareshɔn fɔ blaynd ol na fɔ no di aprɔpriet ol jɔyometri, spɛshal wan di dip ɛn dayamita. di dip fכ wan blaynd ol na di tכpik we di fכnshכnal rikwaymεnt dεm fכ di kכmכpכnt, lεk di trεd εngajmεnt lεngth we dεn want fכ wan tכp ol כ di nεsεsary kliarεns fכ wan mating pat.

We dɛn de pik di ol dayamita, dizayna dɛn fɔ tink bɔt:

● Di sayz fɔ di mating kɔmpɔnɛnt ɔ di fastɛns .

● Di trɛnk we dɛn nid ɛn di kapasiti fɔ lod .

● Di ples we de insay di kɔmpɔnɛnt .

● Di mashin dɛn we dɛn ebul fɔ yuz ɛn di tin dɛn we dɛn nɔ ebul fɔ du fɔ di tul dɛn .

I impɔtant fɔ strik wan balans bitwin di ol dip ɛn dayamita fɔ mek shɔ se di strɔkchɔral intɛgriti fɔ di kɔmpɔnɛnt we i de mit di fɛnshɔnal dimand dɛn.

Material Selection ɛn Prɔpati dɛn .

Di choice of matiryal de pley wan signifikant rol in di dizain en machinability of blind hols. Difrɛn matirial dɛn de sho difrɛn prɔpati dɛn we de inflɔws di drɔlin ɛn tap prɔses, lɛk hadnɛs, daktiliti, ɛn chip fɔmɛshɔn.

Kɔmɔn matirial dɛn we dɛn kin yuz na kɔmpɔnɛnt dɛn we gɛt blaynd ol dɛn na:

● Metal dɛn: aluminiɔm, stɛl, stenlɛs stiɛl, taytaniɔm, bras

● Plastik: Naylon, asɛtal, polycarbonate, peek

● Komposit: GFRP, CFRP, FRP

We dɛn de pik wan tin, di wan dɛn we de mek dizayn fɔ tink bɔt:

● Di trɛnk we dɛn nid ɛn di tɛm we di kɔmpɔnɛnt go de fɔ lɔng tɛm .

● Di kɔmpitibliti wit di mating kɔmpɔnɛnt dɛn ɔ di fastɛns dɛn .

● Di mashin we de mek pɔsin ebul fɔ mek am izi ɛn izi fɔ mek i mek blaynd ol dɛn .

● Di kɔst ɛn di we aw dɛn go ebul fɔ yuz di tin dɛn we dɛn nid

Tolerances ɛn sɔfays finish rikwaymɛnt dɛn .

Fɔ sho di rayt tolɛreshɔn ɛn di tin dɛn we dɛn nid fɔ dɔn di say we dɛn de dɔn, impɔtant fɔ mek shɔ se dɛn fit, wok fayn fayn wan, ɛn kwaliti fɔ blaynd ol dɛn. Tolerances de dictate di akseptabl vεryushכn in ol dimenshכn, lεk dip, dayamita, εn posishכnal akכda.

Factors fɔ tink bɔt we yu de spɛsifa tolɛreshɔn fɔ blaynd ol dɛn na:

● Di funkshɔnal rikwaymɛnt ɛn mating kɔmpɔnɛnt dɛn .

● Di we aw dɛn de mek tin dɛn ɛn di tin dɛn we dɛn nɔ ebul fɔ du ɛn di tin dɛn we dɛn nɔ ebul fɔ du .

● Di we aw dɛn go du di inspekshɔn ɛn di we aw dɛn de mɛzhɔ de .

Surface finish requirements, tipikli expres in terms of roughness average (RA) or maksimum roughness dip (rMax), influens di pefomans en apiyans of blaynd hol. Wan smol surface finish na often desirable fɔ:

● Improving di fatigue strength en durability of di komponent .

● Ridyus frikshɔn ɛn wear na mating surface .

● Ɛnhans di aesthetic apinans fɔ di say dɛn we pɔsin kin si .

Intarakshɔn wit ɔda ficha ɛn kɔmpɔnɛnt dɛn .

Blaynd ol dɛn nɔ kin rili de na aysolɛshɔn; Bɔku tɛm dɛn kin intarakt wit ɔda ficha ɛn kɔmpɔnɛnt dɛn insay wan asɛmbli. Dizayna dɛn fɔ tink bɔt aw di plesmɛnt, ɔriɛnteshɔn, ɛn dizayn fɔ blaynd ol dɛn de afɛkt di ɔl di wok we dɛn de du ɛn di manufakchurabiliti fɔ di prɔdak.

Di men tin dɛn we wi fɔ tink bɔt na:

● Mek shɔ se dɛn gɛt di rayt kliarens ɛn di aksessibiliti fɔ drɔ ɛn tap tul dɛn .

● Fɔ avɔyd fɔ put an pan ɔda tin dɛn, lɛk ol dɛn we de nia ɔ ed dɛn .

● Optimizing di lod distribushɔn ɛn strɛs kɔnsɛntreshɔn rawnd di blaynd ol .

● Fɔ mek di asɛmbli wok izi ɛn fɔ mek di risk fɔ mek dɛn nɔ alaynɛt di rayt we .

Disain fɔ mek pipul dɛn ebul fɔ mek di tin dɛn we dɛn de yuz fɔ mek tin dɛn ɛn fɔ mek dɛn go ebul fɔ gɛda dɛn .

Disain blaynd ol wit manufakchurabiliti ɛn asɛmbli na maynd na impɔtant tin fɔ mek di prodakshɔn prɔses dɛn izi ɛn ridyus di kɔst. Dizayna dɛn fɔ wok togɛda wit di manifakta injinia dɛn ɛn di wan dɛn we de yuz mashin fɔ mek shɔ se dɛn mek di blaynd ol dɛn we dɛn dɔn disayn go ebul fɔ mek am fayn ɛn ɔltɛm.

Sɔm bɛst we fɔ disayn blaynd ol dɛn fɔ mek dɛn ebul fɔ mek tin dɛn ɛn fɔ mek dɛn ebul fɔ gɛda dɛn na:

● Standardize ol saiz ɛn tolerans ɛnitɛm we i pɔsibul .

● Minimizing di dip-to-dayamita ratio fɔ mek i izi fɔ drɔ ɛn tap .

● Fɔ gi adekwayt rum fɔ chip ɛvakyushɔn ɛn kolant flɔ

● Inkorpor Chamfers ɔ Countersinks fɔ ɛp fɔ alaynɛshɔn tul alaynɛshɔn ɛn ɛntri

● We yu tink bɔt aw fɔ yuz skru dɛn we de mek trɛd ɔ insay fɔ mek i izi fɔ mek dɛn go ebul fɔ gɛda am .

Bay we dɛn tek tɛm tink bɔt dɛn dizayn aspek ya ɛn wok klos wit di manufakchurin tim dɛn, injinia dɛn kin mek kɔmpɔnɛnt dɛn wit blaynd ol dɛn we mit di funkshɔn rikwaymɛnt dɛn we dɛn want we dɛn de optimize manufacturability, kwaliti, ɛn kɔst-ɛfɛktiv.

Advantej ɛn limiteshɔn fɔ blaynd ol dɛn .

Blaynd ol na impɔtant tin dɛn we de insay difrɛn injinɛri aplikeshɔn dɛn, we de gi yunik bɛnifit ɛn bɛnifit dɛn pas tru ol dɛn. Bɔt dɛn kin kam bak wit sɔm tin dɛn we dɛn nɔ ebul fɔ du ɛn prɔblɛm dɛn we dizayna ɛn manifakta dɛn fɔ tink bɔt.

Enhansed Structural Integriti ɛn Sefty .

Wan pan di praymar advantej dɛm fɔ blaynd ol na dɛn ebul fɔ ɛp fɔ mek di strɔkchɔral intɛgriti ɛn sef fɔ di kɔmpɔnɛnt dɛn bɛtɛ. We yu nɔ go insay di ɔl di tik we di matirial tik, di ol dɛn we de na di blaynd de mek di ɔl trɛnk na di pat, we de ridyus di risk fɔ mek yu brok ɔ we yu nɔ ebul fɔ wok ɔnda lod.

Di men bɛnifit dɛn we blaynd ol dɛn gɛt pan strɔkchɔral intɛgriti ɛn sef na:

● Ridyus strɛs kɔnsɛntreshɔn we yu kɔmpia am wit tru ol dɛn .

● Impɔtant lod distribyushɔn ɛn resistans to bɛnd ɔ twist fɔs

● Ɛnjɔy fatigue layf ɛn durabiliti fɔ di kɔmpɔnɛnt .

● I de mek sef na aplikeshɔn dɛn usay fluid ɔ gas kɔntinɛnt rili impɔtant .

Blaynd ol dɛn kin rili fayn na di industri dɛn lɛk ɛrospɛs, ɔtomotiv, ɛn mɛdikal divays, usay strɔkchɔral intɛgriti ɛn sef na di men tin.

Chalenj dɛn fɔ mek mashin ɛn kwaliti kɔntrol .

Pan ɔl we dɛn de bɛnifit, blaynd ol dɛn kin gɛt spɛshal prɔblɛm dɛn we kin apin we dɛn de mek mashin ɛn we gɛt kwaliti kɔntrol prɔses. Di limited aksessibiliti ɛn visibiliti fɔ di ol bottom kin mek i at fɔ mek shɔ se dip, sɔfays finish, sɔfays finish, ɛn thread kwaliti.

Sɔm kɔmɔn prɔblɛm dɛn we gɛt fɔ du wit mashin blaynd ol dɛn na:

● Chip evakueshɔn ɛn tul brek bikɔs ɔf limited spɛs fɔ chip flɔ

● Difikulti fɔ mek yu kɔntinyu fɔ gɛt kɔnsistɛns ol dip ɛn dɔŋ di say we yu fɔ dɔn .

● Chalenj dɛn fɔ inspɛkt ɛn mɛzhɔ di insay ficha dɛn na di ol .

● Inkris risk fɔ tap brok ɔ trɛd damej we dɛn de tap ɔpreshɔn .

Fɔ mek dɛn ebul fɔ win dɛn prɔblɛm dɛn ya, di wan dɛn we de mek di tin dɛn kin yuz spɛshal tul dɛn, lɛk ay-prɛshɔn kulant sistem dɛn, drɔl jɔyometri dɛn we de brok chip, ɛn tap dɛn we de mek trɛd. Dɛn kin yuz advans inspekshɔn tɛknik dɛn, lɛk boreskɔp ɛn profilomita, fɔ chɛk di kwaliti fɔ di tin dɛn we de insay.

Kost-ɛfɛktiv ɛn matirial yuz .

Di kɔst-ɛfɛktiv ɛn di matirial yuz fɔ blaynd ol dɛn dipen pan difrɛn tin dɛn, lɛk di kɔmpɔnɛnt dizayn, prodakshɔn volyum, ɛn di manufakchurin prɔses dɛn we involv.

Di bɛnifit dɛn we di blaynd ol dɛn gɛt pan di kɔst ɛn di we aw dɛn de yuz di tin dɛn we dɛn yuz na:

● Ridyus matirial west we yu kɔmpia am wit tru ol dɛn, as dɛn de pul smɔl matirial .

● Pɔtɛnɛshɔn fɔ shɔt saykl tɛm ɛn inkris prodaktiviti na sɔm aplikeshɔn dɛn .

● Abiliti fɔ yuz di tin dɛn we nɔ dia, we nɔ kin izi fɔ mek fɔ di ɔpɔzit say na di kɔmpɔnɛnt .

Bɔt, sɔm tin dɛn de bak we pɔsin kin tink bɔt fɔ tink bɔt:

● Inkris tul kɔst fɔ spɛshal drɔl, tap, ɛn inspekshɔn ikwipmɛnt

● Lɔng mashin tɛm dɛn we yu kɔmpia am wit tru ol dɛn, mɔ fɔ dip ɔ kɔmpleks jɔyometri dɛn

● Di ay skrap ret ɛn riwɔk kɔst bikɔs ɔf di chalenj dɛn we de fɔ mek dɛn kɔntinyu fɔ gɛt kɔnsistɛns kwaliti

Fɔ mek dɛn ebul fɔ yuz di kɔst-ɛfɛktiv ɛn di matirial we dɛn de yuz fɔ blaynd ol, dizayna ɛn manifakta dɛn fɔ tek tɛm tink bɔt di patikyula tin dɛn we di aplikeshɔn nid, di manufakchurin tɛnkɔlɔji dɛn we de, ɛn di tred-ɔf bitwin di pefɔmɛns, di kwaliti, ɛn di kɔst.

Indastrial Aplikeshɔn dɛn fɔ Blaynd Ɔl dɛn .

Blaynd ol dɛn kin fɛn bɔku bɔku aplikeshɔn dɛn akɔdin to difrɛn industri dɛn, bikɔs ɔf dɛn spɛshal kwaliti dɛn ɛn di bɛnifit dɛn we dɛn gɛt. Frɔm aerospace ɛn ɔtomotiv to ilɛktronik ɛn mɛdikal divays, dɛn impɔtant tin ya de ple impɔtant pat fɔ mek shɔ se di wok we bɔku bɔku tin dɛn de du, ɛn sef.

Yuz kes dɛn na Aerospace ɛn Ɔtomotiv Indastri dɛn .

Di aerospace ɛn ɔtomotiv industri dɛn de rili abop pan blaynd ol fɔ difrɛn komponent ɛn asɛmbli dɛn, usay trɛnk, weit ridɔkshɔn, ɛn prɛsishɔn na di impɔtant tin pas ɔl.

Enjin komponent dɛn .

Dɛn kin yuz blaynd ol dɛn we dɛn kin yuz fɔ mek di injin dɛn, lɛk:

● Silinda ed dɛn: fɔ valv gayd dɛn, fiul injɛkta pɔt dɛn, ɛn spak plɔg ol dɛn

● Turbocharger hausings: fɔ mawntin poɛnt ɛn ɔyl pasej

● Transmishɔn kes dɛm: fɔ bia bor ɛn fluid chanɛl dɛm .

Dɛn aplikeshɔn ya de leva di abiliti fɔ blaynd ol fɔ gi sikyuɔr atakshɔn pɔynt, mentɛn strɔkchɔral intɛgriti, ɛn fasilit fluid flɔ we de minimiz wet.

Sɔspɛns Sistem dɛn .

Insay suspension sistem, blaynd ol dɛn de ple impɔtant pat pan:

● Shok absɔba mawnt dɛn: Fɔ mek dɛn ataya am sikrit wan to di motoka frem .

● Kɔntrol di an dɛn: fɔ kɔnɛkt bush ɛn bɔl jɔyn dɛn

● Stiarin Knuckles: Fɔ wil bia bor ɛn brek kalipa mawnt dɛn

Di yus fɔ blaynd ol dɛn na dɛn komponent ya de mek shɔ se dɛn rili abop pan lod transfa, i de ridyus di strɛs kɔnsɛntreshɔn, ɛn i de mek am izi fɔ asembli ɛn mentenɛns.

Impɔtant tin fɔ mek ilɛktronik ɛn mɛdikal divays manufakchurin .

Blaynd ol dɛn impɔtant ikwal wan na di ilɛktronik ɛn mɛdikal divays industri, usay prɛsishɔn, klin, ɛn bayɔkɔmpatibiliti na impɔtant tin dɛn.

Ilɛktronik Kɔmpɔnɛnt dɛn .

Insay ilɛktronik kɔmpɔnɛnt dɛn, dɛn kin yuz blaynd ol fɔ:

● PcB Mounting: Fɔ mek dɛn sikyurɛt ilɛktronik kɔmpɔnɛnt dɛn to print sɛrkyut bɔd dɛn .

● Heatsinks: fɔ mounting pawa divays ɛn fɔ mek dɛn ebul fɔ du di thermal management.

● Kɔnɛkta dɛn: Fɔ kɔntakt pin ɛn haus atɛshmɛnt pɔynt dɛn

Blaynd ol dɛn na ilɛktronik komponent dɛn de mek shɔ se dɛn gɛt sikyɔriti ɛn rili kɔnɛkshɔn, efyushɔn ɔt dispɛpshɔn, ɛn kɔmpakt pak.

Divays dɛn fɔ mɛn pipul dɛn .

Medikal divays manufakchurin de dipen pan blaynd ol fɔ difrɛn aplikeshɔn dɛn, lɛk:

● Implant ɛn prostɛtiks: fɔ skru ol dɛn na ɔtpidik implant ɛn dɛnt prɔstɛsis

● Surgical Instruments: Fɔ mawntin pɔynt ɛn fluid chanɛl dɛn na ɛndoskopik tul ɛn bayɔpsi divays dɛn .

● Diagnostik ikwipmɛnt: fɔ sɛns pɔt ɛn sampul chɛmba dɛn na blɔd analaiza ɛn DNA sikwinsa dɛn

Di yus fɔ blaynd ol na mɛdikal divays dɛn de mek shɔ se bayɔkɔmpatibiliti, stɛrilayz kɔmpitibliti, ɛn prɛsis fluid hanlin we de mentɛn strɔkchɔral intɛgriti ɛn minimiz kɔntaminɛshɔn risk dɛn.

Kes Study: Rial-Wɔl Aplikeshɔn dɛn .

Fɔ sho di prɛktikal aplikeshɔn dɛn fɔ blaynd ol dɛn, lɛ wi chɛk tu rial-wɔl kes stɔdi dɛn:

1. Fiul Injɛkta Nɔz:

wan. Chalenj: Disain wan fiul injekta noz wit prɛsis fiul flɔ chanɛl ɛn sikyuɔr mawntin pɔynt dɛn.

B. Sɔlv: Inkorpɔret blaynd ol fɔ di fiul chanɛl ɛn mawntin trɛd, mek shɔ se dɛn de sɛn di fiul ɔltɛm ɛn dɛn kin ebul fɔ gɛt atɛshmɛnt we dɛn kin abop pan to di injin.

c. Rizult: Impruv fiul efyushɔn, ridyus di efyushɔn, ɛn ɛkstend injɛkta layf.

2. Ɔtpidik Implant:

wan. Chalenj: Divɛlɔp wan hip implant wit sikyuɔr fikseshɔn ɛn optimal lod distribyushɔn.

B. Sɔlv: Yuz blaynd ol fɔ di skru trɛd ɛn porous kɔtin, fɔ protɛkt osseointegration ɛn ridyus strɛs shild.

c. Rizult: Enhans implant stεbiliti, fasta pasεnt rεkכvri, εn rεdכks risk fכ implant fεil.

Dɛn kes stɔdi ya de sho aw dɛn kin tayl blaynd ol dɛn to spɛshal aplikeshɔn dɛn, adrɛs yunik chalenj dɛn ɛn deliv supia pefɔmɛns insay rial-wɔl sɛnɛriɔ.

Best praktis in blaynd hol dizain ɛn mashin .

Fɔ mek shɔ se dɛn dɔn impruv blaynd ol dɛn fayn fayn wan na difrɛn injinɛri aplikeshɔn dɛn, i rili impɔtant fɔ adopt di bɛst we fɔ disayn ɛn fɔ mek mashin.

Fɔ mek shɔ se prɛsishɔn ɛn kɔnsistɛns .

achiv prɛsishɔn ɛn kɔnsistɛns insay blaynd ol dizayn ɛn . CNC mashin nid fɔ gɛt kɔmbaynshɔn fɔ robust dizayn prɔsis, ɔptimayz mashin paramita, ɛn strɔng prɔses kɔntrol. Sɔm impɔtant tin dɛn we wi fɔ tink bɔt na:

● Difayn klia ɛn achievable tolerance spesifikeshɔn dɛn bays pan di aplikeshɔn rikwaymɛnt dɛn .

● Fɔ pik di rayt mashin prɔses ɛn tul dɛn fɔ di spɛshal matirial ɛn ol jɔyometri .

● Optimizing cutting parameters, lɛk fid ret, spindle spid, ɛn dip fɔ kɔt, fɔ minimiz tul diflɛshɔn ɛn vaybreshɔn

● Implimɛnt Statistikal Prɔses Kɔntrol (SPC) tɛknik fɔ monitar ɛn mentein prɔses stebiliti .

● Ɔltɛm yu fɔ kalibrayt ɛn mek di mashin tul dɛn ɛn di tin dɛn we dɛn de yuz fɔ mɛzhɔ fɔ mek shɔ se yu gɛt kɔrɛkt ɛn ripitabiliti .

We dɛn fala dɛn prɔsis ya, injinia ɛn mashin man dɛn kin kɔnsistɛntli prodyuz blaynd ol dɛn wit di dimɛnshɔn dɛn we dɛn nid, sɔfays finish, ɛn kwaliti kwaliti dɛn.

Kwaliti ɛshyureshɔn ɛn inspekshɔn tɛknik dɛn .

Kwaliti ɛshyurishɔn ɛn inspekshɔn na impɔtant step dɛn fɔ mek shɔ se di blaynd ol dɛn we de na di blaynd ol dɛn de wok ɛn di we aw dɛn de wok. Di impɔtant kwaliti kɔntrol mɛsej dɛn na:

● Divɛlɔp wan kɔmprɛhɛnsif inspekshɔn plan we de difayn di impɔtant dimɛnshɔn, tolɛreshɔn, ɛn kwaliti kwaliti dɛn we dɛn fɔ verify .

● Implimɛnt in-prɔses inspekshɔn tɛknik, lɛk statystik sampling ɛn ɔtomatik gej, fɔ no ɛn kɔrɛkt ɛni devyashon ali insay di manufakchurin prɔses .

● Kɔndɔkt di las inspekshɔn dɛn we dɛn de yuz prɛsishɔn mɛzhɔmɛnt tul dɛn, lɛk kɔdinɛt mɛzhɔmɛnt mashin dɛn (CMM dɛn), bore gej dɛn, ɛn trɛd gej dɛn, fɔ asɛs di akkuracy ɛn kɔnfɔmans fɔ blaynd ol dɛn .

● Dokumɛnt inspekshɔn rizɔlt ɛn mentein traceability rɛkɛd fɔ kwaliti ɛshyurishɔn ɛn kɔntinyu fɔ impɔtant improvement purposes .

Ifektiv kwaliti ɛshyureshɔn ɛn inspekshɔn tɛknik dɛn ɛp fɔ no ɛn protɛkt difɛkt, ridyus skrap ɛn riwɔk, ɛn mek shɔ se blaynd ol dɛn mit di spɛsifikɛd rikwaymɛnt dɛn ɔltɛm.

Trenin ɛn Skil Divɛlɔpmɛnt fɔ Machinist dɛn .

Invɛstmɛnt insay trenin ɛn skil divɛlɔpmɛnt fɔ mashinist dɛn impɔtant fɔ ajɔst ay kwaliti blaynd ol ɛn optimiz di mashin prɔses. Di men tin dɛn we dɛn kin pe atɛnshɔn pan na:

● Fɔ gi kɔmprɛhɛnsif trenin bɔt di prinsipul dɛn fɔ blaynd ol mashin, inklud tul sɛlɛkshɔn, kɔt paramita, ɛn bɛst prɔsis fɔ spɛshal matirial ɛn aplikeshɔn dɛn

● Divɛlɔp han-on skils tru prɛktikal ɛgzampul ɛn simulshɔn, we de alaw mashin pipul dɛn fɔ gɛt ɛkspiriɛns fɔ sɛt ɛn ɔpreshɔn mashin tul dɛn fɔ blaynd ol mashin .

● Ɛnkɔrej kɔntinyu fɔ lan ɛn sheb no bɔt tin dɛn tru wokshɔp, sɛminari, ɛn pe-to-pi mentɔri program dɛn

● Fɔ protɛkt krɔs-fɔnshɔn kɔlabɔreshɔn bitwin mashin pipul dɛn, injinia dɛn, ɛn kwaliti pɔshɔnal dɛn fɔ fos wan kɔlchɔ fɔ kɔntinyu fɔ impɔtant ɛn fɔ mek nyu tin dɛn

Bay we dɛn gi di wan dɛn we de yuz mashin wit di skil ɛn no we dɛn nid, ɔganayzeshɔn dɛn kin ɛp fɔ mek di blaynd ol mashin wok dɛn wok fayn, fɔ mek dɛn ebul fɔ du dɛn wok fayn fayn wan, ɛn fɔ mek dɛn kɔnsistɛns.

Klin ɛn mentenɛns fɔ blaynd ol dɛn .

Fɔ klin ɛn mentenɛns di blaynd ol dɛn fayn fayn wan impɔtant fɔ mek shɔ se dɛn de wok fɔ lɔng tɛm ɛn fɔ mek dɛn nɔ gɛt dɔti ɔ fɔ mek dɛn nɔ pwɛl. If yu yuz di we aw yu de klin fayn fayn wan ɛn di tin dɛn we yu go yuz fɔ klin na:

● Yuz kɔmprɛsd ɛya ɔ vaykum sistem fɔ pul chips, dɔti, ɛn tin dɛn we nɔ klin frɔm di blaynd ol .

● Employing Ultrasonic Cleaning Techniques fɔ klin di intrikal jɔyometri dɛn ɛn di say dɛn we at fɔ rich fayn fayn wan.

● Fɔ yuz di rayt tin dɛn fɔ klin, lɛk sɔlvɛnt, digreas, ɔ smɔl ditajɛn, i go bi se na di tin dɛn we dɛn nid ɛn di tin dɛn we dɛn nid fɔ yuz

● Yuz spɛshal tin dɛn fɔ klin, lɛk brɔsh we dɛn kin yuz fɔ klin, swab, ɛn klos dɛn we nɔ gɛt lint, fɔ akses ɛn klin di blaynd ol fayn fayn wan .

Apat frɔm we dɛn kin klin am ɔltɛm, i impɔtant fɔ mek dɛn impruv wan prɛvɛntiv mentenɛns program we gɛt fɔ du wit inspekshɔn, lɔbrikeshɔn, ɛn riples di tul ɛn kɔmpɔnɛnt dɛn we dɔn pwɛl ɔ we dɔn pwɛl. Dis we fɔ du tin kin ɛp fɔ mek di tɛm we dɛn nɔ de wok nɔ bɔku, fɔ mek di layf we mashin tul dɛn de liv lɔng, ɛn fɔ mek di blaynd ol dɛn we de na di blaynd gɛt kwaliti ɛn fɔ mek dɛn nɔ gɛt wanwɔd.

FAQ dɛn .

K: Wetin na di men difrɛns bitwin blaynd ol ɛn tru ol?

A: Blaynd ol dɛn nɔ de go insay di wan ol tik we de na wan pat, we tru ol dɛn kin pas kɔmplit wan frɔm wan say to di ɔda say. Blaynd ol dɛn gɛt bɔt ɛn dɛn kɔmpleks to mashin pas tru ol dɛn.

K: Aw blaynd ol dɛn de ɛp fɔ mek di strɔkchɔral intɛgriti fɔ di kɔmpɔnɛnt dɛn bɛtɛ?

A: Blaynd ol dɛn de mentɛn di strɔkchɔral intɛgriti fɔ wan kɔmpɔnɛnt bay we dɛn nɔ go insay tru di ɔl tik, we de ridyus di strɛs kɔnsɛntreshɔn. Dɛn de impruv lod distribyushɔn ɛn resistans to bɛnd ɔ twist fɔs, ɛnhans di fatigue layf ɛn di tɛm we di pat de te.

K: Wetin na di mɔs kɔmɔn industri dɛm we de yuz blaynd ol tɛknɔlɔji?

A: Dɛn kin yuz blaynd ol dɛn na di erospace, ɔtomotiv, ilɛktroniks, ɛn mɛdikal divays industri. Dɛn industri ya nid kɔmpɔnɛnt dɛn wit ay trɛnk-to-weyt rɛsɛshɔn, prɛsis asɛmbli, ɛn spɛshal funkshɔnaliti, we blaynd ol kin gi.

K: Wetin na di men prɔblɛm dɛn we dɛn kin gɛt we dɛn de mek blaynd ol dɛn we dɛn de mek lɛk mashin?

A: Di men chalenj dɛm fɔ mashin blaynd ol dɛm inklud chip ɛvakyushɔn ɛn tul brek bikɔs ɔf limited spɛs, mentɛn kɔnsistɛns ol dip ɛn sɔfays finish, ɛn difikulti fɔ inspɛkt ɛn mɛzhɔ intanɛnt ficha dɛm. Tapping operations de mek bak risk fɔ tap brok ɔ thread damej.

K: Aw di evolushɔn fɔ matirial dɛn dɔn inflɔws blaynd ol mashin prɔsis?

A: Di evolushɔn fɔ di matirial dɛn dɔn mek dɛn mek spɛshal tul dɛn, lɛk ay-prɛshɔn kulant sistɛm ɛn chip-brɛkin drɔl jɔyometri, fɔ adrɛs di chalenj dɛn we de fɔ mashin blaynd ol dɛn na di tin dɛn we at ɔ we gɛt mɔ advans. Nyu matirial dɛn dɔn bak ɛkspɛn di aplikeshɔn ɛn pefɔmɛns kapabiliti fɔ di kɔmpɔnɛnt dɛn wit blaynd ol dɛn.

K: Wetin na di mɔs kɔmɔn saiz ɛn kayn blaynd ol dɛn we dɛn kin yuz na industri?

A: Di mɔs kɔmɔn blaynd ol saiz dɛn de frɔm smɔl dayamita fɔ ilɛktronik kɔmpɔnɛnt to big saiz fɔ ɔtomotiv ɛn aerospace aplikeshɔn. Blaynd ol dɛn we gɛt trɛd, ol dɛn we gɛt kɔntabɔr, ɛn spat fes dɛn na sɔm pan di kayn dɛn we dɛn kin yuz mɔ na difrɛn industri dɛn.

K: Aw yu go no di rayt dip fɔ wan blaynd ol?

A: Di rayt dip fɔ wan blaynd ol na in dɛn kin disayd bay di fɛnshɔnal rikwaymɛnt dɛn fɔ di kɔmpɔnɛnt, lɛk di trɛd ɛnjɔymɛnt lɔng we dɛn want ɔ kliarens fɔ mating pat dɛn. Dizayna dɛn fɔ tink bɔt tin dɛn lɛk di ol dayamita, di tin dɛn we dɛn yuz fɔ mek di tin dɛn we dɛn gɛt, ɛn di kapasiti we dɛn gɛt fɔ bia wit lod we dɛn de sho di dip dip ol dɛn we de na di ol.

K: Wetin na di bɛst we fɔ mek shɔ se di trɛd dɛn we de na wan blaynd ol klin ɛn prɛsis?

A: Fɔ mek shɔ se di trɛd dɛn klin ɛn prɛsis insay wan blaynd ol, yuz di rayt we fɔ tap, lɛk fɔ yuz ay kwaliti tap dɛn we gɛt di rayt jɔyometri ɛn kɔtin, put di wata we de kɔmɔt na di wata we de kɔt, ɛn kɔntrol di spid ɛn fɔs dɛn we de tap. Klin ɛn inspekshɔn ɔltɛm fɔ di ol dɛn we dɛn dɔn tap we yu de yuz trɛd gej ɛn vishɔn we yu de si kin mek di trɛd kwaliti kɔntinyu fɔ de.