injiniyɛri ni masinw ka mara kɔnɔ, . Dingɛw jɔyɔrɔ ka bon kosɛbɛ fɛn suguya caman dilanni n’u baarakɛcogo la. Olu la, fiyentɔw ka dingɛw, n’u bɛ Weele fana ko dingɛ minnu tɛ Tɛmɛ, olu nafa ka bon kosɛbɛ. Nin barokun in kun ye ka kunnafoni bɛɛ lajɛlen di fiyentɔw ka dingɛw kan, u baarakɛcogo, ani u dilanni n’u dilanni kɛcogo ɲumanw kan.

Fiyentɔw ka dingɛw faamuyali .

Ɛntɛrinɛti ni masinko diɲɛ kɔnɔ, dingɛw jɔyɔrɔ ka bon kosɛbɛ fɛn suguya caman dilanni n’u dilanni na. Dingɛ suguya wɛrɛw la, fiyentɔw ka dingɛw bɛ bɔ kɛnɛ kan k’a sababu kɛ u jogo kɛrɛnkɛrɛnnenw ye ani u kɛcogo caman. Nin yɔrɔ in laɲini ye ka faamuyali dafalen di fiyentɔw ka dingɛw kan, i n’a fɔ u ɲɛfɔli, u jogo, u kɔnɔfɛnw, u baarakɛminɛnw, ani u baarakɛcogo izini suguya caman na.

Fiyentɔw ka dingɛw ɲɛfɔli n’u jogo .

Fiyentɔ dingɛ dɔ, n’a bɛ fɔ fana ko dingɛ min tɛ tɛmɛn, o ye dingɛ sugu dɔ ye min bɛ sɔgɔ, ka sɔgɔ, walima ka sɛgɛn fo ka se a juguman kɛrɛnkɛrɛnnen ma, k’a sɔrɔ a ma kari ka taa baarakɛminɛn fan dɔ fɛ. O kɔrɔ ye ko fiyentɔ dingɛ bɛ duguma, a tɛ i n’a fɔ dingɛ-kɔnɔ-fɛn, o bɛ don fɛn in girinya bɛɛ la.

Fiyentɔw ka dingɛw jogo jɔnjɔnw ye:

● A yɔrɔ dɔ donna baarakɛminɛn kɔnɔ, ni a juguya ɲɛfɔlen don .

● Da wulilen kelen ani dakun dagalen kelen (jukɔrɔ) .

● A bɛ se ka siri walima ka a kɛ fɛn ye min tɛ sɔgɔ, ka kɛɲɛ ni a kɛcogo ye .

● A bɛ dɔ fara a jɔcogo dafalen kan ni a bɛ tali kɛ dingɛw kɔnɔ .

Fiyentɔw ka dingɛw bɛ danfara bɔ ni dingɛw ye cogo caman na:

jogoɲumanw . | Fiyentɔw ka dingɛ . | through-hole . |

Dunya | Yɔrɔ dɔw . | Faalen |

A bɛ ban . | Kelen dafalen, kelen datugulen . | U fila bɛɛ bɛ da wuli . |

Barika | sanfɛ . | Ka lajigin |

Machining . | A ka gɛlɛn kosɛbɛ . | A ka nɔgɔn . |

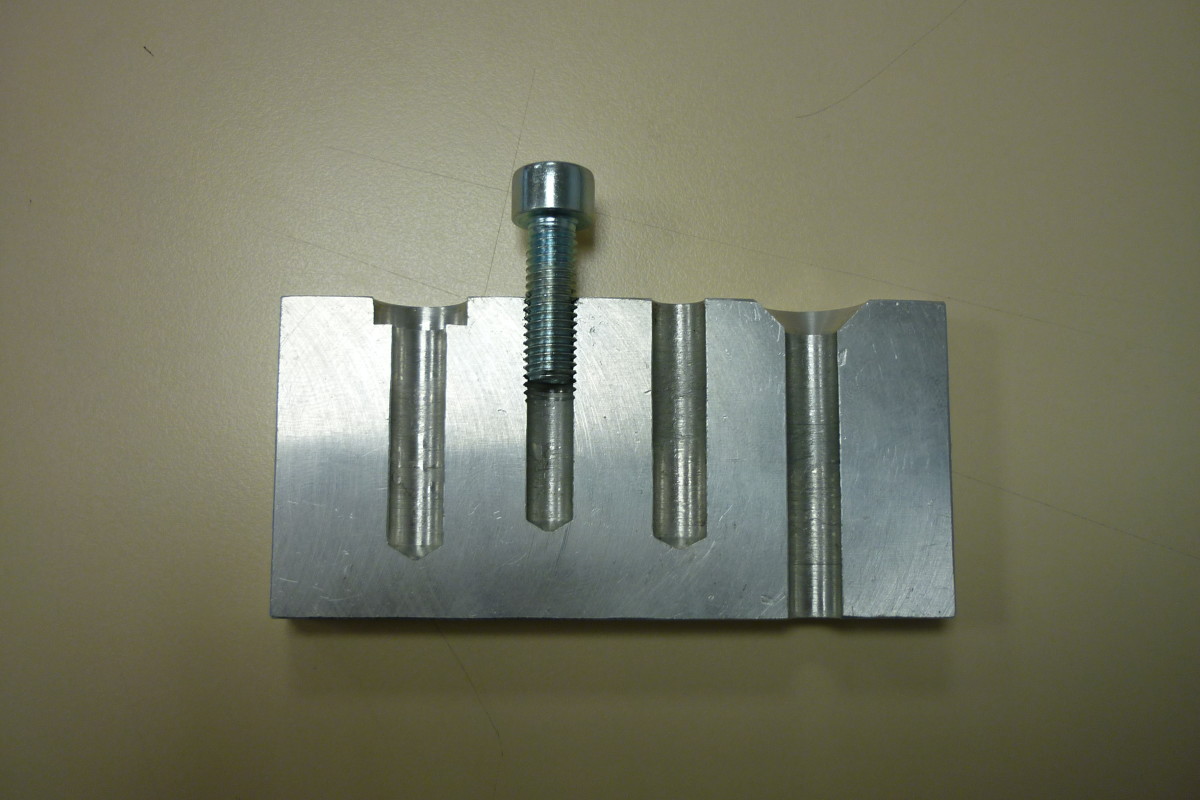

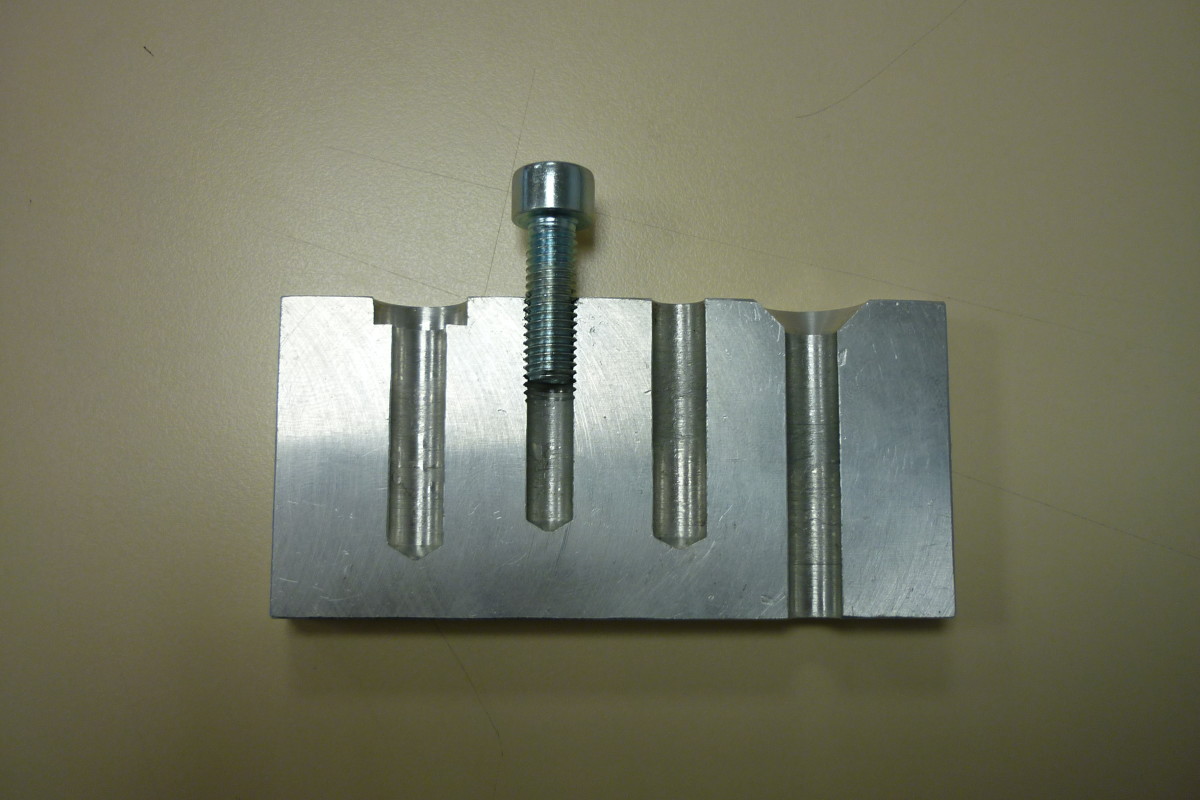

Fɛn minnu bɛ kɛ ani baarakɛminɛn minnu bɛ kɛ ka dingɛ fiyentɔw dilan .

Fiyentɔw ka dingɛw bɛ se ka dilan fɛn caman na, ka kɛɲɛ ni a kɛcogo kɛrɛnkɛrɛnnen ye ani a ka nafolo wajibiyalenw. Fɛn minnu bɛ kɛ ka caya, olu dɔw bɛ sɔrɔ fiyentɔw ka dingɛw kɔnɔ, olu dɔw ye:

● Nɛgɛw: aluminiyɔmu, nɛgɛ, nɛgɛ, titaniyɔmu, a ɲɔgɔnnaw.

● Plastikiw: akiriliki, nilon, polikarbonati, ɲɛkisɛ, a ɲɔgɔnnaw.

● Composites: polimɛri barikamaw (CFRP), polimɛri barikamaw (GFRP), a ɲɔgɔnnaw.

Walasa ka fiyentɔw ka dingɛw dilan, baarakɛminɛnw ni masin suguya caman bɛ baara kɛ, i n’a fɔ:

● Drills: Twist drills, spot drills, core drills, a ɲɔgɔnnaw.

● CNC masinw: CNC Mills, CNC lathes, CNC drills, wdfl.

● Baarakɛminɛn minnu bɛ mɔgɔ sɛgɛn: Baro minnu bɛ mɔgɔ sɛgɛn, kunkolo sɛgɛnnenw, a ɲɔgɔnnaw.

● Pompiw: Pompi minnu bɛ duguma, pɔmpi minnu bɛ kɛ ni spiral ye, pompi roll, a ɲɔgɔnnaw (walasa ka dingɛ fiyentɔw ye)

Fiyentɔw ka dingɛw baarakɛcogo izini suguya caman na .

Fiyentɔw ka dingɛw bɛ baara caman sɔrɔ izini suguya caman kɔnɔ k’a sababu kɛ u nafa ɲɔgɔn tɛ ani u bɛ se ka kɛ fɛn caman ye. Misali dɔw bɛ sɔrɔ iziniw na, fiyentɔw ka dingɛw nafa ka bon kosɛbɛ, olu ye:

1. Aerospace:

kelen. Avionw ka yɔrɔw jateminɛcogo nɔgɔman .

B. Fastener dingɛw bɛ Airframe structures kɔnɔ .

C. Fuel injection nozzles bɛ sɔrɔ jet motɛriw kɔnɔ .

2. Mobili:

kelen. Motɛri bloki ani transmission component design .

B. Suspension ani frein system yɔrɔw .

C. Dingɛw minnu bɛ siri ni sirilanw ye ani sensɛriw .

3. Elektroniki:

kelen. PCB jiginni dingɛw ye yɔrɔw ye .

B. Heatsink Attachment Points .

C. Enclosure design ka ɲɛsin ɛntɛrinɛti minɛnw ma .

Yɔrɔ kɛrɛnkɛrɛnnenw ni lajɛw minnu bɛ kɛ cogoya la minnu bɛ kɛ ni fiyentɔw ye, olu ye:

● Jogindaw ni u siriyɔrɔw sirilenw .

● Ka sow ni bushingw kɛ .

● Ji ni gazi bɔli siraw .

● Sensor ani sonda jiginni yɔrɔw .

● Baarakɛminɛnw ni fɛnw labɛncogo .

Dingɛ suguyaw n' u baarakɛcogo Engineering kɔnɔ .

Dingɛw ye fɛn jɔnjɔn ye ɛntɛrinɛti ni masinw na, minnu bɛ baara kɛ ni fɛn caman ye u yɔrɔw dilanni n’u baaracogo la. Nin yɔrɔ in bɛ dingɛ suguya wɛrɛw sɛgɛsɛgɛ minnu bɛ kɛ ka caya ɛntɛrinɛti la, ni u sinsinnen bɛ dingɛw kan minnu bɛ kɛ ni fɛnw ye minnu bɛ kɛ ni fɛnw ye minnu bɛ wuli, dingɛw minnu bɛ kɛ ka fɛnw sɔgɔ, ani ɲɛda minnu bɛ kɛ yɔrɔw ye. Ka fara o kan, an bɛna kuma fiyentɔw ka dingɛw nafa kan baarakɛcogo la ani u nɔfɛkow dilancogo ni ɲɛnajɛko la.

dingɛ suguya wɛrɛw n' u baaracogo .

counterbored holes .

Dingɛ min bɛ Kɛ ni 'kɔnɔna ye, o ye dingɛ ye min janya ka bon ni dingɛ ye min bɛ Dòn baarakɛminɛn dɔ la, o kɔ fɛ, dingɛ fitinin dɔ bɛ Bɔ min bɛ Taa ka Tɛmɛ a janya tɔ kan. A cɛmancɛ yɔrɔ min ka bon, o bɛ wele ko counterbore, wa a bɛ a to fɛn sirilan kunkolo ka sigi ni baarakɛminɛn sanfɛla ye walima a duguma.

Dingɛw minnu bɛ kɛ ka fɛnw kɛlɛ, olu jogo:

● Dingɛw dilanni senfɛ-senfɛ: counterbore ani through-hole fitininw .

● Jiginni fla bɛ sɔrɔ counterbore portion kɔnɔ .

● A bɛ sirilanw ladon minnu kun ye silinda ye .

Dingɛw minnu bɛ kɛ ni fɛnɲɛnamafagalanw ye, olu baarakɛcogo:

● Aw bɛ bolokɔniw, juruw walima fɛn wɛrɛw siri ni u sanfɛla ye .

● ka clearance kɛ ka ɲɛsin fɛn sirilan kunkolo ma .

● Ka yɔrɔw lajɛ minnu lajɛlen don .

countersunk holes .

Jatebɔ-yɔrɔ dɔ bɛ i n’a fɔ dingɛ min bɛ Kɛ ni 'kɔnɔna ye nka a bɛ Kɛ ni cogoya ye min bɛ Kɛ ni 'kɔnɔna ye a cɛmancɛ-yɔrɔ la min ka bon ni a duguma-yɔrɔ fla ye. O cogo la, fɛn min bɛ kɛ ni fɛn ye, o bɛ kɛ sababu ye ka fɛnw siri ni kun fla ye, u ka sigi ni baarakɛminɛn sanfɛla ye, ka ɲɛda cogoya nɔgɔman ni nɔgɔyalen dilan.

countersunk dingɛw cogoya:

● Dingɛw dilanni senfɛ-senfɛ: countersink ani through-hole fitininw .

● cogo la min bɛ kɛ ni kon ye, o bɛ sɔrɔ fɛnɲɛnamafagalan yɔrɔ la .

● A bɛ sirilanw ladon ni kunkolo fla ye .

countersunk dingɛw baarakɛcogo:

● Ka fɛn dɔ di min bɛ kɛ ka ɲɛgɛnɛ kɛ .

● Aerodinamiki jiginni ni a ɲɛnabɔli dɔgɔyali awiyɔnw ni mɔbiliw kɔnɔ .

● Ka fɛnw lajɛlenw ka ɲɛnajɛw yiriwa .

Spot Faces .

Spot face ye counterbore ye min man dun, min bɛ kɛ ka yɔrɔ flakɛlen ni nɔgɔlen dɔ Dabɔ dingɛ dɔ lamini na. A ka c’a la, a bɛ kɛ ka jɛɲɔgɔnya kɛ ni fɛn sirilan walima kolikɛnɛ kun ye, ka sigiyɔrɔ ɲuman ni doni tilali sabati.

Spot ɲɛda cogoya:

● Sɔgɔsɔgɔninjɛ min bɛ kɛ ka dingɛ dɔ lamini .

● A bɛ yɔrɔ flakɛlen dɔ Dabɔ, min bɛ jɔ .

● A bɛ sirilan sigiyɔrɔ ni a doni tilali ɲɛ .

Spot faces (yɔrɔw ɲɛda) baarakɛcogo:

● Ka ɲɔgɔn sɔrɔ yɔrɔ fla la ka ɲɛsin fɛnw sirilanw ni u kolanw ma .

● Ka fɛnw lajɛlenw tiɲɛni ni u sabatili bonya .

● Ka masinw yɔrɔw cogoya ɲɛ .

Nafa minnu bɛ sɔrɔ fiyentɔw ka dingɛw la .

Fiyentɔw ka dingɛw bɛ nafa caman di baarakɛcogo la ɛntɛrinɛti ni masinw na:

1. Fanga bonya : Fiyentɔw ka dingɛw bɛ yɔrɔ dɔ jɔcogo dafalen mara ni u tɛ don u bonya bɛɛ la, ka degun hakɛw dɔgɔya.

2. Girinyali dɔgɔyali : Ni fɛn minnu tɛ mako ɲɛ, olu bɔli dabila, fiyentɔw ka dingɛw bɛ dɛmɛ ka fɛnw girinya bɛɛ lajɛlen dɔgɔya k’a sɔrɔ u ma fanga tiɲɛ.

3. Datugulan ɲɛnabɔlen : Fiyentɔw ka dingɛw bɛ se ka kɛ ka ɲɛgɛnɛsira walima bɔrɔw dilan walasa ka tulumafɛnw, gaziw walima jiw mara.

4. Thread engagement enhanced : Fiyentɔw ka dingɛw bɛ dilan ka caya sirilanw na ni u bɛ tali kɛ dingɛw la, o bɛ na ni ɲɔgɔndan barikamaw ni lakanalenw ye.

A bɛ nɔ min bila dilancogo ni ɲɛnajɛko la .

Dingɛ suguya sugandili bɛ se ka nɔba bila fɛnw dilanni n’u ɲɛnajɛcogo la minnu dilannen don ni ɛntɛrinɛti ye:

1. Flush surfaces (Flush surfaces) : Dingɛ minnu bɛ kɛ ka u siri ani ka u kɛ ka u siri, olu bɛ a to sirilanw bɛ sigi ni yɔrɔ ye, ka ɲɛda kɛ cogo nɔgɔman na ani ka a kɛ min bɛ wuli.

2. Saniya ni baarakɛcogo ɲuman: Dingɛ minnu dilannen don ka ɲɛ ani minnu dilannen don ni masinw ye, olu bɛ kɛ sababu ye ka fɛn dɔ yecogo bɛɛ lajɛlen diyabɔ ani ka a ye.

3. Ergonomiw ɲɛnabɔlen : Flush surfaces ani dingɛw minnu bɛ bila yɔrɔ ɲuman na, olu bɛ se ka fɛn dɔ ka ergonomiw bonya, o bɛ a to a ka di ani a bɛ se ka baara kɛ ni a ye.

4. Marka kɛcogo basigilen: Dingɛ suguyaw baaracogo ɲuman bɛ se ka kɛ sababu ye ka taamasiyɛn kɛcogo basigilen ni dɔnta sɔrɔ fɛn caman na.

Masini fɛɛrɛw fiyentɔw ka dingɛw kama .

Fiyentɔw ka dingɛw jɔyɔrɔ ka bon kosɛbɛ ɛntɛrinɛti baara suguya caman na, wa u dilanni tigitigi nafa ka bon walasa ka fɛn laban in baarakɛcogo n’a kɛcogo ɲuman sɔrɔ. Nin yɔrɔ in bɛna sɛgɛsɛgɛli kɛ masinko fɛɛrɛ suguya caman na minnu bɛ kɛ ka dingɛ fiyentɔw dilan, i n’a fɔ sɔgɔli, sɛgɛn, sɔgɔli, ani fɛɛrɛ kɔrɔlenw i n’a fɔ marifa sɔgɔli ani trepanning. An bɛna kuma fana baarakɛminɛnw ni minɛnw jateminɛw kan, ka fara gɛlɛyaw kan minnu bɛ sɔrɔ masinko siratigɛ la ani u furakɛcogo la.

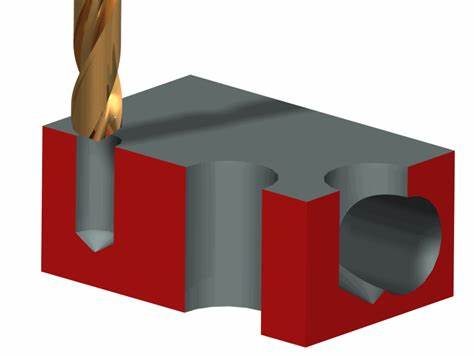

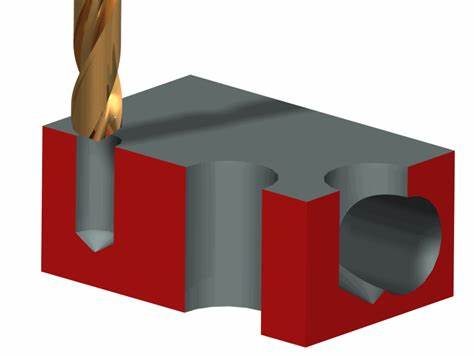

Drilling ani Boring fɛɛrɛw .

Drilling ye fɛɛrɛ ye min ka ca ni tɔw bɛɛ ye fiyentɔw ka dingɛw dilanni na. Fɛn minnu bɛ kɛ ka fiyentɔw sɔgɔ, olu bɛ kɛ senfɛ-senfɛ, o bɛ tali kɛ:

1. Ka drill bitiki bɛnnen sugandi ka da dingɛ cɛmancɛ ni fɛn ɲininen kan.

2. Ka dunuya jɔ walima ka baara kɛ ni drill bitiki ye ni dunuya taamasiɲɛ ye walasa ka dingɛ juguya ɲuman sɔrɔ.

3. Aw bɛ baarakɛminɛn lakana kosɛbɛ walasa ka lamaga bali a sɔgɔli waati la.

4. Aw bɛ tigɛji kɛ ka drill bitiki tulu kɛ ka chips bɔ.

5. Ka dingɛ da teliya ni balo hakɛ bɛnnen na, ka drill bitiki kɔsegin tuma ni tuma walasa ka chips saniya.

6. Ka dingɛ juguya ni a jogo sɛgɛsɛgɛ ni sumanikɛlanw ye.

Walasa ka tiɲɛni mara ani ka drilling filiw bali minnu bɛ kɛ tuma caman na:

● Aw bɛ baara kɛ ni drill bits sharp ye, minnu ka ɲi kosɛbɛ, minnu bɛnnen don fɛn ma min bɛ sɔgɔ.

● Aw bɛ aw jija ka drill bitiki ni baarakɛminɛn in ɲɔgɔnna labɛn ka ɲɛ.

● Aw bɛ degun sabatilen, min bɛ kɔlɔsi, o kɛ a sɔgɔli waati la.

● Aw bɛ teliya ni balo hakɛ ladilan ka kɛɲɛ ni fɛn ni dingɛ hakɛ ye.

● Aw bɛ to ka chips bɔ dingɛ kɔnɔ walasa ka drill bit kari bali ani ka dingɛ sanuman dɔ lajɛ.

Boring ye fɛɛrɛ wɛrɛ ye min bɛ kɛ ka dingɛ fiyentɔw dilan, kɛrɛnkɛrɛnnenya la ni a ka kan ka kɛ ni fɛn ye min bɛ se ka kɛ ka ɲɛ ani ka kɛ ni dugukolo ye. Boring ye ka baara kɛ ni tigɛminɛn ye min bɛ kɛ ni yɔrɔ kelen ye walasa ka dingɛ dɔ bonya min tun bɛ sɔgɔ ka kɔrɔ fo ka se a bonya ni a juguman ma.

Fɛɛrɛ minnu bɛ taa ɲɛ: Marifa sɔgɔli ni Trepanning .

Marifa sɛgɛsɛgɛli ye masinko fɛɛrɛ kɔrɔlen ye min bɛ kɛ ka dingɛ fiyentɔw dilan minnu ka dun, minnu bɛ kɛ tigitigi ni u janya ni u janya hakɛ ye. O kɛcogo bɛ kɛ ni marifa-minɛn kɛrɛnkɛrɛnnen ye ni nɛnɛmadalan ye min bɛ tigɛ-tigɛ-minɛn di min bɛ tigɛ-ji lase drill tip ma, ka chips bɔ ka ɲɛ ani ka drill kari bali.

Trepanning ye fɛɛrɛ wɛrɛ ye min bɛ taa ɲɛ fiyentɔw ka dingɛ belebelebaw dilanni na. O ye ka baara kɛ ni trepanning baarakɛminɛn kɛrɛnkɛrɛnnen ye min bɛ sɛrɛkili dɔ tigɛ ka don baarakɛminɛn kɔnɔ, ka koro gɛlɛn to yen min bɛ se ka bɔ kɔfɛ. A ka ca a la, trepanning bɛ kɛ ni dingɛ cɛmancɛ wajibiyalen ka bon kojugu drilling fɛɛrɛ kɔrɔw la.

Baarakɛminɛnw ni minɛnw jateminɛw .

Baarakɛminɛnw ni minɛnw bɛnnenw sugandili nafa ka bon kosɛbɛ fiyentɔw ka dingɛw dilanni na. Jateminɛba dɔw ye:

● Ka drill bit material ɲuman sugandi ani ka da ka kɛɲɛ ni baarakɛminɛn ye ani dingɛ cogoya ɲininen.

● Ka baara kɛ ni masinw ye minnu ka ɲi kosɛbɛ, minnu ka gɛlɛn, minnu fanga ni u sabatili bɛnnen don.

● Ka baara kɛ ni baarakɛminɛnw ye minnu bɛnnen don walasa ka u labɛn ka ɲɛ ani ka baarakɛminɛnw lamagacogo bali.

● Ka baara kɛ ni tigɛjiw ni nɛnɛfɛnw ye walasa ka funteni dɔgɔya, ka baarakɛminɛnw ɲɛnamaya ɲɛ, ani ka dingɛw cogoya ɲɛ.

Tapping fɛɛrɛw fiyentɔw ka dingɛw kama .

Tapping (Tapping) ye kɔnɔna jiriw dilanni taabolo ye fiyentɔw ka dingɛ kɔnɔ min tun bɛ sɔgɔ ka kɔrɔ. Piki suguya ni a bonya ɲuman sugandili nafa ka bon kosɛbɛ walasa ka jiri suguya ɲininen sɔrɔ ani ka pompi kari bali. Pompi suguya minnu bɛ kɛ tuma caman na, olu dɔw bɛ kɛ fiyentɔw la, olu dɔw ye:

● Pompiw duguma: A dilannen don ni jiribolo surun ye ani jiri dafalenw fo ka se pompi jukɔrɔ, a bɛnnen don ka siri ka taa dingɛ fiyentɔ dɔ jukɔrɔ.

● Spiral point taps: A bɛ ni pointed end ani spiral flutes ye minnu bɛ chips ɲɛminɛ ka taa ɲɛfɛ, a ka ɲi fiyentɔw ka dingɛw ma dingɛw kɔnɔ.

● Pompiw dilanni: A bɛ kɛ ka jiriw dilan ni fɛn ye min bɛ fɛnw bila ka bɔ u la sanni ka tigɛ, o bɛ na ni jiri barikamaw ye ani ka chip dilan dɔɔni.

Ni aw bɛ fiyentɔw ka dingɛw gosi, a nafa ka bon kosɛbɛ:

● Aw bɛ a lajɛ ni tulu ni chip bɔli bɛrɛ bɛnnen don walasa ka pɔnpe kari bali.

● Aw bɛ pompi ni dingɛ aksidanw labɛncogo ɲuman mara.

● Aw bɛ degun sabatilen, min bɛ mara ani ka pɔnpe in kɔsegin tuma ni tuma walasa ka chips tiɲɛ.

● Aw bɛ baara kɛ ni tapping guide walima fixture ye walasa ka perpendicularity sɔrɔ ani ka pompe wobble bali.

Gɛlɛyaw bɛ kɛ jirituru ni sɔgɔli la .

Masini fiyentɔw ka dingɛw bɛ na n’a yɛrɛ ka gɛlɛyaw ye, minnu ɲɛsinnen bɛ fɔlɔ chip bɔli ma ani baarakɛminɛnw labɛnni ma. Ko minnu bɛ kɛ tuma caman na k’a sɔrɔ u bɛ baara kɛ ni fiyentɔw ye, olu dɔw ye:

● chip congestion (puce congestion) : Ni dingɛ juguya bɛ ka caya, chip (puce) bɔli bɛ gɛlɛya ka taa a fɛ, o bɛ na ni baarakɛminɛnw tiɲɛni ye ani dingɛ cogoya jugu.

● Baarakɛminɛnw labɛncogo : ka drill bitiki walima pompi ni dingɛ aksidan ka ɲɔgɔndɛmɛ ɲuman mara, o nafa ka bon kosɛbɛ baarakɛminɛnw sɛgɛsɛgɛli balili la ani ka dingɛ tilennen sabati.

● nɛnɛmadalan jiginni : ka a lajɛ ko nɛnɛmadalan bɛnnen bɛ se tigɛda ma, o bɛ se ka gɛlɛya, kɛrɛnkɛrɛnnenya la, dingɛ fiyentɔw kɔnɔ.

Walasa ka se sɔrɔ o gɛlɛyaw kan, masinw bɛ se ka fɛɛrɛ suguya caman ta ani ka fɛɛrɛw tigɛ minnu bɛ se ka bana kunbɛn, i n’a fɔ:

● Aw bɛ baara kɛ ni nɛnɛmadalan ye min bɛ tansiyɔnba la walima ka tɛmɛ ni nɛnɛmafɛnw ye minnu bɛ se ka kɛ ka chips bɔ ka ɲɛ.

● Ka baara kɛ ni ɲɛminɛlanw ye, pilotiw ka dingɛw, walima fɛn kɛrɛnkɛrɛnnenw ye minnu bɛ kɛ ka baarakɛminɛnw labɛn.

● Waati ni waati ka baarakɛminɛn in kɔsegin walasa ka chips kari ani ka bɔ.

● Baarakɛminɛnw sugandili ni chip-breaking geometries walima coatings ye minnu bɛ chip bɔli nɔgɔya.

● Ka tigɛcogo paramɛtɛrɛw ladilan, i n’a fɔ teliya ni balo hakɛ, walasa ka chip dilancogo n’a bɔcogo ɲɛ.

Dilanko jateminɛw fiyentɔw ka dingɛw kan .

Yɔrɔw dilanni ni fiyentɔw dingɛw ye, o bɛ jateminɛ kɛ kosɛbɛ walasa ka baarakɛcogo ɲuman, fɛn dilanni, ani fɛn laban bɛɛ ka jogo ɲuman sɔrɔ. Nin yɔrɔ in bɛna sɛgɛsɛgɛli kɛ dilancogo kunbabaw kan, ɛntɛrinɛti injiniyɛriw ka kan ka jateminɛ kɛ cogo min na ni u bɛ fiyentɔw ka dingɛw don u kɔnɔfɛnw na, i n’a fɔ dingɛ jateminɛ, fɛnw sugandili, muɲuli, ani jɛɲɔgɔnya ni fɛn wɛrɛw ye.

Hole Geometry: A juguya ani a cɛmancɛ .

Fiyentɔw ka dingɛw labɛncogo fɔlɔ dɔ ye ka dingɛ jateminɛcogo bɛnnen dɔn, kɛrɛnkɛrɛnnenya la, a juguya n’a cɛmancɛ. Dingɛ fiyentɔ dɔ juguya bɛ Fɔ a ka c’a la ni a yɔrɔ in ka baarakɛcogo wajibiyalenw ye, i n’a fɔ jiribolo-yɔrɔ janya ɲininen walima dingɛ min bɛ Taa-ka-bɔ walima min ka kan ka Bɔ a la ka ɲɛsin jɛɲɔgɔnya yɔrɔ dɔ ma.

Ni u bɛ dingɛ cɛmancɛ sugandi, dilanbagaw ka kan ka jateminɛ kɛ:

● furuɲɔgɔnya yɔrɔ walima a sirilan hakɛ .

● Fanga ni doni tacogo wajibiyalen .

● Yɔrɔ min bɛ sɔrɔ yɔrɔ kɔnɔ .

● Masini seko ni baarakɛminɛnw dantigɛli .

A nafa ka bon kosɛbɛ ka balansi don dingɛ juguya ni a cɛmancɛ cɛ walasa ka yɔrɔ in jɔcogo dafalen sɔrɔ ka sɔrɔ ka baarakɛcogo ɲininiw dafa.

Material Selection ani Propriétés .

Fɛn sugandili jɔyɔrɔ ka bon fiyentɔw ka dingɛw dilanni n’u dilanni na. Fɛn suguya caman bɛ jogo caman jira minnu bɛ nɔ bila sɔgɔli ni sɔgɔli kɛcogo la, i n’a fɔ gɛlɛya, ductility, ani chip formation.

Fɛn minnu bɛ kɛ ka caya, olu bɛ kɛ fɛn minnu na ni dingɛ fiyentɔw ye, olu ye:

● Nɛgɛw: aluminiyɔmu, nɛgɛ, nɛgɛ inox, titanium, brass

● Plastikiw: nilon, asetali, polikarbonati, peek .

● Composites: GFRP, CFRP, FRP .

Ni fɛn dɔ sugandira, fɛn dilannikɛlaw ka kan ka jateminɛ kɛ:

● A yɔrɔ fanga ni a muɲuli wajibiyalen .

● Bɛnkan min bɛ kɛ ni furuɲɔgɔnya yɔrɔw ye walima a sirilanw .

● Fiyentɔw ka dingɛw dilanni n’u dilanni nɔgɔya .

● O fɛnw musaka ni u sɔrɔli .

Tolerances ani Surface Finish wajibiyalenw .

Tolerances bɛnnenw ni surface fini wajibiyalenw ɲɛfɔli nafa ka bon walasa ka fiyentɔw ka dingɛw bɛncogo ɲuman, u baara ani u jogo ɲuman sabati. Tolerances ( muɲuni ) bɛ , o bɛ , min bɛ sɔn , o bɛ , fɛn minnu bɛ sɔn , i n' a fɔ u juguya , u cɛmancɛ , ani u jɔyɔrɔ tiɲɛni .

Fɛn minnu ka kan ka jateminɛ ni u bɛ muɲuliw ɲɛfɔ fiyentɔw ka dingɛw kama, olu ye:

● Baarakɛcogo wajibiyalenw ani cɛnimusoya yɔrɔw .

● fɛn dilanni taabolo seko ni dantigɛli .

● Sɛgɛsɛgɛli ni sumanikɛcogo minnu bɛ sɔrɔ .

Surface Finish wajibiyalenw, minnu bɛ fɔ cogoya la gɛlɛya hakɛ cɛmancɛ (RA) walima gɛlɛya hakɛ maksimali (Max) siratigɛ la, olu bɛ nɔ bila fiyentɔw ka dingɛw baaracogo n’u cogoya la. A ka ca a la, a ka ɲi ka a kɛ a ɲɛda la:

● Ka yɔrɔ in sɛgɛn fanga ni a muɲuni ɲɛ .

● ka ɲɔgɔnkanu dɔgɔya ani ka u sɛgɛn cɛnimusoya yɔrɔw la .

● Ka yɔrɔw yecogo ɲɛnatɔmɔlenw bonya ka ɲɛ .

jɛɲɔgɔnya ni fɛn wɛrɛw ni a yɔrɔw ye .

Fiyentɔw ka dingɛw man teli ka sɔrɔ u dan na; U ka teli ka baara kɛ ni fɛn wɛrɛw ye ani fɛn wɛrɛw lajɛyɔrɔ kɔnɔ. Dilanbagaw ka kan ka jateminɛ kɛ cogo min na fiyentɔw ka dingɛw bilali, u ɲɛsincogo ani u dilanni bɛ nɔ bila fɛn dilannen ka baarakɛcogo bɛɛ lajɛlen na ani a dilanni na.

Jateminɛba minnu kɛra, olu ye:

● A bɛ se ka kɛ ko a bɛ se ka kɛ ka fɛnw sɛgɛsɛgɛ ani ka se ka u ta ka ɲɛ .

● Ka i yɛrɛ tanga fɛn wɛrɛw ma minnu bɛ se ka i bali, i n’a fɔ dingɛw walima dakunw kɛrɛfɛ .

● Ka doni tilali ni degun hakɛ ɲɛnabɔ fiyentɔw ka dingɛ lamini na .

● Ka lajɛ kɛcogo nɔgɔya ani ka farati dɔgɔya min bɛ se ka kɛ ka ɲɛsin ɲɔgɔn ma .

Design for Manufacturability ani a lajɛ .

Fiyentɔw ka dingɛw dilanni ni u dilanni n’u lajɛli ye, o nafa ka bon kosɛbɛ walasa ka sɛnɛfɛnw dilanni taabolo nɔgɔya ani ka musakaw dɔgɔya. Dilanbagaw ka kan ka jɛ ka baara kɛ ni fɛn dilanni injiniyɛriw ni masinw ye walasa ka a dɔn ko fiyentɔw ka dingɛ minnu dilannen don, olu bɛ se ka dilan ka ɲɛ ani ka kɛ tuma bɛɛ.

Fiyentɔw ka dingɛw dilanni fɛɛrɛ ɲuman dɔw bɛ sɔrɔ u dilanni n’u lajɛcogo la, olu dɔw ye:

● Ka dingɛ hakɛw ni muɲuli kɛ kelen ye ni a bɛ se ka kɛ tuma o tuma .

● ka juguya ni a cɛmancɛ hakɛ dɔgɔya walasa ka sɔgɔli ni sɔgɔli nɔgɔya .

● ka yɔrɔ bɛnnen di chip evacuation ani coolant flow ma .

● Ka chamfers walima countersinks don a kɔnɔ walasa ka dɛmɛ don baarakɛminɛnw labɛnni na ani u doncogo la .

● Ka jateminɛ kɛ ni jurukisɛ walima fɛnw doncogo ye walasa ka u lajɛ nɔgɔya la .

Ni u ye nin dilancogo fanw jateminɛ koɲuman ani ka baara kɛ ɲɔgɔn fɛ ni fɛn dilanko jɛkuluw ye, ɛntɛrinɛti injiniyɛriw bɛ se ka yɔrɔw dilan minnu bɛ ni fiyentɔw ye minnu bɛ baarakɛcogo ɲininenw dafa ka sɔrɔ ka fɛn dilanni, a jogo ɲuman ani a musaka kɛcogo ɲɛ.

Fiyentɔw ka dingɛw nafaw ni danw .

Fiyentɔw ka dingɛw ye fɛn nafamaw ye ɛntɛrinɛti baara suguya caman na, minnu bɛ nafa kɛrɛnkɛrɛnnenw ni nafaw di dingɛw kɔnɔ. Nka, u bɛ na ni dan ni gɛlɛya dɔw ye fana, dilanbagaw ni fɛn dilannikɛlaw ka kan ka minnu jateminɛ.

structurel integrité ni a ka lakana sabatili .

Fiyentɔw ka dingɛw nafa fɔlɔ dɔ ye u ka se ka fɛnw jɔcogo dafalen n’u lakanani sabati. Ni u ma don fɛn in girinya bɛɛ la, fiyentɔw ka dingɛw bɛ yɔrɔ fanga bɛɛ mara, ka dɔ bɔ kari walima dɛsɛ farati la doni kɔrɔ.

Fiyentɔw ka dingɛw nafa jɔnjɔnw sigicogo dafalen ni u lakanani siratigɛ la, olu ye :

● Degunw hakɛ dɔgɔyali ka kɛɲɛ ni dingɛw ye .

● A ka doni tilatilali ani a ka se ka wuli walima ka se ka wuli fanga la .

● Sɛgɛn ɲɛnamaya bonya ani a yɔrɔ muɲuni .

● ka dɔ fara lakana kan baara kɛtaw la minnu na ji walima gazi minɛni nafa ka bon kosɛbɛ .

Fiyentɔw ka dingɛw nafa ka bon kɛrɛnkɛrɛnnenya la iziniw kɔnɔ i n’a fɔ aerospace, mobili, ani furakɛli minɛnw, yɔrɔ minnu na, u jɔcogo dafalen ni u lakanani de ka bon kosɛbɛ.

Gɛlɛyaw masinw ni jogoɲini na .

Hali n’u bɛ nafa sɔrɔ, fiyentɔw ka dingɛw bɛ gɛlɛya kɛrɛnkɛrɛnnenw lase masinko ni jogoɲini taabolo la. Dingɛ jukɔrɔla sɔrɔli danma ani a yecogo bɛ se ka gɛlɛya ka a to a ka se ka dunuya, dugukolo sanfɛla dafalen, ani jiri cogoya ɲuman sɔrɔ.

Gɛlɛya minnu bɛ sɔrɔ tuma caman na, n’olu bɛ sɔrɔ masin fiyentɔw ka dingɛw la, olu dɔw ye:

● chip evacuation ani baarakɛminɛnw kari ka da yɔrɔ danma kan chip flow kama .

● Gɛlɛya bɛ dingɛ juguya ni duguma da la cogo basigilen na .

● Gɛlɛya minnu bɛ dingɛ kɔnɔna yɔrɔw sɛgɛsɛgɛli n’u sumani na .

● Ka dɔ fara a ka pompi kari walima a ka juru tiɲɛni kan tapping baara senfɛ .

Walasa ka se sɔrɔ o gɛlɛyaw kan, fɛn dilannikɛlaw bɛ baarakɛminɛn kɛrɛnkɛrɛnnenw kɛ, i n’a fɔ nɛnɛmadalan minnu bɛ degunba la, chip-breaking drill geometries, ani thread-forming taps. Sɛgɛsɛgɛli fɛɛrɛ kɔrɔlenw, i n’a fɔ borescopes ani profilometers, olu bɛ kɛ ka kɔnɔnafɛnw cogoya sɛgɛsɛgɛ.

Musow ka musaka ni fɛnw baaracogo .

Fiyentɔw ka dingɛw musaka ni u kɛcogo fɛnw bɛ bɔ fɛn suguya caman na, i n’a fɔ a yɔrɔw dilanni, u dilanni hakɛ, ani u dilanni taabolo minnu bɛ o ko la.

Fiyentɔw ka dingɛw nafa musaka ni fɛnw baaracogo siratigɛ la, olu dɔw ye:

● Fɛnw tiɲɛni dɔgɔyali ni u bɛ tali kɛ dingɛw kɔnɔ, bawo fɛn caman bɛ bɔ .

● A bɛ se ka kɛ siɲɛ surunw na ani ka dɔ fara baarakɛcogo kan baara dɔw la .

● Se ka baara kɛ ni fɛnw ye minnu sɔngɔ ka dɔgɔ, minnu tɛ masina caman ye, ka ɲɛsin yɔrɔ fan dɔ ma .

Nka, nafa minnu bɛ se ka sɔrɔ, olu fana bɛ yen minnu ka kan ka jateminɛ:

● Baarakɛminɛnw musakaw cayara ka ɲɛsin sɛgɛsɛgɛli kɛrɛnkɛrɛnnenw ma, pɔmpiw ma, ani sɛgɛsɛgɛli minɛnw ma .

● Masina waati janw ni dingɛw ta ye, kɛrɛnkɛrɛnnenya la, jateminɛ juguw walima jateminɛ gɛlɛnw na .

● Sɔgɔsɔgɔninjɛ hakɛ caman ani baara seginni musakaw ka da gɛlɛyaw kan minnu bɛ sɔrɔ jogo ɲuman sabatili la .

Walasa ka fiyentɔw ka dingɛw, fɛn dilannikɛlaw ni fɛn dilannikɛlaw ka musaka dɔgɔyali n’u kɛcogo ɲuman sɔrɔ, olu ka kan ka jateminɛ kɛ kosɛbɛ baarakɛcogo la, fɛn dilanni fɛɛrɛ minnu bɛ sɔrɔ, ani jagokɛcogo minnu bɛ kɛ baara kɛcogo, a jogo ɲuman ani a musaka cɛ.

Fiyentɔw ka dingɛw baarakɛcogo iziniw kɔnɔ .

Fiyentɔw ka dingɛw bɛ baara caman sɔrɔ izini suguya caman kɔnɔ, k’a sababu kɛ u jogo n’u nafaw ye minnu tɛ kelen ye. K’a ta aerospace ni mobili la ka se ɛntɛrinɛti ni furakɛli minɛnw ma, o fɛn nafamaw jɔyɔrɔ ka bon kosɛbɛ walasa ka fɛn jatebaliya baarakɛcogo, a dannaya ani a lakanani sabati.

Baara kɛ ni ko kɛlenw ye aerospace ani mobili baarakɛyɔrɔw la .

Aerospace ni mobili baarakɛlaw bɛ u jigi da fiyentɔw ka dingɛw kan kosɛbɛ fɛn suguya caman na ani lajɛw la, fanga, girinya dɔgɔyali, ani u tiɲɛni nafa ka bon kosɛbɛ.

Motɛri yɔrɔw .

Fiyentɔw ka dingɛw bɛ kɛ ka caya motɛri yɔrɔw la, i n’a fɔ:

● Silindri kunkolow: ka ɲɛsin valve guides ma, fɛnɲɛnamafagalan pikiri kɛyɔrɔw, ani buji dingɛw .

● Turbochargeur so: ka ɲɛsin jiginni yɔrɔw ma ani tulu tɛmɛsira ma .

● Transmission cases: ka ɲɛsin sɛgɛnw ni jibolisiraw ma .

O baarakɛcogo ninnu bɛ kɛ sababu ye ka fiyentɔw ka dingɛw seko kɛ walasa ka nɔrɔli yɔrɔw lakana, ka sigicogo dafalen mara, ani ka ji bɔli nɔgɔya ka sɔrɔ ka girinya dɔgɔya.

Suspension systèmes .

Suspension systems kɔnɔ, fiyentɔw ka dingɛw jɔyɔrɔ ka bon kosɛbɛ:

● Shock absorber mounts: Walasa ka a siri mobili karamɔgɔ la .

● Kunnafoni minnu bɛ sɔrɔ a kɔnɔ: walasa ka busiw ni bolokuruw don ɲɔgɔn na .

● Bololabaarakɛminɛnw: ka ɲɛsin wotoroninw ma minnu bɛ se ka wuli ani ka u bila kalini kɛ ni frein ye .

Fiyentɔw ka dingɛw kɛli o yɔrɔw la, o bɛ doni tali dannayalen sabati, ka degunw hakɛ dɔgɔya, ani ka u lajɛli ni u ladonni nɔgɔya.

Nafa bɛ ɛntɛrinɛti ni furakɛli minɛnw dilanni na .

Fiyentɔw ka dingɛw nafa ka bon o cogo kelen na ɛntɛrinɛti ni furakɛli minɛnw dilanni na, yɔrɔ minnu na, u bɛ se ka kɛ fɛn nafamabaw ye, u saniyacogo, ani u ka ɲɛnamaya kɛcogo ɲuman ye fɛn nafamabaw ye.

Elektroniki yɔrɔw .

Elektroniki yɔrɔw la, fiyentɔw ka dingɛw bɛ kɛ:

● PCB jiginni: walasa ka ɛntɛrinɛti yɔrɔw lakana ka taa ciriw la minnu sɛbɛnnen don .

● Heatsinks: Ka ɲɛsin fanga minɛnw jiginni ma ani ka funteni maracogo nɔgɔya .

● Connecteurs: Ka ɲɛsin mɔgɔw ma minnu bɛ se ka u ka so jɔ ani ka so kɔnɔ fɛnw siri .

Fiyentɔw ka dingɛw bɛ ɛntɛrinɛti yɔrɔw la, olu bɛ ɲɔgɔndan lakananenw ni dannayalenw sɔrɔ, ka funteni jɛnsɛn ka ɲɛ, ani ka pakew kɛ minnu ka surun.

Furakɛcogo minɛnw .

Furakɛcogo minɛn dilanni bɛ da fiyentɔw ka dingɛw kan baara suguya caman kama, i n’a fɔ:

● Implants et prothèses : ka ɲɛsin kurukuruw dingɛw ma minnu bɛ kɛ ka ɲɛsin kolotugudaw ma ani ɲinw dilanni .

● Opereli minɛnw: Walasa ka yɔrɔw ni jibolisiraw bila endoskopi baarakɛminɛnw ni biyɔpisi minɛnw na .

● Sɛgɛsɛgɛli minɛnw : Sensɔrɔlanw ni sɛgɛsɛgɛlikɛlanw kama joli sɛgɛsɛgɛli ni ADN sinsinniw kɔnɔ .

Fiyentɔw ka dingɛw kɛli furakɛli minɛnw na, o bɛ a to biyocompatibilité, sterilisation compatibilité, ani ji minɛcogo tigitigi ka sɔrɔ ka sigida dafalen mara ani ka nɔgɔya faratiw dɔgɔya.

Ko minnu kɛra: Baarakɛcogo lakikaw .

Walasa ka fiyentɔw ka dingɛw baaracogo ɲumanw jira, an ka diɲɛ kɔnɔko lakika fila sɛgɛsɛgɛ:

1. Fuel Injector Nozzle:

kelen. Gɛlɛya: Aw bɛ fɛnɲɛnamafagalan pikirijikɛlan dɔ dilan ni sɛnɛfɛnw bɔli sira tigitigiw ye ani ka jiginni yɔrɔw lakana.

B. Fɛn min bɛ se ka kɛ: Fiyentɔw ka dingɛw don fɛnɲɛnamafagalanw ni jiginni jiriw la, ka sɛnɛfɛnw dicogo sabati ani ka u siri ni dannaya ye motɛri la.

C. O kɔlɔlɔ : sɛnɛfɛnw nafa ka bon, u bɔli bɛ dɔgɔya, ani pikirijikɛlan ɲɛnamaya janyalen.

2. Joli-sira-funu-kɔnɔ-fɛnw:

kelen. Gɛlɛya: Aw bɛ hip implant dɔ labɛn ni fixation secure ye ani ka doni tilatilali ɲuman kɛ.

B. Fɛn min bɛ se ka kɛ: Aw bɛ dingɛ fiyentɔw kɛ ka juruw siri ani ka u datugu, ka osseointegration (osseointegration) sabati ani ka degunw tanga.

C. O kɔlɔlɔ : fɛnw doncogo sabatili ka bon, banabagatɔ kɛnɛyali teliya la, ani fɛn dontaw dɛsɛli farati bɛ dɔgɔya.

Nin ko kɛlenw b’a jira cogo min na fiyentɔw ka dingɛw bɛ se ka kɛ baarakɛminɛn kɛrɛnkɛrɛnnenw ye, ka gɛlɛya kɛrɛnkɛrɛnnenw ɲɛnabɔ ani ka baara kɛcogo ɲuman lase diɲɛ kɔnɔko lakikaw la.

Fɛɛrɛ ɲumanw bɛ kɛ fiyentɔw ka dingɛ dilanni na ani masinw na .

Walasa ka fiyentɔw ka dingɛw waleya ka ɲɛ ɛntɛrinɛti baara suguya caman na, a nafa ka bon kosɛbɛ ka fɛɛrɛ ɲumanw ta u dilanni n’u dilanni na.

Ka a jira ko a bɛ se ka kɛ ko a bɛ se ka kɛ ko a bɛ se ka kɛ .

ka se ka tiɲɛni ni ɲɔgɔndɛmɛ sɔrɔ fiyentɔw ka dingɛ dilanni na ani . CNC masinw bɛ dilancogo barikamaw, masinw kɛcogo ɲumanw, ani baarakɛcogo kɔlɔsili gɛlɛnw faralen ɲɔgɔn kan. Jateminɛ nafama dɔw ye:

● Tolerance specifications jɛlenw ni minnu bɛ se ka sɔrɔ, olu ɲɛfɔli ka da a ɲinini wajibiyalenw kan .

● Ka masinw kɛcogo ni baarakɛminɛnw sugandi minnu bɛnnen don fɛn kɛrɛnkɛrɛnnenw ni dingɛw jateminɛcogo ma .

● tigɛcogo ɲumanw, i n’a fɔ balo hakɛ, sɔgɔli teliya, ani tigɛ juguya, walasa ka baarakɛminɛnw deflection ni yɛrɛyɛrɛ dɔgɔya .

● Ka jateminɛ kɛcogo kɔlɔsili (SPC) fɛɛrɛw waleya walasa ka taabolo sabatili kɔlɔsi ani k’a mara .

● Aw bɛ to ka masinw ni sumanikɛminɛnw jateminɛ ani ka u ladon walasa ka a dɔn ni a bɛ se ka kɛ ko a bɛ se ka kɛ tiɲɛ ye ani ka segin a kan .

Ni u bɛ tugu o walew kɔ, ɛntɛrinɛti ni masinw bɛ se ka to ka dingɛ fiyentɔw dilan ni u hakɛw ye minnu wajibiyalen don, u bɛ se ka kɛ u ɲɛda la, ani u ka jogo ɲumanw.

Jogoɲumanya ni sɛgɛsɛgɛli fɛɛrɛw .

Jogoɲumanya ni sɛgɛsɛgɛli ye fɛɛrɛ nafamaw ye walasa ka dingɛw dafalen ni u baarakɛcogo sabati. Jogoɲini fɛɛrɛ nafamaw dɔw ye:

● Sɛgɛsɛgɛli bolodacogo bɛɛ lajɛlen dɔ labɛn min bɛ dantigɛliw, muɲuliw, ani jogoɲumanw ɲɛfɔ minnu ka kan ka sɛgɛsɛgɛ .

● Sɛgɛsɛgɛli fɛɛrɛw waleyali la, i n’a fɔ jateminɛ kɛcogo ani otomatiki jateminɛ, walasa ka fɛn dɔw dɔn ani ka u latilen u dilanni daminɛ na .

● Ka sɛgɛsɛgɛli labanw kɛ ni sumanikɛminɛnw ye minnu bɛ se ka kɛ ka ɲɛ, i n’a fɔ koordinatɛri sumani masinw (CMM), bore jateminɛnanw, ani jiriw jateminɛnanw, walasa ka fiyentɔw ka dingɛw tiɲɛni n’u kɛcogo jateminɛ .

● Sɛgɛsɛgɛli jaabiw sɛbɛn ani ka tugu sɛbɛnw mara walasa ka jogoɲumanya sabati ani ka ɲɛtaa kɛ ka taa a fɛ .

Jogoɲumanya ni sɛgɛsɛgɛli fɛɛrɛ ɲumanw bɛ dɛmɛ ka fiɲɛw dɔn ani ka u bali, ka dɔ bɔ fɛn tiɲɛnenw ni baarakɛcogo kura la, ani ka a lajɛ ko fiyentɔw ka dingɛw bɛ se ka wajibi kofɔlenw dafa tuma bɛɛ.

Degeli ni seko yiriwali masinw ye .

Ka wari bila kalan ni seko yiriwali la masinw fɛ, o nafa ka bon walasa ka fiyentɔw ka dingɛ ɲumanw sɔrɔ ani ka masinw kɛcogo ɲɛ. Yɔrɔ kolomaw ye ninnu ye:

● Ka kalan bɛɛ kɛ fiyentɔw ka dingɛ dilanni sariyakolow kan, i n’a fɔ baarakɛminɛnw sugandili, tigɛcogo, ani kɛcogo ɲumanw ka ɲɛsin fɛn kɛrɛnkɛrɛnnenw ni baarakɛcogo ma .

● Bololabaarakɛlaw ka sekow yiriwali degeliw ni simulatigɛw fɛ, o b’a to masinw bɛ se ka dɔnniya sɔrɔ masinw sigili n’u baaracogo la fiyentɔw ka dingɛ masinw kama .

● Ka dusu don kalan ni dɔnniya tilali la ka taa a fɛ, baarakɛjɛkuluw, kalanjɛw, ani ɲɔgɔndɛmɛ porogaramuw fɛ .

● Ka jɛkafɔw kɛ ɲɔgɔn fɛ masinw, ɛntɛrinɛti kalanbagaw, ani baarakɛlaw cɛ minnu bɛ baara kɛ ɲɔgɔn fɛ walasa ka ɲɛtaa sabatili ni kokuradonni ladamu sabati .

Ni jɛkuluw bɛ masinw labɛn ni seko ni dɔnko wajibiyalenw ye, jɛkuluw bɛ se ka fiyentɔw ka dingɛ masina kɛcogo ɲuman, a tiɲɛni ani a kɛcogo ɲuman sabati.

Fiyentɔw ka dingɛw saniyali ni u ladonni .

Fiyentɔw ka dingɛw saniyacogo ɲuman ni u ladonni nafa ka bon walasa u ka baara kuntaalajan ani u ka nɔgɔ walima u ka tiɲɛni bali. Saniya fɛɛrɛ ɲumanw ni baarakɛminɛnw ye:

● Aw bɛ baara kɛ ni fiɲɛ walima fiɲɛ samata ye walasa ka chips, fɛnɲɛnamafagalanw ani nɔgɔw bɔ fiyentɔw ka dingɛ kɔnɔ .

● Ka baara kɛ ni saniya fɛɛrɛw ye minnu bɛ kɛ ni ultrasonic ye walasa ka jateminɛ kɛ ka ɲɛ ni jateminɛ gɛlɛnw ye ani yɔrɔ minnu sɔrɔli ka gɛlɛn .

● Ka saniya fura bɛnnenw kɛ, i n’a fɔ furajiw, degreasers walima safinɛ nɔgɔmanw, ka kɛɲɛ ni fɛnw ni a kɛcogo ye .

● Ka baara kɛ ni saniyaminɛn kɛrɛnkɛrɛnnenw ye, i n’a fɔ burusi, swabs, ani finiw minnu tɛ fɛn kɛ, walasa ka se ka don fiyentɔw ka dingɛ kɔnɔ ani ka u saniya ka ɲɛ .

Ka fara saniya sabatili kan tuma bɛɛ, a nafa ka bon ka ladonni kunbɛnni porogaramu dɔ sigi sen kan min kɔnɔ, sɛgɛsɛgɛli bɛ kɛ tuma ni tuma, ka tulu kɛ, ani ka baarakɛminɛnw ni fɛn tiɲɛnenw falen walima minnu tiɲɛna. O fɛɛrɛ in bɛ dɛmɛ don ka jɔli waati dɔgɔya, ka masinw ka ɲɛnamaya janya, ani ka fiyentɔw ka dingɛw cogoya n’u dafalen mara waati kɔnɔ.

Ɲininkaliw jaabiw .

J: Danfaraba jumɛnw bɛ fiyentɔw ka dingɛw ni dingɛw cɛ?

A: Fiyentɔw ka dingɛw tɛ don yɔrɔ dɔ janya bɛɛ la, ka sɔrɔ dingɛw bɛ tɛmɛ pewu ka bɔ fan kelen fɛ ka taa fan wɛrɛ fɛ. Fiyentɔw ka dingɛw bɛ duguma ani u ka gɛlɛn masin na ka tɛmɛ dingɛw kan.

J: Fiyentɔw ka dingɛw bɛ fɛnw jɔcogo dafalen bonya cogo di?

A: Fiyentɔw ka dingɛw bɛ yɔrɔ dɔ jɔcogo dafalen mara ni u tɛ don u bonya bɛɛ la, ka degunw hakɛ dɔgɔya. U bɛ doni tila-tilacogo n’a kɛlɛli ɲɛ ka ɲɛsin fanga kɔrɔtalen walima wulili ma, ka sɛgɛn waati ni a yɔrɔ in muɲu.

J: Industri minnu ka teli ka kɛ, olu ye jumɛnw ye minnu bɛ baara kɛ ni fiyentɔw ye?

A: Fiyentɔw ka dingɛw bɛ kɛ ka caya aerospace, mobili, ɛntɛrinɛti ani furakɛli minɛnw dilanni na. O iziniw bɛ fɛnw ɲini minnu fanga ni u girinya hakɛ ka bon, u lajɛcogo tigitigi, ani u ka baarakɛcogo kɛrɛnkɛrɛnnenw, fiyentɔw ka dingɛw bɛ se ka minnu di.

J: Gɛlɛyabaw jumɛnw bɛ fiyentɔw ka dingɛw dilanni senfɛ?

A: Gɛlɛyabaw minnu bɛ masin fiyentɔw ka dingɛw kɔnɔ, olu ye chip evacuation ani baarakɛminɛnw kari ye ka da yɔrɔ danma kan, ka dingɛ juguya ni dugukolo sanfɛla dafalen mara, ani gɛlɛyaw kɔnɔnafɛnw sɛgɛsɛgɛli n’u sumani na. Tapping operations fana bɛ kɛ farati ye ka pompi tiɲɛ walima ka juru tiɲɛ.

J: Fɛnw jiginni ye nɔ bila fiyentɔw ka dingɛ masina kɛcogo la cogo di?

A: Fɛnw jiginni kɛra sababu ye ka baarakɛminɛnw kɛrɛnkɛrɛnnenw labɛn, i n’a fɔ nɛnɛmadalan minnu bɛ degunba la ani chip-breaking drill geometries, walasa ka gɛlɛyaw ɲɛnabɔ minnu bɛ kɛ ni masinw ye fiyentɔw ka dingɛw kɔnɔ minnu ka gɛlɛn walima minnu bɛ taa ɲɛ. Fɛn kuraw fana ye fɛnw ni u ka baarakɛcogo seko bonya ni dingɛw ye minnu bɛ fiyentɔw la.

J: Fiyentɔw ka dingɛw hakɛ ni u suguya jumɛnw de bɛ kɛ iziniw kɔnɔ?

A: Fiyentɔw ka dingɛ hakɛ minnu ka ca kosɛbɛ, olu bɛ daminɛ ni cɛmancɛ fitininw ye ɛntɛrinɛti yɔrɔw la ka taa a bila hakɛ caman na mobili ni aerospace baarakɛcogo la. Fiyentɔw ka dingɛw, dingɛw minnu bɛ wuli, ani ɲɛda minnu bɛ kɛ ni nɛgɛ ye, olu bɛ sɔrɔ suguya caman na minnu bɛ kɛ ka caya izini suguya caman na.

J: I bɛ se ka dingɛ fitinin dɔ juguya bɛnnen dɔn cogo di?

A: Fiyentɔ dingɛ juguya bɛnnen bɛ dɔn ni yɔrɔ in ka baarakɛcogo wajibiyalenw ye, i n’a fɔ jiri sirili janya ɲininen walima a bɔli yɔrɔw la minnu bɛ kɛ ɲɔgɔn fɛ. Dilanbagaw ka kan ka fɛnw jateminɛ i n’a fɔ dingɛ cɛmancɛ, fɛnw fanga, ani doni-ta-seko ni u bɛ dingɛw juguya fiyentɔw ɲɛfɔ.

J: Fɛɛrɛ minnu bɛ se ka kɛ ka ɲɛ, olu ye jumɛnw ye minnu bɛ se ka kɛ sababu ye ka jiribuluw saniya ani ka u kɛ cogo jɛlen na?

A: Walasa ka jirisun saniyalenw ni tigitigiw sɔrɔ dingɛ fiyentɔ la, aw bɛ baara kɛ ni tapping fɛɛrɛ ɲumanw ye, i n’a fɔ ka baara kɛ ni pɔnpe ɲumanw ye minnu bɛ ni jateminɛ ni finimugu bɛnnenw ye, ka tigɛjiw kɛ, ani ka tapping teliya ni fanga kɔlɔsi. Ni aw bɛ to ka dingɛw saniya ani ka u sɛgɛsɛgɛ ni jiriw jateminɛnanw ye ani ka fɛnw ye minnu bɛ se ka yeli kɛ, olu bɛ se ka jiri cogoya mara.