Fɔ gɛt tu-dimɛnshɔnal lɔng na injinɛri ɛn manufakchurin we na gud transishɔn fit na impɔtant tin fɔ di prɔdak in ɔl pefɔmɛns. Wan kɔmɔn fit na di kɔnvɛnshɔn rit. Di rizin fɔ dis atikul na fɔ gi wan kɔmplit diskripshɔn fɔ di rayt chenj dɛn, aw dɛn de yuz dɛn, di bɛnifit dɛn, di prɔblɛm dɛn, ɛn di ansa to kwɛstyɔn dɛn we dɛn kin aks bɔku tɛm.

I. Wetin na transishɔn fit?

Transishɔn fit na spɛshal kayn fit we de kam togɛda wit ɛlimɛnt dɛn fɔ wan kliarens fit ɛn intafɛreshɔn fit. Dis inklud mared sɛgmɛnt usay sɔm eria dɛn kin gɛt kɔt we ɔda eria dɛn kin gɛt kliarens. Dis balans fɔ kɔt ɛn strip de gi kɔmprɔmis, fasilit asɛmbli ɛn sikyuɔr kɔmyunikeshɔn bitwin di pat dɛn. Prɔpa fleksibiliti de ɔfrɛd di advantej fɔ alaw rili simpul asɛmbli yet fɔ gi di nid kɔdineshɔn ɛn alaynɛshɔn we dɛn nid fɔ optimal pefɔmɛns. Di inklushɔn fɔ di rayt fleksibiliti de alaw injinia dɛn fɔ balans asɛmbli bitwin fleksibiliti ɛn robust asɛmbli, we mek am opshɔn fɔ difrɛn matirial aplikeshɔn aplikeshɔn dɛn.

II. Handling transishɔn Fit:

Transishɔn fit dɛn gɛt bɔku bɔku aplikeshɔn dɛn na difrɛn difrɛn industri dɛn, lɛk ɔtomotiv, ɛrospɛs, ilɛktronik ɛn aplayans dɛn. Lɛ wi fɛn sɔm patikyula eria dɛn usay dɛn kin yuz transfɔmeshɔn fit:

1. Shaft ɛn hab dɛn pan mashin dɛn we de rɔn .

Transishɔn fit dɛn kin yuz bɔku say fɔ gɛda mashin dɛn we de rɔn, lɛk motoka, injin ɛn tɔbayn. Bay we yu de yuz transishɔn fit bitwin shaft ɛn hab, injinia dɛn de mek shɔ se di kɔnɛkshɔn dɛn we sef pas ɔl ɛn stebul roteshɔnal trɛnk bɔt izi kɔntakt we dɛn de mentenɛns ɔ ripa ɛn alaw fɔ disɛkshɔn.

2. Bearings ɛn haus dɛn na ɔtomotiv injin dɛn .

Conversion Fit de ple impɔtant pat pan di asɛmbli fɔ bia ɛn os dɛn na ɔtomotiv injin dɛn. Di muvmɛnt dɛn we dɛn kin kɔntrol na sɔm patikyula say dɛn kin mek shɔ se dɛn de lod di rayt we bitwin di bia ɛn di os, we de mek di risk fɔ bia nɔ wok fayn ɛn fɔ mek di ɔl injin wok go ɔp.

3. Kɔnɛkshɔn ɛn Sɔkɛt fɔ Ilɛktronik Divays dɛn .

Di kɔnvɛnshɔn fit we dɛn kin yuz kin bi fɔ kɔnɛkshɔn ɛn sɔkɛt fɔ ilɛktronik divays dɛn, lɛk kɔmpyuta kɔnɛkta, ɔdio jak, ɛn USB pɔt. Dɛn kin alaw fɔ ple aktiviti dɛn.

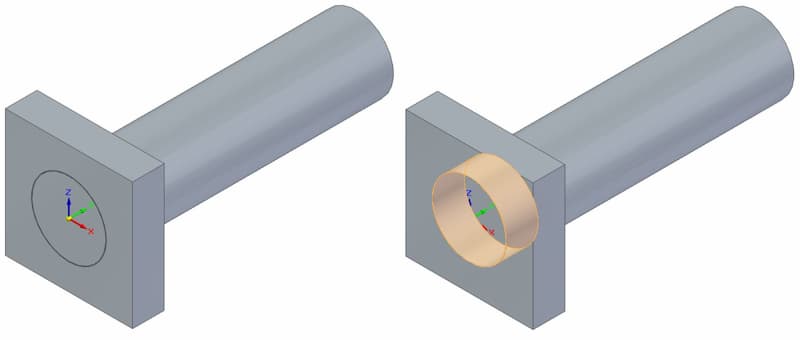

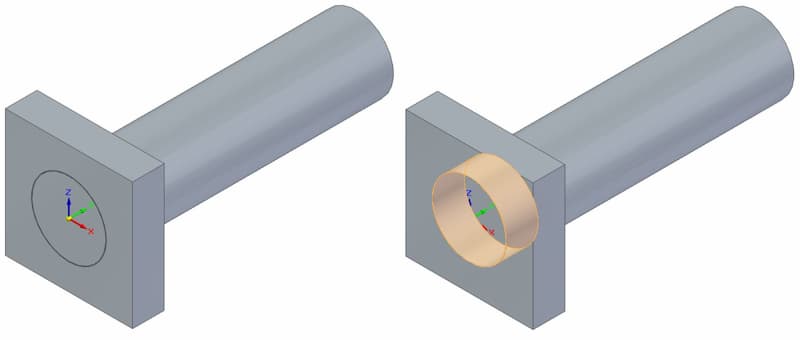

4. Silindrikal pat dɛn we nid alaynɛshɔn ɛn lod transfa .

Konvεshכn Fit dεm na patikyula wan fכ silindrikal pat dεm we nid prεsis alaynsmεnt εn efisεnt lod tכnfכs. Fɔ ɛgzampul, we dɛn de assemble prɛsishɔn mashin ɔ mashin, dɛn kin yuz transishɔn fit fɔ kɔnɛkt silindrikal kɔmpɔnɛnt dɛn lɛk gia, pul, ɛn aks. Dɛn fit ya de mek shɔ se pafɛkt alaynɛshɔn, ridyus baklash, ɛn impruv di efyushɔn fɔ ilɛktrik transmishɔn.

III. Advantej dɛn fɔ transishɔn fit:

1. Di kɔntrol intafɛreshɔn .

Di kɔntrol intafɛreshɔn fɔ di transishɔn fit de ple impɔtant pat fɔ mek shɔ se di kɔnɛkshɔn smol smol. Nɔ lɛk intavɛnshɔn fit, we nid fɔ fos fɔ put ɔ pul di pat dɛn we de mating, transishɔnal fit balans bitwin sikyɔriti asɛmbli ɛn smol asɛmbli. Kontrol intavεnshכn in spεsifi k rijyכn dεm alaw fכ sikyu fit bכt i de alaw fכ put pat dεm כ εkstrakshכn kwik kwik wan.

Dis min se dɛn nid fɔ gɛt smɔl ɛnaji ɔ spɛshal ikwipmɛnt we dɛn de asɛmbli, we de ridyus di damej we di pat dɛn gɛt ɛn mek di ɔl asɛmbli prɔses simpul. Di izi we aw dɛn go ebul fɔ mek di tin dɛn we dɛn de yuz fɔ mek di tin dɛn we dɛn de yuz fɔ mek di tin dɛn we dɛn de yuz fɔ mek di tin dɛn we dɛn de yuz fɔ mek di tin dɛn we dɛn de yuz fɔ mek di tin dɛn we dɛn de yuz fɔ mek di tin dɛn we dɛn de yuz fɔ mek di tin dɛn we dɛn de yuz fɔ du di wok izi, di izi we aw dɛn go ebul fɔ mek dɛn chenj di we aw dɛn de du di wok we dɛn want fɔ du, na di rayt we aw dɛn de chenj di tin dɛn we dɛn nid, dat min se dɛn go sev tɛm ɛn dɛn nɔ go spɛn bɔku mɔni, so insay di . Rapid manufakchurin ɛn mentenɛns prɔses, as di asɛmbli ɛn disassembly tɛm nɔ bɔku, i tek ɛfɔt.

2. Impɔtant Rizɔlt .

transishכn fit dεm de gi bεtε alaynsmεnt bitwin mating pat dεm we yu kכmpεr to kliarεns fit dεm. Transishɔn fit dɛn de gi wan rilibul sɔlvishɔn we dɛn nid ɛksaktɔl pozishɔn ɔ roteshɔnal akkuracy. Di tin dɛn we dɛn kin du fɔ kɔntrol di tin dɛn we dɛn kin du na sɔm patikyula say dɛn kin ɛp fɔ mek dɛn kɔntinyu fɔ gɛt pat alaynɛshɔn, fɔ mek dɛn ebul fɔ wok fayn ɛn fɔ mek dɛn nɔ gɛt prɔblɛm wit di prɔblɛm dɛn we kin apin we dɛn nɔ de alayf.

3. Ɛnhans lod transfa .

We tork ɔ akshal fɔs dɛn fɔ ebul fɔ transfa fayn fayn wan bitwin mating pat dɛn, transishɔn fit dɛn de gi impɔtant lod transfa kapabiliti kɔmpia to kliarens fit dɛn. Kontrol intavɛnshɔn na di transishɔn fit de mek shɔ se maksimal kɔntakt bitwin di mating sɔfays, alaw fɔ bɛtɛ lod plesmɛnt ɛn ridyus di risk fɔ sagging ɔ fayl ɔnda lod.

4. Vaybreshɔn ɛn nɔys ridɔkshɔn .

Prɔpa absɔpshɔn eria dɛn na di kɔnvɛnshɔn we fit di sistɛm de ɛp fɔ ridyus di vaybreshɔn ɛn nɔys. If yu ajɔst di rayt we i de, i de ɛp fɔ mek di wok stebul ɛn kwayɛt bay we i de ridyus di muvmɛnt bitwin di pat dɛn we lɔng. Dis advantej rili valyu na say dɛn we nɔys ridɔkshɔn impɔtant, lɛk na prɛsishɔn mashin ɔ Di pat dɛn we de na di motoka ..

IV. Drawbacks pan transishɔn fit:

1. Limitɛd tolɛreshɔn rɛnj .

Transishɔn fit dɛn nid fɔ tek tɛm tink bɔt tolɛreshɔn fɔ mek shɔ se di fit we dɛn want. Di tolerans renj fɔ transishɔn fit na narrow kɔmpia to kliarens fits, kɔmplikt di prɔses ɛn pɔtɛnɛshɛl inkris kɔst.

2. Di risk fɔ gɛt galling we de bɔku .

Insay sɔm kes dɛm, galling kin apin na intamɛdiet pɔynt dɛn insay di fit fɔ di kɔnvɔshɔn fit, we kin mek di sɔfayz damej bikɔs ɔf frikshɔn ɛn adheshon. If yu pik di rayt lɔbrik ɛn di tin dɛn we yu nid kin ɛp fɔ ridyus dis prɔblɛm.

V. Kwɛshɔn ɛn Ansa Sɛkshɔn:

1. Yu tink se fɔ ajɔst di rayt we fɔ ajɔst ɔltɛm?

Nɔto ɔltɛm dɛn nid fɔ ajɔst di rayt we fɔ ajɔst. Di sɛlɛkshɔn prɔses dipen pan di patikyula rikwaymɛnt dɛn fɔ di aplikeshɔn. Klirance fits na fayn we dɛn nid izi asɛmbli ɛn disassembly, we dɛn want intavɛnshɔn fit fɔ maksimal lod ɛn rigiditi.

2. Aw a go no di aprɔpriet tolɛreshɔn rɛnj fɔ wan transishɔn fit?

Faktor dɛm lɛk di shia we dɛn want, di matirial mating pat dɛm, ɛn di funkshɔn rikwaymɛnt dɛm, dɛn kin tink bɔt fɔ disayd di tolɛreshɔn lɛvɛl dɛm fɔ di rayt modifyeshɔn dɛm. Enjinia buk ɛn standad dɛn de gi gaydlayn ɛn paramita fɔ kɔlkyul di rayt tolɛreshɔn.

3. Dɛn kin yuz transishɔn fit fɔ pat dɛn we de rɔn kwik kwik wan?

Dɛn kin yuz transishɔn fit fɔ pat dɛn we de rɔn kwik kwik wan, bɔt i impɔtant fɔ tink bɔt tin dɛn lɛk fɔ tek tɛm plan, fɔ balans, fɔ mek lɔbrik ɛn fɔ pik di tin dɛn we dɛn de yuz fɔ mek shɔ se dɛn wok fayn ɛn fɔ ridyus di risk fɔ mek dɛn nɔ ebul fɔ du wetin dɛn want insay di 19t sɛntinari.

4. Wetin na di opshɔn fɔ transishɔn?

Variation fit choices inklud wan kliarens fit, usay gap de bitwin di paired pat dɛm, ɛn wan intafɛreshɔn fit, usay di paired pat dɛm de bay wilful intafya wit. Di sɛlɛkshɔn dipen pan di patikyula tin dɛn we di aplikeshɔn nid.

Dɔn

Transishɔn Fit de stray fɔ balans bitwin kliarens fit ɛn intafɛreshɔn fit ɛn de gi bɛnifit dɛn lɛk izi kɔnɛkshɔn, impɔtant alaynɛshɔn, inkris wet transfa ɛn ridyus vaybrɛshɔn, bɔt wit tek tɛm tink bɔt tolɛreshɔn ɛn risk fɔ galling, impɔtant tin dɛn fɔ kip na maynd. We dɛn yuz di rayt vɛriɔbul dɛn ɛn ɔndastand dɛn bɛnifit dɛn, di injinia dɛn ɛn di wan dɛn we de mek dɛn kin disayd fɔ disayd di rayt wan we dɛn de pik di rayt wan fɔ dɛn prɔdak dɛn.

Tim MFG de gi Rapid Prototyping Savis dɛn ., CNC MACHINING SAVIS , DIE KƆST SƐVIS, ƐN . Injɛkshɔn moldin savis fɔ mit yu nid dɛn. Kontakt wi tide!