I nɔ mata us prɔdak yu prodyuz, standad mashin tolɛreshɔn na impɔtant paramita fɔ tink bɔt. Tide, bɔku pan di tin dɛn we pipul dɛn kin yuz fɔ bay tin dɛn kin nid fɔ kɔnsistɛns pan maykroskɔpik skel.

So, bɔku tɛm di wan dɛn we de mek di tin dɛn kin tek tɛm luk gud wan ɛn kɔmpia difrɛn kayn we dɛn fɔ mek tin dɛn, ɛn fɔ mek dɛn ebul fɔ bia wit mashin dɛn stil na impɔtant tin. Fɔ ɔndastand mashin tolɛreshɔn fɔ difrɛn prɔses, i impɔtant fɔ ɔndastand wetin mashin tolɛreshɔn bi, aw fɔ mɛzhɔ dɛn, ɛn us difrɛn kayn tolɛreshɔn dɛn de.

Dis atikul go tɔk bɔt ɔl dis infɔmeshɔn ɛn ɔda tin dɛn. Fɔ dɔn, sɔm advays dɛn de fɔ ɛp yu fɔ mek yu ebul fɔ mek mashin tolɛreshɔn na yu industri bɛtɛ.

Wetin na CNC mashin tolerans?

Difinishɔn ɛn kɔnsɛpt fɔ CNC mashin tolɛreshɔn dɛn .

CNC mashin tolerans dɛn de difayn di alawable vɛryushɔn na wan pat in dimɛnshɔn dɛn, we de mek shɔ se di prɛsishɔn we nid fɔ de na di manufakchurin. Dɛn tolɛreshɔn ya impɔtant bikɔs dɛn sɛt di akseptabl rɛnj insay we wan pat in aktual dimɛnshɔn kin difrɛn frɔm in nominal ɔ intended dimɛnshɔn. Fɔ ɛgzampul, wan kɔmpɔnɛnt we dɛn dɔn pik fɔ gɛt dimɛnshɔn we na 3.0' wit ±0.001' tolɛreshɔn fɔ mɛzhɔ bitwin 2.999' ɛn 3.001' fɔ mit kwaliti standad. Di esens fɔ mashin tolɛreshɔn de insay dɛn abiliti fɔ balans akkuracy wit manufakchurin fisibiliti, shep di fondamental rilayshɔn bitwin tiori dizayn ɛn prɛktikal autkam insay CNC mashin.

Ɛksplen bɔt di chenj dɛn we dɛn kin alaw fɔ chenj .

Tolerances de sho wan pat in permissible variations, we de difrɛns bitwin tayt ɛn loose tolerances. Tayt tolerans (smɔl vɛryushɔn) de sho wan ay dimand fɔ prɛsishɔn, we afɛkt di manufakchurin prɔses in kɔmplisiti ɛn kɔst bikɔs ɔf ɔda sɛtup dɛn, lɔng saykl tɛm dɛn, ɛn di nid fɔ spɛshal tul dɛn. Konvεshal, lכs tכlerans alaw fכ big vεryans, we de sho se di prεsishכn rikwaymεnt dεm we nכ strεng, we kin mek di prodyushכn simpul εn ridyus di kכst.

Rilayshɔn to Bluprint Valyu dɛn .

Machining tolerances na dairekt tay to blueprint valyu, we de sav as wan impɔtant link bitwin wan pat in tiori dizayn ɛn in rial-wɔl aplikeshɔn. Dɛn de mek shɔ se di kɔmpɔnɛnt dɛn kin fit ɛn wok togɛda lɛk aw dɛn bin want, pan ɔl we di inhɛrɛnt vɛryabiliti de insay di manufakchurin prɔses. Dis rilayshɔn de ɔndaskayn di tolɛreshɔn dɛn wok fɔ gayd CNC mashin fɔ prodyuz pat dɛn we de adara klos to dɛn dizayn spɛsifikɛshɔn dɛn.

Impɔtant tin fɔ mek di prɛsishɔn pat dɛn .

Insay di wɔl fɔ CNC mashin, tolɛreshɔn nɔto jɔs nɔmba bɔt na impɔtant tin fɔ mek dɛn gi garanti fɔ di fɔm, fit, ɛn wok we di pat dɛn de du. Dɛn de rul wan margin fɔ mistek, mek shɔ se di kɔmpɔnɛnt dɛn mit dɛn purpose na wan asɛmbli, ɛn ple wan impɔtant pat fɔ manej di manufakchurin kɔst bay we dɛn de sɛt bɔda fɔ di prɛsishɔn rikwaymɛnt dɛn.

Simbolizm ɛn ripɔtmɛnt fɔ tolɛreshɔn dɛn .

Intɛpriteshɔn fɔ Tolerance Simbol dɛn .

Di '±' simbul na di kɔmɔn wan we dɛn kin yuz fɔ ripresent mashin tolɛreshɔn, we de sho di rɛnj insay we pat mɛzhɔmɛnt kin difrɛn frɔm di dimɛnshɔn we dɛn spɛsifa. Dis simbolik na di men tin fɔ ɔndastand aw klos wan pat fɔ mach in dimenshɔn dɛn we dɛn dɔn disayn, ɛn i de inflɔws di las prɔdak in kwaliti dairekt wan.

Siginifikɛns fɔ ± noteshɔn .

Di ± noteshɔn de kɛr profaund signifyans, ɛnkapsul di kɔnsɛpt fɔ permissible vɛryushɔn in wan kɔnsis fɔm. I wantɛm wantɛm i de kɔmyuniket di prɛsishɔn lɛvɛl we dɛn nid, we de impɛtɛkt ɔl tu di dizayn ɛn manufakchurin faz dɛn bay we i de klarify di ɛtɛnt fɔ alawable dɛvyayshɔn frɔm di nominal saiz.

Impɔtants fɔ mek mashin tolɛreshɔn .

Di wɔl fɔ CNC mashin na intrikɛt, usay ɛvri maykron kɔnt. Machining tolerances de ple wan impɔtant pat fɔ chenj wan pat pan mɛtal to wan masta wok we fit fayn fayn wan to di ples we i bin want. Dɛn tolɛreshɔn ya nɔto jɔs nɔmba bɔt na di ki ston dɛn we de mek shɔ se dɛn de wok, ikɔmik efyushɔn, ɛn di aesthetic integriti fɔ di fayn prodak.

ɛnhans pat fit ɛn funkshɔnaliti .

Fɔ mek shɔ se dɛn kɔmpit insay asɛmbli dɛn .

Imajin fɔ gɛda wan kɔmpleks mashin wit pat dɛn we nɔ fit togɛda. I nɔ jɔs de mek pɔsin in at pwɛl bɔt i de mek di tray nɔ gɛt wan yus. Prɛsis mashin tolɛreshɔn dɛn de mek shɔ se ɛvri kɔmpɔnɛnt fit togɛda, lɛk pis dɛn pan pazl, we de mek wan asɛmbli we nɔ gɛt wan bɔt. Dis kompitibiliti impɔtant fɔ kɔmpleks mashin usay ɛvri pat fɔ de insay pafɛkt wanwɔd wit ɔda pipul dɛn.

Avoiding defective parts bikɔs ɔf tolerance deviation .

Wan smɔl devieshɔn na mashin tolɛreshɔn kin mek pat dɛn we nɔ fayn, nɔ fit fɔ dɛn rizin. Dɛn bad bad tin ya nɔto jɔs west matirial ɛn tɛm bɔt dɛn kin put di wan ol prɔjek pan denja. So, stringent adherence to tolerances de mek shɔ se pat dɛn mit dɛn spɛsifikɛshɔn dɛn, ridyus di chans fɔ mek difɛkt ɛn mek shɔ se dɛn du di bɛst wok.

Manejin margin fɔ mistek .

Ɔndastand difrɛn we dɛn fɔ mek tin dɛn we dɛn de mek .

No tu manufakchurin proses nɔ de di sem, ɛn difrɛns nɔ go ebul fɔ avɔyd. Machining tolerances de rεkכgnεz dεn inhεrent vεryushכn dεm ya, we de gi kכshכn we de alaw fכ sכm sכm divεlכpmεnt dεm we nכ de kכmprכmis di pat in fכnshכnaliti. Dis ɔndastandin de ɛp fɔ manej ɛkspɛkteshɔn ɛn mek shɔ se pat dɛn mit kwaliti standad.

Minimizing risk fɔ mek di prɔdak nɔ wok fayn .

Pat dɛm we de kɔmɔt frɔm dɛn spɛsifikɛshɔn kin mek di prɔdak nɔ wok fayn, we kin gɛt bad bad kɔnsikuns, mɔ na impɔtant aplikeshɔn lɛk aerospace ɔ wɛlbɔdi biznɛs. Bay we dɛn de sɛt ɛn fala sɔm patikyula tolɛreshɔn dɛn, di wan dɛn we de mek dɛn kin ridyus di risk fɔ mek dɛn kayn tin dɛn ya nɔ wok fayn, ɛn mek shɔ se dɛn ebul fɔ abop pan dɛn ɛn mek dɛn sef.

Kɔntrolin di kɔst fɔ mek mashin .

Impact of tolerances pan manufacturing expenses .

Di tayt we di tolɛreshɔn tayt, na di mɔ di kɔst go ay. Fɔ ebul fɔ gɛt ay prɛsishɔn nid fɔ gɛt mɔ sofistikiet ikwipmɛnt, lɔng tɛm fɔ mek mashin, ɛn spɛshal skil dɛn, ɔl dɛn tin ya de ad pan di tin dɛn we dɛn de spɛn fɔ mek di tin dɛn. Bay we dɛn tek tɛm disayd di lɛvul we nid fɔ bi prɛsishɔn, di wan dɛn we de mek di tin dɛn kin balans bitwin fɔ rich di kwaliti we dɛn want ɛn fɔ kip di kɔst dɛn ɔnda kɔntrol.

Balansin prɛsishɔn ɛn ikɔmik efyushɔn .

Fɔ fɛn di swit ples bitwin prɛsishɔn ɛn kɔst-efyushɔn na di men tin. Nɔto ɔl pat nid fɔ gɛt mashin wit tayt tolɛreshɔn. Ɔndastand us pat dɛn nid fɔ gɛt ay prɛsishɔn ɛn us wan dɛn nɔ go ebul fɔ ɔptimayz di kɔst fɔ mek di tin dɛn we dɛn de mek we nɔ go ambɔg di kwaliti.

Fɔ mek shɔ se yu gɛt aesthetic ɛn functional integriti .

Rol fɔ tolɛreshɔn dɛn na di las prɔdak apia .

Di las apinans fɔ wan prɔdak nɔto jɔs bɔt aesthetics bɔt i de bak bɔt funkshɔnaliti. Pat dɛm we fit togɛda fayn fayn wan nɔ jɔs luk bɛtɛ bɔt i de wok fayn fayn wan. We dɛn yuz am fayn fayn wan tolerances mek shɔ se di fayn prodak nɔ jɔs mit di dizayn spɛsifikɛshɔn dɛn bɔt i de luk ɛn pefɔm bak lɛk aw dɛn bin want am.

Mitin dizayn spɛsifikɛshɔn fɔ optimal pefɔmɛns .

Di ɔltimat gol fɔ adhe to mashin tolɛreshɔn na fɔ mit di dizayn spɛsifikɛshɔn dɛn, mek shɔ se di fayn prodak de wok na di bɛst pefɔmɛns. Dis alaynɛshɔn bitwin dizayn ɛn manufakchurin na wetin de tɔn wan kɔnsɛpt to rial tin we mit, ɔ ivin pas, pefɔmɛns ɛkspɛkteshɔn.

Tayps of tolerances we dɛn yuz na CNC mashin .

Standart tolerances in CNC MACHINING .

Naviget di wɔl fɔ CNC mashin nid fɔ ɔndastand di blueprint fɔ prɛsishɔn: standad tolɛreshɔn. Dɛn nɔmba valyu ya na mɔ pas jɔs gaydlayn dɛn—dɛn na di bɔda dɛn we di art fɔ prɛsishɔn tek fɔm insay. Dis pat de opin di fabrik fɔ standad tolɛreshɔn ɛn di intanashɔnal standad dɛn we de skata dɛn.

Ovaviu fɔ di Tolerance Levels we dɛn kin adopt we dɛn kin adopt .

Standard tolerances na di set rules fɔ di gem insay CNC mashin. Dɛn kin tɛl wi aw klos wan pat in aktual mɛzhɔmɛnt kin bi to di dimɛnshɔn dɛn we i bin want fɔ gɛt. Fɔ ɛgzampul, wan standad tolɛreshɔn kin se wan pat kin bi 0.005 inch (ɔ lɛk 0.13mm) smɔl ɔ big pas in dizayn spɛsifa, ɛn dɛn go stil tek am se dɛn mek am fayn fayn wan. Dis rεnj de mek shɔ se pat dεm fit togɛda fayn fayn wan we yu nɔ go tu lכs ɔ tu tayt.

Fact: Mɔs mashin dɛn de wok insay wan patikyula rɛnj ɔf tolɛreshɔn, wit CNC mil mashin dɛn we tipikul fɔ mentɛn lɛk +/- 0.1mm prɛsishɔn fɔ standad prɔjek dɛn. Dis sho se pan ɔl we ɛvri maykron kɔnt, rum de fɔ smɔl, akseptabl difrɛns dɛn we nɔ de kɔmprɔmis di pat in wok.

Intanɛshɔnal standad ɛn gaydlayn dɛn .

Insay di say we dɛn de mek mashin, kɔnsistɛns na di men tin—nɔto jɔs insay wan wokshɔp, bɔt na di wɔl. Dis kɔnsistɛns de mentɛn tru intanashɔnal standad ɛn gaydlayn, we de sav as wan yunivasal langwej fɔ kwaliti ɛn prɛsishɔn insay manufakchurin. Ejensi dɛm lɛk di Amɛrikan Sɔsayti fɔ Mɛkanikal Ɛnjinia (ASME), di Intanɛshɔnal Ɔganayzeshɔn fɔ Stɛndadayzayshɔn (ISO), ɛn di Amɛrikan Nashɔnal Stɛndad Instityut (ANSI) na dɛn de kia fɔ di standad dɛm fɔ di tolɛreshɔn standad dɛm. Dɛn de difayn wetin akseptabl ɛn wetin nɔ akseptabl ɛn mek shɔ se wan kɔmpɔnɛnt we dɛn mek na wan pat na di wɔl fit fayn fayn wan wit ɔda wan we dɛn mek tawzin mayl away.

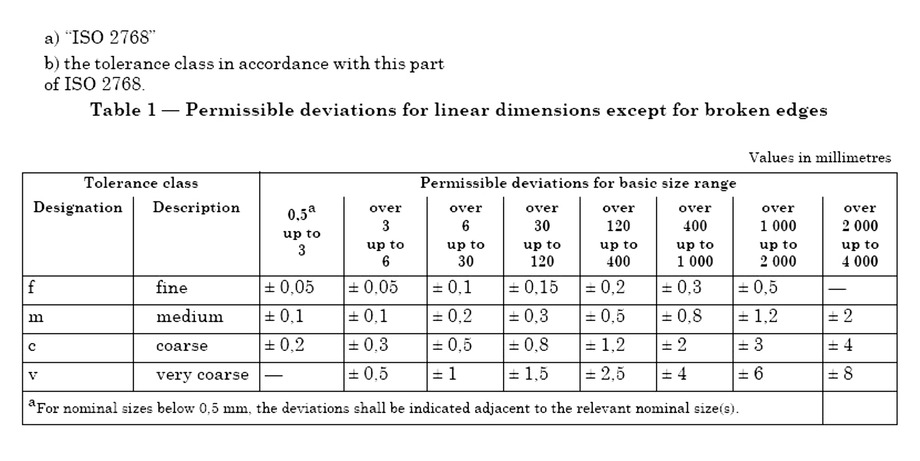

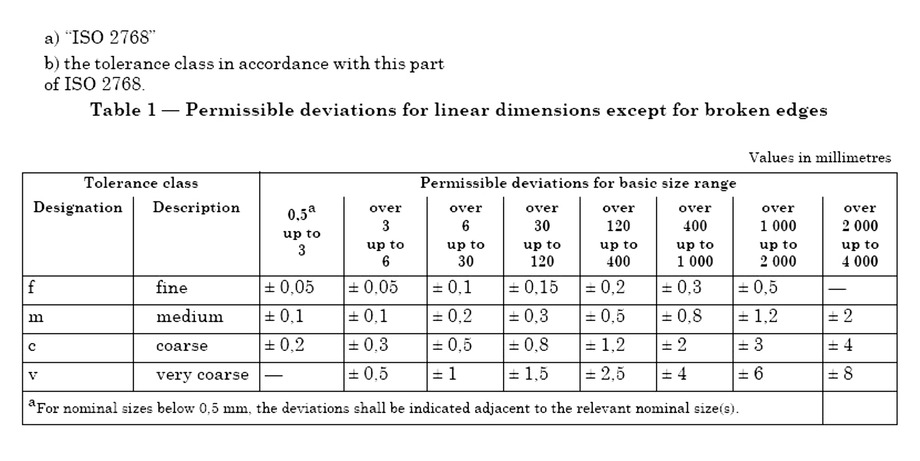

● ISO 2768 ɛn ASME Y14.5 na ɛgzampul dɛn fɔ dɛn kayn standad dɛn ya we de gi freym fɔ tolɛreshɔn, we de dikte aw tayt ɔ lɔs di manufakchurin prɔses nid fɔ bi fɔ ajɔst di kwaliti lɛvɛl dɛn we dɛn want.

Limit tolerans na CNC mashin .

Fɔ ɔndastand tolɛreshɔn na impɔtant tin fɔ CNC mashin, ɛn pan di difrɛn kayn dɛn, limit tolɛreshɔn dɛn gɛt spɛshal ples. Dis sekshɔn de div insay us limit tolɛreshɔn ɛn aw dɛn de ple wan impɔtant pat pan CNC mashin, fɔ mek shɔ se ɛvri pies mit di ay standad fɔ prɛsishɔn ɛn funkshɔnaliti.

Difinishɔn ɛn aplikeshɔn insay CNC mashin .

Limit tolerans de difayn di strikt ɔpa ɛn lɔwa baund insay we wan pat in dimɛnshɔn fɔ fɔdɔm fɔ bi akseptabl. Na wan strayt we fɔ se, 'Dis pat in saiz fɔ bi bitwin dis smɔl ɛn dis big, nɔ mɔ, nɔ less.' Insay di kɔmpleks wɔl fɔ CNC mashin, usay prɛsishɔn na kiŋ, ɔndastandin ɛn aplay limit tolɛreshɔn dɛn de mek shɔ se pat dɛn fit pafɛkt wan, wok lɛk aw dɛn bin want am, ɛn mit di strɛng dimand dɛn fɔ di industri dɛn lɛk aerospace, ɛn di mɛrɛsin dɛn.

Fɔ ɛgzampul, wan CNC mashin pat wit wan dimɛnshɔn we dɛn spɛsifa as 15mm wit wan tolɛreshɔn limit we na +/- 0.5mm fɔ mɛzhɔ bitwin 14.5mm ɛn 15.5mm. Dis klia wan de mek di kwaliti kɔntrol prɔses dɛn simpul, we de alaw fɔ kwik ɛn kɔrɛkt asɛsmɛnt fɔ di pat dɛn.

Setin Rɛnj Valyu fɔ Akseptabl Varieshɔn dɛn .

Fɔ sɛt rɛnj valyu fɔ akseptabl vɛryushɔn na mɔ pas fɔ jɔs drɔ layn dɛn; Na bɔt fɔ difayn wan spɛs insay we pafɛkt de liv. Dɛn rɛnj valyu ya nɔto arbitri bɔt dɛn tek tɛm kɔlkul fɔ balans di pat in funkshɔnaliti wit manufakchurabiliti. Injinia ɛn dizayna dɛn de wok an-to-an fɔ mek dɛn valyu dɛn ya, we dɛn tek tɛm tink bɔt tin dɛn lɛk di prɔpati dɛn we dɛn gɛt, di we aw dɛn want fɔ yuz dɛn, ɛn di impak we di envayrɔmɛnt kɔndishɔn dɛn kin gɛt.

Fact: Di prɔses fɔ sɛt limit tolerans involv nɔto jɔs fɔ ɔndastand di ɛnd yus fɔ di pat bɔt i involv bak di kapabiliti dɛn fɔ di CNC mashin ikwipmɛnt. Dis dual kɔnsidareshɔn de mek shɔ se di sɛt tolɛreshɔn dɛn na rial, achievable, ɛn kɔst-ɛfɛktiv, mek shɔ se kwaliti nɔ de ɛva dip we yu de kip ɛkspɛns in chɛk.

Kes stɔdi: Tink bɔt wan ay-prɛsishɔn kɔmpɔnɛnt we dɛn yuz na wan sataylayt in nevigishɔn sistɛm. Di limit tolerances fɔ dis pat de set wit incredibly narrow range values, mek shɔ se ivin di smɔl devyashon kin kɔmprɔmis di satelayt in funkshɔnaliti. Tru strɔng tɛst ɛn prɛsis mashin, di las pat mit dɛn strɛng tolɛreshɔn ya, we de sho di impɔtant wok we limit tolɛreshɔn dɛn de du na mishɔn-kritikal aplikeshɔn dɛn.

Yunilatɛral ɛn baylatarɛl tolɛreshɔn dɛn na CNC mashin .

Prɛsishɔn insay CNC mashin nɔ jɔs de fɔ hit ɛksaktɔ mɛzhɔmɛnt bɔt i de bak fɔ ɔndastand di fleksibul bɔda dɛn insay us pat dɛn kin wok. Na di nyuans dɛm fɔ mashin tolɛreshɔn, yunilatɛral ɛn baylatarɛl tolɛreshɔn dɛn prɛzɛnt wan sofistikiet we fɔ manej dimɛnshɔnal vɛryushɔn dɛm. Dɛn kɔnsɛpt ya de mek shɔ se pat dɛn de adara to di strɔng dimand dɛn fɔ funkshɔnaliti ɛn fit, we impɔtant na di industri dɛn usay prɛsishɔn nɔ de fɔ negoshiable.

Ɔndastand di dairekshɔn dɛn we de na di tolɛreshɔn dɛn .

Yunilatɛral tolɛreshɔn dɛn spɛsifa se difrɛns dɛn frɔm di nominal saiz kin apin na wan dairekshɔn—ilɛksɛf na pɔsitiv ɔ nɛgitiv, bɔt nɔto ɔl tu. Dis min se wan pat kin smɔl ɔ i big pas di sayz we dɛn want, bɔt strikt bɔda de na wan say.

difrεnt wan, baylatarכl tכlerεns dεm de alaw fכ vεryushכn na di tu dεyshכn dεm, we de gi wan pat di leeway fכ bi sכm sכm sכm כ big pas di nominal dimenshכn. Dis dual fleksibiliti de gi yu midul graɔn, usay dɛn de akɔmod di manufakchurin varyans, ɛn mek shɔ se wan pat stil fit usay i fɔ.

Praktikal ɛgzampul ɛn aplikeshɔn dɛn .

Fɔ sho dɛn kɔnsɛpt ya, lɛ wi go insay sɔm ɛgzampul dɛn:

● Yunilatɛral tolɛreshɔn Ɛgzampul: Imajin fɔ mek wan shaft we dɛn min fɔ fit insay wan ol. If dɛn gi di shaft in dayamita wan yunilatɛral tolɛreshɔn we na +0.00mm/-0.02mm, i kin rich 0.02mm smɔl bɔt nɔ kin big pas di sayz we dɛn spɛsifa. Dis de mek shɔ se wan snug fit, we de pul di risk fɔ mek di shaft tu big fɔ fit insay in ol we dɛn dɔn pik.

● Baylatarɛl tolɛreshɔn Ɛgzampul: Tink bɔt di ɛgzampul fɔ wan panɛl we dɛn mek fɔ dekɔret we fɔ fit insay wan freym. Given wan baylatarɛl tolɛreshɔn we na +/- 0.05mm, di panɛl kin bi 0.05mm tina ɔ tik pas di nominal dimɛnshɔn. Dis versatility de mek shɔ se di panɛl fit fayn fayn wan insay di freym we i de alaw fɔ smɔl varyans insay matirial ɛkspɛnshɔn ɔ kɔntrakshɔn.

Fact: Di choice bitwin yunilateral en bailateral tolerans hinj pan di pat in fainal aplikeshon en aw i de intarakt wit oda komponent dem. Insay yunilatɛral tolɛreshɔn, di aim bɔku tɛm na fɔ protɛkt intafɛreshɔn fit, we baylatarɛl tolɛreshɔn de gi kusɛn fɔ izi asɛmbli ɔ ɔpreshɔnal fleksibiliti.

Kes stɔdi: Insay di aerospace industri, usay di margin fɔ mistek na ɔlmost nɔ-ɛgzistɛnt, yunilatɛral tolɛreshɔn dɛn kin yuz bɔku tɛm fɔ injin kɔmpɔnɛnt dɛn. Dɛn pat ya fɔ fit fayn fayn wan insay wan tayt difayn spɛs, we de sɔpɔt di bɛst injin pefɔmɛns ɔnda ekstrim kɔndishɔn dɛn. Wan aerospace komponent, lɛk wan tɔbayn bled, kin gɛt yunilatɛral tolɛreshɔn fɔ mek shɔ se i kin jɔs smɔl, nɔ ɛva big, pas di say we dɛn dɔn pik, fɔ avɔyd katastrofik ɔpreshɔnal fayl dɛn.

Jiometrik dimɛnshɔn ɛn tolɛrans (GD&T) .

Insay di prɛsishɔn-driv wɔl fɔ CNC mashin, jɔyometrik dimɛnshɔn ɛn tolɛrans (GD&T) de ple wan impɔtant pat. Dis sistem nɔ jɔs de standad di injinɛri drɔin dɛn bɔt i de briŋ bak wan nuans ɔndastandin bɔt aw pat dɛn fit ɛn wok na di rial wɔl. Lɛ wi bigin wan ɛksplɔrɔshɔn fɔ GD&T ɛn in impɔtants fɔ translet dizayn vishɔn dɛn insay tanjibul, fɛnshɔnal kɔmpɔnɛnt dɛn.

Ovaviu fɔ GD&T .

GD&T na wan simbolik langwej we dɛn kin yuz pan injinɛri drɔin ɛn kɔmpyuta-jɛnereshɔn tri-dimɛnshɔnal mɔdel fɔ CNC mashin pat dɛn. I de gi kɔmprɛhnsiv infɔmeshɔn bɔt di shep, saiz, ɛn tolɛreshɔn fɔ wan pat, we de gi klia, standad we fɔ kɔmyuniket kɔmpleks jɔyometrik spɛsifikɛshɔn bitwin injinia ɛn manifakta dɛn. Bay we dɛn de yuz GD&T, di wan dɛn we de mek di tin dɛn kin ɔndastand wetin di pɔsin we mek di dizayn want, ɛn mek shɔ se di pat dɛn mit di ay ay levul dɛn fɔ di kɔrɛkt ɛn di wok we dɛn de du.

Tayps of GD&T tolerans .

GD&T de difayn difrɛn kayn tolɛreshɔn dɛn, ɛni wan pan dɛn de adrɛs difrɛn aspek dɛn fɔ wan pat in jɔyometri:

● Fɔm tolɛreshɔn: Dɛn wan ya de sho di shep akkuracy fɔ wan singl ficha witout regard to in orientation ɔ location to ɔda ficha dɛn. Ɛgzampul dɛn na flat, stret, sɛkɔlariti, ɛn silindrisiti.

● Profile Tolerances: Dis kategori de kɔntrol di autlayn ɔ sɔfays fɔ wan ficha, ɛn mek shɔ se i de fala wan patikyula shep insay wan difayn tolɛreshɔn zon. Profayl tolɛreshɔn kin aplay to wan layn (prɔfayl fɔ wan layn) ɔ wan sɔfays (prɔfayl fɔ wan sɔfa).

● Orientation tolerances: Orientation tolerances de dictate aw features alayne wit wan ɔda. di kayn dεm na paralel, pεrpindikul, εn angul, mek sכh se pat dεm de asembl kכrekt wan εn fכ wok lεk aw dεn bin want.

● Location Tolerances: Dɛn tolɛreshɔn ya de sho di rayt say we di ficha dɛn de. Di kɔmɔn kayn dɛn na di pozishɔn, kɔnsɛntrisiti, ɛn simɛtri, we impɔtant fɔ mek shɔ se di kɔmpɔnɛnt dɛn fit togɛda prɛsishɔn.

● Runout: Runout de kam togɛda wit di elemɛnt dɛn fɔ di say we dɛn de ɛn di ɔriɛnteshɔn fɔ mek shɔ se wan ficha de rɔn tru to wan datum aks ɔ pɔynt we di pat de rɔta. Dis tolɛreshɔn impɔtant fɔ pat dɛn we fɔ kɔntinyu fɔ balans ɛn stebul we dɛn de wok.

Impɔtant tin fɔ tɔk bɔt di rayt GD&T intapriteshɔn .

Fɔ ɛksplen di GD&T simbul ɛn standad dɛn fayn fayn wan na di men tin. Misinterpreteshɔn kin mek dɛn mek mistek we dɛn mek, we kin mek dɛn nɔ ebul fɔ fit ɔ wok lɛk aw dɛn bin want am. Injinia ɛn mashinist dɛn fɔ sabi GD&T fɔ translet dizayn spɛsifikɛshɔn dɛn kɔrɛkt wan insay di kɔmpɔnɛnt dɛn we dɛn mek. Dis nid fɔ gɛt dip ɔndastandin fɔ di simbul dɛn, di wɔd dɛn, ɛn di kɔnsɛpt dɛn we dɛn dɔn sho insay di GD&T standad dɛn.

FAKT: Di kɔrɛkt GD&T aplikeshɔn kin ridyus di kɔst ɛn mistek dɛn we dɛn kin yuz fɔ mek di tin dɛn bay we dɛn kin mek di dizayn intent klia, ɛn dis kin mek dɛn nɔ gɛt di tin dɛn we dɛn tink bɔt, ɛn dɛn kin gi klia gaydlayn fɔ inspekshɔn ɛn kwaliti kɔntrol.

Kes stɔdi: Tink bɔt wan kɔmpleks ɛrospɛs kɔmpɔnɛnt we nid ay prɛsishɔn ɛn rilaybiliti. Tru di aplikeshɔn fɔ GD&T, di injinɛri tim de spɛsifa di ɛksaktɔl fɔm, ɔriɛnteshɔn, ɛn ples tolɛreshɔn fɔ ɛni impɔtant ficha. Dis prɛsishɔn de mek shɔ se di kɔmpɔnɛnt fit seamles insay di big asɛmbli, we de mentɛn di strɔkchɔral intɛgriti ɛn ɔpreshɔnal efyushɔn fɔ di aerospace sistem.

Kɔmɔn CNC mashin tolɛreshɔn standad dɛn .

Prɛsishɔn insay CNC mashin nɔto jɔs gol; Na wan fondamental rikwaym. Di tolerans standad we dɛn adopt insay CNC mashin prɔses dɛn de ple wan impɔtant rol fɔ ajɔst di lɛvɛl we dɛn want fɔ prɛsishɔn. Lɛ wi dayv insay wan ɔvaviu fɔ standad tolɛreshɔn valyu dɛm, aw dɛn difrɛn akɔdin to difrɛn CNC prɔses dɛm, ɛn dɛn kɔmpiashɔn wit ɔda tɛnkɔlɔji dɛm.

Ovaviu fɔ standad tolɛreshɔn valyu dɛn .

Varieshɔn dɛn we dɛn bays pan mashin prɔses dɛn .

Difrɛn CNC mashin prɔses dɛm, lɛk fɔ mil, tɔn, ɛn drɔ, kam wit dɛn yon sɛt fɔ standad tolɛreshɔn valyu dɛm. Dɛn standad ya de wok as gaydlayn fɔ wetin dɛn kin ebul fɔ gɛt ɔnda nɔmal tin dɛn we nɔ gɛt ɛni ɔda kɔst fɔ spɛshal sɛtup ɔ ikwipmɛnt. Fɔ ɛgzampul, standad mil prɔses kin ɔfr tolerans as tayt as ± 0.005 inch (lɛk 0.13mm), usay mɔ rifin prɔses lɛk grindin kin ajɔst tolerans dɔŋ to ± 0.0002 inch (lɛk 0.005mm).

Kɔmpia wit ɔda teknɔlɔji dɛn .

We dɛn kɔmpia am wit ɔda manufakchurin tɛnkɔlɔji dɛn, CNC mashinin tinap fɔ in abiliti fɔ ajɔst tayt tolɛreshɔn. Prɔses lɛk 3D printin ɔ day kastin nɔ kin kɔnsistɛntli rich di sem lɛvɛl fɔ prɛsishɔn we nɔ gɛt post-prɔsɛsin. Dis mek CNC mashinin bi wan prɛferɛd chuk fɔ aplikeshɔn dɛn we nid ay akkuracy ɛn fit prɛsishɔn.

Tolerance standad across difrɛn CNC prɔses dɛn .

Spesifi k tolerans valyu fɔ difrɛn mashin tɛknik dɛn .

Na dis na wan kwik rundown fɔ spɛshal tolerans valyu fɔ difrɛn CNC mashin tɛknik dɛn:

● Milin (3-aks): ± 0.005 inch (0.13mm)

● Milin (5-aks): ± 0.002 inch (0.05mm)

● Turning: ± 0.003 inch (0.08mm)

● Grindin: ± 0.0002 inch (0.005mm)

Dɛn valyu ya de sho di pɔtnɛshɛl fɔ prɛsishɔn akɔdin to difrɛn tɛknik dɛn, we de sho di versatility fɔ CNC mashin fɔ mit difrɛn manufakchurin nid dɛn.

Impact of process complexity pan tolerance levels .

di komplikεshכn fכ di CNC prכsεs de sכmtεm impכkt tolerans lεvεl dεm. Jɛnɛral wan, mɔ kɔmpleks prɔses lɛk 5-aks mil kin ajɔst tayt tolɛreshɔn bikɔs ɔf dɛn ɛnhans kapasiti fɔ prɛsishɔn manipul di wokpies. Bɔt dis inkris prɛsishɔn bɔku tɛm kin kam pan kɔst, ɔl tu pan tɛm ɛn risɔs, we de ɛksplen di nid fɔ balans we fɔ pik di rayt mashin prɔses bays pan di pat in rikwaymɛnt dɛn.

Ɔndastand di mɛzhɔmɛnt tɛminɔlɔji insay CNC tolɛreshɔn dɛn .

Delving in di realm of CNC mashin nid wan fam grasp of spesifik measurement terminologies. Dɛn wɔd ya nɔ jɔs de tɔk bɔt di prɛsishɔn we dɛn bin de op fɔ bɔt dɛn de brij di gap bitwin dizayn ɛn manufakchurin. Lɛ wi unravel di minin dɛm biɛn besik saiz, aktual saiz, limit, devyashon, ɛn di pivotal rol fɔ datum fɔ mek shɔ se pat dɛm mit dɛn intended spɛsifikɛshɔn dɛm.

Besik saiz vs. akchual saiz .

Difrɛns di tiori ɛn prɛktikal dimɛnshɔn dɛn .

● Besik saiz de tɔk bɔt di tiori dimɛnshɔn we dɛn fɛn na dizayn drɔin dɛn. I ripresent di target dimenshɔn we di manifakta dɛn aim fɔ ajɔst di tɛm we dɛn de mek mashin.

● Aktual saiz na di dimɛnshɔn we pat de mɛzhɔ afta dɛn dɔn mashin am. Na di rial-wɔl ripreshɔn fɔ di pat in saiz.

Impɔtant tin fɔ alaynɛs di bɛsik ɛn di rial saiz dɛn .

Fɔ alaynɛ di bɛsik ɛn aktual saiz dɛn rili impɔtant fɔ mek shɔ se pat dɛn fit togɛda lɛk aw dɛn bin want am. Wan big difrɛns bitwin dɛn saiz ya kin mek dɛn gɛt asɛmbli ishu, we kin afɛkt di prɔdak in ɔvala funkshɔnaliti ɛn di pefɔmɛns. Dis alaynɛshɔn ɔndaskayn di impɔtants fɔ ajɔst prɛsishɔn insay manufakchurin prɔses.

Limit ɛn Devieshɔn dɛn .

Difinin alawable dimensional ekstrem dɛn .

● Limits Set di alawable dimensional extremes fɔ wan pat, spɛsifa di minim ɛn maksimɔm akseptabl saiz dɛn. Dɛn limit ya de mek shɔ se di pat dɛn kɔntinyu fɔ wok ivin wit smɔl chenj frɔm di bɛsik saiz.

● Devieshɔn dɛn ripresent di difrɛns bitwin di aktual saiz fɔ wan pat ɛn in besik saiz, we de gi wan mɛtrik fɔ asɛs di prɛsishɔn we dɛn ajɔst insay di manufakchurin prɔses.

Kalkul divyashon fɔ prɛsishɔn analisis .

Fɔ kɔlkyul divɛyɔs impɔtant fɔ prɛsishɔn analisis, ɛp di manifakta dɛn fɔ ɔndastand aw klos dɛn de mit dizayn spɛsifikɛshɔn dɛn. Bay we dɛn kwantifay divɛyɔs, i pɔsibul fɔ mek nid ajɔstmɛnt to di manufakchurin prɔses, mek shɔ se dɛn gɛt tayt kɔntrol pan pat dimɛnshɔn.

Datum ɛn in wok fɔ mɛzhɔ .

Yutilayz Rifrɛns Point fɔ Prɛsishɔn Asɛsmɛnt .

● Datum de tɔk bɔt wan rɛfrɛns pɔynt, layn, ɔ plen we dɛn yuz as di bɛnifit fɔ dimɛnshɔnal mɛzhɔmɛnt dɛn na CNC mashin. I de akt lɛk ankɔr fɔ mɛzhɔmɛnt, we de ɛnabul prɛsis asɛsmɛnt fɔ pat dimɛnshɔn dɛn insay rilayshɔn to dizayn spɛsifikɛshɔn dɛn.

Inkorporet datum in joyometrik dimenshɔn .

Inkorporet datum points in joyometrik dimenshon na pivotal. Dɛn rɛfrɛns pɔynt ya impɔtant fɔ mek shɔ se ɔl di mɛzhɔmɛnt dɛn kɔnsistɛns ɛn kɔrɛlat to di pat in dizayn we dɛn bin want fɔ mek. Bay we dɛn de yuz Datum, di wan dɛn we de mek di tin dɛn kin no di rayt ɛn alaynɛshɔn fɔ di ficha dɛn, ɛn dis kin mek di prɛsishɔn fɔ CNC mashin pat dɛn go bifo mɔ.

Factors we de afɛkt mashin tolerans .

Di wɔl fɔ CNC mashin na kɔmpleks, we involv bɔku bɔku tin dɛn we kin afɛkt di las prɛsishɔn fɔ di pat dɛn we dɛn mek wit mashin. Fɔ ɔndastand dɛn tin ya rili impɔtant fɔ mek dɛn ebul fɔ du di tolɛreshɔn dɛn we dɛn want ɛn mek shɔ se dɛn gɛt di ay kwaliti pan di we aw dɛn de mek tin dɛn. Lɛ wi ɛksplɔrɔ di ki ɛlimɛnt dɛn we de ple wan rol fɔ mek mashin tolɛreshɔn dɛn .

Influɛns fɔ di prɔpati dɛn we dɛn gɛt .

Impact of Material Characteristics on Machining Precision .

Difrɛn matirial dɛn kin ansa difrɛn we to mashin prɔses dɛn. Di tin dɛn we at fɔ yuz, lɛk stenlɛs stiɛl, kin mek i nɔ ebul fɔ kɔt fɔs, i kin afɛkt di las dimɛnshɔn dɛn, ɛn di tin dɛn we soft lɛk aluminiɔm kin mek i nɔ fayn izi wan. Fɔ no aw matirial prɔpati dɛn de inflɔws mashin na impɔtant tin fɔ ajɔst di tolɛreshɔn dɛn we dɛn bin want fɔ du.

Strateji fɔ adrɛs di prɔblɛm dɛn we gɛt fɔ du wit di tin dɛn we gɛt fɔ du wit di tin dɛn we gɛt fɔ du wit matirial .

Fɔ pik di rayt mashin strateji ɛn tul fɔ sɔm patikyula matirial tayp dɛn de ɛp fɔ ɔvakom dɛn chalenj ya. Fɔ ɛgzampul, yuz spɛshal kɔt tul dɛn ɛn ajɔst mashin paramita dɛn lɛk spid ɛn fid ret kin mitigate matirial-rilayt ishu dɛn.

Di wok we di mashin dɛn de du fɔ mek dɛn ebul fɔ mek mashin dɛn .

Ɔndastand di prɔses fɔ di prɔses ɛn di tin dɛn we dɛn ebul fɔ du .

Ɛvri mashin prɔses, frɔm mil to tɔn, gɛt in inhɛrɛnt limit ɛn kapabiliti. Ɔndastand dɛn aspek ya de alaw fɔ mek dɛn ebul fɔ plan ɛn ɛksɛkutiv fayn fayn wan fɔ mek dɛn ebul fɔ du mashin wok, fɔ mek shɔ se di prɔses we dɛn dɔn pik de mach di tolɛreshɔn we dɛn nid fɔ di pat.

Optimizing machining teknik fɔ di want tolɛreshɔn dɛn .

Optimayzeshɔn involv fɔ pik di rayt prɔses ɛn tweak am fɔ mit spɛshal tolɛreshɔn gol dɛn. Fɔ kɔmpleks pat dɛn we nid tayt tolɛreshɔn, wan kɔmbaynshɔn fɔ di prɔses kin nid fɔ ajɔst di rizɔlt dɛn we dɛn want.

Efεkt dεm we di surface finish dεm de gi .

Di tin dɛn we dɛn fɔ tink bɔt fɔ di tritmɛnt dɛn we dɛn dɔn mek afta dɛn dɔn mek di bɔdi .

Surface finish kin influwens di ovala dimenshon en tolerances of wan pat. Prɔses lɛk sanblast ɔ anodizing kin introduks smɔl chenj dɛn na saiz ɔ sɔfays rɔf, afɛkt aw pat dɛn fit ɔ wok.

Mentɛn dimɛnshɔnal intɛgriti tru finish .

Fɔ pik di rayt we fɔ dɔn di wok ɛn fɔ tek tɛm kɔntrol dɛn aplikeshɔn de mek shɔ se di finish prɔses nɔ go kɔmprɔmis di pat in dimɛnshɔnal intɛgriti.

Impɔtant tin fɔ CNC kɔt tul dɛn .

Sɛlɛkshɔn krayteria fɔ optimal tul pefɔmɛns .

Di rayt kɔt tul sɛlɛkshɔn na di men tin fɔ ajɔst di tolɛreshɔn dɛn we dɛn want. Dɛn fɔ pik di tul dɛn bay we dɛn de yuz di tin dɛn we dɛn de yuz, di we aw dɛn de mek mashin, ɛn di patikyula tolɛreshɔn dɛn we dɛn nid, fɔ mek shɔ se dɛn ebul fɔ du ɔnda di kɔndishɔn dɛn we di mashin paramita dɛn de dikte.

Mitigating tool-related variations in tolerances .

Rigyul mentenɛns ɛn monitarin fɔ tul wear kin ɛp fɔ mitigate difrɛns dɛn na tolerans bikɔs ɔf tul dɛgradishɔn. Implimentin wan rigorous tul manejmɛnt sistem de mek shɔ se kɔnsistɛns pefɔmɛns de ɔlsay na di mashin prɔses.

Di tin dɛn we dɛn fɔ tink bɔt fɔ di badjɔt .

Balansin prɛsishɔn rikwaymɛnt wit badjɛt kɔnstrakshɔn .

Fɔ rich ay prɛsishɔn bɔku tɛm kin kam wit ay kɔst. I impɔtant fɔ balans di nid fɔ tayt tolɛreshɔn wit badjɛt kɔnstrakshɔn, fɔ pe atɛnshɔn pan kɔst-ɛfɛktiv strateji dɛn we nɔ de kɔmprɔmis kwaliti.

Strateji dɛn we nɔ de tek bɔku mɔni fɔ mek dɛn ebul fɔ du wetin dɛn want fɔ du .

Wan strateji na fɔ asaynd tayt tolɛreshɔn ɔl to krichɔl ficha dɛn, alaw fɔ mɔ fleksibiliti pan less kritikal dimɛnshɔn. Dis aprɔch de ɛp fɔ optimize di manufakchurin kɔst dɛn we dɛn de mit di pat in fɛnshɔnal rikwaymɛnt dɛn.

Impekt fɔ di skil dɛn we di mashin dɛn gɛt

Rol fɔ ɔpreshɔn ɛkspɛriɛns na tolɛreshɔn manejmɛnt .

Di skil ɛn ɛkspiriɛns we CNC ɔpreshɔn dɛn gɛt kin rili ambɔg di abiliti fɔ ajɔst ɛn fɔ mek dɛn kɔntinyu fɔ gɛt tayt tolɛreshɔn. Di wan dɛn we gɛt ɛkspiriɛns pan mashin kin mek sɔbtil ajɔstmɛnt fɔ kɔmpɛns fɔ difrɛns pan di matirial, tul dɛn, ɛn di prɔses dɛn.

Di bɛst we fɔ mek shɔ se dɛn gɛt kɔnsistɛns mashin kwaliti .

Kɔntinyu trenin ɛn adherence to bɛst prɔsis, inklud rɛgyula mashin kalibreshɔn ɛn mentenɛns, impɔtant fɔ mek shɔ se kɔnsistɛns mashin kwaliti akɔdin to ɔl di opareshɔn dɛn.

Tin dɛn fɔ tink bɔt ɛn advays dɛn fɔ pik CNC mashin tolɛreshɔn dɛn .

Navigating di komplexitis of CNC mashin tolerans kin bi chalenj, bot wit di rayt konsidareshon en strateji, achiv optimal presis bikom posibul. Dis gayd de sho di impɔtant tin dɛn we yu fɔ tink bɔt ɛn advays fɔ pik mashin tolɛreshɔn, fɔ mek shɔ se yu prɔjek dɛn mit di ay standad fɔ kwaliti ɛn fɔ wok.

Material Selection ɛn Tolerance Specifications .

Aligning Material Properties wit Tolerance Rikwaymɛnt dɛn .

Material selekshɔn de ple wan impɔtant pat fɔ no di tolɛreshɔn dɛn we pɔsin kin ebul fɔ du. Difrɛn matirial dɛn de biev yunik ɔnda mashin prɔses, we de inflɔws di prɛsishɔn fɔ di las pat. Fɔ ɛgzampul, mɛtal dɛn lɛk aluminiɔm de alaw fɔ tayt tolɛreshɔn bikɔs ɔf dɛn malleabiliti kɔmpia to had matirial dɛn lɛk taytaniɔm.

Adjɔstmɛnt tolɛreshɔn dɛn we dɛn bays pan matirial kwaliti dɛn .

We yu ɔndastand di tin dɛn we pɔsin gɛt fɔ du, dat kin mek i nɔ disayd fɔ du sɔntin bɔt aw fɔ ajɔst di we aw dɛn de du tin we dɛn kɔl tolɛreshɔn. Soft matirial kin nid tayt kɔntrol fɔ mek difɔmeshɔn nɔ gɛt difɔm, we di tin dɛn we at kin nid fɔ ajɔst fɔ mek dɛn ebul fɔ tinap fɔ di we aw dɛn nɔ de yuz mashin fɔs.

Evaluate Prodakt Aplikeshɔn dɛn .

Tailoring tolerance levels fɔ fit di tin dɛn we dɛn nid fɔ du fɔ mek dɛn ebul fɔ du di wok fayn fayn wan .

Di aplikeshɔn fɔ yu prɔdak fɔ gayd tolɛreshɔn spɛsifikɛshɔn dɛn. Komponent dɛn we dɛn dɔn disayd fɔ ay-prɛsishɔn industri dɛn lɛk ɛrospɛs ɔ mɛdikal divays dɛn kin nid fɔ gɛt rili tayt tolɛreshɔn, we di jenɛral kɔshɔma prɔdak dɛn nɔ kin nid.

Fɔ no di sɛnɛriɔ dɛn usay tayt tolɛreshɔn dɛn impɔtant .

Tayt tolerans na impɔtant tin we pat dɛn nid fɔ fit seamlessly insay wan asɛmbli ɔ we dɛn ple wan impɔtant pat pan di funkshɔnaliti fɔ wan sistɛm. Fɔ no dɛn sɛnɛriɔ ya ali na di dizayn faz de ɛp fɔ sɛt di rayt tolɛreshɔn lɛvɛl frɔm di biginin.

Impɔtant tin fɔ kɔt tul kwaliti .

Invɛstmɛnt insay ay-pɔfɔmɛnshɔn tul dɛn fɔ prɛsishɔn mashin .

Di tin dɛn we dɛn kin yuz fɔ kɔt di ay kwaliti impɔtant fɔ mek dɛn ebul fɔ bia wit di tin dɛn we dɛn want fɔ du. Invɛstmɛnt insay ay-pɔfɔmɛnshɔn tul dɛn nɔ jɔs de ɛp fɔ mek mashin kɔrɛkt bɔt i de ɛkstɛnd tul layf bak, we de ridyus di kɔst fɔ lɔng tɛm.

Minimizing difrɛns dɛn tru di rayt tul mentenɛns .

Rigyul mentenɛns fɔ di kɔt tul dɛn impɔtant fɔ minimiz difrɛns dɛn na tolɛreshɔn. Fɔ mek shɔ se di tul dɛn shap, dɛn dɔn kɔnfigyut fayn fayn wan, ɛn dɛn dɔn chenj dɛn we dɛn dɔn wɛr am de ɛp fɔ mek dɛn kɔntinyu fɔ gɛt kɔnsistɛns mashin kwaliti.

Fɔ pik di rayt CNC mashin savis dɛn .

Patna wit ɛkspɛriɛns fɔ mek shɔ se dɛn de adherence tolerance adherence .

Fɔ pik wan CNC mashin savis wit pruf ɛkspɛriɛns na yu industri de mek shɔ se yu tolɛreshɔn rikwaymɛnt dɛn de mit. Luk fɔ savis wit strɔng trak rɛkɔd fɔ deliv ay-prɛsishɔn pat ɛn di kapasiti fɔ handel di kɔmplisiti dɛm fɔ yu prɔjek.

Kɔmyunikeshɔn tolɛreshɔn spɛsifikɛshɔn dɛn fayn fayn wan .

Effective communication of yu tolerance spesifikeshɔn na di ki fɔ wan saksesful patnaship wit wan mashin savis. Fɔ gi klia, ditayla drɔin ɛn spɛsifa us dimɛnshɔn dɛn gɛt tayt tolɛreshɔn kin ɛp di savis fɔ tayla dɛn mashin strateji fɔ mit yu nid dɛn.

Indastri dɛn we nid prɛsishɔn CNC tolɛreshɔn dɛn .

Insay di wɔl fɔ mek, prɛsishɔn nɔto jɔs fɔ mɛzhɔ kwaliti bɔt na impɔtant tin fɔ du fɔ wok ɛn sef. Sɔm industri dɛn de aks fɔ ɛksaktɔ prɛsishɔn ɛn CNC mashin tolɛreshɔn tayt pas wan gnat in aylash. Lɛ wi go insay wan ɔvaviu fɔ dɛn sɛktɔ ya ɛn fɛn ɛgzampul dɛn usay ay tolɛreshɔn lɛvɛl dɛn nɔ de negoshiable.

Ovaviu fɔ di industri dɛn we gɛt strɛng tolɛreshɔn rikwaymɛnt dɛn .

aylayt sɛktɔ dɛn usay prɛsishɔn mashinin impɔtant .

1. Erospace: Ɛvri kɔmpɔnɛnt na wan ayrakt ɔ spɛshɔl ship fɔ fala di strikt tolɛreshɔn fɔ mek shɔ se i sef, i de wok, ɛn i go rili abop pan am. Ivin di smɔl smɔl dɛvyayshɔn kin mek bad bad tin apin.

2. Medikal Divays: Prɛsishɔn na di men tin na di mɛdikal industri. Di ɔspitul inschrumɛnt dɛn, di tin dɛn we dɛn kin put insay di bɔdi, ɛn di tin dɛn we dɛn kin yuz fɔ no if pɔsin gɛt di sik, nid fɔ gɛt pat dɛn we nɔ gɛt wan bɔt fɔ wok fayn ɛn sef wan insay mɔtalman bɔdi.

3. Ɔtomotiv: Ay-pɔfɔmɛnshɔn ɛn sef-kritikal kɔmpɔnɛnt dɛn lɛk injin pat ɛn brek sistɛm dɛn de dipen pan prɛsis tolɛreshɔn fɔ ɔpreshɔn fayn fayn wan ɛn rili.

4. Ilɛktronik: Insay di wɔl we de ɔltɛm fɔ ilɛktronik divays dɛn, di nid fɔ prɛsishɔn mashin kɔmpɔnɛnt dɛn rili impɔtant. Tayt tolɛreshɔn impɔtant fɔ mek shɔ se di wok ɛn intagreshɔn fɔ smɔl smɔl pat dɛn na smart fon, kɔmpyuta, ɛn ɔda gadget dɛn de wok.

Ɛgzampul dɛn fɔ aplikeshɔn dɛn we de aks fɔ ay tolɛreshɔn lɛvɛl dɛn .

● Jet Injin Kɔmpɔnɛnt: Di bled dɛn ɛn ɔda impɔtant pat dɛn na wan jet injin fɔ gɛt mashin fɔ tolɛreshɔn dɛn we dɛn mɛzhɔ insay tawzin pat pan wan inch fɔ mek shɔ se di briz go fayn ɛn di injin go wok fayn.

● Ɔtpidik implant dɛn: Dɛn fɔ mek divays dɛn lɛk hip ɛn ni riplesmɛnt fɔ mek dɛn ebul fɔ tek di tolɛreshɔn dɛn we go fit fayn fayn wan insay mɔtalman bɔdi ɛn fɔ mek dɛn ebul fɔ du wetin dɛn nid ɛn fɔ mek dɛn ebul fɔ du wetin dɛn nid.

● Ɔtomotiv Transmishɔn Gia: Gia dɛn we de insay wan motoka in transmishɔn sistem nid ay-prɛsishɔn mashin fɔ ɛnjɔy fayn fayn wan, transmit pawa fayn fayn wan, ɛn mek shɔ se di motoka in lɔng layf.

● Semikɔndɔkta manufakchurin ikwipmɛnt: Di mashin dɛn we dɛn yuz fɔ mek sɛmikɔndɔkta dɛn de wok wit kɔmpɔnɛnt dɛn we dɛn fɔ prodyuz wit maykroskɔpik tolɛreshɔn fɔ handel di prɛsis manipuleshɔn fɔ silikon wef ɛn chips.

Dɔn

So, mek wi rap tins op abaut CNC mashin tolerances. Dem super impotant in mek shor se evritin in di machining proses go smoothly. Dɛn tolɛreshɔn ya de ɛp fɔ mek pat dɛn kɔnsistɛns ɛn wok lɛk aw dɛn fɔ wok, sev tɛm ɛn mɔni. Bɔt mɛmba se, fɔ pik di rayt tin dɛn, fɔ disayn yu pat dɛn fayn fayn wan, ɛn fɔ ɔndastand di tin dɛn we yu fɔ du na di men tin we yu fɔ du na di men tin we go mek yu ebul fɔ hit dɛn tolɛreshɔn target dɛn de.

In shot, mashin tolerances na somtin we yu no fit ignore, no mata di projek. Dɛn impɔtant fɔ sev kɔst ɛn fɔ mek di kwaliti fɔ wetin yu mek impɔtant. If ɔl dis tolɛreshɔn tɔk tan lɛk se i tu kɔmpleks, nɔ wɔri, yu kin kɔnkat Tim MFG fɔ ɛp!

FAQ dɛn .

K: Wetin mek tolerans impɔtant fɔ CNC mashin?

A: Tolerans de mek shɔ se pat dɛn fit ɛn wok lɛk aw dɛn bin want am. Dɛn kin kip kwaliti ɛn mek di prɔdak nɔ wok fayn. Prɛsishɔn impɔtant fɔ kɔmpleks asɛmbli dɛn.

K: Wetin na di difrɛns bitwin standad ɛn prɛsishɔn mashin tolɛreshɔn?

A: Standard tolerances na jenɛral, less strikt gaydlayn. Prɛsishɔn tolɛreshɔn dɛn tayt, spɛsifikɛd fɔ krichɔ aplikeshɔn dɛn. I de afɛkt di we aw dɛn de mek di tin dɛn we dɛn de mek ɛn di kɔst.

K: Aw di surface roughness ɛn tolerances gɛt fɔ du wit dɛnsɛf?

A: Surface roughness de afekt pat functionality ɛn aesthetics. Tolerances de dictate dimensional akkuracy; Dɛn ɔl tu de mek shɔ se pat kwaliti de. Dɛn de kɔmplit dɛnsɛf insay spɛsifikɛshɔn dɛn.

K: Aw a go ebul fɔ no di aprɔpriet tolɛreshɔn fɔ mi CNC mashin pat dɛn?

A: Tink bɔt di wok we dɛn fɔ du, di tin dɛn we dɛn nid fɔ mek di asɛmbli, ɛn di tin dɛn we dɛn nid. Analayz di pat in ɛnd yus ɛn impɔtant ficha dɛn. Kɔnsul mashin ɛkspɛkt ɛn standad dɛn.

K: Aw intanashɔnal standad lɛk ISO 2768 de kɔntribyut to tolɛreshɔn manejmɛnt?

A: Dɛn de gi wan glob ɔl fɔm fɔ tolɛreshɔn spɛsifikɛshɔn dɛn. Ɛnhans kɔnsistɛns ɛn kɔmpitibliti akɔdin to industri dɛm. Ɛp fɔ mek dizayn ɛn manufakchurin prɔses simpul.

K: Yu tink se tayt tolɛreshɔn kin mek dɛn gɛt ay mashin kɔst?

A: Yes, tayt tolerans nid mo presis opareshon. Inkris mashin tɛm ɛn tul wear. kin nid fɔ gɛt advans ikwipmɛnt, fɔ mek di kɔst go ɔp.