Yu dɔn ɛva ol wan hama ɔ twist wan rench ɛn notis dɛn kol, bɔmpi patɛns dɛn de na di handel? Dɛn kɔl dat Knurling . Na wan supa neat we fɔ mek tul ɛn ɔda tin dɛn nɔ jɔs luk fayn bɔt i izi fɔ ol pan. In dis atikul, a go tek yu pan wan fayn trip insay di wɔl fɔ knurling. Wi go lan ɔl bɔt aw dis wɔndaful prɔses de ad spɛshal tɔch to tin dɛn we wi de yuz ɛvride.

Knurling dɔn kam fa frɔm we dɛn de du am wit an to naw yuz fansi mashin dɛn we de mek rili intrɛstin dizayn dɛn. Bɔt wetin na knurling, ɛksaktɔli? Aw i de wok, ɛn wetin mek bɔku tin dɛn gɛt dɛn fayn fayn tin dɛn ya? Wi go daiv insay ɔl dat ɛn mɔ, luk difrɛn kayn knurling patɛn ɛn aw dɛn mek dɛn. If yu jɔs want fɔ no mɔ ɔ yu nid fɔ no bɔt knurling fɔ wan skul prɔjek, stik rawnd! Dis go bi intrestin.

Ɔndastand fɔ knurling .

Ovaviu fɔ Knurling insay Manufakchurin .

Knurling na wan fayn fayn we fɔ mek tin dɛn. Tink bɔt am as we fɔ mek wan tɛkstɔr patɛn pan wan sɔfays. Bɔku tɛm, dɛn kin du am pan mɛtal pat dɛn we dɛn de yuz knurling tul dɛn. Dis patɛn nɔ jɔs luk fayn bɔt i de mek grip bɛtɛ bak. I rili impɔtant na di mɔdan industri. Wetin du? Bikɔs dɛn kin yuz am pan bɔku tin dɛn! Frɔm tul handel to mɛdikal ikwipmɛnt, knurling de mek prɔdak izi ɛn sef fɔ ol.

Historical perspektiv fɔ knurling .

Di wɔd ‘knurling’ kɔmɔt frɔm ‘Knur’. Dis ol wɔd bin min smɔl knot ɔ wan rɔf projɛkshɔn. As tɛm de go, di wɔd bin evolv to ‘knurled’, we de diskrayb di tɛkstɔr patɛn we wi de si pan mashin pat dɛn. Dis evolushɔn nɔ bin jɔs de insay langwej. Di knurling proses sef transfom tu. I bin kɔmɔt frɔm simpul we dɛn we dɛn mek wit an to advans, prɛsis mashin tɛknik dɛn.

Ki Points in Knurling .

Mek wi brok dɔŋ knurling insay simpul pat dɛn:

1. Di kayn knurling: Bɔku kayn dɛn de, lɛk strayt knurling, dayamɔn knurling, ɛn ɛlikal knurling. Ɛni kayn gɛt wan patikyula pɔtn ɛn yuz.

2. Kɔmɔn Difɛkt: Sɔntɛnde, tin kin go rɔng. Ɔnda ɔ ova saiz, sɔfayz damej, ɛn tul wear na kɔmɔn tin dɛn.

3. Achieving Perfect Knurling: Fɔ avɔyd mistek, yu nid fɔ tek tɛm pripia di wok, pik di rayt knurling tul, ɛn yuz lɔbrik. Dɔn bak, fɔ kɔntrol di optimal kɔt spid ɛn adekwayt tul prɛshɔn na di ki.

Fun facts ɛn tips .

● Knurling wil ɛn knurling insɛt na pat pan di tul we rili mek di patɛn.

● Push-tayp knurling tul ɛn flotin knurling tul dɛn na difrɛn kayn tul dɛn we dɛn kin yuz fɔ difrɛn aplikeshɔn dɛn.

● Di patɛn we de na kɔyn ed? Dat na knurling! I dɔn du fɔ mek di kɔyn izi fɔ grip ɛn at fɔ kɔmpia.

Ilɛksɛf yu de wok wit lath ɔ mashin, di rayt tin dɛn, patɛn, ɛn di we aw dɛn de du am de mek ɔl di difrɛns. Ɛn nɔ fɔgɛt bɔt aesthetics. Wan pat we gɛt wɛl-knurl nɔ jɔs de wok bɛtɛ, i luk fayn bak!

Di Knurling Proses .

Besik Prinsipul dɛn fɔ Knurling .

Knurling na wan fayn fayn pat fɔ mek tin dɛn. Na ɔltin bɔt fɔ ad patɛns to wan sɔfays. Dɛn patɛns ya nɔto jɔs fɔ luk; Dɛn de ɛp wi fɔ grip tin dɛn bɛtɛ. Knurling tools na di hiro dɛn we de ya. Dɛn de pres patɛns dɛn pan . Di pat dɛn we dɛn mek wit mashin . I tan lɛk stamp, bɔt fɔ mɛtal.

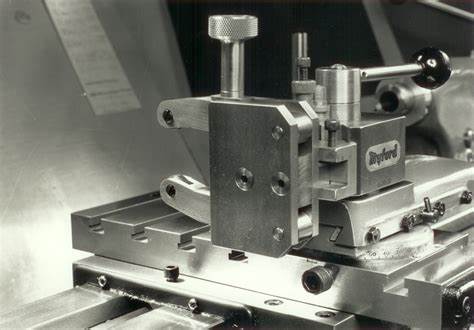

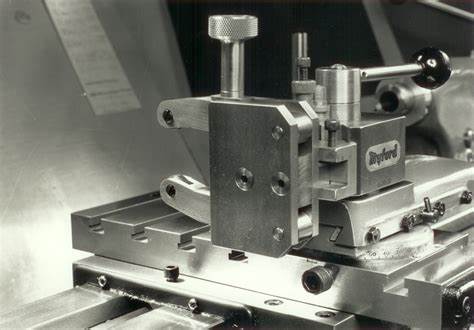

Ikwipmɛnt dɛn we dɛn kin yuz fɔ knurling .

Bɔku tul dɛn kin kam insay knurling:

● Knurling Wheels: Dis na di men pat dɛm we de mek di patɛn.

● Knurling inserts and dies: Dɛn kin kam insay difrɛn shep dɛn fɔ difrɛn patɛn.

● Push-tayp ɛn flotin knurling tul dɛm: Dɛn kin yuz am dipen pan di wok in nid dɛm.

Teknik ɛn di we aw dɛn de du am .

Tu men we dɛn de fɔ du knurling: fɔ rɔl ɛn fɔ kɔt.

1. Rolling Knurling: Dis we ya de rol di patɛn pan di sɔfa. I tan lɛk se yu de rɔl ɔp dɔti wit patɛn rɔla.

2. Fɔ kɔt knurling: Dis na mɔ bɔt fɔ kɔt insay di mɛtal fɔ mek di pɔtn. I tek sɔm mɛtal bɔt i de gi shap, klia dizayn.

Step-by-step gayd fɔ di knurling prɔses .

Lɛ wi waka na di step dɛn:

1. Pripia di wokpies: Mek shɔ se i klin ɛn di rayt saiz.

2. Pik yu tul: Dipen pan us patɛn yu want, pik di rayt knurling tul.

3. Sɛt yu mashin: Ilɛksɛf na lathe ɔ ɔda kayn, sɛt am wit di tul.

4. Put lɔbrikeshɔn: Dis kin ɛp fɔ mek di prɔses smol.

5. Start Knurling: Put di tul pan di wokpies. Kɔntrol di prɛshɔn ɛn di spid.

6. Chɛk yu wok: Luk fɔ kɔmɔn dɛfekt dɛn lɛk sɔfayz damej ɔ tul wear.

Ɛvri step impɔtant fɔ prɛsis ɛn gud-luk rizɔlt. Ilɛksɛf na stret, dayamɔn, ɔ ɛlikal knurling, ɛni kayn gɛt in yon charm ɛn yus. Ɔltɛm aim fɔ wan pafɛkt balans bitwin aesthetics ɛn funkshɔn.

Tul ɛn ikwipmɛnt fɔ knurling .

Ovaviu fɔ Knurling Tul dɛn .

Knurling tuls na di ki in di knurling proses. Dɛn kin yuz dɛn fɔ mek patɛn pan pat dɛn we dɛn mek wit mashin. Dɛn tul ya gɛt difrɛn shep ɛn saiz, ɛn dɛn ɔl fit fɔ difrɛn kayn knurling lɛk strayt knurling, dayamɔn knurling, ɛn ɛlikal knurling. I impɔtant fɔ tek tɛm pripia di wok ɛn pik di rayt knurling tul fɔ di wok.

Knurling Wheels: Tayp ɛn Yuz

Knurling wils na di pat pan di tul we rili mek di patɛn. Sɔm kayn dɛn de:

● Stret wil: Dɛn kin yuz am fɔ mek i stret, fɔ mek layn dɛn rawnd di pat.

● Dayagɔnal wil: Gret fɔ dayamɔn knurling, mek wan criss-krɔs patɛn.

● Hɛlikal wil: Dɛn tin ya na fɔ ɛliks knurling, we de mek wan spiral patɛn.

Dɛn kin pik ɛni kayn wil bay di patɛn we dɛn want ɛn di say we dɛn fɔ dɔn.

Knurling Inserts: Fɔnkshɔnaliti ɛn sɛlɛkshɔn krayteria

Knurling inserts na pat pan di tul we de ol di wil. We yu de pik insay, tink bɔt:

1. Material: Tof matirial Ridyus di tul wear.

2. Sayz ɛn shep: Match wit di wokpies ɛn knurling wil.

3. Tayp fɔ knurling: difrɛn insɛt fɔ difrɛn patɛn.

Kɔrɛkt sɛlɛkshɔn impɔtant fɔ avɔyd kɔmɔn dɛfɛkt dɛn lɛk sɔfayz damej.

Advansmɛnt dɛn na Knurling Tul Tɛknɔlɔji .

Dis biɛn tɛm, dɛn dɔn mek kol advansmɛnt dɛn na Knurling Tul dɛn:

● Push-tayp ɛn flotin knurling tul dɛm: Dɛn wan ya de gi mɔ fleksibiliti ɛn kin adap to say dɛm we nɔ ivin.

● Ɔtomatik sistem dɛn: Dɛn kin mek prɛsishɔn ɛn spid na di knurling prɔses bɛtɛ.

● Advanced Materials: Nyu matirial fɔ wil ɛn insay de ridyus wear ɛn ɛkstɛnd tul layf.

Dɛn advansmɛnt ya de ɛp fɔ ajɔst mɔ prɛsis patɛns wit smɔl chata ɔ vaybreshɔn mak. Mɛmba se, di rayt tul ɛn teknɔlɔji de mek ɔl di difrɛns fɔ mek ay kwaliti, tɛkstɔr sɔfays.

Dimenshon dem weh dey di measuring fo knurling .

Ɔndastand di mɛzhɔmɛnt fɔ knurling .

Measuring in knurling na di ki fɔ mek i rayt. I tan lɛk fɔ mɛzhɔ fɔ nyu furniture – akkuracy na ɔltin. Dɛn kin yuz knurling tul dɛn fɔ mek patɛn pan pat dɛn we dɛn mek wit mashin. Bɔt bifo ɛn afta yuz dɛn tul ya, wi nid fɔ mɛzhɔ. Dis de mek shɔ se di knurling prɔses mit di dizayn rikwaymɛnt dɛn ɛn avɔyd kɔmɔn dɛfɛkt dɛn.

Aw fɔ mɛzhɔ dayamita bifo ɛn afta knurling .

1. Bifo yu nurling: Yuz kalipa fɔ mɛzhɔ di ɔrijinal dayamita fɔ di wokpies.

2. Afta yu dɔn knurl: Mekɔp bak. Di dayamita kin go ɔp bikɔs di patɛn kin ad matirial to di say we i de.

Dis chenj na saiz na impɔtant tin, mɔ fɔ pat dɛn we nid fɔ fit fayn fayn wan wit ɔda pipul dɛn.

Analyzing knurling angle ɛn knurl dayamita

● Knurling angle: Dis na di angle fɔ di patɛn na di pat. Fɔ ɛgzampul, Straight Knurling gɛt difrɛn angul we yu kɔmpia am wit dayamɔn knurling.

● Knurl dayamita: Dis de tɔk bɔt di sayz fɔ di knurling wil ɔ insɛt dɛn we dɛn yuz. I de afɛkt aw dip ɛn waid di patɛn de.

Prɔpa analisis fɔ dɛn aspek ya de mek shɔ se wan prɛsis ɛn aesthetic finish. I impɔtant fɔ tek tɛm pripia di wok ɛn pik di rayt knurling tul fɔ di autkam we yu want. Mɛmba se, wan knurl we dɛn dɔn yuz fayn fayn wan de mek di grip bɛtɛ ɛn ad to di say we yu de dɔn.

Di kayn dɛn we dɛn kin yuz fɔ knurling .

Difrɛn difrɛn we dɛn fɔ mek tin dɛn we dɛn kɔl knurling ɛn dɛn kwaliti dɛn .

Knurling patterns na lɛk di finga prɛnt dɛm na di manufakchurin wɔl – ɛvri wan yunik ɛn funkshɔnal. Lɛ wi dayv insay sɔm kɔmɔn kayn dɛn:

● Stret/Standard Knurl: Dis na di mɔs besik patɛn, we de mek stret layn dɛn along di aks fɔ di wokpies. Bɔku tɛm dɛn kin yuz am fɔ wan simpul, ifɛktiv grip.

● Rayt-an knurl: Dɛn patɛns ya de angul to di rayt say. Dɛn fayn fɔ pat dɛn we dɛn go tɔn kloksayz.

● Left-handed Knurl: Di opozit to rayt-an, dis patɛns dɛn angle to di lɛft, we fayn fɔ yuz kɔntra-klɔksayz.

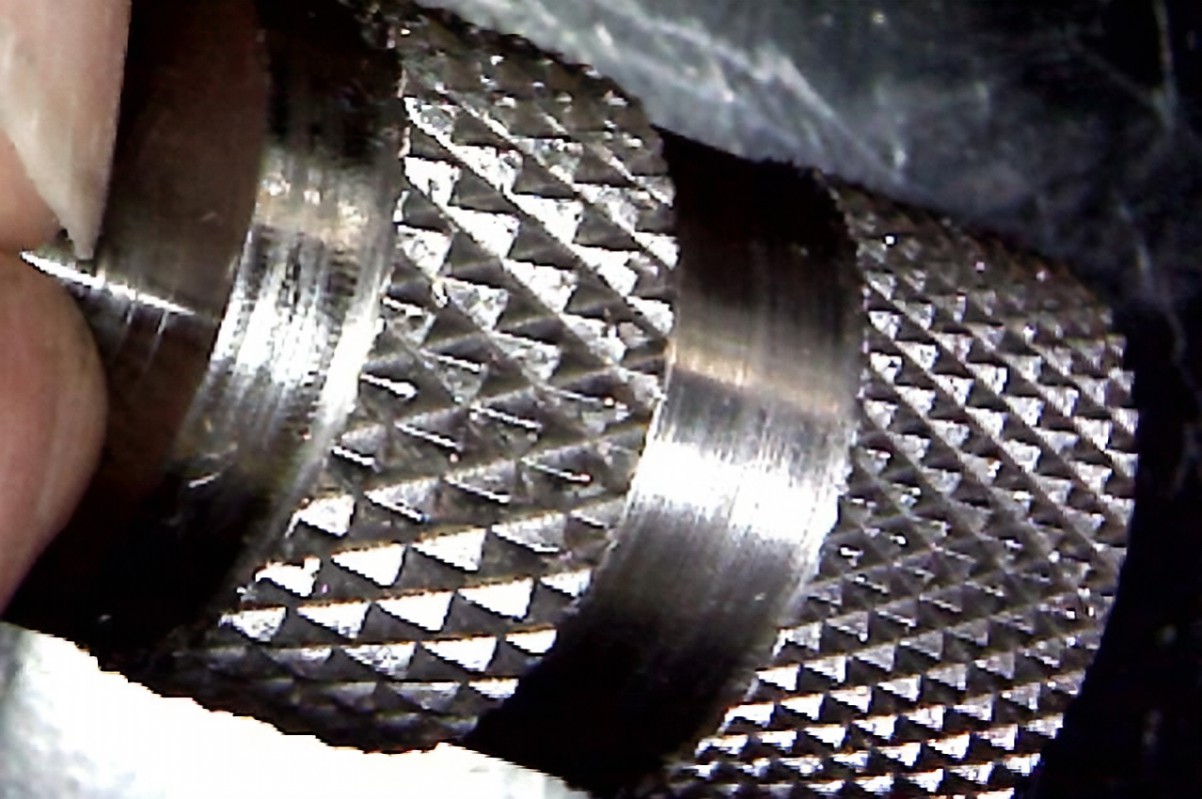

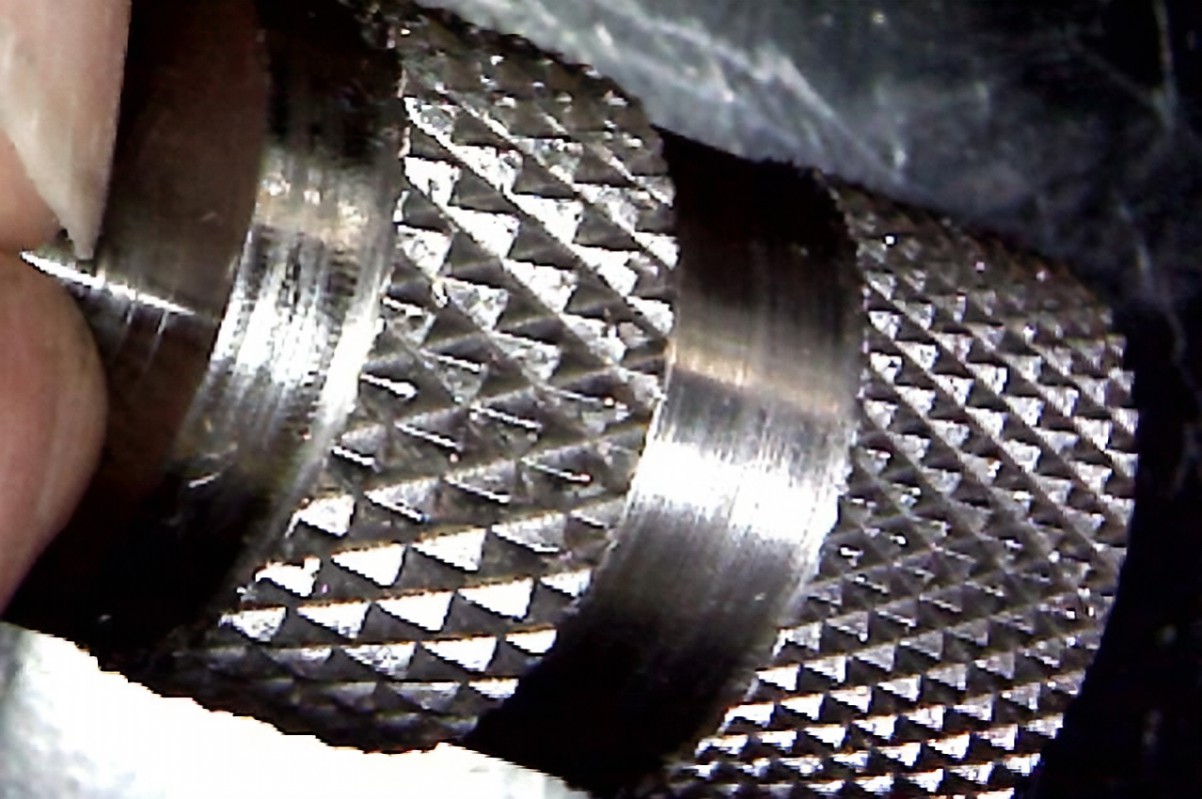

● Diamond Knurl: Na klashik choice, Diamond Knurls de mek wan criss-kros patɛn. Dɛn kin gi fayn fayn grip ɛn wan luk we kin mek pɔsin in yay fayn.

● Kɔnkav ɛn kɔnvɛks knurl: Dɛn patɛns ya kin kɔba insay ɔ na do, we kin gi wan spɛshal fil ɛn grip.

● Square ɛn Beveled Knurl: Dɛn kin mek skwea ɔ angul patɛn, bɔku tɛm dɛn kin yuz am fɔ mek dɛn tɔch am fɔ mek dɛn fayn.

Kɔmparativ analisis fɔ knurling patɛn .

Ɛni patɛn de sav wan rizin. Lɛ wi kɔmpia:

● Grip: Daymɔnd ɛn standad knurls de gi di bɛst grip.

● Aesthetics: Dɛn kin pik skwea ɛn beveled patɛn fɔ dɛn luk.

● Functionality: Dɛn kin pik rayt ɛn lɛft-an knurl bay di dairekshɔn we dɛn nid fɔ muv.

Insay di knurling prɔses, fɔ pik di rayt patɛn rili impɔtant. I dipen pan di aplikeshɔn ɛn di surface finish we yu want. Ilɛksɛf yu de yuz knurling wil ɔ insay, mɛmba se ɛni patɛn gɛt in trɛnk. Fɔ mek yu ebul fɔ du di rayt wok, tek tɛm pripia di wok ɛn pik di rayt tin fɔ yuz fɔ nurling. Dis de mek shɔ se big autkam, fri frɔm kɔmɔn difɛkt dɛn lɛk po patɛn difinishɔn ɔ sɔfayz damej.

Materials we fit fɔ knurling .

Metals ɛn dɛn fit fɔ knurling .

Knurling lɛk mɛtal dɛn. Most mashin pat fɔ knurling na . ayɛn . Wetin du? Bikɔs mɛtal dɛn kin tranga ɛn dɛn kin ol patɛn fayn fayn wan. Na sɔm tɔp pik dɛn:

● Aluminium: I izi fɔ knurl, fayn fɔ layt pat dɛn.

● Stilin: I at pas aluminiɔm, we pafɛkt fɔ pat dɛn we gɛt ebi ebi wok.

● Brass: Soft, izi fɔ knurl, ɛn luk shayn.

εvri mεtal de riak difrεnt wan insay di knurling prכsεs. Di men tin na fɔ tek tɛm pripia di wok ɛn yuz di rayt tin dɛn we dɛn kɔl knurling tul dɛn.

Knurling wit Plastik: Chalenj ɛn Tɛknik

Plastik dɛn kin mek pɔsin gɛt trik. Dem soft en kin deform. Bɔt i nɔ pɔsibul. Na dis na aw fɔ knurl plastic:

1. Lɔw prɛshɔn: Yuz smɔl fɔs fɔ avɔyd sɔfayz damej.

2. Kul tempɔret: Tumɔs ɔt kin mɛlt plastic. Kip am kol.

3. Shap Tul dɛn: Dul tul dɛn kin drɛg ɛn pwɛl di plastic.

Wit dis tips, yu kin mek tekstur plastic pat wit prɛsis patɛn.

Knurling in Woodworking: Di tin dɛn we pɔsin kin ebul fɔ du ɛn di tin dɛn we i nɔ ebul fɔ du ɛn di tin dɛn we i nɔ ebul fɔ du

Wood na wan uncommon choice fɔ knurling, bɔt i pɔsibul. Di prɔblɛm dɛn na:

● Softness: Wud kin split ɔ chip.

● Gren: Di gren na di wud de afɛkt di patɛn.

Fɔ wok wit wud, yuz shap shap knurling tul dɛn ɛn go slo. Dis kin mek di tul wear ɛn di say we di wata pwɛl nɔ bɔku.

Fɔ sɔma, ilɛksɛf na mɛtal, plastic, ɔ wud, di rayt matirial ɛn knurling tɛknik de mek ɔl di difrɛns. Mɛmba fɔ pik di aprɔpriet knurling tul ɛn kɔntrol di optimal kɔt spid fɔ di bɛst rizɔlt. Ɛni matirial gɛt in yon kwaliti ɛn aplikeshɔn dɛn na di wɔl fɔ knurling.

Knurling aplikeshɔn dɛn na difrɛn industri dɛn .

Indastrial Aplikeshɔn dɛn .

Insay di industrial wɔl, knurling na big tin. I de yuz pan mashin pat lɛk tul ɛn mashin kɔmpɔnɛnt. Wetin du? fɔ bɛtɛ grip ɛn prɛsishɔn. Na ya yu go si am:

● Tul handel: fɔ wan nɔ-slip grip.

● Mekanikal pat dɛm: usay prɛsishɔn ɛn grip na di ki.

Di prɔdak dɛn we dɛn de yuz fɔ bay tin dɛn .

Luk rawnd yu os. Knurling de de tu. Tink bɔt:

● Kichin gadget dɛn: Lɛk nɔb dɛn we de na stov.

● Spɔt ikwipmɛnt: Fɔ da ekstra grip de.

Medikal ɛn Erospɛs yuz dɛn .

Na ya, knurling na ɔl bɔt sef ɛn prɛsishɔn. I de na:

● Sɔj tul dɛn: Fɔ ɔpreshɔn dɛn we nɔ de chenj, we nɔ de slip.

● Erospace komponent: usay evri milimita impɔtant.

Yuz Knurling in Manufakchurin ɛn Mashin .

Insay manufakchurin, knurling de ɔlsay. I de pan:

● Dayal ɛn switch dɛn: Fɔ kɔntrol izi, kɔrɛkt wan.

● Masin Pat: Fɔ mek shɔ se dɛn fit jɔs rayt.

Knurling in konsuma ilektroniks: Enhancing functionality ɛn aesthetics .

Yu gadget dem don knurling tu. I dɔn yus fɔ:

● Impruv grip: Pan tin dɛn lɛk kamɛra.

● Ad wan kul luk: Fɔ mek gadget nɔ jɔs wok fayn, bɔt i luk fayn bak.

Di rol we knurling de ple na jɔy ɛn art .

Knurling nɔ jɔs de wok; I fayn bak. Jewelers yuz am fɔ:

● Ad tɛkstɔr: to ring ɛn breslɛt dɛn.

● Krio yunik patɛn: Fɔ mek ɛni wan pan dɛn spɛshal.

Knurling in ripa ɛn mentenɛns wok .

Fɔ wok wok, fɔ knurling na impɔtant tin. I de ɛp wit:

● Bɛtɛ tul handlin: So wrench nɔ go slip.

● Durability: Fɔ mek pat dɛn kin las fɔ lɔng tɛm.

Insay ɛvri industri, knurling tul ɛn prɔses dɛn rili impɔtant. Dɛn kin mek prɔdak dɛn sef, izi fɔ yuz, ɛn ivin fayn mɔ. Ilɛksɛf i de na ay-prɛsishɔn fil dɛm lɛk aerospace ɔ sɔntin we kɔmɔn lɛk kichin tul, knurling de ple pat fɔ mek wi wɔl wok bɛtɛ.

Teknɔlɔji advansmɛnt dɛn na Knurling .

Di nyu tin dɛn we dɛn dɔn mek fɔ knurling tul ɛn mashin dɛn .

Di knurling proses don si som kul chenj dem dis mont. Nyu tul ɛn mashin dɛn de mek knurling smat ɛn izi. Na dis na di nyu tin:

● Advanced Knurling Wheels: Dɛn wil dɛn ya kin tranga ɛn dɛn kin las fɔ lɔng tɛm.

● Prɛsishɔn Knurling Inserts: Dɛn de alaw fɔ mek dɛn gɛt mɔ ditayla patɛn.

● Ɔtomatik Knurling mashin dɛn: Dɛn mashin dɛn ya kin du di wok kwik kwik wan ɛn dɛn nɔ kin mek mistek.

Dɛn nyu tin dɛn ya min se pat dɛn we dɛn mek wit mashin kin luk bɛtɛ ɛn dɛn kin wok fayn.

Di intasekshɔn fɔ knurling ɛn nanoteknɔlɔji .

Nanotek na lɛk wan mini supahiro insay knurling. Na ɔltin bɔt fɔ wok pan wan supa smɔl skel. Dis min se:

● Super Precise Patterns: Wi de tɔk smɔl smɔl, ditayli knurling.

● Matirial dɛm we de las fɔ lɔng tɛm: Nanotech de mek matirial dɛn strɔng.

● Smɔl smɔl tin dɛn fɔ smɔl smɔl wok dɛn: Pafɛkt fɔ smɔl ɔ dilik pat dɛn.

Di tin dɛn we go apin tumara bambay: Ɔtomɛshɔn ɛn Prɛsishɔn na Knurling

We wi de luk bifo, Knurling de get ivin smat. Na dis fɔ ɛkspɛkt:

● Mɔ ɔtomɛshɔn: mashin dɛn go du mɔ pan di wok.

● Ivin bɛtɛ prɛsishɔn: ɛkspɛkt ivin mɔ ditayla patɛn.

● Smart Tul dɛn: Tul dɛn we de ajɔst dɛnsɛf fɔ di pafɛkt knurl.

In shot, knurling no bi jos fo put lain fo metal mo. Na fɔ yuz teknɔlɔji fɔ mek tin dɛn we prɛsis, we go de fɔ lɔng tɛm, ɛn luk fayn. Ilɛksɛf na yu motoka, yu fon, ɔ ivin yu jɔyri, knurling de de, ɛn i de bɛtɛ ɔltɛm.

Kɔmɔn difɛkt dɛn na knurling ɔpreshɔn .

Fɔ no ɛn adrɛs di sayz kwɛstyɔn dɛn .

Sayz impɔtant na Knurling. Ɔnda ɔ ova saiz pat na kɔmɔn tin dɛn. Na dis fɔ du:

● Measure bifo ɛn afta: ɔltɛm chɛk di sayz fɔ yu wokpies bifo ɛn afta knurling.

● Adjɔst di prɛshɔn fɔ di tul: Di prɛshɔn we yu gɛt kin go ɔp pasmak. Less pressure kin ridyus am.

Fɔ gɛt di sayz rayt impɔtant fɔ di pat dɛn we nid fɔ fit fayn fayn wan.

Surface damage ɛn in prɛvɛnshɔn .

Nɔbɔdi nɔ want pat we dɛn skrach ɔ we dɔn pwɛl. Surface damage kin bi ed-aks. Fɔ mek i nɔ apin:

● Yuz Sharp Tul: Dull Tul kin ambɔg di say we yu de.

● Kɔntrol spid: If yu fast, i kin mek yu mek mistek. Go slo ɛn stedi.

● Put lɔbrik: Dis de ridyus frikshɔn ɛn damej.

We yu tek kia ɔf dɛn tin ya, dat kin mek yu pat dɛn luk fayn.

Adrɛs di Tul Wear ɛn Mentɛnans .

Tul wear de afɛkt kwaliti. Fɔ kip tul dɛn we de ɔp shep:

● Chɛk ɔltɛm: Ɔltɛm inspɛkt yu knurling tul dɛn.

● Fɔ kip fayn: kip dɛn klin ɛn sef we dɛn nɔ de yuz dɛn.

● Riples we nid de: If dɛn dɔn pwɛl wan tul, na tɛm fɔ nyu wan.

Gud tul mentenɛns min se smɔl prɔblɛm dɛn de dɔŋ di layn.

Fɔ mek shɔ se di pɔtn difinishɔn ɛn kɔnsistɛns .

Di patɛn nid fɔ jɔs rayt. Fɔ prɛsis patɛn difinishɔn:

● Prɛshɔn we nɔ de chenj: Dis kin mek di pɔtn ivin ivin.

● Rayt tul fɔ di wok: Difrɛn patɛn dɛn nid difrɛn tul dɛn. Pik di rayt tin fɔ yuz fɔ nurling.

● Wach fɔ chata ɔ vaybreshɔn mak: Dɛn tin ya kin mek yu patɛn mɛs. Kip ɔltin stebul.

Wan pafɛkt patɛn min se wan pat nɔ jɔs de du in wok bɔt i de luk fayn fɔ du am. Mɛmba se, insay knurling, di ditil dɛn de mek ɔl di difrɛns. If na simpul strayt knurling ɔ mɔ kɔmpleks dayamɔn knurling, ɛvri stɛp impɔtant fɔ avɔyd dɛn kɔmɔn dɛfɛkt dɛn ya.

Di bɛst prɔsis fɔ di bɛst knurling finish dɛn .

Pripia di Wokpies fɔ Knurling .

Fɔs tin fɔs, tek tɛm pripia di wok. Na so yu go du:

● Klin di say we yu de: Ɛni dɔti ɔ ɔyl kin mɛs di knurling.

● Chɛk di sayz: Mek shɔ se na di rayt saiz fɔ yu knurling tul.

● Inspek fɔ si if i nɔ fayn: Ɛni bad bad tin we bin dɔn pwɛl bifo tɛm kin wɔs wit knurling.

Wan wokpies we dɛn dɔn pripia fayn fayn wan na di fɔs tin we yu fɔ du fɔ mek yu ebul fɔ dɔn di wok pafɛkt wan.

Selekt di rayt knurling tul .

Fɔ pik di rayt tul rili impɔtant. Na dis fɔ tink bɔt:

● Tayp fɔ Knurl: Stret, Daymɔnd, Ɛlikal? Ɛni wan pan dɛn nid difrɛn tul.

● Material of the Workpiece: Soft mɛtal dɛn nid difrɛn tul dɛn pas wan dɛn we at.

● Sayz fɔ di patɛn: Big ɔ smɔl patɛn dɛn nid difrɛn knurling wil ɔ insɛt.

Di rayt tul de mek ɔl di difrɛns.

Di rol we lɔbrik de ple fɔ knurling .

Lubrikeshɔn na di men tin. I de ɛp bay we yu:

● Ridyus frikshɔn: Lɛs frikshɔn min se di sɔfayz damej nɔ bɔku.

● Improving tool life: Lubrication de ɛp fɔ mek di tul nɔ west.

● Ɛnhans patɛn kwaliti: Wan smol ɔpreshɔn de lid to bɛtɛ patɛn.

Ɔltɛm, put lɔbrik bifo yu bigin.

Setin optimal kot spid .

Spid impɔtant. Na dis mek:

● Tu fast: Yu de risk fɔ gɛt po patɛn kwaliti ɛn yu de wɛr mɔ.

● Tu slo: I kin tek tu lɔng ɛn i nɔ kin mek di pɔtn fayn fayn wan.

● Jɔs rayt: I de mek shɔ se yu gɛt klin, kɔnsistɛns patɛn.

Fɛn di optimal kɔt spid fɔ yu spɛshal wok.

Balancing tool prɛshɔn fɔ pafɛkt finish dɛn .

Las las, di prɛshɔn:

● Tumɔs prɛshɔn: I kin mek di wok nɔ fayn ɔ i kin mek di tul pwɛl.

● Tu smɔl prɛshɔn: Di patɛn nɔ go fɔm kɔrɛkt wan.

● Balans prɛshɔn: de mek pɔsin gɛt pafɛkt, kɔnsistɛns patɛn.

Fɔ balans di prɛshɔn impɔtant fɔ da pafɛkt knurl de.

Mɛmba se, ɛvri step na di knurling prɔses kin kɔntribyut to di fayn luk ɛn fil fɔ di prɔdak. Frɔm di fɔs pripiamɛnt to di fayn prɛshɔn we dɛn aplay, ɛni ɛlimɛnt de ple wan rol fɔ ajɔst wan prɛsis, tɛkstɔr, ɛn aesthetically pleasing knurled surface. If na fɔ prɛktikal grip ɔ fɔ ɛp fɔ mek di sɔfays finish fayn, fɔ fala dɛn bɛst prɔsis ya go ɛp fɔ mek shɔ se di tɔp-notch rizɔlt dɛn na yu knurling prɔjek dɛn.

Dɔn

In dis komprehensiv gayd, wi don delv in di multifaceted wold of Knurling, wan pivotal proses in modna manufakchurin. Frɔm in istri rut dɛm, usay di wɔd evolv frɔm ‘knur’ to di naw we dɛn kin yuz naw ‘knurled’, to di intrɛstin prinsipul dɛm we de difayn di knurling ɔpreshɔn, wi dɔn kɔba di bɔku bɔku joyn fɔ dis tɛknik.

Wi dɔn ɛksplɔrɔ di bɛsis prinsipul dɛm fɔ knurling, ditayli di knurling ɔpreshɔn ɛn di ikwipmɛnt we dɛn yuz, lɛk knurling wil ɛn insɛt. Ɛni tul de ple impɔtant pat, ɛn di advansmɛnt dɛn na dɛn teknɔlɔji de kɔntinyu fɔ mek di prɔses go bifo. Wan dip div insay di mɛtɔd dɛn, we bin difrɛns bitwin fɔ rɔl ɛn fɔ kɔt knurling, bin gi wan prɛktikal, stɛp-by-stɛp gayd fɔ masta di knurling prɔses.

Ɔndastand di mɛzhɔmɛnt dɛn na knurling – frɔm dayamita chenj prɛ ɛn post-prɔses to analayz angul ɛn knurl dayamita – dɔn bi impɔtant fɔ ajɔst prɛsishɔn. Wi dɔn luk bak pan difrɛn knurling patɛn dɛn, dɛn spɛshal kwaliti dɛn, ɛn aw dɛn kɔmpia insay difrɛn aplikeshɔn dɛn.

Di atikul bin sho di we aw Knurling bin de yuz bɔku bɔku tin dɛn akɔdin to di tin dɛn we dɛn bin de yuz fɔ mek tin dɛn, lɛk mɛtal, plastic, ɛn ivin wud, ɛn ɛni wan pan dɛn bin de sho difrɛn prɔblɛm dɛn ɛn di we aw dɛn bin de du tin. Dis versatility de extend to in aplikeshɔn dɛn na difrɛn industri dɛn – frɔm industrial kɔmpɔnɛnt ɛn kɔshɔma prodak to in krichɔ yus insay mɛdikal, aerospace, ɛn kɔshɔma ilɛktroniks, nɔ fɔ tɔk bɔt in atis ɛksprɛshɔn dɛn insay jɔyri ɛn art.

Teknɔlɔji advansmɛnt dɛn dɔn bi wan fokal pɔynt, usay di intasekshɔn fɔ knurling wit nanoteknɔlɔji ɛn tren to ɔtomɛshɔn ɛn prɛsishɔn de sho se di fiuja usay knurling de kɔntinyu fɔ evolv ɛn intagret wit kɔt-ɛj tɛnkɔlɔji dɛn.

Dɛn bin tɔk bɔt di kɔmɔn tin dɛn we kin apin we dɛn de du knurling ɔpreshɔn, lɛk di sayz we dɛn gɛt, di say we dɛn de pwɛl di wɔl, di we aw dɛn de wɛr tul, ɛn di we aw dɛn nɔ de gri wit dɛnsɛf, wit sɔlv ɛn di bɛst we fɔ du tin. Dɛn tin ya we dɛn kin du, lɛk fɔ pripia fɔ wok, fɔ pik di tul dɛn, fɔ mek dɛn gɛt lɔbrik, fɔ kɔt di spid we dɛn kin kɔt fayn fayn wan, ɛn fɔ mek dɛn balans di tul dɛn, na impɔtant tin fɔ mek dɛn ebul fɔ gɛt pafɛkt finish dɛn.

Riflɛkt pan Knurling in kɔrɛnt ɛn fiuja rol na difrɛn industri dɛm, i klia se dis prɔses nɔto jɔs wan manufakchurin tɛknik bɔt na art fɔm we de miks funkshɔnaliti wit aesthetics. As teknɔlɔji de go bifo, Knurling go kɔntinyu fɔ ple wan impɔtant pat pan di manufakchurin, push bɔda dɛn fɔ prɛsishɔn, dizayn, ɛn efyushɔn. Dis gayd dɔn aim fɔ ɛp di wan dɛn we de rid wit wan gud ɔndastandin bɔt knurling, fɔ mek shɔ se dɛn dɔn pripia fayn fayn wan fɔ yuz dɛn prinsipul ɛn tɛknik dɛn ya na dɛn prɔfɛshɔnal wok.

FAQ we de na di wɔl.

K: Wetin mek knurling impɔtant fɔ mek tin dɛn?

A: Knurling de mek tekstur pattern pan pat. I de ɛp fɔ mek grip go bifo fɔ di kɔmpɔnɛnt dɛn we dɛn kin yuz an fɔ wok. Yuz fɔ aesthetic ɛn functional purposes.

K: Wetin na di kɔmɔn mashin dɛn we dɛn kin yuz fɔ knurling?

A: Lathes ɛn . CNC mashinin we kɔmɔn pas ɔl. Specialized knurling tools tu yuz. kin intagret insay prodakshɔn layn dɛn.

K: Aw fɔ no di rayt kɔt spid fɔ knurling?

A: Material tayp de dikte spid. Di manifakta in gaydlayn dɛn de gi di say fɔ bigin. tray ɛn mistek fayn-tyus di prɔses.

K: Tips fɔ pik di aprɔpriet knurling tɛknik fɔ difrɛn matirial dɛn .

A: Tink bɔt matirial had ɛn daktiliti. Selekt patɛn bays pan di grip we yu want. Adjɔst prɛshɔn ɛn spid akɔdin to dat.

K: Aw an knurling ɛn mashin knurling difrɛn pan prɛsishɔn ɛn aplikeshɔn?

A: Mashin we de knurling mɔ prɛsis, kɔnsistɛns. Hand Knurling de gi portability, fleksibiliti. mashin dɛn we dɛn kin lɛk fɔ mek dɛn prodyuz ay-volyum.