Views: 0

Knurling, a machining process employed on essence workpieces, involves creating a textured pattern on their face. This article delves into the complications of knurling, furnishing an in-depth understanding of its significance, styles, and operations, and will illustrate. Also, each point will be expanded upon to offer a further comprehensive view of knurling.

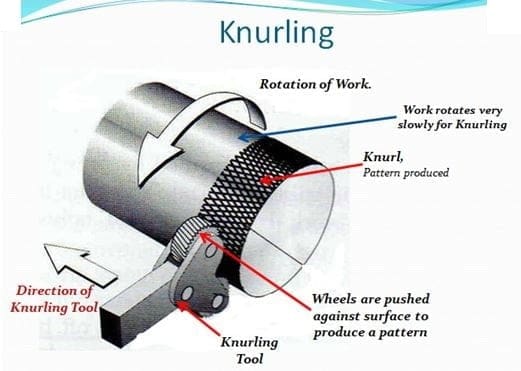

Knurling using a lathe or CNC milling machine is a mechanical process that produces horizontal, straight, or diamond-shaped fibers on the work surface aesthetically and functionally; the primary purpose of knurling is to improve gripping capabilities. Accordingly, knurling has become an extensively employed fashion across different areas.

The process of knurling involves screwing the material's face through the operation of force. This distortion creates crests or grooves that ameliorate disunion and grip. By altering the face texture, knurling provides a tactile advantage, providing a secure hold on objects similar to handles, clods, tools, etc.

The purpose of knurling revolves around perfecting grip, enhancing aesthetics, and adding functionality. The textured patterns created through knurling enable gripping on objects, precluding slippage and easing precise control. Also, knurling can serve ornamental purposes, adding visual appeal to products.

The primary idea of knurling is to enhance grip, particularly when handling objects in grueling conditions or surroundings. Knurled shells offer an increased measure of disunion, allowing for maintained control and stability. This is especially pivotal in operations where a secure grip is essential, like with hand tools, sporting equipment, or medical device and equipment.

Knurling can be fulfilled through two main styles: single-point knurling and form knurling.

Single-point knurling involves using a single-point slice tool to press into the workpiece's face, creating the desired pattern. This system is generally employed for small-scale knurling operations and enables the product to have fine, precise patterns.

In single-point knurling, a single slice tool with a knurling pattern is pressed against the workpiece's face, displacing the material to form the asked-for texture. This system provides a high level of control and quality, making it suitable for intricate or custom-made designs. Single-point knurling is frequently employed in jewelry pieces, watchmaking, or any operation requiring intricate face detailing.

Form knurling involves using specially designed knurling bus or dies to shape the pattern on the workpiece. This system is commonly used in large-scale production and can achieve colorful knurling patterns, including straight, slant, or diamond-shaped ones.

Knurling patterns can vary depending on the intended purpose and operation. While there are multitudinous patterns available, the most common ones include straight knurling, slant knurling, and diamond knurling.

Straight knurling consists of similar lines running across the workpiece's face. This pattern provides excellent grip and is generally used in operations where a secure hold is essential.

Diagonal knurling features lines that cross each other at a slant angle. This pattern offers an advanced grip in multiple directions and is frequently used on tools or products that require further superior grip.

Slant knurling patterns consist of cutting lines that form a slant grid-type pattern on the workpiece's face. This pattern provides a secure grip in multiple directions, allowing for enhanced control and usability. This form of knurling is frequently used in areas where a strong grip is needed, like with wrenches, screwdrivers, or bike handles.

Diamond knurling consists of diamond-shaped patterns being formed by cutting slant lines. This pattern offers both aesthetic appeal and an excellent grip, making it suitable for very specific projects.

Ridges follow a spiral or circular path. Enhances friction and mechanical retention, suitable for shafts, press-fit pins, and threaded assemblies.

Small, closely spaced ridges for subtle grip and a refined appearance, used on precision instruments, pens, and camera knobs.

Large, widely spaced ridges offering strong grip for heavy-duty tools, industrial handles, and fitness bars.

Knurling applied inside holes or cavities. Improves retention and friction in press-fit inserts, bushings, and sleeves.

Tailored patterns based on design or functional requirements. Combines grip, mechanical retention, and visual appeal for high-end or specialized parts.

| Knurl Pattern | Description | Typical Applications | Key Benefits |

|---|---|---|---|

| Diamond Knurl | Intersecting diagonal lines forming diamond-shaped ridges | Tool handles, knobs, fitness bars, machine dials | Maximum grip, prevents slipping, ideal for hand-operated parts |

| Straight Knurl | Parallel ridges along the part axis | Rotating knobs, dials, adjustment screws | Tactile feedback, precise rotational control |

| Diagonal Knurl | Ridges cut at a single diagonal angle | Hand tools, knobs, decorative metal parts | Good grip, enhanced aesthetic appeal |

| Helical / Circular Knurl | Spiral or circular ridges around the part | Shafts, press-fit pins, threaded assemblies | Increases friction and mechanical retention |

| Fine Knurl | Small, closely spaced ridges | Precision instruments, pens, camera knobs | Subtle grip, refined surface finish |

| Coarse Knurl | Large, widely spaced ridges | Heavy-duty tools, industrial handles, fitness bars | Strong grip for high-force operations |

| Internal Knurl | Knurling applied inside holes or cavities | Press-fit inserts, bushings, sleeves | Improves retention and friction internally without adhesives |

| Custom / Specialty Knurl | Tailored pattern based on design requirements | High-end consumer products, medical instruments, prototypes | Combines grip, mechanical retention, and visual appeal; fully customizable |

Diamond knurling patterns consist of cutting slant lines that then form diamond-shaped crests on the workpiece's face. This pattern offers a visually charming texture while providing a dependable grip. Diamond knurling is generally seen on things such as pen barrels, ornamental items, or jewelry pieces.

One practical illustration of knurling is in the production and rapid manufacturing of ministry or outfit clods. Knurled clods are generally used in artificial settings to provide an established grip, enabling precise adaptations or control. The knurled pattern on the clump's face ensures a secure hold, particularly in slippery or slithery conditions. Knurled clods play a vital part in ministry and outfit, where precise control is needed. The knurled texture on these clods enhances grip, allowing the ability to make accurate adaptations or manipulate controls with ease.

One of the most common applications of knurling is enhancing grip. Raised ridges or diamond patterns on a part surface prevent slippage, making it ideal for:

Tool handles, wrenches, and screwdrivers

Machine knobs, adjustment screws, and control dials

Fitness equipment such as barbells and bicycle handlebars

Knurled surfaces provide tactile feedback, ensuring secure handling even in wet, oily, or high-stress environments.

Knurling can also improve mechanical assembly:

Metal pins or shafts with knurled sections “bite” into plastic or softer metals, enhancing retention without adhesives

Shafts, fasteners, and bushings use knurling for interference fits and improved stability in assemblies

This application is particularly useful in low- to medium-volume production where fasteners or components must stay secure under load.

Beyond function, knurling adds visual appeal to parts:

Premium consumer products like camera knobs, pens, and hardware use fine knurl patterns for a stylish finish

Medical and surgical instruments leverage knurled surfaces for both grip and professional aesthetics

Knurling elevates a part’s look while maintaining practical utility.

Knurling can also be applied as a surface repair or enhancement technique:

When cylindrical parts become slightly undersized due to wear, knurling can restore diameter by creating a raised textured surface

It can increase surface friction in metal-plastic interfaces for longer-lasting assemblies

While less common today, this approach demonstrates the versatility of knurling beyond standard grip applications.

Knurled surfaces are widely used across multiple industries:

Automotive & Industrial Machinery: Adjustment knobs, gear shifters, wheel rims

Consumer Electronics & Products: Flashlight bodies, camera knobs, premium pens

Tooling & Equipment: Hand tools, grips, and mechanical controls

Medical Devices: Surgical instruments requiring secure handling

Plastic-Metal Assemblies: Press-fit components, inserts, and bushings

Enhanced Grip: Prevents slipping in high-stress or manual operations

Improved Mechanical Fit: Increases retention in assemblies without adhesives

Visual & Tactile Appeal: Adds professional finish to functional components

Cost-Effective Process: Adds texture and functionality efficiently during production

Knurling can be performed on various accouterments, including things such as aluminum, brass, and plastics. Softer accouterments like plastic may require a different approach to achieve optimal results.

While knurling is generally performed on specific items, it can also be applied to plastics and other accouterments. Still, softer accouterments may require careful consideration, as an inordinate amount of force during the knurling process can lead to material distortion or damage. Specialized knurling methods such as cold knurling or using softer knurling, may be employed for accouterments like injection molding plastics or softer blends.

Yes, knurling can be performed on desultorily shaped workpieces. Still, it may require special knurling tools or equipment to ensure proper alignment and satisfactory results.

Knurling can be acclimated to desultorily shaped workpieces through the use of custom processes or driving. These processes help to stabilize the workpiece and ensure that the knurling tool or wheel maintains proper alignment during the operation. By accommodating irregular shapes, knurling can be applied to a wider range of things, expanding its versatility across industries.

No, knurling finds operations in both artificial and consumer products. It's generally used in automotive-related items, hand tools, electrical connectors, and in jewelry design.

While knurling is heavily employed in artificial operations, its range extends far beyond that. Knurled shells can be set up in an array of consumer products, including automotive-related ones, gearshift clods, hand tools like screwdrivers or pliers, electrical connectors, and jewelry designs to add texture and visual appeal. Knurling has become an essential factor when it comes to specific products, enhancing both their functionality and aesthetic appeal.

Knurling is a machining process that adds grip, functionality, and visual appeal to a broad range of products. By comprehending the purpose, styles, and patterns associated with knurling, manufacturers and contrivers can harness its power to enhance the usability and aesthetics of their creations. Whether it's for artificial products or consumer products, the art of knurling continues to shape our world, furnishing enhanced grip and tactile functions. Contact TEAM MFG for rapid prototype services and low volume manufacturing services today!

TEAM MFG is a rapid manufacturing company who specializes in ODM and OEM starts in 2017.