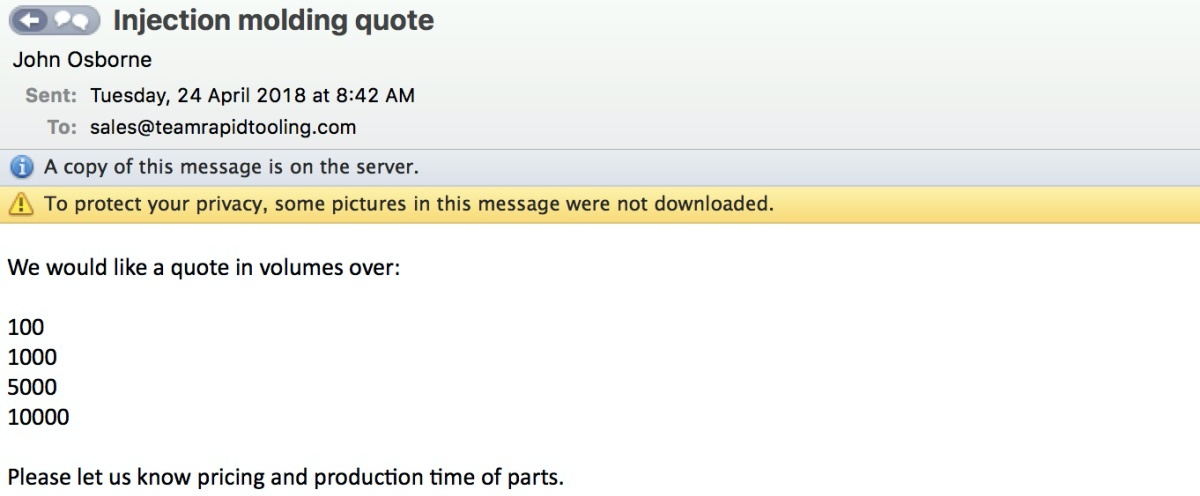

| Specification | Details |

|---|---|

| Project | I-Tap Battery Powered Device

|

| Process Involved | Rapid Tooling / Injection Mold, Rapid Injection Molding, Silk-Printing |

| Part Quantity | 4 Plastic Parts total (3 parts in ABS, 1 part in TPE) |

| Mold Quantity | 2 Family Molds |

| Mold Structure | MUD Mold Base, Switch Gate |

| Mold Steel | Chinese P20 |

| Injection Material | ABS (Front, Rear Cover, Cap), TPE (Button) |

| Sample Order | 100 Units |

| Mold & Molding Lead Time | 22 Calendar Days |

I-Tap is a intelligent, battery-powdered device designed to dramatically upgrade the efficiency of manual beer taps at locations everywhere- while providing vital data and making it possible for stadium & arenas to save up 2 million us in lost revenues annually .

A US based company contacted TEAM MFG to create new product case for their device, their president John Osborne sent us the email for inquiry. As considered the case might have modification/revise, the customer would like to have a small-volume to verify the design, and test the market.

As the customer have a forecast of 10000 units in the future, we suggest to rapid tooling solutions to cover low-volume manufacturing to medium volume production up to 100,000 parts.

Rapid tooling is a manufacturing process that involves creating a mold, die or tool to produce small to medium volume parts before the mass production. It is a faster manufacturing techniques that used less expensive materials to deliver functional parts quickly and cost-effectively. Comparing with the traditional production mold, rapid tooling can have a much shorter time as little as 7 days, also, the cost can be reduced up to 30 to 50+ percentage .

| Category | Details |

|---|---|

| Speed | Significantly shorter lead time compared to conventional mold-making. |

| Cost-Effective | Lower cost molds, suitable for prototypes or short runs. |

| Versatility | Enables design validation, functional testing, and market evaluation before committing to production tooling. |

| Materials | Often uses aluminum or softer steels (e.g., P20) for mold fabrication. |

| Applications | Producing 100 – 100,000 parts for testing or early-stage market release. |

| Design verification: Test assembly, ergonomics, and product function. | |

| Bridge tooling: Meet production needs while full production tooling is prepared. | |

| Pilot runs: Early product launches or clinical trials (medical, automotive, consumer electronics). |

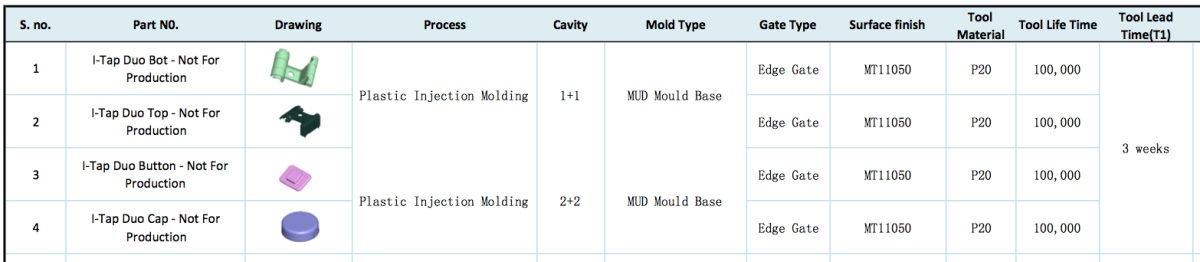

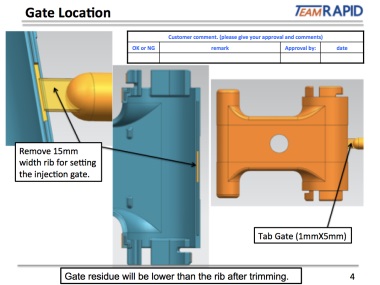

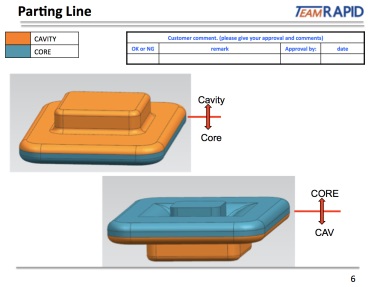

For this project TEAM MFG suggested 2 family molds for all these 4 parts to cut down the cost. Applying with the switched gate method we can mold the cap in ABS, and button in TPE separately.

Customer approved our quotation proposal, we moved forward to design for manufacturing stage:

Quotation/DFM Approval → Mold Review Meeting → Mold Design → Cavity & Electrode CNC Machining → EDM Machining → Wire Cutting → CMM Measurement → Mold Assembly → Fitting Mold → Mold Trial

The samples came out well. We test the assembly, it fits well too. We ship 5 units sample to the customer by FedEx. The customer was happy with the sample, and placed the larger order 1000 unit in the following weeks.

“Choosing Team MFG was one of the best decisions we made for the I-Tap project. Their combination of technical expertise, attention to detail, and customer service made our product launch a success.”

TEAM MFG is a manufacturing company who specializes in metal and plastic parts customization. We offer rapid prototyping and low to high volume manufacturing services. Injection molding, CNC machining, and die casting are the main services at TEAM MFG, we have a full capabiltiy to make your products from rapid prototypes to end product assembly. Are you working on your new project? Contact us at enquiry@teamrapidtooling.com to get strong supports now!

content is empty!

TEAM MFG is a rapid manufacturing company who specializes in ODM and OEM starts in 2017.