| Item | Details |

|---|---|

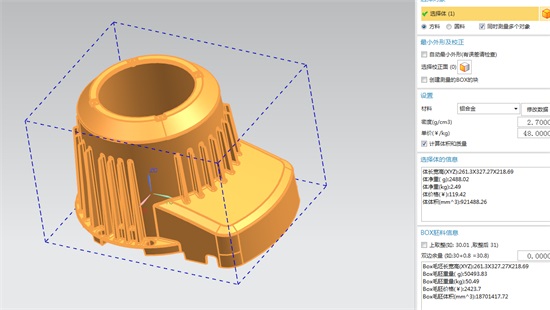

| Project | Motor Protection Cap |

| Process Involved | Pressure Die Casting Tool, Aluminum Die Casting |

| Part Quantity | 1 (Size: 261.3 × 327.27 × 218.69 mm) |

| Mold Quantity | 1 (Size: 750 × 550 × 735.2 mm) |

| Mold Layout | 1 × 1 |

| Mold Steel | H13 (48–52 HRC) |

| Casting Material | ADC 12 (Aluminum Alloy) |

| Sample Order | 50 PCS |

| Mold & Casting Lead Time | 35 Calendar Days |

The client is the world's leading manufacturer of fans and motors. As a technology company, the company has been continuously setting global market standards since our foundation in 1963. With over 20,000 products, offering the right, energy-efficient and intelligent solution for practically every task in ventilation and drive technology.

It is a new version cap which is used to protect the motor on the machine. As the motor now had been switch to the new one, the size now is bigger, so the cap need to be larger and stronger than the old version one. The client sent the drawings and requirement to TEAM MFG, our engineer got back quickly in the end of the day. The price was competitve, client was happy with our quotation.

Our experienced engineers came up with DFM that suggested the parting lines, gate location, ejection, draft, and undercuts etc. This helps the customer to know how the mold structure would be, and some suggestions to optimize the design for saving costs.

Mold design → Semi-CNC machining Electrodes making → Heat treatment → Fine-CNC machining → EDM machining → Mold fitting → Mold polishing → Tool assembly → Mold trial

The sample came out well. As no post-machining and post-finishing requirement, we cut the gate and overflows, then processed first part inspection.

TEAM MFG follows up ISO9001 quality management system in every single process. Quality is our life, we invest a series of inspection instruments such as CMM, Caliper, Projector, Height Measuring Instrument, Shore Hardness Tester etc, to guarantee every product is fully inspected including dimensional inspection, appearance check, and assembly test.

“Thanks to TEAM MFG, we now have a stronger, properly sized Motor Protection Cap that fits the new motor perfectly. Their combination of technical expertise, quality control, and fair pricing made this partnership invaluable.” —— Leo, Buyer

We've casted over 400,000 components at TEAM MFG, from tiny aluminum cover to massive aluminum housings. Whether you need 10 rapid prototypes next week or 10,000 production pressure die casting parts next quarter, our dedicated casting cell runs the exact parameters covered in this guide—delivering perfect parts while you focus on growing your business. Ready for your next pressure die casting project? Contact out team at enquiry@teamrapidtooling.com to get strong supports.

content is empty!

TEAM MFG is a rapid manufacturing company who specializes in ODM and OEM starts in 2017.