Outdoor products are continuously challenged by nature’s elements. From intense sunlight to sudden rainstorms and wide temperature swings, materials used outdoors must withstand a variety of environmental stressors without degrading over time. Unfortunately, many materials become brittle, fade, or lose structural integrity when exposed to prolonged UV radiation, humidity, or mechanical wear.

This is where ABS plastic stands out. Acrylonitrile Butadiene Styrene, or ABS, is a widely used thermoplastic known for its strength, impact resistance, and ease of processing. When specially engineered with weather-resistant properties, ABS plastic becomes an ideal solution for manufacturers of outdoor goods who require durable, low-maintenance materials.

Before understanding the benefits of weather-resistant ABS plastic, it’s important to identify the environmental threats it is designed to combat.

Ultraviolet radiation from the sun is one of the most damaging elements to plastics. Long-term exposure can cause many materials to yellow, fade, or become brittle. This not only affects aesthetics but also compromises the structural integrity of outdoor products.

Water can penetrate unprotected materials, leading to warping, swelling, rust, or mold. Outdoor products must be resistant to moisture to avoid performance failures or safety issues.

Outdoor conditions often involve significant changes in temperature between day and night or across seasons. Repeated cycles of heating and cooling can cause expansion and contraction in materials, leading to cracks, warping, or fatigue over time.

High humidity levels can also accelerate the aging of plastics and promote the growth of mold or mildew, especially on items with textured surfaces or seams.

ABS plastic engineered for weather resistance is specifically designed to endure these conditions, maintaining its performance and appearance year-round.

Standard ABS is not inherently weather-resistant. However, several specialized formulations and modifications have been developed to make ABS plastic more suitable for outdoor use.

One of the most common approaches to enhancing ABS for outdoor applications is the addition of UV stabilizers. These additives absorb or reflect UV light, preventing it from breaking down the polymer chains in ABS plastic. UV-stabilized ABS retains its color, gloss, and strength even after prolonged sun exposure.

A highly effective way to increase weather resistance is by blending ABS with ASA (Acrylonitrile Styrene Acrylate). ASA offers excellent resistance to UV radiation and environmental stress cracking. The resulting ABS/ASA blend combines the structural benefits of ABS with the superior weather resistance of ASA, making it ideal for high-performance outdoor parts.

This blend is widely used in automotive trims, garden tools, and enclosures that require extended life under open-air conditions.

In addition to inherent material changes, manufacturers often apply surface coatings or treatments to boost the weatherability of ABS plastic. These can include:

UV-resistant paints or clear coats

Hydrophobic coatings to repel moisture

Textured finishes to reduce glare and improve grip

Such treatments not only protect the material but also enhance the appearance and tactile quality of outdoor products.

Thanks to its adaptability and durability, weather-resistant ABS plastic is found in a wide range of outdoor products. Some of the most common applications include:

Electronics installed outdoors—such as smart home devices, surveillance cameras, lighting fixtures, and weather sensors—require protective housings that resist environmental damage. ABS plastic enclosures are lightweight, durable, and capable of being molded into complex shapes with integrated seals or vents.

Because ABS can be manufactured with tight tolerances, it helps protect internal components from dust, rain, and UV radiation. It’s also easy to customize with ports, clips, and mounting brackets.

Many components of recreational equipment—such as bicycle parts, toy vehicles, and sports gear—are made with weather-resistant ABS plastic. Its impact resistance and surface durability make it ideal for equipment that is frequently handled or subjected to rough use.

Garden tools like trimmer housings, watering equipment, and lawnmower handles benefit from the lightweight, corrosion-resistant nature of ABS. Unlike metals, ABS does not rust, and unlike wood, it doesn’t rot or splinter—making it a low-maintenance choice for outdoor tool design.

Automotive and recreational vehicles often utilize ABS plastic for parts like bumper covers, mirror housings, fender liners, and grilles. These components face constant UV and moisture exposure. ABS, especially when blended with ASA, holds up well over time, providing a glossy finish and excellent impact resistance.

Boats and recreational vehicles operate in challenging environments with high UV exposure and saltwater or road debris. Marine-grade ABS plastic is resistant to corrosion and degradation, making it perfect for dashboards, storage bins, vents, and trim in boats, trailers, and RVs.

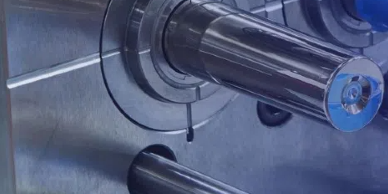

One of the key reasons ABS plastic is favored in outdoor product manufacturing is its excellent compatibility with injection molding—a fast, efficient, and scalable production method. This manufacturing process not only allows for complex, high-quality parts but also offers advantages in color stability, design flexibility, and cost-effectiveness. Let’s break down the specific benefits:

Unlike materials that require painting or surface treatments after molding, ABS plastic can be pre-colored during the compounding stage. This means color is uniformly distributed throughout the material, becoming an integral part of the product itself rather than just a surface coating. As a result, molded-in colors are highly resistant to common outdoor issues such as fading, chipping, or scratching caused by prolonged UV exposure or physical wear. For outdoor products that need to retain a clean, vibrant appearance—like lawn equipment housings, exterior lighting covers, or children’s playsets—molded-in color with ABS plastic offers a maintenance-free and visually consistent solution.

Injection molding with weather-resistant ABS plastic enables manufacturers to produce intricate parts with complex geometries in a single operation. Whether it’s internal ribs for structural strength, detailed surface textures, or built-in mounting features, ABS flows easily within molds and fills even the most detailed cavities. The process ensures exceptional consistency from one part to the next, making it ideal for high-volume production runs. This consistency translates into better-fitting parts, fewer assembly issues, and a higher-quality end product that can withstand the rigors of outdoor use.

Cost is a critical consideration for any outdoor product, especially when durability cannot be compromised. ABS plastic offers an excellent balance of performance and affordability. It provides comparable weather resistance and impact strength to more expensive engineering plastics and metals, but at a significantly lower cost. Additionally, because ABS has a relatively low melting temperature, it requires less energy to process, which reduces overall manufacturing expenses. Faster cycle times in injection molding also mean more units can be produced in less time, contributing to lower per-unit costs and more competitive pricing.

In summary, injection molding with ABS plastic enables manufacturers to create durable, cost-effective, and visually appealing outdoor products that perform reliably season after season.

As outdoor products continue to evolve with smart technology, modern aesthetics, and consumer demand for longevity, materials used in their production must rise to the challenge. Weather-resistant ABS plastic meets this demand by offering a perfect balance of toughness, adaptability, and environmental resilience.

Its ability to withstand sunlight, moisture, and impact—combined with its cost-effectiveness and processing versatility—makes it a top choice for manufacturers across industries.

If you're exploring material options for your next outdoor product line or need high-performance components molded to your exact specifications, ABS plastic should be at the top of your list.

For professional-grade plastic injection molding services, Team Rapid MFG Co., Ltd. offers custom solutions using weather-resistant ABS and other high-performance materials. Visit www.team-mfg.com to learn more, or reach out to discuss how we can help you develop durable, cost-effective outdoor products built to last.

TEAM MFG is a rapid manufacturing company who specializes in ODM and OEM starts in 2017.