Electric Discharge Machining (EDM) plays a crucial role in modern manufacturing, creating precise parts in industries like aerospace and automotive. But what makes Sinker EDM different from Wire EDM, and which is right for your project?

In this post, you'll learn how each EDM type works, including their pros, cons, and best applications. By the end, you'll understand the key factors that make each EDM technique unique and be able to decide which is best suited to your manufacturing needs.

Electrical Discharge Machining, or EDM, is a highly specialized manufacturing process that uses electrical discharges (sparks) to shape materials. Unlike traditional machining, which relies on physical cutting, EDM relies on controlled sparks to erode and shape metal precisely. This unique approach makes EDM ideal for working on hard metals and achieving high precision in intricate designs.

The spark erosion process follows a precise sequence. First, two electrodes position near each other, while dielectric fluid fills the gap between them. Computer controls maintain proper spacing throughout the operation.

During material removal, high voltage creates powerful sparks. These sparks generate local temperatures reaching 8,000-12,000°C, melting metal at contact points. The dielectric fluid then washes away debris as the process repeats thousands of times per second.

Key Point: The dielectric fluid plays three essential roles: insulator, coolant, debris remover.

| Characteristic | Traditional Machining | EDM |

|---|---|---|

| Contact Method | Direct tool contact | Non-contact sparks |

| Forces Applied | High mechanical stress | Zero physical force |

| Material Range | Limited by hardness | Any conductive metal |

| Precision Level | Tool-dependent | Micro-level accuracy |

| Heat Impact | Mechanical heat | Controlled thermal effect |

EDM offers significant advantages over traditional methods. It cuts super-hard metals like titanium and tungsten while creating intricate shapes impossible through conventional machining. The process maintains tight tolerances, produces no mechanical stress, and works perfectly on delicate components.

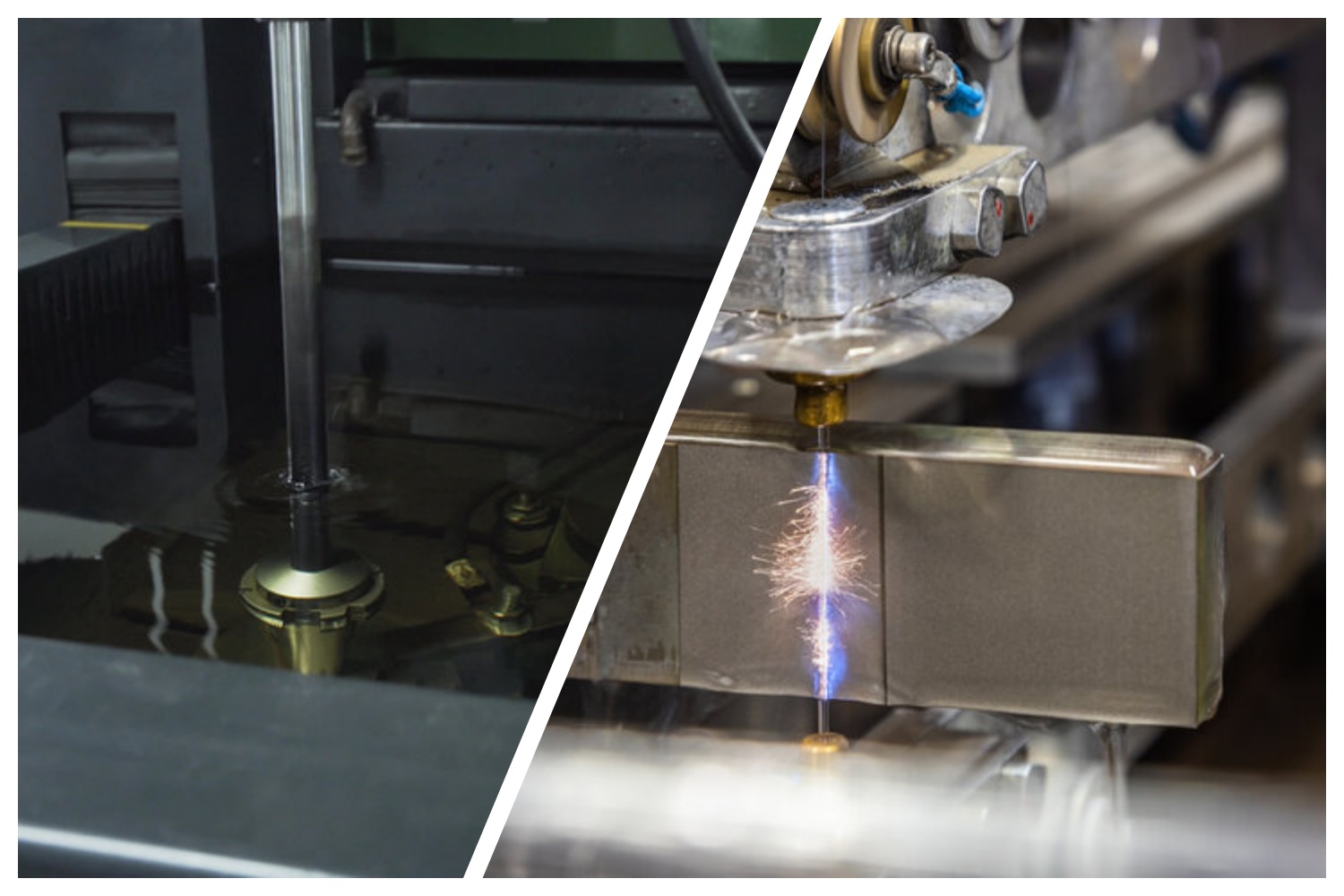

In daily situations, there are two primary types of EDM machines: Sinker EDM and Wire EDM.

Sinker EDM, also known as ram EDM or cavity EDM, is a precise machining process used to shape complex 3D cavities in conductive materials.

Sinker EDM works by placing an electrode and the workpiece in a dielectric fluid. The electrode, often made of graphite or copper, is pre-shaped to match the desired cavity shape. When voltage is applied, the dielectric fluid allows sparks to jump across the narrow gap between the electrode and workpiece. Each spark erodes a small amount of material, shaping the workpiece without direct contact. This process minimizes mechanical stress and allows for high precision in complex geometries.

A typical Sinker EDM machine includes these essential components:

Shaped Electrode: A custom-machined tool that mirrors the shape of the desired cavity. Commonly made of graphite or copper, it’s gradually lowered into the workpiece during the process.

Dielectric Oil: A hydrocarbon-based fluid that insulates the electrode from the workpiece, controlling spark generation and cooling the workpiece by flushing away debris.

Power Source: Provides the electrical energy needed to generate sparks and maintain a controlled erosion rate.

Sinker EDM is particularly suited to industries requiring precision cavities and complex internal geometries, such as:

Mold Making: Creating detailed injection molds, extrusion dies, and stamping dies.

Blind Cavities: Machining internal shapes that don’t pass through the entire material thickness.

Intricate Internal Shapes: Ideal for deep ribs, keyways, and splines.

Tool & Die Manufacturing: Used to produce high-precision tools and dies for industrial production.

Sinker EDM offers several key advantages, making it a valuable tool for complex part production:

Ability to Create Complex 3D Shapes: Perfect for intricate designs where conventional tools fall short.

Low-Stress Machining: As a non-contact process, it avoids mechanical stresses on both the electrode and workpiece.

Precision for Deep Cavities: Ideal for crafting detailed shapes with tight tolerances in hardened metals.

Despite its strengths, Sinker EDM has certain limitations:

Slower Machining Speed: The process can be time-intensive, especially for high-precision tasks.

High Power Consumption: Requires significant energy, making it less efficient than other machining options.

Limited to Conductive Materials: Sinker EDM only works on conductive metals, limiting its material versatility.

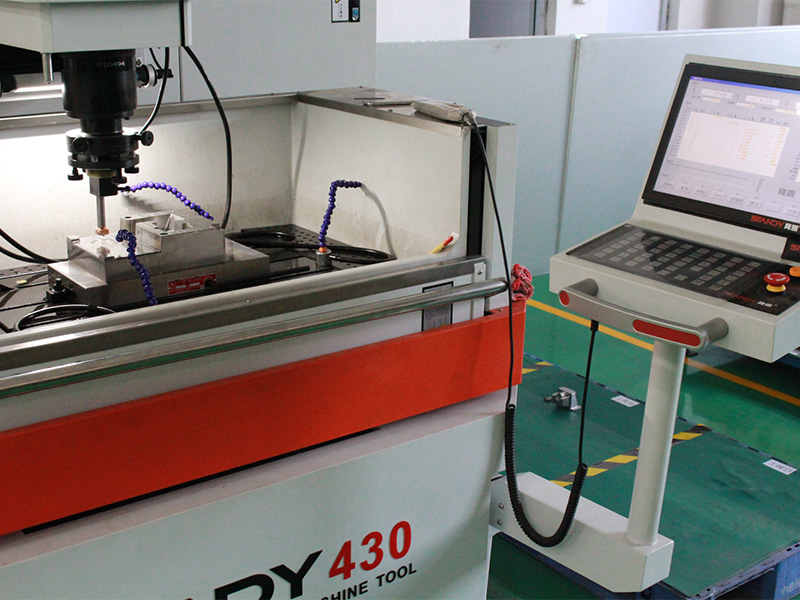

Wire Electrical Discharge Machining (EDM) is a precise, non-contact method for cutting conductive materials. It uses a charged wire, guided by CNC technology, to create intricate shapes without touching the workpiece.

In Wire EDM, a thin metal wire—usually brass—is fed through a CNC-guided system. This wire, charged with an electrical current, creates sparks between itself and the workpiece. Each spark erodes a small amount of material, shaping the workpiece without physical contact. Deionized water acts as a dielectric fluid, controlling the spark gap, cooling the workpiece, and removing debris. This process enables Wire EDM to cut complex contours and achieve tight tolerances.

A Wire EDM machine includes several critical components that ensure precision and control:

Brass Wire: The cutting tool, which is continuously fed to maintain sharpness and accuracy.

CNC Guide System: Guides the wire along programmed paths to create precise cuts.

Deionized Water: Serves as the dielectric fluid, providing controlled conductivity, cooling, and debris flushing.

Wire EDM is essential for industries that require high-precision parts. Typical applications include:

Extrusion Dies and Punches: Used for high-precision tools in manufacturing.

Medical Devices: Suitable for small, intricate components in surgical equipment.

Aerospace Components: Ideal for high-precision parts requiring tight tolerances.

Complex Gears and Parts: Produces delicate, detailed parts that conventional tools cannot handle.

Wire EDM offers several advantages that make it highly valuable for precision machining:

High Precision: Can achieve exceptionally tight tolerances, ideal for intricate designs.

Clean Edges: Cuts with no mechanical force, reducing the need for additional finishing.

Versatile for Delicate Cuts: Works well for fine, detailed profiles and parts with tight tolerances.

While Wire EDM is effective, it has limitations:

Material Restrictions: Only works on conductive materials, limiting versatility.

High Initial Cost: Equipment and setup can be expensive, especially for complex applications.

Oxide Layer Formation: May require additional finishing steps to remove surface oxide on certain metals.

| Aspect | Sinker EDM | Wire EDM |

|---|---|---|

| Tool Type | Custom-shaped electrode | Thin wire electrode |

| Dielectric Fluid | Hydrocarbon oils | Deionized water |

| Movement | Electrode sinks into the workpiece | Wire moves along X and Y axes |

| Ideal Applications | Molds, dies, blind cavities | Precision profiles, punches, intricate parts |

| Machining Process | Uses a shaped electrode to form complex 3D cavities | Utilizes a continuously moving wire for 2D profile cutting |

| Electrode Type | Custom electrode made of graphite or copper | Thin brass or coated wire |

| Geometry and Capabilities | Best for 3D shapes and blind cavities | Ideal for 2D profiles and fine cuts |

| Surface Finish Quality | Leaves a slightly rougher surface, may require additional finishing | Produces smooth edges with minimal finishing needed |

| Speed and Efficiency | Slower but precise for complex shapes | Faster for thin profiles, continuously cuts material |

| Material Types | Suitable for thicker, more rigid pieces | Better suited for thinner sections and high-precision materials |

| Tolerance and Precision | Precise, especially for deep cavities | High tolerance, ideal for intricate and tight-profile cuts |

| Tooling Requirements | Custom electrodes are required, leading to localized wear | Uses a continuous wire feed, ensuring uniform wear distribution |

| Cost and Operational Impact | Higher cost due to custom electrodes, ideal for low-volume, complex designs | Higher initial setup cost but efficient for high-precision applications |

Production Volume: For small batch or custom parts, Sinker EDM is often ideal, while Wire EDM suits high-precision mass production.

Material Type and Thickness: Sinker EDM handles thicker, rigid materials, whereas Wire EDM excels with thin profiles and delicate parts.

Budget: Initial setup costs for Wire EDM can be higher, but it may reduce costs in high-precision applications.

Surface Finish: Wire EDM generally provides a smoother finish, reducing the need for post-processing.

Part Geometry: Complex 3D shapes or internal cavities are best suited for Sinker EDM, while Wire EDM is ideal for 2D profiles and intricate cuts.

Tolerance Requirements: For extremely tight tolerances, Wire EDM is typically the preferred choice.

Sinker EDM is ideal for projects needing complex 3D shapes, such as:

Mold and Die Making: Excellent for creating injection molds and forming dies.

Blind Cavities: Best for deep cavities and internal features that do not go through the workpiece.

Tooling for Industrial Use: Preferred for creating durable, detailed tools where thickness and structural integrity are crucial.

Wire EDM is preferred in applications requiring high precision and clean cuts, such as:

High-Precision Parts: Ideal for aerospace and medical components where accuracy is essential.

Thin Profiles: Suits thin or delicate parts, ensuring no mechanical stress or deformation.

Complex, Tight-Tolerance Cuts: Perfect for intricate profiles and fine cuts that demand strict tolerances.

Sinker EDM and Wire EDM play a critical role in tool building. Benefits from these two processes, toolmakers can achieve complex geometries and surface details that conventional machining cannot easily deliver.

In tool making, sinker EDM is primarily used for shaping cavity features. By using a CNC-machined electrode, sinker EDM transfers complex 3D geometry directly into hardened tool steel.

Typical tooling applications include:

Injection mold cavities and core details

Deep ribs, narrow slots, and blind pockets

Sharp internal corners that milling cutters cannot reach

Fine textures or detailed forming surfaces

Precision profile cutting is the main application of wire EDM, it is an essential process for tool components that require exact outlines and tight tolerances. The thin wire follows a programmed path to cut through hardened materials with exceptional accuracy.

Common wire EDM tooling uses include:

Punches and dies for stamping and blanking

Mold inserts and sliders with complex contours

Extrusion and forming dies

Precision plates and guide components

Ejector Pin hole

In real-world tool making, sinker EDM and wire EDM are often used together to maximize efficiency and precision. A typical workflow may involve:

Wire EDM to cut the outer profile or separate inserts with tight tolerances

Sinker EDM to machine internal cavities, deep features, or complex 3D forms

Final polishing or fitting where required

By combining both methods, toolmakers can achieve complex tooling designs while controlling cost, lead time, and quality.

Sinker EDM and Wire EDM differ significantly in process, applications, and benefits. Understanding each method's strengths and limitations is essential for achieving precise results. Sinker EDM is ideal for creating complex 3D shapes, while Wire EDM excels in high-precision, 2D profile cuts. Consulting EDM experts can help determine the best solution for specific applications, especially in complex manufacturing. Consider factors like part geometry, material type, tolerance requirements, and production volume when selecting between Sinker EDM and Wire EDM to ensure optimal efficiency and precision.

Need sinker EDM, wire EDM services, or a combination of advanced machining processes for tool building? TEAM MFG provides complete machining and tooling solutions—from concept support to end products by using high-accuracy EDM and CNC technologies.

Ready to start your project? Send us your 3D designs and specifications, and our experts will provide a detailed quote within 24 hours.

· Phone: +86-15625312373

· Email: ericchen19872017@gmail.com

· 10+ Years of Experience: Expert engineering support for complex EDM projects.

· Rapid Turnaround: From prototype development to mass manufacturing.

· Global Quality Standards: Precision-driven results for Aerospace, Medical, and Automotive industries.

A: Initial setup costs run higher for Sinker EDM due to custom electrode requirements. Wire EDM offers lower setup costs but needs continuous wire replacement. Overall project costs depend on:

Part complexity

Production volume

Material type

Required precision

A: No, EDM is limited to electrically conductive materials, making it unsuitable for most plastics and ceramics. For non-metals, consider:

Laser cutting

Waterjet cutting

CNC milling

A:

| Process | Standard Tolerance | Best Achievable |

|---|---|---|

| Sinker EDM | ±0.0001 | ±0.00008 |

| Wire EDM | ±0.0001 | ±0.00005 |

A: Industries requiring precision components use EDM frequently. Aerospace and medical device industries rely on Wire EDM for intricate, high-tolerance parts. Automotive and tooling industries use Sinker EDM for molds, dies, and durable tools with complex internal shapes.

A: Wire EDM typically operates faster than Sinker EDM, especially for thin profiles or 2D cuts. Sinker EDM is slower but is preferred for deep, complex cavities. Operational speed for both depends on factors like material thickness, part geometry, and required finish.

Looking for EDM manufacturing solutions? Team Mfg delivers both Wire EDM and Sinker EDM services for your production needs.

We support:

Prototype development

Small batch production

Mass manufacturing

Custom projects

TEAM MFG is a rapid manufacturing company who specializes in ODM and OEM starts in 2017.