Daminɛ kuma

1.1. Masini fɛɛrɛw lajɛlen .

Masina ye baara ye min nafa ka bon kosɛbɛ fɛn dilanni na min bɛ kɛ ka fɛnɲɛnamafagalanw dilan ani k’u ban ka kɛ yɔrɔ tigitigiw ni u yɔrɔw ye. Nin wale in nafa ka bon walasa ka fɛn ɲumanw dilan izini suguya caman na, k’a ta mobili ni aerospace la ka se furakɛli ni musakabɔlaw ma. Masiniw kɛcogo jɔnjɔn dɔw ye:

● Milling .

● Drilling .

● Yɛlɛma .

● Grinding .

O fɛɛrɛ ninnu cɛma, jirituru nafa ka bon kɛrɛnkɛrɛnnenya la walasa ka dingɛw da masinw yɔrɔw la. Dingɛw bɛ baara kɛ kun caman na, i n’a fɔ ka jiw tɛmɛ, ka fɛnw bɔli daminɛ, ani ka se ka fɛn caman lajɛ ɲɔgɔn fɛ.

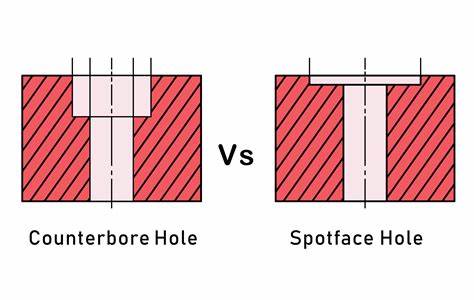

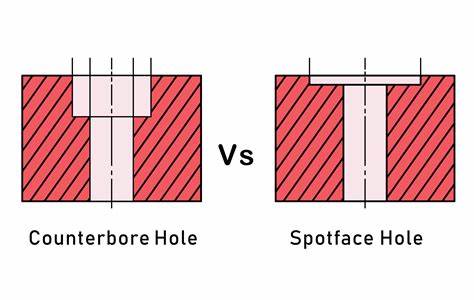

1.2. Spotface vs. counterbore dingɛw: a daminɛlan .

Ni a bɛ fɔ masinw ka dingɛw ma, suguya fila minnu bɛ kɛ ka caya, olu ye spotface ani counterbore dingɛw ye. Hali n’u bɛ se ka kɛ i n’a fɔ u bɛ ɲɔgɔn na u ɲɛ fɔlɔ la, danfara bɛ u fila ni ɲɔgɔn cɛ.

● Spotface dingɛw ye fɛnw ye minnu ka dun, minnu bɛ duguma, minnu bɛ kɛ ka fɛnw di minnu bɛ kɛ ka ɲɛ, minnu bɛ kɛ ni u bɛ kɛ ni fɛnw ye minnu bɛ se ka sigi.

● Faan wɛrɛ fɛ, dingɛw bɛ ɲɔgɔn sɔsɔ, olu ye bɔgɔdaga jugumanw ye minnu b’a to sirilan kunw bɛ sigi ni baarakɛminɛn sanfɛla ye walima a duguma.

O dingɛw jɔyɔrɔ ka bon kosɛbɛ walasa ka ɲɔgɔndɛmɛ ɲuman sɔrɔ, ka sirili lakana, ani ka kɛ cogo saniyalen na, min bɛ kɛ ni baara ye masinw yɔrɔw la.

1.3. A nafa ka bon kosɛbɛ ka dingɛw sɔrɔ masinw yɔrɔw la .

Tiɲɛni ye fɛnba ye masinko la, wa o ye tiɲɛ ye kɛrɛnkɛrɛnnenya la ni a bɛ tali kɛ . Dingɛw dabɔli . Dingɛ minnu ma kɛ ni masin ye, olu bɛ se ka gɛlɛya caman lase mɔgɔ ma, i n’a fɔ:

● A yɔrɔw labɛncogo jugu .

● sirili min tɛ se ka kɛ .

● ji bɔli ni a dɛsɛli jimafɛnw na .

● ka dɔ bɔ fɛn laban bɛɛ ka jogo ɲuman na ani a ka baara kɛcogo la .

Ni spotface tigitigi ni counterbore dingɛw dabɔra, fɛn dilannikɛlaw bɛ se k’a lajɛ k’u ka masinw yɔrɔw bɛ bɛn sariyaw ma minnu ka bon kosɛbɛ ani u ka baarakɛcogo.

1,4. Nin gafe in kuntilenna jɔnjɔnw .

Nin gafe bɛɛ kɔnɔ, an bɛna an yɛrɛ su ji la ka taa a fɛ ka don Spotface ni counterbore dingɛw kɔnɔ. An ka kuntilenna jɔnjɔnw ye ka:

1.A bɛ ɲɛfɔli jɛlen kɛ ani ka danfara don spotface ni counterbore dingɛw cɛ .

2.Aw bɛ u ka baarakɛcogo kɛrɛnkɛrɛnnenw n’u nafaw sɛgɛsɛgɛ masinw na .

3. Aw bɛ laadilikanw ni fɛɛrɛ ɲumanw di walasa ka spotface tigitigi dilan ani ka dingɛw kunbɛn .

4.Shighlight diɲɛ kɔnɔ misaliw ni ko kɛlenw sɛgɛsɛgɛli minnu bɛ o dingɛw nafa jira izini suguya caman na .

Nin gafe in laban na, i bɛna faamuyali jɔnjɔn sɔrɔ spotface ni counterbore dingɛw kan ani u bɛ don cogo min na ka ɲɛ i ka masinko taabolo la.

Faamuyali spotface dingɛw .

2.1. Spotface dingɛw ɲɛfɔli n’u cogoyaw .

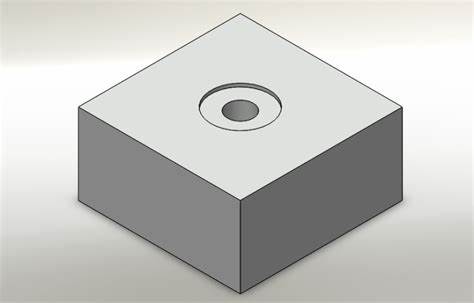

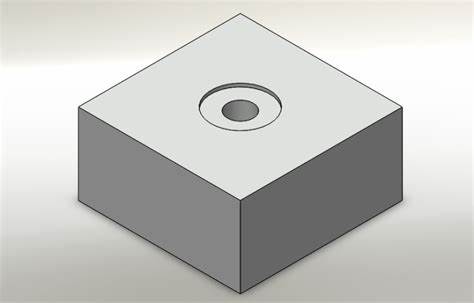

Spotface, n’a bɛ fɔ fana ko spotfacing, o ye recess machine ye min ka surun, a bɛ fla-fla la, a bɛ kɛ baarakɛminɛn ye. A ka c’a la, a bɛ dabɔ dingɛ dɔ lamini na min bɛ yen walima yɔrɔ kɛrɛnkɛrɛnnen dɔ la, fɛn min sirilan, i n’a fɔ bololanɛgɛ walima juru, o bɛna sigi yɔrɔ min na. Spotface (yɔrɔ) kun fɔlɔ ye ka yɔrɔ jɛlen, hali a sirilan di walasa a ka lafiɲɛ.

Spotfaces (yɔrɔw) bɛ dɔn u juguya ma, a ka c’a la, u bɛ se ka kɛ yɔrɔ fla ye. U cogoya ye sɛrɛkili ye ani u cɛmancɛ bɛ Bɛn ni sirilan kunkolo walima u ka jɛɲɔgɔnya yɔrɔ bonya ye. Spotface (yɔrɔ) duguma bɛ jɔ dingɛ aksidan na, ka a lajɛ ni a bɛ bɛn a sirilan ma ka ɲɛ.

Spotfaces bɛ Kɛ ko dɔw la minnu na baarakɛminɛn in yɔrɔ fɔlɔ tɛ kelen ye, a ka gɛlɛn, walima a tɛ jɔ dingɛ dakun na. Ni u ye yɔrɔ dɔ dilan, masinw bɛ se k’a lajɛ ko sirilan sigilen bɛ yɔrɔ fla la, ka jɛɲɔgɔnya sabatilen ni lakananen di.

2.2. Spotface dɔ dabɔli taabolo .

Walasa ka spotface (yɔrɔ) dɔ Dabɔ, masinw bɛ tugu nin fɛɛrɛ caman kɔ:

1.Aw bɛ yɔrɔ dɔn: Spotface ka kan ka dabɔ yɔrɔ min na, aw bɛ o dɔn ka da a sirilan yɔrɔ kan ani baarakɛminɛn in dilanni kan.

2.Drill the initiarly hole: Ni spotface bɛ fara dingɛ kan min bɛ yen, aw bɛ tɛmɛ nin sen in kan. N’o tɛ, aw bɛ dingɛ dɔ da yɔrɔ kofɔlen na, k’a lajɛ ni a bɛ tilennen to a sanfɛla la.

3.Spotfacing baarakɛminɛn sugandi: Spotfacing baarakɛminɛn dɔ sugandi min cɛmancɛ ni a juguya hakɛ bɛnnen don spotface hakɛ ɲininen na.

4.Set up the machine: Aw bɛ spotfacing baarakɛminɛn sigi masin sɔgɔlan kɔnɔ ani ka teliya ni balo hakɛ ladilan ka kɛɲɛ ni baarakɛminɛn dilannikɛla ka ladilikanw ye ani baarakɛminɛn ye.

5.Aw bɛ yɔrɔ min bɛ yɔrɔ la, o da: Spotfacing baarakɛminɛn jigin dɔɔni dɔɔni ka don baarakɛminɛn kɔnɔ, ka tilennen to a ɲɛda la. Baarakɛminɛn bɛna fɛn tigɛ walasa ka duguma yɔrɔ flakɛlen, nɔgɔlen dɔ dilan.

6.Spotface lajɛ: Spotface janya ni a juguya jateminɛ walasa a ka se ka wajibiyalenw dafa. Aw bɛ a yɔrɔ lajɛ ni a ɲɛ tɛ a la walasa ka a dɔn ni a ma kɛ cogo la min tɛ se ka kɛ.

Ni nin wale ninnu kɛra, masinw bɛ se ka yɔrɔ tigitigiw ni ɲɔgɔn cɛ minnu bɛ lajɛ laban kɛcogo ɲuman n’a kɛcogo ɲɛ.

2,3. Spotface dingɛw baarakɛcogo n’u nafaw .

Spotface dingɛw bɛ nafa caman di, wa u bɛ kɛ baara suguya caman na iziniw kɔnɔ. Baarakɛminɛn minnu bɛ kɛ tuma caman na, olu dɔw ye:

● Sigiyɔrɔw sirili: Yɔrɔw bɛ kɛ yɔrɔ ye min bɛ kɛ ka fɛnw siri, hali ni u bɛ kɛ yɔrɔ ye min bɛ se ka kɛ fɛn ye min bɛ se ka kɛ fɛn ye min bɛ se ka kɛ fɛn ye min bɛ se ka kɛ fɛn ye min bɛ se ka kɛ fɛn ye min bɛ se ka kɛ fɛn ye min bɛ se ka kɛ fɛn ye min bɛ se ka kɛ fɛn ye min bɛ se ka kɛ fɛn ye min bɛ se ka kɛ fɛn ye min bɛ se ka kɛ fɛn ye.

● Sigiyɔrɔmayɔrɔw : jisigiyɔrɔw la, yɔrɔw bɛ se ka yɔrɔ nɔgɔlenw dilan walasa ka gaziw walima O-ringw kɛ walasa u ka se ka u siri, o bɛ ji bɔli bali.

● Bearing surfaces: Spotfaces bɛ se ka kɛ yɔrɔ fla ye, min bɛ jɔ, walasa birikiw ka lafiɲɛ, ka dɔ bɔ sɛgɛn na ani ka jiginni nɔgɔya.

● Kuranko yɔrɔw : Kuranko minɛnw kɔnɔ, yɔrɔw bɛ se ka yɔrɔ fla dilan yɔrɔw kama i n’a fɔ switchw walima ɲɔgɔndanw ka se ka wuli u kan, ka a jira ko u bɛ ɲɔgɔn sɔrɔ cogo bɛnnen na ani ko u bɛ se ka baara kɛ cogo bɛnnen na.

Spotface dingɛw misali lakikaw waleyali la, olu dɔw ye:

● Mobili motɛriw: Spotfaces bɛ kɛ silinda kunw kan walasa ka yɔrɔ fla di walasa kunkolow ka se ka sigi u kan, ka hali fanga siri ani ka sigilan lakananen sɔrɔ.

● Aerospace components (Aerospace yɔrɔw) : awiyɔnw jɔcogo la, spotfaces (yɔrɔw) bɛ kɛ ka sirili dingɛw lamini walasa ka yɔrɔ kelen di, min bɛ kɛ ka ɲɛ, min bɛ kɛ ka fɛnw siri, ka degunw hakɛ dɔgɔya ani ka lajɛ in dafalen bɛɛ lajɛlen ɲɛ ka taa a fɛ.

Ni u ye spotface dingɛw don u ka dilanw kɔnɔ, ɛntɛrinɛti ni masinw bɛ se ka:

● Aw bɛ sirilan sigiyɔrɔw ni u labɛncogo ɲɛ .

● Sealing baarakɛcogo ɲɛ .

● Aw bɛ dɔ bɔ sɛgɛn na furuɲɔgɔnya yɔrɔw la .

● Aw ye aw jija kuran yɔrɔw ka baara kɛcogo ɲuman .

● Ka dɔ fara lajɛ laban bɛɛ ka jogo ɲuman n’a ka dannaya kan .

Spotface dingɛw bɛ se ka kɛ i n’a fɔ kunnafoni fitinin, nka u jɔyɔrɔ ka bon kosɛbɛ masinw yɔrɔw ni u lajɛw ka baara kɛcogo n’u ka ɲɛnamaya janw na.

Sɛgɛsɛgɛli kɛra counterbore dingɛw kan .

3.1. Kontɔrɔsi dingɛw ye mun ye?

Kùncɛbaya dingɛ ye masin-yɔrɔ sugu dɔ ye min bɛ Kɛ ni dingɛ ye min janya ka bon ni dingɛ fitinin ye min bɛ Dòn dingɛ fitinin dɔ kan. Dingɛ belebeleba in bɛ Weele ko counterbore, wa a bɛ Taa a yɔrɔ dɔ la dɔrɔn baarakɛminɛn na. Dingɛ fitinin min bɛ Weele ko piloti dingɛ, a ka c’a la, o bɛ Taa sira bɛɛ fɛ.

Kɔnɔnatumuw ka dingɛ dɔ jogo jɔnjɔnw ye:

● Profil stepped ni a cɛmancɛ fila bɛ .

● Jiginni yɔrɔ fla bɛ yen min bɛ jɔ dingɛ kɔnɔ .

● juguman min bɛ a to counterbore ka se ka a ka fɛn sirilan kunkolo ladon .

Ni an y’a suma ni spotface dingɛw ye, counterbore dingɛw bɛ ni recess jugu ye ani sen bɛ ye ka caya diamètre fila ninnu cɛ. Hali ni spotfaces bɛ kɛ fɔlɔ ka sigiyɔrɔ fla dilan, counterbores dabɔra ka sirilan kunkolo dogo baarakɛminɛn kɔnɔ.

3.2. counterbore dingɛw nafa n’u baarakɛcogo .

Kùncɛbaya dingɛw bɛ baara nafama caman Kɛ masinw na wa u bɛ Kɛ baara caman na. Baara fɔlɔ dɔw minnu bɛ kɛ ni counterbore dingɛw ye olu dɔw ye:

1.Accommodating fastener heads: counterbores bɛ a to bolokɔni, kurukuru, walima fɛn wɛrɛ min bɛ kɛ ka a siri ni a ye, o bɛ sigi ni baarakɛminɛn sanfɛla ye walima a duguma. O bɛ kɛ sababu ye ka saniya kɛ ani ka sirilan kunkolo bali ka cɛnimusoya yɔrɔw bali.

2.Ka yɔrɔ di: Tuma dɔw la, fɛnw bɛ kɛ ka baarakɛminɛnw walima fɛn wɛrɛw jira minnu ka kan ka tɛmɛ dingɛ kɔnɔ.

3.Enhancing Assembly: Counterbores bɛ se ka dɛmɛ don ka furuɲɔgɔnya yɔrɔw labɛn ani ka u sɔrɔ lajɛ waati la, ka taabolo nɔgɔya ani ka kɛ tiɲɛ ye.

Misali minnu bɛ sɔrɔ counterbore dingɛw la izini baarakɛcogo la olu ye:

● Mobili: Motɛri blokiw kɔnɔ, fɛnw bɛ kɛ ka bolokɔniw kunkolow dogo minnu bɛ silinda kun siri, ka yɔrɔ nɔgɔlen dɔ dilan walasa gazi ka se ka siri a la.

● Aerospace : counterbore dingɛw bɛ sɔrɔ awiyɔnw jɔcogo la, u bɛ kɛ yɔrɔ minnu na walasa ka flush surfaces dilan rivets ni fɛn wɛrɛw kama minnu bɛ fɛnw siri, ka dɔ bɔ drag and improving aerodynamiques la.

● Elektroniki: Circuit boards (PCB) sɛbɛnnenw kɔnɔ, counterbores (daɲɛw) bɛ kɛ ka recesses (dadonw) dilan component (yɔrɔw) ɲɛminɛbagaw ye, o b’a to u bɛ se ka sigi ni board (kurun) sanfɛla ye.

3,3. counterbore holes in engineering jaw: decoding taamasiyɛnw .

Injiniyɛri jaw la, counterbore dingɛw bɛ jira ni taamasiyɛn kɛrɛnkɛrɛnnenw ni sɛbɛnni ye. Nin taamasiyɛn ninnu faamuyali nafa ka bon kosɛbɛ masinw ni injiniyɛriw bolo walasa u ka yɔrɔw kɔrɔ fɔ ka ɲɛ ani k’u dilan ni dingɛw ye minnu bɛ ɲɔgɔn sɔsɔ.

Taamaʃyɛn jɔnjɔn min bɛ Kɛ 'kɔnɔna na, o ye sɛrɛkili ye min kɔnɔna na, sɛrɛkili fitinin dɔ bɛ a kɔnɔ. Kɛnɛma-yɔrɔ bɛ counterbore diamètre jira, ka sɔrɔ kɔnɔna sɛrɛkili bɛ pilote hole diamètre jira. Dimensions wɛrɛw, i n’a fɔ counterbore depth ani pilote hole depth (n’o ye fiyentɔw ka dingɛ ye), u bɛ wele cogoya la ni ɲɛmɔgɔya sinsinniw ni dimensions nafaw ye.

Nin ye misali ye min b’a jira cogo min na counterbore hole bɛ se ka jira injiniyɛri ja dɔ kɔnɔ:

⌴ 10,0 x 5,0.

⌴ 6,0 ka se .

Nin misali in na : - sɛrɛkili min ka bon ni '⌴' taamasiyɛn ye, o bɛ jatebɔlan jira, a cɛmancɛ ye milimɛtɛrɛ 10,0 ye ani a juguya ye milimɛtɛrɛ 5,0 ye. - Sɛrɛkili fitinin min bɛ a kɔnɔ, o bɛ piloti dingɛ jira, a cɛmancɛ ye milimɛtɛrɛ 6,0 ye min bɛ tɛmɛ baarakɛminɛn bɛɛ fɛ (THRU).

Ni u ye u yɛrɛ dɔn o taamasiyɛnw ni o sɛbɛnw na, masinw ni ɛntɛrinɛti injiniyɛriw bɛ se ka dilancogo laɲini fɔ ka ɲɛ ani k’a lajɛ ko counterbore dingɛw dilannen don ka kɛɲɛ ni fɛn ɲɛfɔlenw ye.

Sɛgɛsɛgɛli min bɛ kɛ ni ɲɔgɔn ye: Spotface ni counterbore dingɛw .

danfara jɔnjɔnw ni ɲɔgɔn bɔcogo .

Spotface ni counterbore dingɛw bɛ ɲɔgɔn Bɔ dɔw la, nka u fana bɛ danfara Bɔ ɲɔgɔn na. U fila bɛɛ ye silindaw ye minnu dilannen don ka kɛ baarakɛminɛn ye, a ka c’a la, dingɛ dɔ bɛ yen min bɛ yen. Nka, a juguya, a cogoya ani a weleli taamasiyɛnw b’u bɔ ɲɔgɔn na.

Depite ye danfaralan jɔnjɔn ye. Kɔnɔnatumuw ka dun, u dabɔra walasa ka fɛn sirilan kunkolo minɛ ka ɲɛ duguma. O ni ɲɔgɔn cɛ, yɔrɔ minnu bɛ yɔrɔ la, olu ka surun, u bɛ dunuya dɔɔnin dɔrɔn di walasa ka yɔrɔ flakɛlen, nɔgɔlen dɔ dilan walasa a sirilan ka sigi a kan.

Siginidenw ko la, spotfaces (yɔrɔ) bɛ ni silinda nɔgɔman ye ni duguma fla ye. Kɔrɔɲɔgɔnmaw fana bɛ ni silinda ye nka u bɛ ni stepped profile ye, ni u cɛmancɛ janya ka bon ka tɛmɛn ka taa hole diamètre fitinin na.

Callout taamasiyɛnw kan injiniyɛri jaw bɛ spotfaces ni counterbores danfara. Spotfaces bɛ baara Kɛ ni counterbore symbol (⌴) ye ni 'sf' ye kɔnɔna na, ka sɔrɔ counterbores bɛ baara Kɛ ni ⌴ taamaʃyɛn dɔrɔn ye, ka Kɛɲɛ ni cɛmancɛ ni juguman hakɛw ye.

Danfara minnu bɛ baarakɛcogo la: Fastener kunkolow ladonni .

Danfara fɔlɔ min bɛ spotfaces ni counterbores cɛ, o bɛ sɔrɔ u bɛ fastener kunkolow ladon cogo min na. Kɔnɔnatumuw dilannen don walasa ka fɛn sirilan kunkolo lamini kosɛbɛ, i n’a fɔ bolokɔni walima kuru, baarakɛminɛn sanfɛla jukɔrɔ. O bɛ kɛ sababu ye ka fɛn dɔ kɛ min bɛ kɛ ni fɛn dɔ ye walima min bɛ don a kɔnɔ ani ka sirilan kunkolo bali ka bɔ kɛnɛma.

Faan wɛrɛ fɛ, spotfaces bɛ kɛ yɔrɔ fla ye, yɔrɔ min ka nɔgɔn, walasa ka a sirilan kun lafiɲɛ, ka sigiyɔrɔ ɲuman ni ɲɔgɔndɛmɛ sabati. U nafa ka bon kɛrɛnkɛrɛnnenya la ni baarakɛminɛn in sanfɛla tɛ kelen ye walima ni a sirilan ka kan ka sigi yɔrɔ wɛrɛ la min tɛ degere 90 ye.

Spotfaces jɔyɔrɔ ka bon kosɛbɛ walasa ka a lajɛ ni fɛnw sirilanw bɛ sigi ka ɲɛ ani ka degun bɛnnenw kɛ ka sɔrɔ u ma baarakɛminɛn sanfɛla tiɲɛ.

Depth and Design Application: Danfara jɔnjɔnw .

Spotfaces ni counterbores juguya bɛ tali kɛ u ka dilancogo baarakɛcogo la. Kɔnɔnatumuw ka dun, a ka c’a la, u bɛ bɛn sirilan kunkolo janya ma. O juguya bɛ sira Di sirilan kunkolo ma a bɛɛ lajɛlen na lafiɲɛbɔ kɔnɔ, ka fɛn dɔ Kɛ min bɛ Kɛ ni flush ye walima min bɛ Dòn a la. Kɔnɔnatumuw bɛ kɛ ka caya ni sirilan sigicogo ɲuman, min tɛ mɔgɔ ɲɛnafin bɔ, o bɛ ɲini ɲɛnajɛko walima baarakɛcogo la.

O ni ɲɔgɔn cɛ, spotfaces (yɔrɔw) bɛ juguya ka tɛmɛ, a ka c’a la, u bɛ se ka kɛ yɔrɔ fla ye, hali ka kɛ yɔrɔ ye min bɛ kɛ ka a siri. A ka c’a la, spotface (yɔrɔ) juguya tɛ se milimɛtɛrɛ 5 ma, bawo a kuntilenna fɔlɔ ye ka sigiyɔrɔ nɔgɔlen di sanni ka sirilan kun dogo ka ɲɛ.

Desizɔn min bɛ kɛ ni spotface walima counterbore ye, o bɛ bɔ dilancogo kɛrɛnkɛrɛnnenw na, i n’a fɔ mago bɛ fɛn min na, o ye ka fɛnw kɛ ka ɲɛ, ka ɲɔgɔn lajɛ, walima ka kɛ ɲɔgɔn fɛ yɔrɔ la min tɛ kelen ye.

Suguya | Spotface . | counterbore . |

Dunya | A ka dɔgɔ, a ka ca a la a tɛ milimɛtɛrɛ 5 bɔ, a bɛ se ka kɛ yɔrɔ fla ye, a bɛ kɛ cogo nɔgɔman na . | A ka ca a la, a bɛ bɛn sirilan kun janya ma, min dilannen don walasa ka sirilan kunkolo ladon ka ɲɛ . |

Ka labɛn | Simple cylindrical form ni a duguma fla . | Silindriw cogoya ni senna-taama ye, u cɛmancɛ ka bon ka tɛmɛn u cɛmancɛ dingɛ kan . |

Callout taamasiyɛn . | A bɛ baara Kɛ ni counterbore taamaʃyɛn ye (⌴) ni 'sf' ye . | A bɛ baara Kɛ ni counterbore symbol (⌴) dɔrɔn ye, ka fara a cɛmancɛ ni a juguman hakɛw kan . |

Baarakunda | A bɛ yɔrɔ flakɛlen ni nɔgɔlen di walasa ka a sirilan kun sigi, ka sigiyɔrɔ ɲuman ni ɲɔgɔndɛmɛ sabati . | A bɛ don a sirilan kun na kosɛbɛ, i n’a fɔ bolokɔni walima juru, baarakɛminɛn sanfɛ . |

Waleyali | Baara bɛ kɛ ni baarakɛminɛn ye min tɛ kelen ye walima ni a sirilan ka kan ka sigi yɔrɔ wɛrɛ la min tɛ degere 90 ye . | A bɛ kɛ ni a ɲɛda bɛ kɛ fɛn ye min bɛ kɛ ka ɲɛ walima min bɛ don a la walasa a ka kɛ cɛɲi walima baarakɛcogo ye . |

Surface Finish . | Tuma caman na, a bɛ kɛ ni a ɲɛda fini ye min ka ɲi, a muɲuni ka gɛlɛn surface finish kan . | Kɛrɛ kogow sanfɛla fini tɛ gɛlɛya kosɛbɛ, nka a duguma da bɛ fini nɔgɔman de wajibiya hali bi walasa ka sigiyɔrɔ ɲuman sɔrɔ . |

Machining . | A bɛ baarakɛminɛnw sugandili ɲuman de wajibiya, tigɛcogo, ani masinw ka fɛɛrɛw walasa ka yɔrɔ ɲuman ɲininen sɔrɔ . | A ka c’a la, a bɛ tigɛ ka juguya ani a bɛ se ka kɛ wajibi ye ka baarakɛminɛn kɛrɛnkɛrɛnnenw kɛ . |

Surface Finish jateminɛw bɛ sɔrɔ counterbores ani spotfaces kɔnɔ .

Surface finish ye jateminɛ nafama ye ni i bɛ counterbores ni spotfaces suma ɲɔgɔn na. Dingɛ suguya fila bɛɛ bɛ ɲini ka kɛ yɔrɔ ye min ka nɔgɔn, hali a bɛ kɛ cogo bɛnnen na walasa ka sigilanw sigi ka ɲɛ ani ka u siri ɲɔgɔn na. Nka, a ka c’a la, spotfaces (yɔrɔ) bɛ kɛ ni surface (yɔrɔ) fin ye ni i ye a suma ni counterbores (kɔntiriw) ye.

Spotface (yɔrɔ) kun fɔlɔ ye ka yɔrɔ fla ye, yɔrɔ min ka nɔgɔn walasa ka a sirilan kunkolo lafiya, ka a to a ka se ka a siricogo degun ɲuman sɔrɔ ani ka yɔrɔ tiɲɛni bali. O de kosɔn, spotface (yɔrɔ) dɔ sanfɛla laban ka bon kosɛbɛ, wa a ka c’a la, a bɛ minɛ ka ɲɛ kosɛbɛ.

Kɔrɔɲɔgɔnmaw la, kɛrɛfɛ kogow sanfɛla fini tɛ gɛlɛya kosɛbɛ, bawo u bɛ baara kɛ fɔlɔ walasa ka sirilan kunkolo ladon. Kɔnɔnatumu dɔ duguma, a sirilan kun bɛ lafiɲɛbɔ yɔrɔ min na, o bɛ a ɲini hali bi a ka kɛ finimugu ye min bɛ kɛ ka ɲɛ walasa a ka sigi ka ɲɛ.

Masina-taama-cogow ni baarakɛminɛnw minnu bɛ Kɛ ka spotfacew ni kùnkolo-yɔrɔw Dabɔ, olu bɛ Se ka nɔ Blà surface fini sɔrɔlen na. Baarakɛminɛnw sugandili ɲuman, tigɛcogo paramɛtɛrɛw, ani masinw nafa ka bon walasa ka yɔrɔ ɲuman ɲininen sɔrɔ.

Desizɔn tacogo sariyaw: Waati min na baara bɛ kɛ .

Sugandili bɛ kɛ spotface ni counterbore cɛ, o bɛ bɔ fɛn caman na ani porozew wajibiyalenw na. Aw ye nin laadilikan ninnu jateminɛ ni aw bɛ aw ka latigɛ kɛ:

1.Fastener head concealment: Ni aw mago bɛ sirilan kun na ka kɛ fɛn ye min bɛ wuli walima ka don a la ɲɛnajɛ walima baarakɛcogo kunw na, aw bɛ baara kɛ ni counterbore ye. Ni dogoli ma kɛ, yɔrɔ min bɛ se ka kɛ yɔrɔ ye, o bɛ se ka bɔ.

2.Surface condition (Surface condition) : Ni aw bɛ yɔrɔ minnu tɛ kelen ye walima minnu ka gɛlɛn, yɔrɔw bɛ sigiyɔrɔ fla di, yɔrɔ min ka nɔgɔn, ka ɲɛsin fɛnw sirilanw ma, ka a lajɛ ni a bɛ bɛn ɲɔgɔn ma ka ɲɛ ani ka a siri.

3.Assembly Constraints: Aw ye yɔrɔ jateminɛ min bɛ sɔrɔ a sirilan sigili la. Kɔnɔnatumuw bɛ juguya ka tɛmɛ ani a bɛ se ka kɛ ko u tɛ bɛn baarakɛminɛn finmanw ma walima yɔrɔ sirilenw ma.

4.Fastener suguya: Fastener kunkolo jateminɛ ni a bonya bɛ nɔ bila sugandili la spotface ni counterbore cɛ. Aw bɛ a lajɛ ko lafiɲɛbɔ bɛ se ka sirilan kunkolo cogoya ni a bonya kɛrɛnkɛrɛnnenw ladon.

5.Baarakɛcogo sekow: Aw bɛ aw ka masinko sekow jateminɛ ani baarakɛminɛnw minnu bɛ sɔrɔ. A ka c’a la, fɛnɲɛnamafagalanw bɛ tigɛ ka caya ani u bɛ se ka baarakɛminɛn kɛrɛnkɛrɛnnenw wajibiya.

Ni aw ye o kow jateminɛ ani ka u ni aw ka poroze wajibiyalenw bɛn ɲɔgɔn ma, aw bɛ se ka latigɛ kɛ ni kunnafoni ye min bɛ kɛ ni spotface walima counterbore hole ye.

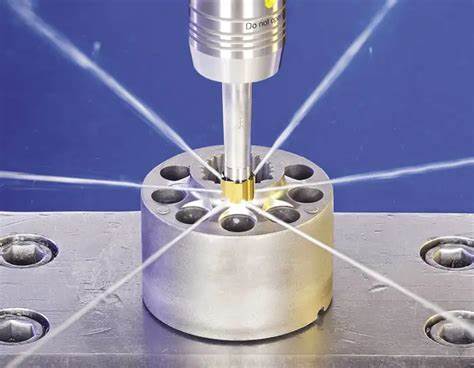

Masina-fɛɛrɛw ni baarakɛminɛnw ye spotface ni counterbore dingɛw ye .

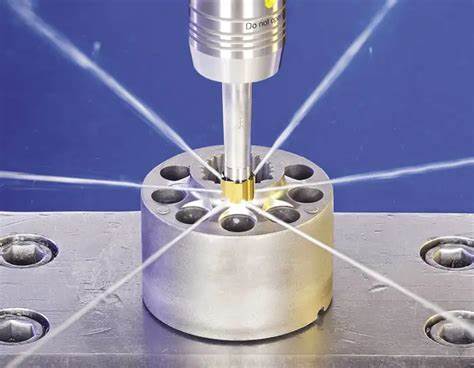

Masini kɛcogo ɲɛfɔli: Ka bɔ piloti dingɛw la ka taa a bila fɛn labanw na .

Spotface ni counterbore dingɛw dabɔli bɛ Kɛ ni masin-minɛn caman ye. Fɛn fɔlɔ min bɛ Kɛ o ye ka piloti dingɛ Dabɔ, o min bɛ Kɛ spotface walima counterbore cɛmancɛ yɔrɔ ye. A ka c’a la, piloti dingɛw bɛ sɔgɔ, ka sɛgɛn, walima ka u sɔgɔ fo ka se u cɛmancɛ ni u juguya ma min wajibiyalen don.

Ni piloti dingɛ Dabɔra, a nɔfɛta ye ka spotface walima counterbore masina. O bɛ Kɛ ni baarakɛminɛn kɛrɛnkɛrɛnnenw ye minnu bɛ Bɛn ni o fɛn in janya n’a juguman ye. A nafa ka bon kosɛbɛ k’a lajɛ ko baarakɛminɛn in bɛ bɛn dafalen ma ni piloti dingɛ ye walasa ka ɲɔgɔndɛmɛ sabati.

A laban na, baarakɛminɛn in bɛ Dòn baarakɛminɛn kɔnɔ walasa ka spotface (yɔrɔ) walima counterbore (fɔlikan) Dabɔ. O kɔfɛ, baarakɛminɛn bɛ kɔsegin, ka yɔrɔ nɔgɔlen, nɔgɔlen walima sennasanbara dɔ to yen, ka kɛɲɛ ni fɛn ye min bɛ kɛ ni masin ye.

Baarakɛminɛnw ni minɛnw ka ɲɛsin counterbore ani spotface machining ma .

Baarakɛminɛn kɛrɛnkɛrɛnnenw bɛ sɔrɔ counterbore ani spotface machining baara fila bɛɛ la. O baarakɛminɛnw bɛ na ni jateminɛ ni hakɛ suguya caman ye walasa ka dingɛw cɛmancɛ ni u juguya suguya caman sɔrɔ.

A ka c’a la, baarakɛminɛnw bɛ kɛ i n’a fɔ drill bits walima end mills, ni piloti tip ye min bɛ don dingɛ kɔnɔ min tun bɛ labɛn ka kɔn. Tigɛdaw dabɔra walasa ka dingɛ fla-fla dɔ Dabɔ ni kogo tilennenw ye. Kɔrɔɲɔgɔnma-minɛn dɔw bɛ ni juguya ye min bɛ Se ka Labɛn walasa ka sirilan kunkolo janya danfaralenw Sɔrɔ.

Spotface baarakɛminɛnw kɔni, tigɛ janya ka surun bawo u mago bɛ dɔrɔn ka lafiɲɛbɔ-yɔrɔba dɔ Dabɔ. U bɛ se ka kɛ ni piloti walima ɲɛjiralan ye min bɛ don u kɔnɔ walasa ka u hakili sigi ni piloti dingɛ ye. A ka ca a la, spotface baarakɛminɛnw bɛ kɛ ni tigɛ ɲɛda ye min bɛ kɛ fla ye walima min bɛ lamini dɔɔni walasa ka sigiyɔrɔ nɔgɔlen sɔrɔ.

Ka fara baarakɛminɛn kɛrɛnkɛrɛnnenw kan, laban-minɛnw ni reamɛriw fana bɛ se ka kɛ ka counterbore ani spotface machining kɛ. Baarakɛminɛn sugandili bɛ bɔ baara wajibiyalen kɛrɛnkɛrɛnnenw na, i n’a fɔ dingɛ hakɛ, a juguya, ani a sanfɛla laban wajibiyalen.

Gɛlɛyaw ni furakɛliw kɛli masinw kɛlɛli la ani spotface holes .

CNC machining counterbore ani spotface holes bɛ gɛlɛya kɛrɛnkɛrɛnnen dɔw jira. O koɲɛba dɔ ye ka ɲɔgɔndɛmɛ mara piloti dingɛ ni masinw ka baarakɛcogo cɛ. Fɛn o fɛn bɛ se ka kɛ, o bɛ se ka kɛ sababu ye ka dingɛ dɔ sɔrɔ min tɛ cɛmancɛ la walima min bɛ kɛ kɛrɛ fɛ, o bɛ se ka kɛ sababu ye ka ɲɔgɔn lajɛ.

Walasa ka se sɔrɔ o gɛlɛya kan, a nafa ka bon ka baarakɛminɛnw kɛ ni awiyɔn bolilaw ye minnu bɛ don a kɔnɔ walima ni ɲɛminɛbagaw ye minnu bɛ bɛn piloti dingɛ kɔnɔ kosɛbɛ. O bɛ dɛmɛ ka baarakɛminɛn in to a cɛmancɛ la ani k’a labɛn masinko waati la. Labɛnni ni baarakɛcogo ɲuman fana nafa ka bon kosɛbɛ walasa baarakɛminɛn ka to a cogo la ani ka a labɛn baara bɛɛ kɔnɔ.

Gɛlɛya wɛrɛ ye ka se ka dugukolo sanfɛla dafalen sɔrɔ, kɛrɛnkɛrɛnnenya la, fɛnw na minnu bɛ se ka tigɛ walima ka don. Ni aw bɛ baara kɛ ni baarakɛminɛnw ye minnu ka nɔgɔn, ni u ka ɲi kosɛbɛ, ni u dacogo bɛnnen don, o bɛ se ka dɛmɛ don ka o kow dɔgɔya. Tigɛ teliya ni balocogo ɲuman, ka fara nɛnɛmadalan baara kan, o fana bɛ se ka kɛ sababu ye ka dugukolo sanfɛla dafalen sɔrɔ.

Ladilikanw ka ɲɛsin baarakɛminɛn ɲumanw sugandili ma baara kelen-kelen bɛɛ kama .

Baarakɛminɛn ɲumanw sugandili ka ɲɛsin counterbore ani spotface machining ma, o nafa ka bon walasa ka se ka sɔrɔ ɲininenw sɔrɔ. Ladilikan dɔw filɛ nin ye minnu ka kan ka to an hakili la:

1.Aw ye dingɛ hakɛ ni a juguya jateminɛ: Aw bɛ baarakɛminɛnw sugandi minnu bɛ bɛn o yɔrɔ cɛmancɛ ni a juguman ma. Ni aw bɛ a kunbɛn, aw bɛ a lajɛ ko baarakɛminɛn bɛ se ka sirilan kun janya.

2.Aw bɛ baarakɛminɛnw ɲini ni pilotiw ye minnu bɛ don u kɔnɔ: Baarakɛminɛn minnu bɛ ni pilotiw walima ɲɛjirabagaw ye, olu bɛ se ka dɛmɛ don ka u hakili to u la ani ka u bɛn ni piloti dingɛ ye.

3.A’ ye baarakɛminɛnw ni finimuguw lajɛ: Baarakɛminɛn minnu dilannen don ni fɛnw ye minnu ka ɲi kosɛbɛ, i n’a fɔ karɔti walima nɛgɛ teliyalen, ani ni dacogo bɛnnenw ye fɛn min bɛ kɛ ni masin ye.

4.Aw ye surface finish requirements jateminɛ: Baarakɛminɛn dɔw dabɔra walasa ka surface finish ɲuman dilan ka tɛmɛ dɔw kan. Baarakɛminɛnw sugandi minnu bɛ ni jateminɛ bɛnnen ye ani dakun labɛnni i mago kɛrɛnkɛrɛnnenw kama.

5.A’ ye baarakɛminɛn in ka fɛn caman kɛcogo jateminɛ: Aw bɛ baarakɛminɛnw ɲini minnu bɛ se ka dingɛ hakɛ ni juguman caman ɲɛnabɔ walasa k’u nafa bonya aw ka butiki kɔnɔ.

Dilancogo jateminɛw ani kɛcogo ɲumanw .

Ni yɔrɔ dɔw bɛ dilan minnu bɛ counterbore walima spotface dingɛw ɲini, fɛɛrɛ ɲuman damadɔ bɛ yen minnu ka kan ka to an hakili la:

1.A’ ye fɛn suguya ɲɛfɔ ka jɛya: Aw bɛ baara kɛ ni taamasiyɛnw ni taamasiɲɛ bɛnnenw ye walasa k’a jira ko dingɛ ye counterbore walima spotface ye. O bɛ dɛmɛ don walasa ka mɔgɔw hakili ɲagami masinko waati la.

2.Aw bɛ hakɛ ɲɛfɔlenw di: Aw bɛ a cɛmancɛ, a juguman ani a hakɛ wɛrɛw jira minnu bɛ tali kɛ ɲɔgɔn na, minnu bɛ kɛ ka ɲɛsin fɛnw ma minnu bɛ kɛ ka fɛnw sɛgɛsɛgɛ walima minnu bɛ kɛ ka fɛnw sɛgɛsɛgɛ. Walasa ka fɛnw kunbɛn, aw bɛ sirilan kun janya jira walasa a ka se ka bɛn a ma ka ɲɛ.

3.Aw ye fɛn jateminɛ: Aw bɛ counterbore ni spotface depths ni diamètres sugandi minnu bɛnnen don fɛn ma min bɛ kɛ ni masin ye. Fɛn dɔw bɛ se ka kɛ fɛn ye min ka dɔgɔn walima min ka dun walasa ka u yɛrɛ tanga ko dɔw ma i n’a fɔ tigɛ walima ka don.

4.Aw ye miiri jamalajɛ wajibiyalenw na: Ni aw bɛ counterbore walima spotface dingɛw ɲɛfɔ, aw bɛ a lajɛ a yɔrɔw bɛna lajɛ cogo min na ani ni yɔrɔ gɛlɛya dɔw bɛ yen walima ni u sirilan wajibiyalen kɛrɛnkɛrɛnnen dɔw bɛ yen.

5.Communicate surface finish magow: Ni surface fini kɛrɛnkɛrɛnnen dɔ wajibiyalen don counterbore walima spotface la, aw ye aw jija ka o ɲɛfɔ ja kan walima dilancogo sɛbɛnw kɔnɔ.

Ni aw ye nin dilancogo jateminɛw ni wale ɲumanw kɛ, ɛntɛrinɛti ni fɛn dilannikɛlaw bɛ se ka dɛmɛ don walasa ka a dɔn ko fɛn minnu bɛ kɛ ka fɛnw kɛlɛ ani minnu bɛ kɛ yɔrɔ ye, olu ka kɛ masin ye ka ɲɛ ani ka ɲɛ.

Aplikasi ni ko kɛlenw sɛgɛsɛgɛli .

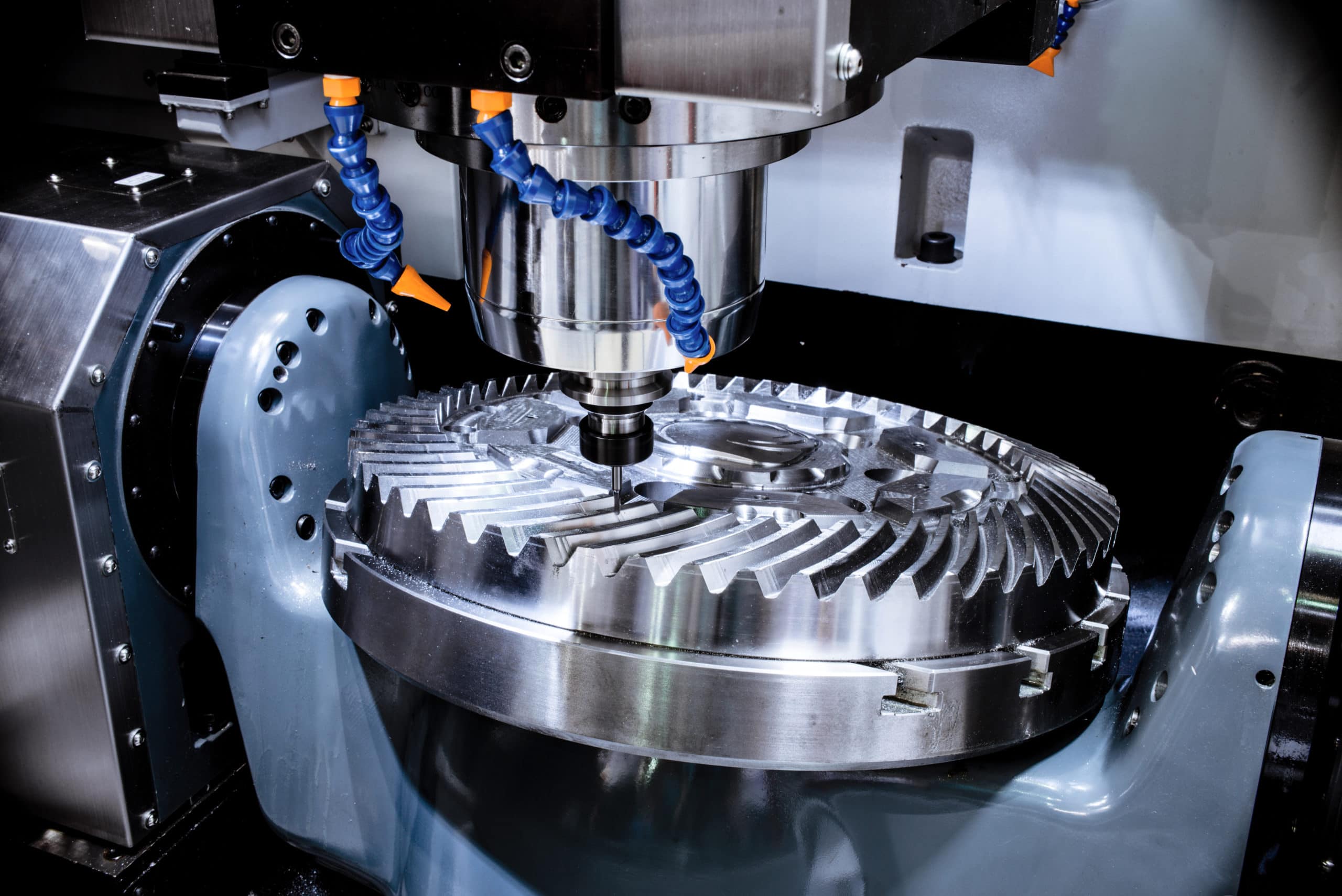

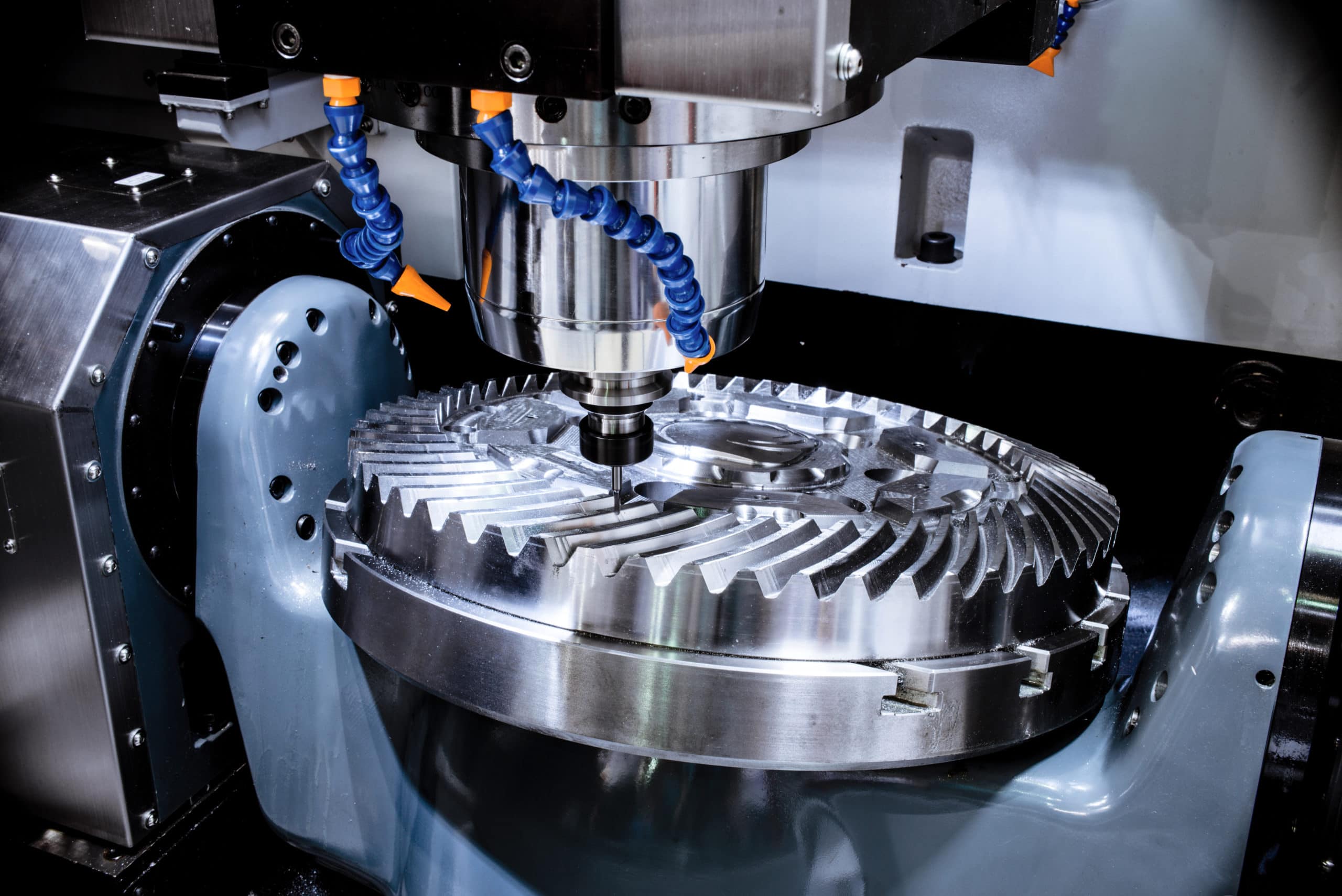

Industri kɛrɛnkɛrɛnnenw ka baarakɛminɛnw: aerospace, mobili, ani fɛn wɛrɛw .

Spotface ani counterbore dingɛw bɛ baarakɛminɛnw sɔrɔ izini caman kɔnɔ, u kelen-kelen bɛɛ n’a ka ɲininiw n’a ka gɛlɛyaw kɛrɛnkɛrɛnnenw. Misali la, aerospace (aerospace) baara la, o masinw ka baarakɛminɛnw nafa ka bon kosɛbɛ walasa ka ɲɔgɔndan lakananenw ni fɛnw falen-falen kɛ awiyɔn yɔrɔw ni ɲɔgɔn cɛ, i n’a fɔ jiginɛw ni motɛri yɔrɔw.

Mobiliko fana bɛ a jigi da kosɛbɛ spotface kan ani ka dingɛw kɛlɛ walasa ka motɛriw, suspension systems, ani fɛn nafama wɛrɛw lajɛ. O fɛnw bɛ a to u bɛ se ka ɲɔgɔn sɔrɔ cogo bɛnnen na, ka u siri cogo la min bɛ lakana, ani ka u yɛrɛ jira fɛn laban na.

Industri wɛrɛw, i n’a fɔ fɛn dilanni bɛɛ lajɛlen, masinw, ani jirifeere, olu fana bɛ baara kɛ ni spotface ni counterbore dingɛw ye baara suguya caman kama. K’a ta mebɛriw dilanni na ka se masinw ka baarakɛminɛnw lajɛli ma, o fɛnw jɔyɔrɔ ka bon kosɛbɛ ɲɔgɔndan barikamaw, minnu bɛ kɛ ka ɲɛ, ani minnu bɛ mɔgɔ ɲɛnajɛ.

Ko minnu kɛra: Spotface ani counterbore action .

Walasa ka spotface ni counterbore dingɛw nafa faamuya ka ɲɛ, an ka diɲɛ kɔnɔko lakika dɔw lajɛ.

Kalansen 1nan : Aerospace component assemblage .

Aerospace dilanko tɔnba dɔ tun bɛ ka koɲɛw sɔrɔ ni a yɔrɔba dɔ lajɛli ye k’a sababu kɛ sirilanw ye minnu ma bɛn. U kɛlen ka spotface dingɛw don dilan na, u sera ka sigiyɔrɔ fla, hali sigilanw dilan sirilanw kama, ka ɲɔgɔndan ɲuman sabati ani ka jɛɲɔgɔnya lakananen sɔrɔ. O yeli nɔgɔman in ye ɲɔgɔnyeko koɲɛw ban ani ka fɛn laban bɛɛ ka jogo ɲɛ.

Kalansen 2nan : Mobili motɛri dilanni .

Mobili dilannikɛla dɔ tun b’a fɛ k’u ka motɛri dilanni kɛcogo ɲɛ ani ka dɔ bɔ waati la min bɛ kɛ ka ɲɛsin fɛnw dilanni ni u saniyacogo ma. U kɛlen ka counterbore holes (boli-boli-yɔrɔw) waleya u ka dilancogo la, u sera ka saniya ni flush (flush) yecogo dɔ Dabɔ sirilanw ye ka sɔrɔ ka dɔ Bɔ fana a mago la ka baara wɛrɛw Kɛ kɔfɛ. O bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε bεε la.

Kalansen 3nan : Mebɛriw dilanni .

Mebɛri dilannikɛla dɔ tun bɛ gɛlɛyaw la ni u ka fɛn dilannenw yecogo cɛɲi ye k’a sababu kɛ u sirilan kunw ye minnu bɛ bɔ kɛnɛ kan. U kɛlen ka counterbore dingɛw don u ka dilanw kɔnɔ, u sera ka fɛn dɔ dilan min bɛ kɛ ka fɛnw siri, ka u ka minɛnw cogoya bɛɛ lajɛlen n’u cogoya bonya. O ɲɛtaa in ye dɛmɛ don walasa k’u ka fɛn dilannenw danfara bɔ sugu la min bɛ ɲɔgɔn sɔrɔ ani ka dɔ fara kiliyanw wasa kan.

Nin ko kɛlenw bɛ nafa yelenw jira, spotface ni counterbore dingɛw bɛ se ka na ni minnu ye iziniw ni baarakɛcogo caman na. Ni porozɛ kelen-kelen bɛɛ ka wajibi kɛrɛnkɛrɛnnenw n’a gɛlɛyaw faamuyara, ɛntɛrinɛti injiniyɛriw ni fɛn dilannikɛlaw bɛ se ka nin fɛn ninnu don a kɔnɔ ka ɲɛ walasa ka fɛn dilannenw cogoya ɲɛ, ka fɛnw dilanni kɛcogo ɲɛ, ani ka baarakɛlaw bɛɛ ka ko kɛlenw ɲɛ.

Ladilikan minnu bɛ sɔrɔ ka masinw kɛcogo ɲuman sugandi aw ka poroze kama .

Ni aw bɛ a latigɛ Spotface ni counterbore dingɛw cɛ aw ka poroze kama, aw ye nin laadilikan ninnu jateminɛ:

1.Aw ka ɲinini kɛcogo kɛrɛnkɛrɛnnenw jateminɛ. Aw ye fɛnw jateminɛ i n’a fɔ ɲɔgɔndan fanga wajibiyalen, fɛn laban yecogo yecogo, ani yɔrɔ walima lajɛli gɛlɛya o gɛlɛya.

2.Aw ye fɛnw jateminɛ minnu bɛ kɛ ka baara kɛ ni u ye. Fɛn suguya caman bɛ se ka kɛ ni masinw ka baarakɛcogo wɛrɛw ye walima fɛnw hakɛ danfaralenw walasa ka ɲɛtaa ɲininenw sɔrɔ. Misali la, fɛn minnu ka nɔgɔn, olu bɛ se ka kɛ yɔrɔ ye min ka dɔgɔn walima min bɛ kɛ ni fɛnw ye minnu bɛ se ka fɛnw tiɲɛ walasa u kana fɛn tiɲɛ walima ka u tigɛ.

3.Aw ye jateminɛ kɛ fɛn dilanni hakɛ ni a waatibolodacogo la. Sugandili min bɛ kɛ spotface ni counterbore dingɛw cɛ, o bɛ se ka nɔ bila a dilanni waati bɛɛ la ani a musaka la. Walasa ka fɛn caman sɔrɔ minnu bɛ kɛ ka caya, a bɛ se ka kɛ ko a bɛ se ka kɛ ka baara kɛ ni counterbore holes ye walasa ka dɔ bɔ baara kɔfɛ fɛɛrɛ wɛrɛw la.

4.Aw ye aw ka kalan kɛ ni masinw walima ɛntɛrinɛti kalanbagaw ye minnu bɛ se kosɛbɛ. Ni siga bɛ aw la, aw bɛ ladilikan ɲini baarakɛlaw fɛ minnu ka dɔnniya bɛ ni spotface ye ani ka dingɛw kɛlɛ minnu bɛ kɛ o cogo kelen na. U bɛ se ka hakilina nafamaw ni ladilikanw di ka da u ka dɔnniya kan.

5.Aw bɛ sɛgɛsɛgɛli kɛ ka ɲɛ ani ka prototyping kɛ. Sani aw ka aw ka dilancogo laban, aw bɛ prototypes (daɲɛ fɔlɔw) dilan ani ka sɛgɛsɛgɛli kɛ ka ɲɛ walasa ka a dɔn ko masinw ka baara kɛcogo sugandilen bɛ fɛn wajibiyalenw bɛɛ dafa ani ka baara kɛ i n’a fɔ a bɛ fɔ cogo min na a kɛcogo laban na.

Kuncɛli

Nin barokun in kɔnɔ, an ye danfaraba minnu bɛ spotface ni counterbore dingɛw cɛ, olu sɛgɛsɛgɛ, masin nafama fila minnu bɛ kɛ ka ɲɛ. Ni u ye u ka jogo kɛrɛnkɛrɛnnenw, masinw taabolo ani u kɛcogo faamuya, baarakɛlaw bɛ se ka latigɛ kɛ ni kunnafoni ye ni u bɛ fɛn bɛnnen sugandi u ka porozew kama. Spotface ni counterbore dingɛw jɔyɔrɔ ka bon kosɛbɛ walasa ka fɛnw lajɛlenw tiɲɛni, u dannaya, ani u kɛcogo ɲuman sabati izini suguya caman kɔnɔ. An bɛ ka taa a fɛ ka fɛn kuraw don fɛn dilanni na, ka nin fɛn misɛnninw fanga minɛ, nka fanga bɛ minnu na, o bɛna kɛ fɛnba ye walasa ka ɲɛtaa sɔrɔ an ka baarakɛyɔrɔ la min bɛ ka wuli tuma bɛɛ.

Ɲininkaliw jaabiw .

J: Danfara jumɛnw bɛ spotface ni counterbore dingɛw cɛ?

A: Spotface dingɛw ka surun, u bɛ kɛ yɔrɔ fla ye walasa ka sirilanw sigi. Kùncɛbaya dingɛw ka dun, o b’a To sirilan kunkolow bɛ Dòn a sanfɛla jukɔrɔ. Spotfacew bɛ ni silinda nɔgɔman ye, ka sɔrɔ counterbores bɛ ni stepped profile ye.

J: Ne bɛ se k’a latigɛ cogo di ko n bɛna baara kɛ ni spotface walima counterbore hole ye n ka poroze kama?

A: Aw ye aw ka baarakɛcogo wajibiyalenw jateminɛ, i n’a fɔ ɲɔgɔndan fanga ani yecogo. Aw bɛ baara kɛ ni fɛn minnu ye, olu jateminɛ, bawo dɔw bɛ se ka fɛnw hakɛ danfaralenw de wajibiya. Aw ye aw lajɛ ni masinw walima injiniyɛriw ye minnu bɛ se kosɛbɛ ani ka sɛgɛsɛgɛli ni prototyping kɛ ka ɲɛ.

J: Spotface ni counterbore dingɛw bɛ se ka dabɔ ni o baarakɛminɛn kelenw ye wa?

A: Hali ni baarakɛminɛn dɔw, i n’a fɔ End Mills ani Reamers, olu bɛ se ka kɛ o fila bɛɛ la, baarakɛminɛn kɛrɛnkɛrɛnnenw bɛ sɔrɔ. A ka c’a la, counterbore baarakɛminɛnw bɛ ni piloti tip ani u juguya ye min bɛ se ka ladilan, ka sɔrɔ spotface baarakɛminɛnw tigɛ janya ka surun. Baarakɛminɛn sugandili bɛ bɔ baara wajibiyalen kɛrɛnkɛrɛnnenw na.

J: fili dɔw ye jumɛnw ye minnu bɛ kɛ tuma caman na ni i bɛ ka dilan dingɛ suguya fila la kelen na?

A: A jɛlen don ko a yɔrɔ suguya bɛ baara kɛ ni taamasiyɛn bɛnnenw ye ani labeli ye walasa ka mɔgɔw hakili ɲagami masinw senfɛ. Aw bɛ hakɛ caman di, i n’a fɔ a cɛmancɛ, a juguman ani a sirilan kunkolo janya ka ɲɛsin counterbores ma. Aw ye fɛnw ni ɲɔgɔn cɛ wajibiyalenw jateminɛ ni u bɛ juguya ni u cɛmancɛw ɲɛfɔ.

J: counterbore ni spotface holes bɛ dɛmɛ don cogo di fɛn dilanni taabolo la?

A: counterbore ani spotface holes bɛ a to a bɛ bɛn ka ɲɛ, a sirili ka ɲɛ, ani a bɛ kɛ cogo saniyalen na, a bɛ se ka kɛ a ka baara laban na. U bɛ se ka sɛnɛfɛnw bɔli nɔgɔya ni u mago bɛ baara kɔfɛ fɛɛrɛ wɛrɛw la ani ka ɲɔgɔn dalajɛ filiw farati dɔgɔya. O fɛnw bɛ kɛ sababu ye ka fɛn dilanni taabolo bɛɛ lajɛlen nafa ani a musaka dɔgɔya.

J: Yala counterbore hole bɛ se ka wuli ka kɛ spotface hole ye walima a kɔfɛ wa?

A: Ka counterbore dingɛ dɔ tigɛli kɛ spotface dingɛ ye, o bɛ se ka kɛ ni dingɛ in dilanni ye fo ka se a jugumanba ma. Nka, ka spotface (yɔrɔ) tigɛli kɛ counterbore (kɔrɔnfɛla) ye, o bɛ se ka kɛ gɛlɛya ye ka tɛmɛ, bawo a bɛ dingɛ juguyali de wajibiya. A ka fisa ka fɛn bɛnnen dilan ani ka a masina kabini a daminɛ na.

J: fili jumɛnw bɛ sɔrɔ ka bɔ ɲɔgɔn na counterbore ani spotface machining kɔnɔ?

A: Aw bɛ aw jija ka ɲɔgɔndɛmɛ ni ɲɔgɔndɛmɛ ɲuman sɔrɔ piloti dingɛ ni masina yɔrɔ cɛ walasa ka aw tanga dingɛw ma minnu tɛ u cɛmancɛ la walima minnu bɛ kɛ kɛrɛ fɛ. Baara kɛ ni baarakɛminɛnw ye minnu ka nɔgɔn, minnu ka ɲi kosɛbɛ, minnu bɛ ni finimugu bɛnnenw ye ani minnu tigɛcogo bɛnnen don walasa ka se ka dugukolo sanfɛla laban sɔrɔ. Aw bɛ baara kɛ ni fiɲɛbɔli ni baarakɛcogo ɲuman ye walasa ka baarakɛminɛnw sabatili mara masinko siratigɛ bɛɛ la.

J: Fɛn minnu bɛ kɛ ka ɲɛsin dugukolo sanfɛla finiko ma, olu ni ɲɔgɔn cɛ danfara bɛ cogo di?

A: Spotface dingɛw ka teli ka kɛ ka ɲɛsin a sanfɛla dafalen ma, bawo u kuntilenna fɔlɔ ye ka sigiyɔrɔ ɲuman sɔrɔ. Kɔnɔnatumuw bɛ se ka kɛ ni fini ye min bɛ gɛlɛya dɔɔni kɛrɛfɛ, nka a duguma yɔrɔ ka kan ka kɛ fɛn ye min bɛ kɛ ka ɲɛ hali bi. Surface Finish wajibiyalenw kɛrɛnkɛrɛnnenw ka kan ka fɔ dilancogo sɛbɛnw kɔnɔ.