Titanium is a remarkable metal with outstanding properties that make it highly desirable for various industries. Here are some key characteristics and benefits of titanium:

● High Strength: Titanium has an excellent strength-to-weight ratio, making it incredibly strong while being lightweight.

● Corrosion Resistance: Titanium is highly resistant to corrosion, even in harsh environments like seawater, acids, and chlorine.

● Heat Resistance: Titanium can maintain its strength and durability even when exposed to extremely high temperatures.

● Biocompatibility: Titanium is non-toxic and compatible with human biology, making it ideal for medical implants and devices.

● Lightweight: Titanium weighs around half as much as copper and slightly more than half of stainless steel, making it an excellent choice for applications where weight is a concern.

Some common applications of titanium include:

● Aerospace engineering (aircraft engines, airframes, rotors)

● Medical industry (surgical implants, instruments, wheelchairs)

● Automotive industry (engine components, suspension springs)

● Sports equipment (golf clubs, bike frames, baseball bats)

CNC (Computer Numerical Control) machining plays a crucial role in modern manufacturing processes, particularly when working with materials like titanium. Here are some key reasons why CNC machining is important:

● Precision: CNC machines can produce parts with extremely high levels of accuracy and precision, ensuring consistent quality.

● Efficiency: CNC machines can operate continuously, reducing labor costs and increasing production output.

● Versatility: CNC machines can be programmed to produce a wide range of complex shapes and designs, enabling manufacturers to meet diverse product requirements.

● Repeatability: CNC programs can be stored and reused, allowing for consistent and repeatable production of parts.

In the case of titanium, CNC machining is often the preferred manufacturing technique due to the following reasons:

● Titanium is difficult to cast or mold effectively due to its high melting point and reactivity with oxygen.

● CNC machining provides the accuracy and precision required for producing high-quality titanium parts.

● It allows for the creation of intricate shapes and designs that would be challenging to achieve through other manufacturing methods.

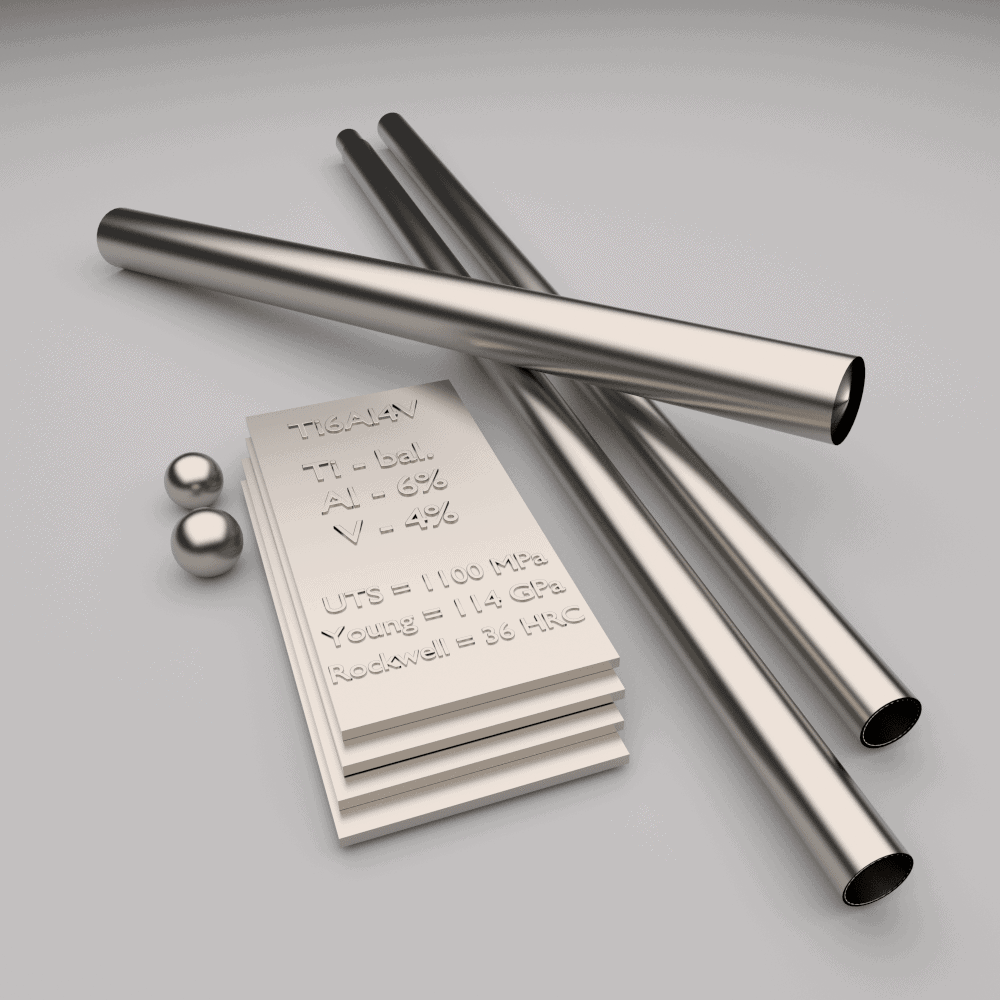

Titanium alloys can be broadly classified into three categories:

● Pure Titanium: This refers to titanium with no added alloying elements. Pure titanium is relatively soft and easy to machine.

● Alpha Alloys: These alloys contain alloying elements like aluminum, oxygen, and nitrogen. They are stronger than pure titanium but less ductile.

● Beta Alloys: These alloys contain alloying elements like molybdenum, iron, vanadium, chromium, and manganese. They are more ductile and can be heat-treated to increase strength.

Pure titanium, also known as commercially pure (CP) titanium, has the following properties:

● Excellent Corrosion Resistance: Pure titanium is highly resistant to corrosion, even in harsh environments.

● Good Formability: Pure titanium is relatively soft and ductile, making it easy to form and machine.

● Moderate Strength: While not as strong as titanium alloys, pure titanium still has good strength compared to other metals.

Common grades of pure titanium include Grade 1 (low oxygen content), Grade 2 (standard oxygen content), Grade 3 (medium oxygen content), and Grade 4 (high oxygen content).

Alpha Titanium Alloys:

● Contain aluminum and tin as primary alloying elements

● Have good strength and creep resistance at high temperatures

● Less ductile than beta alloys

● Example: Ti-5Al-2.5Sn (Grade 6)

Beta Titanium Alloys:

● Contain elements like vanadium, molybdenum, and iron

● More ductile and formable than alpha alloys

● Can be heat-treated to increase strength

● Example: Ti-6Al-4V (Grade 5)

Grade | Alloy/CP | Strength | Formability | Machinability | Typical Applications |

1 | CP | Lowest | Excellent | High | Chemical processing, medical |

2 | CP | Low | High | Moderate | Aerospace, marine |

3 | CP | Medium | Moderate | Low | Airframes, cryogenics |

4 | CP | High | Low | Very Low | Aerospace, industrial |

5 | Ti6Al4V | Very High | Moderate | Low | Aerospace, medical implants |

6 | Ti5Al2.5Sn | High | Moderate | Moderate | Aerospace, engine parts |

7 | Ti-0.15Pd | Low | High | High | Chemical processing |

11 | Ti-0.15Pd | Low | High | High | Desalination, chemical processing |

12 | Ti-0.3Mo-0.8Ni | High | Moderate | Moderate | Marine, chemical systems |

23 | Ti6Al4V ELI | High | High | Low | Orthopedic and dental implants |

When choosing a titanium alloy for machining, consider the following factors:

● Strength Requirements: If high strength is needed, choose a beta alloy like Ti-6Al-4V (Grade 5).

● Formability: For applications requiring high formability, pure titanium (Grades 1-4) or alpha-beta alloys like Ti-6Al-4V (Grade 5) are good choices.

● Machinability: Pure titanium (Grades 1-2) and some alpha alloys are easier to machine than beta alloys.

● Corrosion Resistance: For highly corrosive environments, pure titanium (Grades 1-4) or beta alloys like Ti-0.3Mo-0.8Ni (Grade 12) are recommended.

● Cost: Pure titanium and alpha alloys are generally less expensive than beta alloys.

Titanium has several advantages that make it an attractive choice for various applications:

● High Strength-to-Weight Ratio: Titanium is incredibly strong while being lightweight, weighing about half as much as copper.

● Excellent Corrosion Resistance: Titanium is highly resistant to corrosion, even from substances like seawater, chlorine, and acids.

● Heat Resistance: Titanium can maintain its strength and durability at extremely high temperatures.

● Biocompatibility: Titanium is non-toxic and compatible with human biology, making it ideal for medical implants and devices.

● Machinability: Despite its challenges, titanium can be machined using the right techniques and tools.

● Recyclable: Titanium is recyclable, making it an environmentally friendly choice.

While titanium offers many benefits, it also presents several challenges during machining:

● Heat Buildup: Titanium has low thermal conductivity, causing heat to accumulate at the cutting tool, leading to rapid tool wear.

● Galling: Titanium can adhere to the cutting tool, a phenomenon known as galling, which can damage the tool and the workpiece.

● Chatter and Vibration: Titanium's low modulus of elasticity can cause severe chatter and vibration during machining, affecting surface quality.

● Work Hardening: Titanium can work-harden during machining, becoming harder and more abrasive, further increasing tool wear.

● Cost: Titanium is an expensive material compared to other metals like aluminum or steel.

Titanium vs. Steel:

● Titanium is lighter and more corrosion-resistant than steel.

● Steel is generally cheaper and easier to machine than titanium.

● Titanium has a higher strength-to-weight ratio than steel.

● Titanium is stronger and more heat-resistant than aluminum.

● Aluminum is less expensive and easier to machine than titanium.

● Titanium has a higher strength-to-weight ratio than aluminum.

While titanium offers superior properties, its challenges and cost often make it a choice for applications where its advantages outweigh the drawbacks, such as in aerospace, medical, and high-performance industries.

Titanium is a highly reactive metal. It can react with gases during machining, leading to problems like surface oxidation and embrittlement. This can weaken the components and reduce their corrosion resistance.

Titanium also has a low modulus of elasticity compared to its high strength. This makes it a "gummy" material to machine. Titanium can adhere to the cutting tool, causing tool failure and damage. This is known as galling.

Galling also affects the surface finish quality of the machined titanium parts.

Keeping the temperature cool during machining is a major challenge with titanium. Titanium has low thermal conductivity, which causes heat buildup at the cutting tool location. This leads to rapid tool wear and can negatively impact the quality of the cut surfaces.

Harder titanium alloys require even more care. Larger chip loads and lower RPM on the CNC machine are recommended. Using a high-pressure coolant can also help the cutting tools work better and produce higher quality titanium parts.

Titanium alloys also require high cutting forces, which makes them difficult to cut. These forces can cause:

● Rapid tool wear

● Faulty parts

● High vibration, impacting product quality and surface finish

Titanium alloys have a crystal structure that makes them less flexible. This can increase cutting forces during machining, reducing machinability.

The crystal structure can also lead to residual stresses in the workpiece. These stresses can cause:

● Warping or twisting of the part

● Cracking

● Reduced part lifespan

Titanium's low flexibility also contributes to strain hardening during machining. As the material is cut, it becomes harder and more abrasive to the cutting tools.

Quick Reference Table of Machining Titanium Challenges

| Challenge | Effect | Countermeasure |

|---|---|---|

| Heat build-up | Tool wear, surface burns | High-pressure coolant, sharp tools |

| Work hardening | Higher cutting resistance | Aggressive but controlled cuts |

| Elasticity | Chatter, dimensional errors | Rigid fixturing, dampened tools |

| Low chip conductivity | Chips retain heat | Chip breakers, effective evacuation |

| Reactivity | Tool welding, galling | Coated tools (TiAlN, AlTiN) |

Titanium is a tough material to work with. It has a combination of properties that make conventional machining methods ineffective. Understanding these challenges is important for finding solutions to produce high-quality machined titanium parts.

● Heat Accumulation: Titanium's low thermal conductivity causes rapid heat buildup at the tool location. This increases tool wear and hardens the titanium further, exacerbating the problem.

● "Gummy" Material: Titanium's low modulus of elasticity compared to its high strength makes it a "gummy" material. It can adhere to the cutting tool, causing tool failure and poor surface finish.

● Chatter and Springback: Titanium's elasticity can cause workpiece vibration (chatter) and springback at the cut location, creating poor machining conditions and compromising tolerances.

Choosing the right cutting tool is crucial for machining titanium. Coated high-speed steel tools, made of tungsten, carbon, and vanadium, can maintain hardness up to 600°C. They allow deeper cuts and reduce chipped edges.

As titanium's popularity grows, tool manufacturers are developing specialized solutions:

● Coatings: Heat-resistant coatings like titanium aluminum nitride (TiAlN) or titanium carbo-nitride (TiCN) can extend tool life.

● Uneven Cutting Edges: Uneven spacing between cutting edges helps disrupt chatter.

Use high-quality titanium-specific tools and replace dull tools frequently. Consider smaller diameter tools with more cutting edges to maintain metal removal rates while reducing heat buildup.

Tool coatings can greatly improve a tool's ability to withstand the heat generated when machining titanium. TiAlN (titanium aluminum nitride) is a suitable coating that:

● Provides lubricity to combat built-up edges, galling, and chip welding.

● Is well-suited for the high temperatures experienced when machining titanium.

Titanium is prone to causing tool chatter (vibration), so reducing vibration is crucial. Secure the workpiece firmly to prevent deflection. Use high-quality CNC machines with extremely rigid tooling setups. Consider using shorter cutting tools to reduce tool deflection.

Conventional Milling: In this traditional method, chip width starts thin and increases, putting more heat into the workpiece and increasing strain hardening.

Climb Milling: Chip width starts high and decreases, promoting heat transfer to the chip instead of the workpiece. It also creates a cleaner shear and pulls chips behind the cutter, preventing interference.

Climb milling is a useful strategy to keep chips in check when machining titanium.

Keeping the temperature down is crucial when machining titanium. Since titanium doesn't conduct heat well, most of the energy goes into the cutting tool. This heat can cause:

● Premature tool failure

● Dulling of tools and more rubbing, generating even more heat

● Fire risk with some materials

Use generous amounts of coolant to bring down temperatures. A high-pressure cooling system that blasts the work area and tool with 10% concentrated coolant works well. Increasing coolant concentration may also help.

Exposing your tools to shock and jarring forces adds extra strain, leading to quicker wear. Avoid inserting the tool directly into the titanium. Instead:

● Gently arc the tool inward to ease it into the cut

● Follow thick-to-thin milling in the same direction (clockwise or counterclockwise) as the tool

At the end of the cut, use a chamfer (sloped groove). This lets the tool gradually lose depth, easing the transition with less force.

Sharp tools are necessary for efficient titanium cutting. However, titanium can quickly dull your tools. Inspect them regularly and replace any showing signs of wear.

A dull tool will generate more heat and wear out even faster, compounding the issue.

Galling: Titanium readily alloys with other materials, causing galling and rewelding of edges during cutting. Keeping heat down, using sharp tools, and lubricants can reduce this.

Chipping: When metal pieces being cut off compress and adhere to the cutting edge, it's called chipping. More buildup impacts performance and can severely damage the tool.

Sharp tools and lubricants also help minimize chipping during titanium machining.

One of the biggest challenges when machining titanium is keeping everything cool. Titanium's low thermal conductivity causes rapid heat buildup at the tool location.

An obvious solution to excessive heat is using more coolant. Blasting the work zone and tool with 10% concentrated coolant will keep the contact area cool. It will also wash away any heat-carrying chips.

For turning applications, the position and pressure of the coolant are crucial. With the right application, much higher surface speeds and metal removal rates can be achieved.

However, high-pressure coolant can sometimes cause material redeposition onto the part's surface. This can be overcome by planning the cutting strategy and reducing coolant pressure for the final finish cuts.

Titanium is prone to work hardening. As the material is cut, it becomes harder and more abrasive to the tooling.

Maintaining a constant feed rate ensures that cutting work-hardened material is kept to a minimum. This prevents further work hardening and excessive tool wear.

If possible, increasing the feed rate can be beneficial. It means the tool spends less time in a specific area, allowing less heat buildup and work hardening at the cutting edge.

Carbide-tipped tools with a PVD coating are best suited for cutting titanium. Newer coatings like TiAlN (titanium aluminum nitride) are also available.

Titanium is a relatively springy material, so a sharp tool is absolutely critical. Blunt tools will rub the surface and cause chatter.

Coatings like TiAlN improve a tool's ability to withstand the high heat when machining titanium. They provide lubricity and are well-suited for high temperatures.

Regular tool inspection and replacement of dull tools is necessary, as dull tools generate more heat and wear out faster.

Titanium can produce long chips that can easily damage tooling and mark the workpiece surface. Long, thin chips also do not assist with transferring heat away from the work zone.

Using tooling and tool paths that create smaller, thicker chips is ideal when machining titanium. Proper chip control is essential.

Secure workholding is critical when machining titanium. It removes vibration from the process, allowing better cutting data.

Many titanium parts have thin sections, so using custom workholding solutions for final operations yields better results. It often allows greater access and support for the component.

Choosing the right tool path is as important as selecting the correct tool when machining titanium.

Tool paths that ensure constant cutter engagement in the workpiece are necessary. For example, a trochoidal pattern when cutting a slot reduces the time any one flute is engaged, limiting heat buildup.

Arcing the tool into and out of the workpiece reduces shock and abrupt motions that can severely damage tools.

After CNC machining, titanium parts can be improved with various surface finishing treatments. These treatments can serve functional or aesthetic purposes.

Polishing is a common surface finishing technique. It helps to smoothen and enhance the appearance of titanium parts.

Anodizing is an electrochemical process that creates a durable, decorative oxide coating on the titanium surface. It improves corrosion and wear resistance.

Chroming involves depositing a thin layer of chromium onto the titanium part. It enhances surface characteristics like appearance, hardness, and corrosion resistance.

Powder Coating is a dry finishing process where a charged powder is applied and then cured under heat. It offers excellent durability and corrosion protection for titanium parts.

PVD (Physical Vapor Deposition) Coating is a vacuum deposition process that creates very thin, hard coatings on titanium parts. PVD coatings improve properties like wear and corrosion resistance.

Brushing is a simple mechanical process of creating patterns or textures on the titanium surface using abrasive filaments. It can produce attractive finishes like hairline or circular brush patterns.

These surface treatments allow titanium's properties to be tailored for specific functional requirements or desired aesthetic effects in various applications.

Titanium is widely used in the aerospace industry due to its exceptional properties. It has a high strength-to-weight ratio, outstanding corrosion resistance, and can withstand extremely hot environments.

In aerospace, CNC machined titanium parts include:

● Aircraft engine components like turbine blades and compressor parts

● Airframe structures and components

● Rotors and shafts

Titanium drives aircraft production - about two-thirds of global titanium supply goes into aircraft engines and airframes.

Compared to most metals, titanium has superior corrosion resistance. This makes it perfect for withstanding the harsh seawater environment in marine applications.

Titanium marine parts include:

● Propeller shafts

● Underwater robotics components

● Rigging equipment

● Ball valves

● Marine heat exchangers

● Fire system piping

● Pumps

● Exhaust stack liners

● Onboard cooling systems

While aluminum dominates the automotive sector, titanium's exceptional properties make it suitable for certain automotive parts:

● Engine valves and valve springs

● Retainers

● Suspension springs

● Brake calipers and pistons

● Connecting rods

● Piston pins

● Engine rockers

Titanium improves performance while reducing weight in these components.

Titanium's biocompatibility, corrosion resistance, and low electrical conductivity make it vital for medical applications. Its physiological pH values promote osseointegration (bone-implant bonding).

Common medical titanium parts include:

● Orthopedic implants (hip, knee)

● Bone plates and screws

● Spinal fixation rods, plates, connectors

● Dental implants, bridges, crowns

● Surgical instruments

Titanium's properties allow it to be used inside the human body, impacting lives daily.

CNC machining titanium is often 3–5 times more expensive than machining aluminum or steel, even for parts of similar geometry. Understanding where these costs come from helps engineers and buyers make smarter design and sourcing decisions.

| Cost Driver | Details | Impact on Cost |

|---|---|---|

| High Raw Material Cost | - Titanium billets cost far more than aluminum or steel due to refining complexity. - Aerospace-grade alloys like Ti-6Al-4V can be up to 10× the price of aluminum per kg. - Scrap (chips, offcuts) often cannot be reused for aerospace/medical applications. | Increases material cost per part and raises the financial risk of scrap or mistakes. |

| Slow Cutting Speeds & Feed Rates | - Titanium’s low thermal conductivity traps heat at the tool tip. - Requires slow feeds and shallow depths of cut. | Longer cycle times → higher machine-hour costs. |

| Tool Wear & Frequent Replacement | - Titanium is abrasive and chemically reactive with cutting tools. - Even coated carbide wears out quickly; advanced tooling (ceramic, PCD) is costly. - Frequent tool changes reduce uptime. | Raises tooling expenses and reduces productivity. |

| Special Fixturing & Machine Setup | - Titanium’s elasticity causes chatter and tool deflection. - Needs rigid fixtures, vibration damping, and high-power CNC machines. | Higher setup costs, especially uneconomical for small batches. |

| Scrap & Rework Risks | - Harder to hold tolerances due to distortion and heat. - Scrap = expensive because both material + machining time are lost. - A single rejected aerospace part can cost hundreds of dollars. | Drives up waste costs and increases project risk. |

| Part Type | Material | Typical Unit Cost | Notes |

|---|---|---|---|

| Aerospace Bracket | Aluminum 6061 | $100 | Fast machining, lower tool wear |

| Aerospace Bracket | Titanium Ti-6Al-4V | $300–$400 | Higher raw material + slow machining |

Note: Costs vary by geometry, volume, and tolerance, but titanium almost always requires more investment.

| Strategy | How It Works | Cost-Saving Benefit |

|---|---|---|

| Optimize Part Design for Machining | - Avoid deep pockets, thin ribs, and overly complex features. - Maintain uniform wall thickness to reduce distortion. | Reduces machining time, rework, and scrap risk. |

| Choose the Right Alloy for the Job | - Not all parts need Ti-6Al-4V aerospace grade. - Use commercially pure titanium or lower-strength alloys for marine/medical use. | Cuts raw material costs while meeting performance requirements. |

| Leverage Additive + Subtractive Hybrid Manufacturing | - 3D print a near-net titanium blank, then CNC machine only critical areas. | Lowers waste material and shortens machining cycles. |

| Batch Production When Possible | - Titanium machining setup is expensive for single parts. - Spreading setup across medium-volume runs improves efficiency. | Reduces per-part cost by distributing setup and tooling expenses. |

| Use Advanced Toolpath Strategies (CAM Software) | - Apply high-efficiency milling (HEM) and adaptive toolpaths. - Improves chip evacuation and heat control. | Extends tool life by 20–40% and boosts throughput. |

| Partner with Experienced Titanium Machinists | - Specialized shops know how to minimize scrap, tool wear, and vibration. - They optimize cutting parameters and fixturing. | Lowers total project cost, even if hourly shop rates are higher. |

Bottom Line: Titanium machining is costly, but with smart design choices, process optimization, and supplier selection, you can cut total expenses by 20–40% while still leveraging titanium’s unmatched performance.

TEAM MFG stands out in the precision machining industry with its state-of-the-art technology and profound expertise, particularly in the realm of CNC machining titanium. The company's advanced machining capabilities are designed to tackle the unique challenges presented by titanium's properties, ensuring precision, efficiency, and quality in every component produced.

The foundation of TEAM MFG's success in titanium machining lies in its adoption of cutting-edge equipment and techniques. Equipped with 5-axis CNC machines, TEAM MFG can perform complex cuts and intricate details on titanium parts with unmatched accuracy. This capability is crucial for industries requiring high precision components, such as aerospace and medical devices.

Furthermore, TeamMfg's commitment to innovation extends to its tooling and programming strategies, specifically tailored for titanium machining. By selecting high-quality tools and optimizing machining parameters, TeamMfg minimizes common issues such as tool wear and material deformation, ensuring a seamless manufacturing process from start to finish. Contact Us today! to discuss your titanium project and get expert guidance.

TEAM MFG's portfolio of success stories reflects the diversity and complexity of projects that the company has undertaken. One notable example includes the production of aerospace-grade titanium components, where TEAM MFG's expertise significantly reduced production time and costs while maintaining strict aerospace standards.

Another success story highlights TEAM MFG's role in the medical industry, where the company's precision machining services facilitated the creation of advanced titanium medical implants. These implants, known for their biocompatibility and durability, have enhanced patient outcomes and further established TEAM MFG as a trusted partner in medical manufacturing.

These success stories demonstrate not only TEAM MFG's technical abilities but also its commitment to customer satisfaction and project success. By collaborating closely with clients, understanding their unique needs, and leveraging its advanced machining capabilities, TEAM MFG has helped numerous businesses transform their innovative ideas into tangible, high-quality titanium parts.

Partnering with TEAM MFG for titanium machining means more than just accessing superior machining services; it's about joining forces with a dedicated ally committed to pushing the boundaries of manufacturing excellence. Whether you're in the aerospace, automotive, medical, or marine industry, TEAM MFG's tailored solutions and unwavering support will ensure your titanium machining projects are successful, on time, and within budget.

TEAM MFG has made lots of titanum parts and prototypes for our customers, they are mostly used in aerospace, medical, and automotive:

| Case | Project Overview | Material & Process | Key Features & Results | Customer Benefit |

|---|---|---|---|---|

| 1. Aerospace Bracket Prototype | A leading aerospace client needed lightweight but strong titanium brackets for interior aircraft structures. | - Material: Ti-6Al-4V (Grade 5 Titanium) - Process: 5-axis CNC milling, precision finishing | - Dimensional accuracy within ±0.02 mm - Surface roughness Ra 0.8 µm - 35% lighter than aluminum version | - Improved structural performance - Increased fuel efficiency |

| 2. Medical Implant Components | A medical device manufacturer required biocompatible titanium implant parts with a fine surface finish. | - Material: Grade 2 & Grade 5 Titanium - Process: CNC turning, precision polishing | - Tolerance: ±0.01 mm - Smooth, mirror-like finish suitable for implants | - Long-term body compatibility - Excellent corrosion resistance |

| 3. Automotive Exhaust Flanges | A European motorsport customer needed titanium flanges that could endure high heat and vibration. | - Material: Ti-6Al-4V - Process: CNC milling, threading, bead blasting | - High thermal stability - Enhanced surface strength - Weight reduction vs. stainless steel | - Improved vehicle performance - Better heat management |

| 4. Custom Titanium Prototype Parts | TEAM MFG regularly supports R&D clients with rapid titanium prototypes for mechanical testing. | - Material: Ti-6Al-4V or CP Titanium - Process: CNC milling, EDM, drilling | - Fast turnaround (within 5–7 days) - Custom geometry and fine detailing | - Faster product validation - Reduced development cost |

Titanium is an exceptional material with a remarkable combination of properties like high strength, lightweight, corrosion resistance, and ability to withstand extreme temperatures. However, these same qualities that make it so desirable also create significant challenges when machining titanium parts.

Overcoming issues like rapid heat buildup, galling, chatter, and work hardening requires carefully controlling factors like:

● Using optimized cutting tools and coatings designed for titanium

● Maintaining rigid and stable setups to minimize vibration

● Adjusting cutting parameters like feed rates and applying high-pressure coolant

● Implementing strategies like climb milling for better chip control

Mastering these techniques allows manufacturers to unlock titanium's full potential across diverse industries.

As manufacturing technologies continue advancing, we can expect to see titanium used more widely across multiple sectors. Improvements in CNC machining capabilities, additive manufacturing processes for titanium, and new titanium alloy developments will drive this expansion.

Aerospace will remain a major driver of titanium demand. But we will also witness growing titanium applications in automotive, energy, consumer goods, and especially the medical field due to its biocompatibility.

With the right expertise and cutting-edge equipment, manufacturers can overcome titanium machining challenges. This will unlock new opportunities to leverage this exceptional metal's properties in innovative products that were previously impossible or uneconomical to produce.

A: Coolant choice is crucial. High-pressure, 10% concentrated coolant cools the tool. Proper coolant prevents overheating, prolonging tool life.

A: Common issues include heat buildup, galling, chatter, and work hardening. These challenges require specialized techniques to overcome.

A: No, standard tools are ineffective. Use coated carbide tools designed specifically for titanium to prevent premature wear.

A: Titanium's low thermal conductivity leads to concentrated heat buildup. Its low modulus makes it "gummy" and prone to chatter.

A: Titanium's heat resistance leads to higher cutting forces required. Proper cooling and optimized parameters are necessary.

A: Climb milling promotes heat transfer to chips instead of workpiece. It also reduces rubbing for better surface finish.

A: Use appropriate coatings like TiAlN and replace dull tools regularly. Stable setups and optimized parameters also reduce wear.

A: Aerospace, medical, automotive, and marine industries utilize machined titanium for its strength, biocompatibility, and corrosion resistance.

TEAM MFG is a rapid manufacturing company who specializes in ODM and OEM starts in 2017.