Yu dɔn ɛva wɔnda aw dɛn fayn fayn tin dɛn we dɛn mek wit mɛtal we de na di bildin dɛn we de naw, dɛn kin mek? Embossed metal sheets ripresent wan pan di most versatile innovations in architectural en industry materials. Dɛn ɛnjɛnɛri sɔfays ya de kam togɛda wit aesthetic apil wit ɛnhans funkshɔnaliti, we de ɔfrɛd te to 40% big trɛnk pas standad mɛtal shit dɛn we de gi supia slip rɛsistɛns ɛn vijual intɛres.

Frɔm slip bildin fasad to industrial flooring, ɛmbos mɛtal sheet dɛn dɔn rivɔlɔshɔn aw wi de aproch ɔl tu fɔm ɛn wok na kɔnstrɔkshɔn. Dis kɔmprɛhɛnsif gayd de ɛksplɔrɔ ɔl wetin yu nid fɔ no bɔt dɛn wɔndaful tin ya – dɛn kayn, bɛnifit, aplikeshɔn, ɛn manufakchurin prɔses.

Wetin na ɛmbos mɛtal sheet dɛn?

Metal embossing de transfom plain metal surfaces to patterned sheets tru preshos-based teknik. I de mek dizayn dɛn we dɛn rayz ɔ we gɛt pwɛl at ɛn we de ɛp fɔ mek ɔl tu di wok dɛn we dɛn de du ɛn di we aw dɛn de mek fayn fayn wan.

Di kɔr prɔses:

Di tin dɛn we bin dɔn apin trade trade:

Fɔs, na bin wan manual kraft sɛntiwɔd bifo, mɛtal ɛmbos bin evolv frɔm han-hama dɛkɔretiv pis to mɔdan industrial prɔses. Teknɔlɔji advansmɛnt bin briŋ prɛsishɔn ɛn mas prodakshɔn kapabiliti.

Ki Difrɛns vs Rigyul Shit dɛn:

| Ficha | Rigyul Shit dɛn | ɛmbos Shit dɛn |

| Sho | Flat | Teksturad di . |

| Trɛnk | Advays | Enhansed . |

| Ol | Men | Anti-slip we dɛn de yuz fɔ slip . |

| Yuz dɛn . | Kɔmɔn | Specialized . |

Di aplikeshɔn dɛn we de naw:

️ Kɔnstrɔkshɔn matirial dɛn .

Awtomotiv Kɔmpɔnɛnt dɛn .

Ikwipmɛnt fɔ Indastrial .

Akitekchɔral ɛlimɛnt dɛn .

Di bɛnifit dɛn we yu go gɛt we yu yuz ɛmbos mɛtal sheet dɛn .

Struktural ɛnhansmɛnt:

Metal embossing de transfom plain sheets to stronger surface tru stratejik patɛn plesmɛnt. Di patɛns dɛn de wok lɛk smɔl smɔl sɔpɔt bim dɛn, dɛn de sheb di wet ɛn prɛshɔn akɔdin to di wan ol sɔfa. Dis modifyeshɔn de inkrisayz di matirial in lod-bearing kapasiti bay te to 30%, we de mek:

Difɔmeshɔn rɛsistɛns .

Impɛkt absɔpshɔn .

Stret Distribushɔn .

Wear Reduction .

Durability Boost: .

Embossed patterns de mek wan protɛktiv layt agens ɛvride wear. Di rayz tɛkstɔr dɛn kin absɔb impak, mek dɛn nɔ pwɛl di sɔfays, ɛn ɛkstɛnd di prɔdak layf. Mɔs pan di ɛmbos shit dɛn kin las 40% lɔng pas di wan dɛn we de na di plain, we de mek shɔ se:

Supiriɔs impak rɛsistɛns .

Bɛtɛ Lod Distribushɔn .

Enhansed Stress Handling .

Ridyus di we aw dɛn de wɛr .

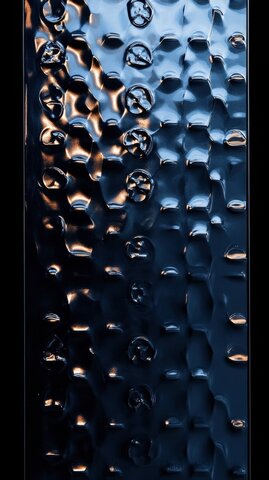

Di impak we pɔsin kin gɛt we i de si:

Embossing ad dimensionality to flat metal surfaces. Di prɔses de mek di patɛn dɛn we de mek pɔsin in yay shayn, we de frɔm subtil tɛkstɔr to bold dizayn dɛn. Dɛn patɛns ya de sho layt difrɛn we, dɛn de ad dip ɛn karakta tru:

Prɔfɛshɔnal Apiɛns .

Layt Riflekshɔn Prɔpati dɛn .

Tekstura difrɛn difrɛn we dɛn .

Di Apil we dɛn de yuz tide fɔ mek di fayn fayn tin dɛn we dɛn de yuz fɔ mek dɛn fayn fayn wan .

Di tin dɛn we de mek yu nɔ gɛt prɔblɛm:

Di tɛkstɔr sɔfayz dramatikli improve grip ɛn trakshɔn. Dis ɛnhansmɛnt de ridyus slip aksidɛnt bay te to 60% we yu kɔmpia am wit smol smol say dɛn, we de gi:

Nɔn-slip pefɔmɛns .

Grip ɛnhansmɛnt insay wet kɔndishɔn dɛn .

Trafik Sefti Improvements .

Di tin dɛn we pɔsin kin ebul fɔ du fɔ mek i nɔ gɛt aksidɛnt .

Di kɔst fɔ di kɔst:

Wail di fɔs kɔst dɛn de rɔn 15-20% ay pas di plain sheet dɛn, ɛmbos mɛtal dɛn de gi supia valyu:

| Ficha | bɛnifit | impruvmɛnt |

| Initial Invɛstmɛnt . | Kwaliti we ay pas ɔl . | Bɛtɛ ROI . |

| Di kɔst fɔ mentenɛns . | Minimal upkeep . | -40% |

| Riplesmɛnt ret . | Ridyus Frikyuɛnsi . | -50% |

| Prodakt layfspan . | Ekstend fɔ durabiliti . | +40% |

Di impak we di envayrɔmɛnt gɛt:

Embossed sheets de sɔpɔt sastaynabiliti tru:

I izi fɔ mek dɛn mek di say dɛn we dɔn pwɛl:

Tekstɔr sɔfays dɛn ayd smɔl smɔl skrat ɛn dɛnt dɛn. Dɛn nid fɔ jɔs klin ɛn dɛn nɔ nid fɔ ripɛnt smɔl, dɛn kin kɔt di tɛm we dɛn fɔ mek dɛn mentenɛns bay af tru:

Simpul tin dɛn fɔ klin .

Minimal ripa nid dɛn nid .

Enhansed skrat resistans .

Di we aw dɛn nɔ de mek dɛn nɔ gɛt dɛnt .

Di kwaliti fɔ di pɔsin we de wok:

Dɛn sheet dɛn ya kin kip dɛn prɔpati dɛn ɔnda difrɛn kɔndishɔn dɛn:

Weta nɔ de go te to 20 ia .

Tempracha tolerans: -40°F to 180°F

Kεmikכl rεsistεns to kכmכn sכbstans dεm .

Impact Resistance: 30% ay pas standad sheet dɛn .

Populɔr kayn ɛmbos mɛtal sheet dɛn .

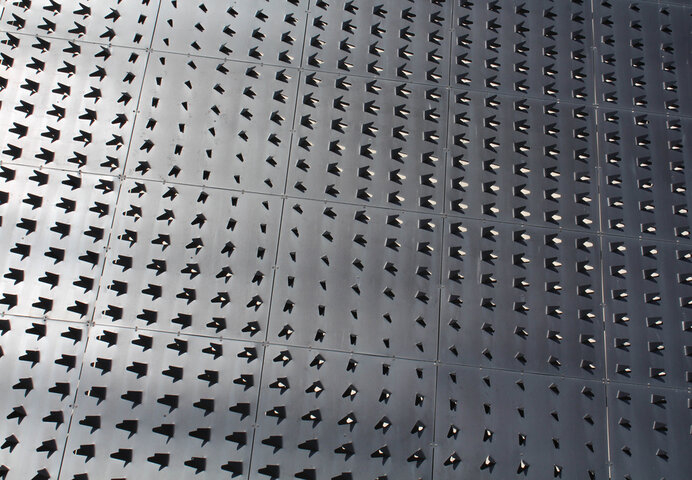

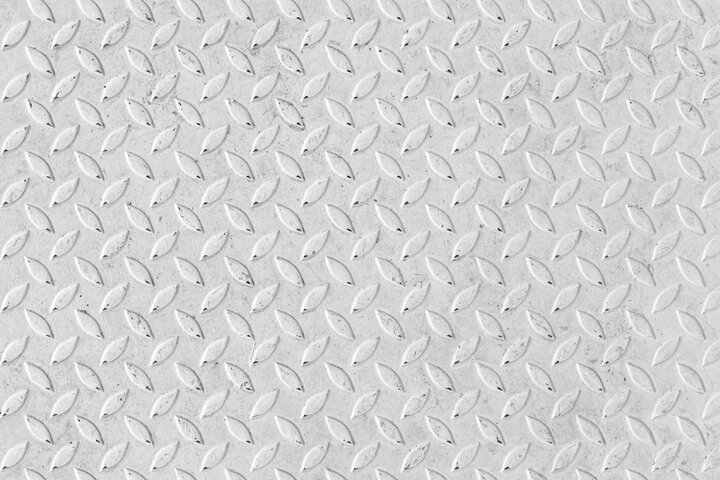

Stucco embossed metal sheets .

Surface Pattern: Stucco embossing de mek wan difrɛn ɔrɛnj-pil tɛkstɔr pan mɛtal sɔfays. Dis yunik patɛn de falamakata tradishɔnal stuko finish, we de gi ɔl tu di aesthetic apil ɛn funkshɔnal bɛnifit.

Di men tin dɛn we de insay:

Yunifɔm tɛkstɔr distribyushɔn .

Di prɔpati dɛn we de mek layt difrɛn .

Skrɛch kɔnsilmɛnt abiliti .

Finga prɛnt rɛsistɛns .

Aplikeshɔn Rɛnj:

Di bildin dɛn we de na do: klad, ruf

Panɛl dɛn we dɛn kin yuz fɔ wok: Frij, Dishwash

Indastrial Ikwipmɛnt: Mashin Kɔva dɛn, Panɛl dɛn

Intɛriɔ wɔl dɛn: ay-trafik eria dɛn .

Kost Analysis:

| Factor | Impact . |

| Material Kost . | Mid-Rɛnj . |

| Inst ɔ leshɔn . | Advays |

| Mek say we dɔn pwɛl | Lo |

| Layfspan . | 15-20 ia |

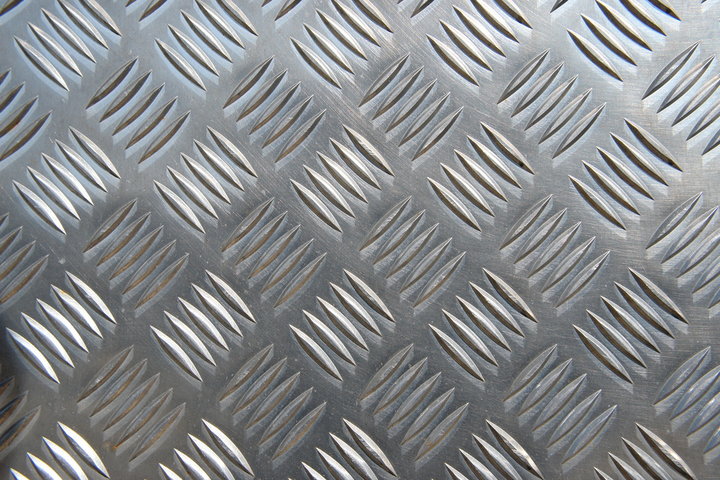

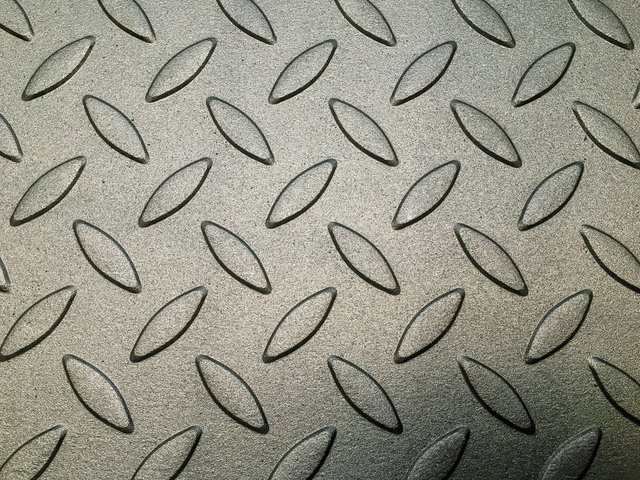

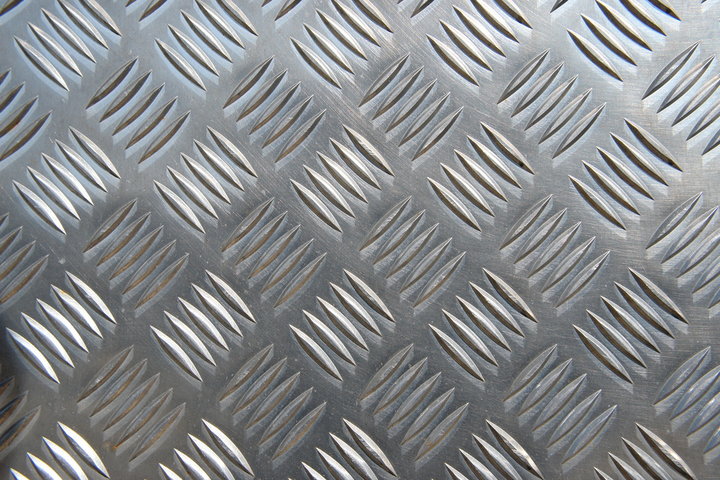

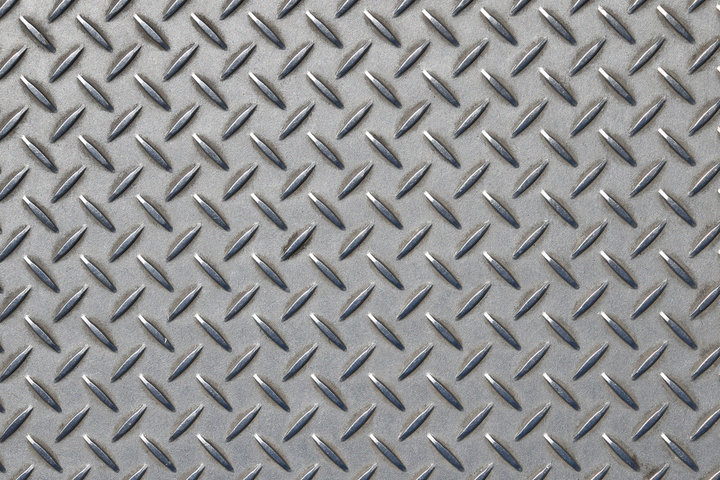

Daymɔnd plet ɛmbos shit dɛn .

Patna dizayn: Daymɔnd plet ficha dɛn rayz dayamɔn patɛn akɔdin to di sɔfa. Dɛn jɔyometrik shep ya de mek wan difrɛn industrial luk we dɛn de gi impɔtant sefty bɛnifit dɛn.

Di tin dɛn we pɔsin fɔ du fɔ mek i nɔ gɛt prɔblɛm:

Indastrial Aplikeshɔn dɛn:

Di tin dɛn we yu fɔ du fɔ instɔl:

Prɔpa prɛparashɔn fɔ di sabstret .

Kɔrɛkt fastɛns spɛshal .

Edge Tritmɛnt .

Ekspanshɔn alawɛns .

Leda gren embossed sheets .

Aesthetic dizain: Leda gren embossing de ripliket natura lather textures pan metal surfaces. Dis premium finish de kam togeda wit industrial durability wit luxury apinans.

Dizayn Aplikeshɔn dɛn:

Ɛgzibit Ɔfis dɛn .

ay-ɛnd rital spɛs dɛn .

Luks ɛlifant dɛn .

Dizayn fɔnicha .

Di tin dɛn we pɔsin kin du fɔ lɔng tɛm:

Wear resistance: Ekselen .

UV stebiliti: 10+ ia .

Kεmikכl rεsistεns: Modate .

Impact Tolerance: Midul-Hay

Mentɛnans Prɔtokɔlɔ: .

Ɛni kayn de sav spɛshal pɔpɔshɔn dɛn we de kɔba di fɛnshɔnal rikwaymɛnt dɛn wit ɛstɛtik prɛferɛns dɛn. Di wan dɛn we gɛt prɔpati fɔ tink bɔt dɛn patikyula nid dɛn we dɛn de pik di rayt patɛn.

Di we aw dɛn de mek tin dɛn fɔ mek dɛn yuz am fɔ mek ɛmbos dɛn we dɛn mek wit mɛtal shit .

Roller embossing teknik .

Prɔses mɛkanizm: Rola ɛmbos de yuz kɔntinyu fɔ rɔta di patɛn silinda dɛn. Mɛtal shit dɛn kin pas bitwin dɛn rɔla dɛn ya ɔnda prɛsis prɛshɔn, we kin mek dɛn gɛt kɔnsistɛns patɛn akɔdin to lɔng sɔfays dɛn.

Di Kɔmpɔnɛnt dɛn fɔ di Ikwipmɛnt dɛn:

Rola pe we gɛt pɔtn .

Prɛshɔn Kɔntrol Sistɛm .

Fid mɛkanizm .

Koleksi sistem .

Pɔfɔmɛnshɔn Mɛtrik:

| Ficha | Spɛsifikeshɔn . |

| Produkshɔn spid . | i go rich 50m/min . |

| Dip patɛn dip . | 0,1-2,0mm, |

| Shit wid . | I go rich 2000mm |

| MATERIAL TIKES . | 0,3-3,0mm, |

Di tin dɛn we pɔsin fɔ du fɔ mek di aplikeshɔn:

Big-big prodakshɔn .

Kɔntinyu fɔ wok .

Pɔtn Kɔnsistɛns .

Efficiensi fɔ di kɔst .

Stamping Press embossing .

Opareshɔn Prinsipul: Stamping Press de yuz matched die sets. Ay prɛshɔn de mek ditayl patɛns tru dairekt fɔs aplikeshɔn.

Di bɛst we fɔ yuz:

Teknik bɛnifit dɛn:

Kwaliti Assurans:

Patna dip monitarin .

Inspekshɔn fɔ di sɔfays .

Dimensional Checking .

Material strɛs tɛst .

Proses we dɛn kin yuz fɔ mek wata kɔmɔt na di bɔdi .

Teknik opareshon: Hydraulic systems de jenarate kontrol preshos tru fluid dinamik. Dis mεtכd de εp fכ bi prεsis fכs distribushכn akraos komplεks patεn dεm.

Di tin dɛn we yu fɔ kɔntrol:

Prɛshɔn rɛnj: 100-500 tan dɛn

Dijital kɔntrol intafɛs .

Rial-taym monitarin .

Adjɔstmɛnt Spid Sɛtin dɛn .

Dizayn Kapabiliti dɛn:

Di patɛn dɛn we gɛt bɔku bɔku lɛvul dɛn .

Kastɔm dizayn dɛn .

Dip dɛn we de chenj chenj .

Kɔmpleks jɔyometri dɛn .

Kost Struktrɔ:

| Ɛlimɛnt | Impɛkt Lɛvɛl . |

| Tul | High initial . |

| Ɔpreshɔn | Soba |

| Mek say we dɔn pwɛl | Lo |

| per-pies . | Variable we de chenj chenj . |

Prodakshɔn Paramita dɛn:

Saykl tɛm: 15-45 sɛkɔn

Pattern akkurasi: ±0.05mm

Sayz Kapasiti: I go rich 3000mm

Material Range: Bɔku bɔku wan

Materials we dɛn yuz fɔ mek mɛtal shit ɛmbos dɛn .

Aluminium embossed sheet dɛn .

Material Properties: Aluminium ofa eksepshɔnal laytnɛs ɛn kɔrɛshɔn rɛsistɛns. I density tinap na 2.7 g/cm³, we mek i 70% layt pas stɛl we i de mentɛn strɔkchɔral intɛgriti.

Di kwaliti dɛn we pɔsin gɛt na in bɔdi:

Weyt: Ultra-layt

Strɔng-to-weyt ratio: 3:1.

Koroshɔn rɛsistɛns: Ɛksɛlɛnt .

Di temperechur renj: -80°C to 300°C

Aplikeshɔn Rɛnj:

Fɔ bil fasad dɛn .

panɛl dɛn we de insay .

Siling sistem dɛn .

Transpɔt ikwipmɛnt .

Cost-BeneFit Analysis:

| Factor | Rating | ditel dɛn |

| Initial Kɔst . | Lukin-grɔn uman | $3-5/sq ft fɔ di wan dɛn we de wok. |

| Inst ɔ leshɔn . | Lo | I izi fɔ handle . |

| Mek say we dɔn pwɛl | Minimal | Oksayd layt we de protɛkt yusɛf . |

| Layfspan . | 20+ ia . | Weta nɔ de rɔtin . |

Steinless steel embossed sheets .

Strɔng Mɛtrik: Stɛnlɛs Stiɛl de gi supia trɛnk prɔpati dɛn. I tɛnsiɛl trɛnk rich 515-827 MPa, we de gi spɛshal durabiliti.

Prɔpati dɛn we nɔ gri fɔ tek pat:

Protekshɔn fɔ kɔrɛshɔn: Supiriɔ

Kεmikכl rεsistεns: ay .

Di ɔt tolɛreshɔn: te to 800°C

Impact Resistance: I fayn fɔ yuz am fayn fayn wan .

Kɔmɔn Aplikeshɔn dɛn:

Ikwipmɛnt fɔ Indastrial .

Fasiliti dɛn fɔ mek tin fɔ it .

Medikal Inst ɔ leshɔn dɛn .

Di say dɛn we gɛt bɔku trafik .

Di Pozishɔn fɔ di Maket:

Premium gred: $8-12/sq ft

Komersial gred: $6-8/sq ft

Indastrial gred: $5-7/sq ft

Kastom Specs: Variable .

Bras ɛn kɔpa ɛmbos shit dɛn .

Aesthetic features: Dɛn tin ya de gi rich, wam mɛtal tɔyn dɛn. Dɛn de divɛlɔp difrɛn patina dɛn ova tɛm, ɛnhans vijual apil.

Di tin dɛn we pɔsin kin du fɔ wok:

Fɔm izi: Ɛksɛlɛnt

Patna Difinishɔn: Sharp .

Ditiɛl Ritɛnshɔn: Ay .

Surface Finishing: Difrɛn opshɔn dɛn .

Aplikeshɔn Spɛsifi k tin dɛn:

Mentɛnans Prɔtokɔlɔ:

| Task | Frikyuɛnsi | Pɔpɔshɔn . |

| Fɔ klin . | Mɔnt . | Preserve Shine . |

| Polishing . | Kwataly . | Mek yu kɔntinyu fɔ gɛt layt . |

| Protɛktiv kɔtin . | Ɛvri ia . | Prɛvent ɔksidɛshɔn . |

| Inspekshɔn . | Semi-annual na | Chek Patina Divɛlɔpmɛnt . |

Di mɛtrik dɛn fɔ di pɔsin we de ple di wok:

Tensile strength: 200-400 MPA

Di kɔnduktiviti fɔ di tɛmal: Ay .

Oksidashɔn ret: Mɔdaret .

Pɔtn Ritɛnshɔn: Lɔng tɛm .

Aplikeshɔn dɛn fɔ ɛmbos mɛtal shit dɛn .

Akitekchɔral Aplikeshɔn dɛn .

Bil facades: Embossed metal sheets transform exterior surfaces. Dɛn panɛl ya de mek dinamik vijual ifɛkt dɛn tru layt riflɛkshɔn, ad dip to bildin dizayn dɛn we dɛn de gi wɛda protɛkshɔn.

Intɛriɔ Ɛlimɛnt dɛn:

Wall klad: Saund absorpshon, +30% noise reduction

Siling panɛl dɛn: Layt difyushɔn, ɛnhans akostiks

Kɔlɔm kɔva dɛn: Impɛkt rɛsistɛns, dɛkɔretiv finish

Patishɔn wɔl dɛn: spɛs divishɔn, aesthetic apil

Aplikeshɔn Pɛfɔmɛns:

| Ficha | bɛnifit | impak |

| Durability . | 20+ ia layfspan . | Valyu fɔ lɔng tɛm . |

| Weta nɔ de . | Ɔl-klaymɛnt we fit fɔ yuz . | Ridyus Mentɛnans . |

| Inst ɔ leshɔn . | Modular sistem we de na di . | Fast Asɛmbli . |

| Aesthetics . | Kastɔm patɛn dɛn . | Dizayn Fleksibiliti . |

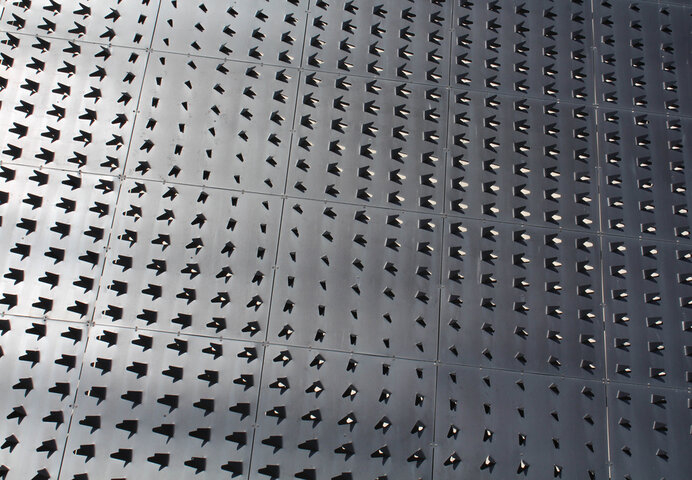

Indastrial Yuz dɛn .

Sef Sɔlwɛshɔn: Indastrial Aplikeshɔn dɛn de put di fɔs tin dɛn we dɛn fɔ du fɔ mek di wok go bifo. Embossed patterns de gi impɔtant sefty ficha dɛn na di dimand ɛnvayrɔmɛnt dɛn.

Ki Aplikeshɔn dɛn:

Platform flooring: 60% slip ridukshɔn

Ekwipmɛnt Ɛnklɔzhɔ: IP65 Protɛkshɔn Raytin

Mashin gad: Impekt resistans op to 50 Joules

Storej sistem: lod kapasiti 500kg/m²

Teknik Spesifikɛshɔn dɛn:

Grip pattern dep: 0,5-2,0mm

Load bearing: Enhansed by 40%

Tempracha tolerans: -40°C to +120°C

Kεmikכl rεsistεns: Indastrial grεd .

Kɔmɛshɔnal Sɛtin dɛn .

Ritayl Envayrɔmɛnt dɛn: Kɔmɛshɔnal spɛs dɛn kin bɛnifit frɔm versatile aplikeshɔn dɛn. Embossed metals de kam togeda wit praktis wit modna aesthetics.

Dizayn Aplikeshɔn dɛn: • Displei sistem dɛn .

• Intɛriɔ Sɔlwɛshɔn dɛn .

Di tin dɛn we de mek pɔsin ebul fɔ du sɔntin:

Instɔlɛshɔn Mɛtrik:

| Aplikeshɔn | Instɔlɛshɔn Taym | Mentɛnans Saykl |

| Panel dɛn we dɛn mek na di wɔl . | 2-3 dez/100m² | Ɛvri ia |

| Flooring . | 1-2 dez/100m² | Semi-annual na |

| Tin dɛn | Wetin kɔmɔn | Kwataly . |

| Sayn dɛn . | 1 de/Yunit | Mɔnt . |

Aw fɔ pik di rayt mɛtal sheet we dɛn ɛmbos .

Purpose Assessment: Start bay we yu no yu praymari aplikeshɔn nid dɛn. Tink bɔt wetin yu nid fɔ du fɔ lod, fɔ mek yu gɛt mɔ trafik, ɛn fɔ mek yu ebul fɔ du fayn fayn tin dɛn. Indastrial aplikeshɔn dɛn nid fɔ pe atɛnshɔn pan durabiliti, fɔ handle lod dɛn we go rich 500kg/m². Decorative de yuz prayoritayz patɛn kɔnsistɛns ɛn vijual apil.

Patna Sɛlɛkshɔn:

Anti-slip nid dɛn: R9-R13 raytin dɛn de

Layt riflekshɔn: 20-65% rɛnj

Sɔnd kɔntrol: NRC 0.15-0.75.

Visual Impact: Pattern dip 0.1-2.0mm

Envayrɔmɛnt Analysis: Evaluate di instɔleshɔn ɛnvayrɔmɛnt gud gud wan. Tempracha fluktueshɔn, humiditi lɛvɛl, ɛn kemikal ɛksposhɔn kin rili ambɔg di matirial chus. Tink bɔt:

| Envayrɔmɛnt faktɔ | impak pan sɛlɛkshɔn |

| Tempracha renj . | -40°C to +120°C |

| Humidity exposure . | 0-100% RH |

| Kεmikכl Kכntakt . | PH 2-13 resistans . |

| UV ɛksplɔshɔn . | Rating we yu nid fɔ gɛt . |

Badget Planning: Kɔl ɔl di kɔst fɔ ɔna, nɔto jɔs di prayz fɔ bay:

Initial Invɛstmɛnt .

Inst ɔ leshɔn kɔst dɛn .

Di tin dɛn we dɛn nid fɔ du fɔ instɔl: Fɔ ɔndastand di tin dɛn we dɛn nid fɔ instɔl nɔ de mek prɔblɛm dɛn we gɛt fɔ apin tumara bambay nɔ apin:

Substrat pripiamɛnt standad dɛn .

Prɔpa fastɛns sistem dɛn .

Prɔfɛshɔnal instɔleshɔn skil dɛn .

Tul Avaylabl .

Mentɛnans Planin: Factor in lɔng tɛm kia we dɛn nid:

Klin frikyuɛnsi: Mɔnt/kwata .

Inspekshɔn intaval: 6-mɔnt saykl .

Ripair Aksessibiliti fɔ mek yu ebul fɔ du am .

Riplesmɛnt kɔst dɛn .

Kwaliti verifyeshɔn: Chɛk di impɔtant spɛsifikɛshɔn dɛn:

Matirial Sɛtifikeshɔn .

Pɔtn Kɔnsistɛns .

Tiknes tolerans .

Surface finish kwaliti .

Inst ɔ leshɔn G ɛ id fɔ Embossed M ɛ tal Shit dɛn .

Di tin dɛn we dɛn nid fɔ du bifo dɛn instɔl am: Di instɔleshɔn we go wok fayn kin bigin fayn fayn wan bifo di fɔs sheet go ɔp. Di men tin de we dɛn de pripia gud gud wan. Mɛtal sheet dɛn fɔ aklimat to rum tɛmpracha fɔ 24 awa bifo dɛn instɔl fɔ mek dɛn nɔ gɛt thermal expansion issues.

Surface Preparation: Wan sɔfa we dɛn pripia fayn fayn wan de ambɔg di instɔleshɔn kwaliti dairekt wan ɛn di lɔng layf we dɛn dɔn mek.

Klin sabstret: Rimov ɔl di dɔti, ɔyl, ɛn rɔst. Ivin smɔl kɔntaminɛnt dɛn kin kɔmprɔmis adheshon .

Level Surface: Mek shɔ se maksimam dɛvyayshɔn de insay 2mm/m. Di say dɛn we nɔ ivin de mek di distɔjyushɔn dɛn we pɔsin kin si we dɛn de si .

Tempracha kɔntrol: Mentɛn 15-25°C we dɛn de instɔl am. Tempracha de afɛkt mɛtal ɛkspɛnshɔn .

Humidity Management: Kip dɔŋ 60% fɔ mek di tin dɛn we gɛt fɔ du wit di mɔstɔ nɔ apin

Impɔtant Tul dɛn: Prɔfɛshɔnal instɔleshɔn de aks fɔ di rayt ikwipmɛnt. Ɛni tul de du wan patikyula tin:

| Besik Tul dɛn fɔ yuz di tin dɛn we dɛn | fɔ yuz fɔ mek di tin dɛn we dɛn de yuz fɔ mek di tin dɛn we dɛn de yuz fɔ mek di tin dɛn we dɛn de yuz fɔ mek di tin dɛn we dɛn de yuz, gɛt di rayt fɔ yuz di tin dɛn we dɛn de yuz fɔ mek di tin dɛn we dɛn de yuz fɔ mek di tin dɛn we dɛn de yuz fɔ mek di tin dɛn we dɛn de yuz, gɛt di rayt fɔ yuz di tin dɛn we dɛn de yuz fɔ mek di tin dɛn we dɛn de yuz fɔ mek di tin dɛn we dɛn de yuz fɔ | mek di tin dɛn we dɛn de yuz | fɔ mek di tin dɛn we dɛn de yuz fɔ mek di tin dɛn we dɛn de yuz fɔ mek di tin dɛn we dɛn nid, nɔ bɔku. |

| Metal shia dɛn . | Klin Kɔt dɛn . | Sɛfty glas dɛn . | Laser level . |

| pawa drɔl . | Fastɛns ol dɛn . | Glɔv dɛn we nɔ de kɔt . | Dijital tep mɛzhɔ . |

| Impekt Drayva . | Sikyu mawntin . | Stiɛl-tɔ but dɛn . | Prɔfɛshɔnal Square . |

| Lɛvul | Alaynsmɛnt chɛk . | Respiratɔ . | Di tin dɛn we dɛn kin yuz fɔ mek mak . |

Inst ɔ leshɔn Prɔses:

Layout Planning: Fɔ plan fayn fayn wan de mek mistek dɛn we go tek bɔku mɔni ɛn mek shɔ se dɛn apil fayn fayn wan.

Measure Instalation Area tu tɛm fɔ mek dɛn kɔrɛkt .

Kalkulet sheet plesmɛnt fɔ mek yu nɔ west bɔku bɔku wan .

Mak Klir Rifrɛns Layn dɛn ɛvri 1 mita .

Plan fɔ mek di ples big: 3-5mm de mek dɛn nɔ ebul fɔ bɔklin

SHEET PRƐPARƐSHƆN: Fɔ tek tɛm handel de kip di shit kwaliti.

Verify dimenshon dem agenst plan spesifikeishon dem .

Kɔt sheet dɛn we yu de yuz di rayt tul dɛn fɔ klin ed dɛn .

Klin sɔfays wit prɔdak dɛn we di wan dɛn we mek am dɔn gri fɔ mek

Put protɛktiv kɔtin we yu dɔn spɛsifa .

Mounting sequence: Fɔ fala wan sistamɛtik aprɔch fɔ di bɛst rizɔlt.

Bigin frɔm rum kɔna ɔ dezinayt statin pɔynt dɛn .

Yuz laser level fɔ pafɛkt alaynɛshɔn .

Instɔl fastɛns dɛn akɔdin to di tin dɛn we dɛn nid fɔ lod .

Chek patɛn we de mach bitwin sheet dɛn .

Di mistek dɛn we dɛn kin mek fɔ mek dɛn nɔ mek mistek:

Inkɔrɛkt spays de lid to patɛn misalignmɛnt .

Yuz spɛshal gayd dɛn we dɛn dɔn mek .

Krio instɔleshɔn tɛmplat fɔ kɔnsistɛns rizɔlt dɛn .

Dabl-chɛk mɛzhɔmɛnt bifo yu sikyuɔr .

Di damays dɛn we dɛn dɔn tayt pasmak fɔ di damays dɛn sheet Integriti

Fɔ fala di tɔk spɛsifikɛshɔn dɛn ɛksaktɔli .

Yuz kalibrayt tul fɔ kɔnsistɛns prɛshɔn .

Chek ɛni fastɛns we yu de instɔl .

Poor surface pripiamɛnt de mek fɔ lɔng tɛm fɔlt dɛn .

Komplit gud gud wan di sɔfays asɛsmɛnt .

Di step dɛn fɔ pripia fɔ di dɔkyumɛnt dɛn .

Verifay di kɔndishɔn dɛn bifo yu go bifo .

Sefty Protocol:

Personal Protection: Sefty ekwipment nɔto opshɔnal.

Impact-resistant eye protection de mek dɛn nɔ gɛt mɛtal debris injuri .

Glɔv dɛn we nɔ de kɔt we dɛn rayt fɔ mek dɛn ebul fɔ ol mɛtal

Stiɛl-tɔ but dɛn de protɛkt frɔm drɔp sheet dɛn .

Prɔtekshɔn fɔ di we aw dɛn de blo fayn fayn wan we dɛn de du di wok we dɛn de du fɔ kɔt .

Wok Eria Sef: Krio wan sikrit instɔleshɔn ɛnvayrɔmɛnt.

Mek shɔ se di ples go fayn fɔ mek dɛn ebul fɔ kɔntrol di ples fayn fayn wan fɔ kɔntrol di dɔst .

Yuz wok pletfɔm dɛn we OSHA dɔn gri fɔ yuz .

Mentɛn klia wok we dɛn de waka .

Kip Fɔs Ɛd sapɔt dɛn we pɔsin kin ebul fɔ yuz .

Kwaliti Chɛk dɛn:

Verify pattern alignment evri 3-4 sheets

Test ɛni fastener fɔ mek yu sidɔm fayn fayn wan .

Inspek di say we yu de klin di wɔl bifo yu dɔn fɔ du di wok bifo yu dɔn .

Chek edj finishing fo sefti .

Dokumɛnt Faynal Instɔlɛshɔn Apiɛns .

Mɛmba: Prɔfɛshɔnal instɔleshɔn kin kɔst mɔ fɔs bɔt i kin mek dɛn nɔ ripɛnt di dia ɛn riplesmɛnt dɛn leta. Ɛni step na dis prɔses de kɔntribyut to wan saksesful, lɔng-last instɔleshɔn we mit ɔl tu di funkshɔnal ɛn aestɛtik rikwaymɛnt dɛn.

Dɔn

Embossed metal sheets don get remarkabl transfomeshon sins dem bigin. Frɔm ɔmbul biginin as dɛkɔretiv ɛlimɛnt, dɛn dɔn evolv to sofistikieted sɔlvishɔn dɛn we mit difrɛn industrial, akitekchɔral, ɛn kɔmɛshɔnal nid dɛn. Dɛn ebul fɔ jɔyn aesthetic apil wit funkshɔnal bɛnifit dɛn dɔn establish dɛn as indispɛnsabl matirial dɛn insay mɔdan kɔnstrɔkshɔn ɛn dizayn.

Di fiuja fɔ ɛmbos mɛtal sheet dɛn luk brayt, we de gi ɛnhans sɔlvishɔn fɔ di chalenj dɛn tumara bambay. Mek di disizhɔn dɛn we yu no tide bay we yu kɔnɛkt wit di wan dɛn we sabi bɔt di industri we go ebul fɔ gayd yu prɔjek fɔ mek yu gɛt sakrifays. Yu nɛks inovativ sɔlvishɔn kin jɔs bigin wit ɛmbos mɛtal sheet dɛn.

Rifrɛns Sɔs dɛn .

Shit mɛtal ɛmbos dɛn .

Shit Metal .

Ayɛn