If yu nɔ gɛt di say we dɛn dɔn polish, di taytaniɔm pat dɛn go luk dɔl ɛn nɔ fayn aesthetically. Na de titanium polishing kam insay ples. Nɔto dat nɔmɔ, polishing titanium kin ɛp bak fɔ mek difrɛn kwaliti dɛn we di taytaniɔm kɔmpɔnɛnt dɛn gɛt, bɛtɛ. I de mek di . Titanium pat ivin beta in ovala kwaliti.

Advantej dɛn fɔ Titanium polishing insay industrial aplikeshɔn dɛn .

Polishing Titanium gɛt bɔku bɛnifit fɔ difrɛn industri dɛn. So, i bɛtɛ fɔ mek yu lɛk fɔ de wit di taytaniɔm pat dɛn we dɛn kin gɛt ɔltɛm, we nɔto polis. Na dis na di bɛnifit dɛn we Titanium polishing gɛt pan industrial aplikeshɔn dɛn:

• SMƆL TƆK: Impruv kɔrɛshɔn ɛn ɔltɛm wear resistans.

Di rɛgyula taytaniɔm matirial dɔn ɔlrɛdi gɛt fayn fayn kɔrɛshɔn ɛn rɛgyula wear rɛsistɛns, we mek i bɛtɛ fɔ yuz fɔ lɔng tɛm. Titanium polishing kin signifyantli improve di rust en regular wear resistance of titanium. Minimizing normal wear en koroshon tu min se yu kip di apiyans of di titanium pats klin en polish.

• SMƆL TƆK: Impruv bayɔkɔmpatibiliti fɔ di taytaniɔm pat dɛn bay we dɛn de polish di taytaniɔm.

Insay mɛdikal aplikeshɔn, polish titanium kin briŋ yu di rikwayd bayɔkɔmpatibiliti ficha. I de mek shɔ se di polish taytaniɔm pat dɛn sef we dɛn yuz am togɛda wit mɔtalman bɔdi. I de mek bak ɛni kemikal ɔ ɔda tin we dɛn nɔ want we dɛn de yuz am we dɛn de yuz mɛrɛsin ɔ ɔda tin dɛn we dɛn nɔ want.

• SMƆL TƆK: Impruv di luk ɛn aesthetics fɔ di titanium pat dɛm.

Non-polished titanium parts go luk ol rugged en no tu aesthetic. We yu polish di titanium pat dɛm, i kin tɔn di luk ɛn aesthetics fɔ am fɔ di bɛtɛ. Polish titanium gɛt lɔng-last aesthetics we luk smol ɛn shayn.

• SMƆL TƆK: Impruv ay-tɛmpracha rɛsistɛns bay taytaniɔm polishing.

Titanium pat kin wok na ay tempɔret wit nɔ prɔblɛm. Bɔt wit polish taytaniɔm, yu kin rayz di tɛmpracha kap ɛn ad mɔ resistans to ay tɛmpracha fɔ di taytaniɔm pat dɛn. I go alaw yu fɔ put di polish taytaniɔm pat dɛn fɔ wok na ekstrim tɛmpracha we yu de kɔntinyu fɔ de fɔ lɔng tɛm.

• SMƆL TƆK: Impruv trɛnk ɛn durabiliti bay taytaniɔm polishing.

Polishing titanium go way pas fɔ mek di taytaniɔm pat dɛn luk wɔndaful-luk. I kin ad mɔ sɔbstans bak insay di taytaniɔm kɔmpɔnɛnt dɛn we go ɛp fɔ mek dɛn trɛnk ɛn fɔ lɔng tɛm bɛtɛ. Polish titanium de resist bak to surface skrat.

Di kayn dɛn we dɛn kin yuz fɔ polish wit taytaniɔm .

Difrɛn gred ɔ lɛvul dɛn de fɔ taytaniɔm polish. Na di kayn titanium polish dɛn we yu kin gɛt insay Rapid Manufakchurin ..

• At.

Rough titanium polish na di cheapest polishing solution fɔ Titanium fɔ ɛni manufakchurin aplikeshɔn. I de gi yu wan rough finish rizulyt pan di titanium . Surface finish part, we nɔ tu shayn ɛn smol. Di rough titanium polishing go yuz titanium polish waks ɛn silikon ɔksayd we dɛn miks insay di abrasive buffing wil.

• Lukin-grɔn uman.

Midul Titanium Polish na wan step ɔpgrɛd frɔm di rɔf taytaniɔm polish tayp. I de yuz wan kɔmbaynshɔn fɔ taytaniɔm polish waks ɛn aluminiɔm ɔksayd insay wan mat abraziv wil fɔ mek di taytaniɔm sɔfa layt smol smol. As a rizulyt, yu get wan smol finish prodak we no tu dull-luk, wit midul kwaliti fo in aesthetics.

• Fayn.

Fine Titanium Polish na di nia-pafɛkt kayn taytaniɔm polish we yu kin gɛt na manufakchurin. Insay dis prɔses, yu nid fɔ ɛksɛrt mɔ prɛshɔn di tɛm we dɛn de du di taytaniɔm polishing ɔpreshɔn. Di waks polish ɛn di soft-kɔtɔn buffing wil we nɔ de kɔm na impɔtant tin fɔ mek fayn polish sɔfays fɔ di taytaniɔm kɔmpɔnɛnt dɛn.

• Lukin-glas.

Mirror polish na di ayest gred fɔ taytaniɔm polish we kin mek di taytaniɔm pat sɔfa luk riflεkt, lɛk miro. Fɔ aesthetics, di miro polish tayp fɔ taytaniɔm na di bɛst, we mek i fayn fɔ yu fɔ yuz di pat dɛn na do. Yu kin akɔmplit dis miro polish bay we yu yuz di sɔft kɔm-kɔtɔn buffing wil ɛn polish taytaniɔm waks.

Titanium polishing step-by-step proses .

Polishing Titanium nid fɔ mek yu go tru di degreasing, klin, sanding, buffing, ɛn finishing process. Na dɛn tin ya na di tin dɛn we wi fɔ du:

• SMƆL TƆK: Digris bay Titanium polishing.

Degreasing min fɔ pul di ɔyl rɛsɛdyu frɔm di titanium pat sɔfa, we yu kin gɛt bɔku tɛm frɔm di step dɛn we dɛn bin dɔn mek bifo. Fɔ dis, yu de yuz di digris ɛjɛn dɛn ɛn sprɛy dɛn ɔlsay na di taytaniɔm pat. Dis prɔses fɔ pul di ɔyl kɔmpɔnɛnt dɛn frɔm di sɔfa. Neks, rɛdi fɔ di say we dɛn de klin di grɔn.

• SMƆL TƆK: Klin.

Di klin we dɛn de klin di taytaniɔm pat dɛn izi fɔ du. Put sɔm klin tin dɛn lɛk sop ɔ glas klin sɔlvushɔn ɛn klin di taytaniɔm pat dɛn we dɛn dɔn digris we yu de dip dɛn insay wan baskɛt we gɛt wata. Kɔntinyu fɔ klin bay we yu was di taytaniɔm pat dɛn bak ɛn bak. Neks, yu kin drɛy di taytaniɔm pat dɛn ɛn pripia dɛn fɔ sand.

• SMƆL TƆK: Sanding.

Sanding nid fɔ mek yu yuz sandpaper ɛn put am na di say we di taytaniɔm kɔmpɔnɛnt dɛn de. Fɔ yuz lɔbrikɛnt impɔtant fɔ mek di sanding go fayn wit di drɔlin mashin. Go wit difrɛn gred dɛn fɔ sand pepa, frɔm di wan we rɔf pas ɔl to di wan we smɔl pas ɔl (200 grit to 2000 grit), fɔ gɛt di bɛst rizɔlt fɔ di taytaniɔm polish.

• SMƆL TƆK: Buffing.

Buffing min fɔ aplay polishing waks fɔ di titanium pat dɛn yuz di buffing wil. Dipen pan di Polish tayp we yu want fɔ ajɔst, yu go nid difrɛn kayn buffing wil ɛn Polish waks ingridiɛnt dɛn. Buffing go mek di titanium surface luk smol en shayn.

• SMƆL TƆK: Di we aw dɛn de dɔn di wok.

Di finishing proses inklud perfekt di polished surface of titanium parts afta buffing. Buffing kin stil lɛf sɔm mak dɛn na di titanium surface, we yu fɔ ayd yuz wan titanium paint polish sɔlvushɔn. Fɔ yuz di pent polish sɔlvishɔn ivin na di mak sɔfa eria na sɔntin we yu fɔ du if yu want fɔ mek di sɔfa polish fɔ di taytaniɔm pat dɛn luk pafɛkt.

Wetin na di impɔtant tin bɔt bayɔkɔmpatibiliti na taytaniɔm polishing pat dɛn?

Insay di mɛdikal industri, bayɔkɔmpatibiliti go mek di taytaniɔm pat dɛn kɔmpitabl ɛn sef fɔ mɔtalman bɔdi. Titanium polishing impɔtant fɔ di titanium pat dɛn we dɛn kin yuz fɔ mɛdikal aplikeshɔn dɛn.

Yu nid fɔ wɔri bɔt sɔfayz skrat fɔ di miro-tayp taytaniɔm polishing finish?

Mirror-type titanium finish na di bɛst fɔ yuz na do we nid maksimal aesthetics. I nɔ de skrach bak ɛn i bɛtɛ fɔ yuz fɔ lɔng tɛm. So, yu nɔ nid fɔ wɔri fɔ skrach di surface fɔ miro-polish titanium.

Dɔn

Yu kin yuz Titanium polishing insay difrɛn industrial aplikeshɔn dɛn fɔ ɔpgrɛd di kwaliti ɛn aesthetics fɔ di taytaniɔm kɔmpɔnɛnt dɛn. Titanium polishing tek sɔm step fɔ dɔn. Di step dem na di sem weda yu want wan rough or mirror finish fo di titanium parts. Titanium polishing go bi bak wan must-do step in sɔm industrial aplikeshɔn dɛn.

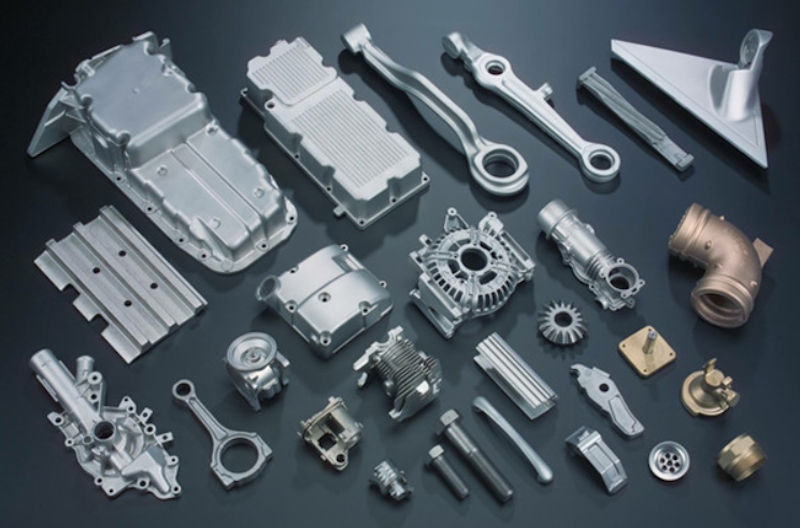

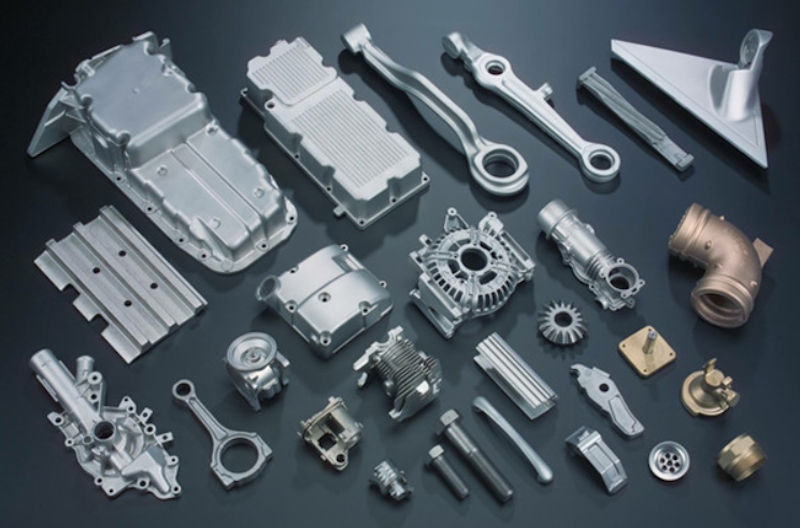

Team MFG offfers Titanium rapid prototyping ., Titanium CNC Machining etc fɔ mit yu prɔjek nid dɛn. Wi kɔstɔma dɛn de frɔm motoka to mɛdikal industri. Kontakt wi tide fɔ aks fɔ kot.