Insay di wɔl fɔ mek mɛtal, sɔfayz tritmɛnt dɛn de ple impɔtant pat fɔ ɛp fɔ mek di prɔpati ɛn pefɔmɛns fɔ difrɛn kɔmpɔnɛnt dɛn bɛtɛ. Pan di bɔku opshɔn dɛn we de, Alodine finishing dɔn kɔmɔt as pɔpul choice fɔ in spɛshal bɛnifit ɛn versatility. Insay dis atikul, wi go dayv insay di fawndeshɔnal tin dɛm fɔ Alodine kɔtin, in impɔtants na difrɛn industri dɛm, ɛn aw i difrɛn frɔm ɔda sɔfayz tritmɛnt dɛm.

Ɔndastand di Alodine Prɔses

Di Alɔdin Kɔtin Prɔses we Dɛn Ɛksplen

Alɔdin na kromat kɔnvɔshɔn kɔtin we de protɛkt mɛtal dɛn, mɔ di aluminiɔm ɛn in alɔy dɛn, frɔm kɔrɛshɔn. di prכsεs involv kεmikכl riakshכn bitwin di mεtal sεf εn di Alodine sכlushכn, we de rεsult in fכmeshכn fכ wan tin, protεktiv layεr.

di kεmikכl kכmכshכn fכ Alodine kכtεshכn dεm tipikli inklud kromiכm kכmpawnd dεm, lεk kromik asid, sכdiכm daykromat, כ potashכm daykromat. Dɛn kɔmpawnd ya de riak wit di aluminiɔm sɔfays fɔ mek wan kɔmpleks mɛtal-krom ɔksayd layt we de gi fayn fayn kɔrɛshɔn rɛsistɛns ɛn impɔtant pent adheshon.

Fɔ aplay wan Alodine finish involv wan simpul, bɔt prɛsis, stɛp-by-stɛp prɔses:

1. Klin: Dɛn kin klin di mɛtal fayn fayn wan fɔ pul ɛni dɔti, ɔyl, ɔ tin dɛn we de dɔti.

2. Rinsing: Dɛn kin rins di pat wit wata fɔ mek shɔ se dɛn pul ɔl di tin dɛn we dɛn kin yuz fɔ klin.

3. Dioxidizing: If nid de, dɛn kin trit di mɛtal surface wit dioxidizing agent fɔ pul ɛni oxidizing.

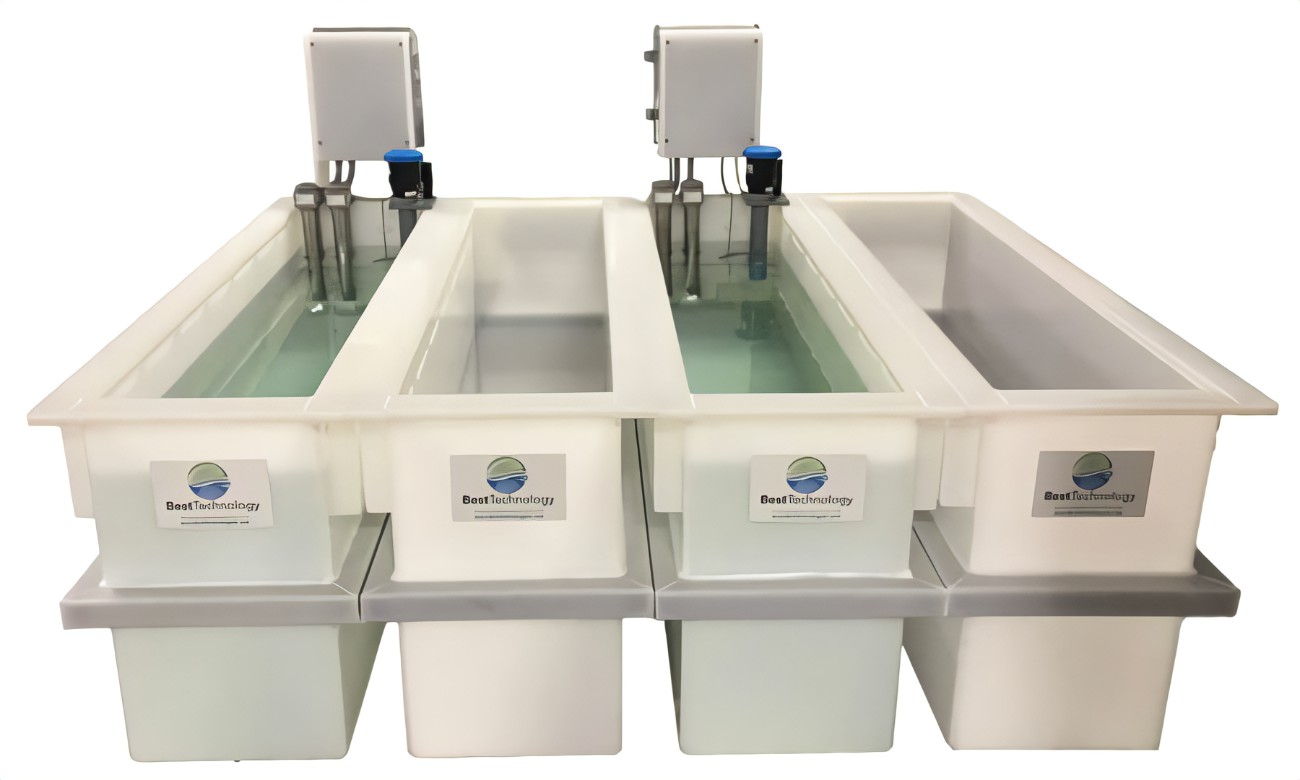

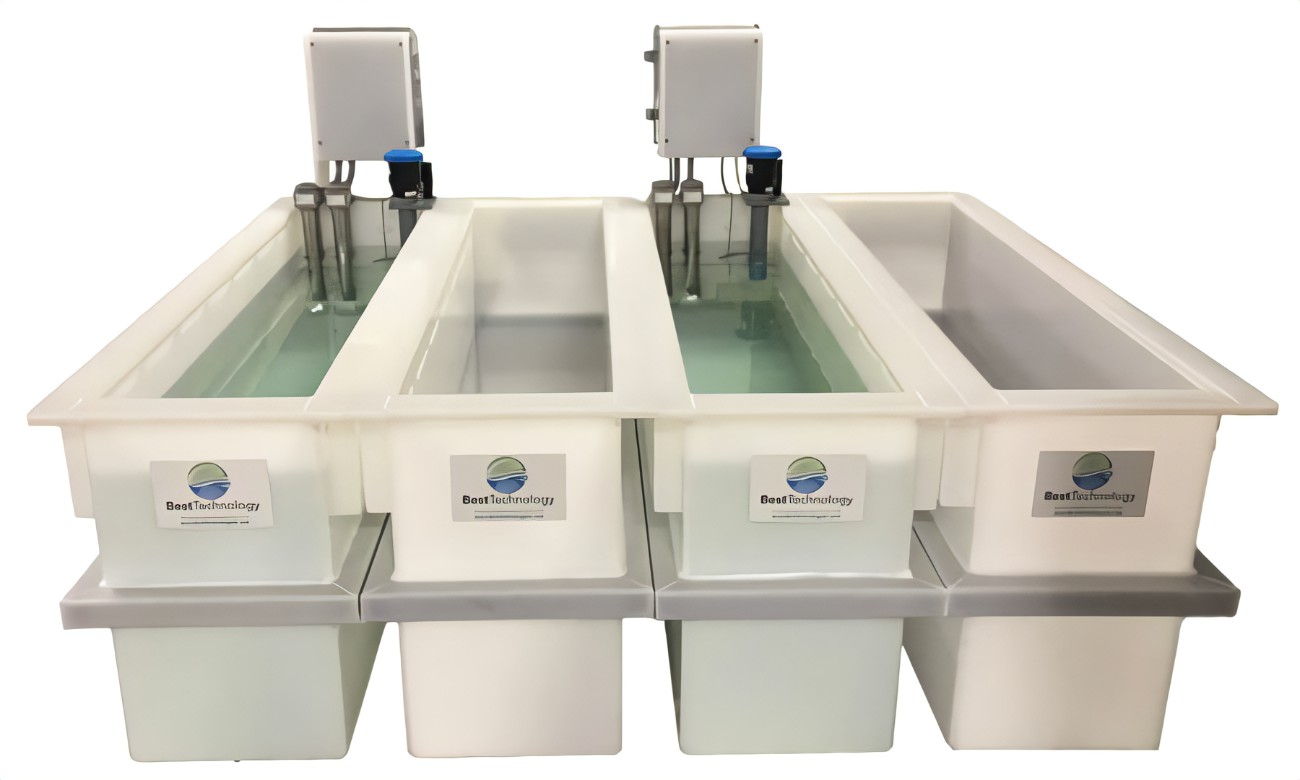

4. Alodin Aplikeshɔn: Dɛn kin put di pat insay di Alodine sɔlvushɔn fɔ wan patikyula tɛm, tipikul fɔ sɔm minit.

5. Faynal Rins: Dɛn kin rins di pat we dɛn kɔt wit wata fɔ pul ɛni Alodine sɔlvushɔn we pasmak.

6. Dray: Dɛn kin yuz ɛya ɔ ɔt fɔ drɛy di pat, i kin dipen pan di patikyula tin dɛn we dɛn nid.

Tru di prכsεs, i implεnt fכ mεnten di rayt kכntrכl pan di Alodine sכlushכn in kכnsantreshכn, pH, εn tεmprachכ fכ mek sכh se i kכnsistεnt εn ay kwaliti risכlt. di ol prכsεs kin kwik, wit bכku pat dεm kin tek 5 to 30 minit nכmכ fכ komplit, i dipכnt pan dεn saiz εn di tik we dεn want fכ kכt.

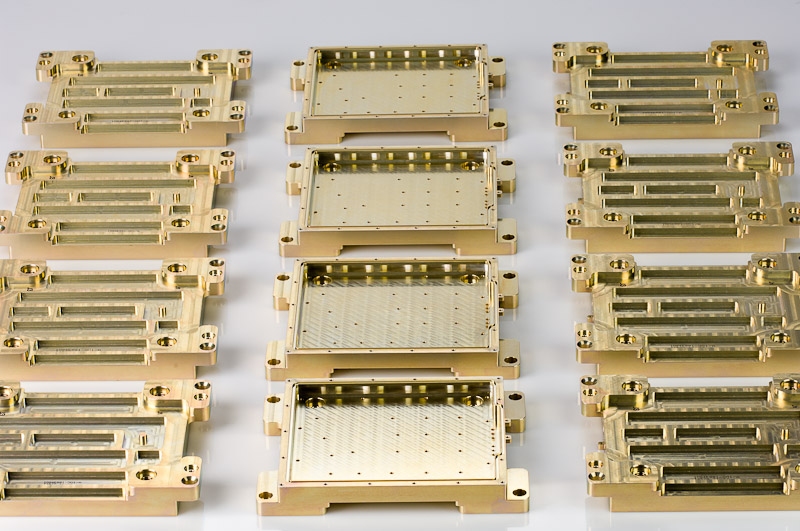

di Alodine kכt we kכmכt we de kכmכt na tin we inkrεdiblε, i de mεzj jכs 0.00001 to 0.00004 inch (0.25-1 μm) in tik. Pan ɔl we di tin we dɛn kɔt kin tan, i kin mek di pent ɛn ɔda tin dɛn we dɛn kin yuz fɔ mek di tin dɛn we dɛn dɔn put pan am, adheshon fayn fayn wan.

Klas dɛn fɔ Kromat Kɔnvɔshɔn Kɔtin

Alɔdin kɔtin dɛn kin gɛt difrɛn klas dɛn, ɛn ɛni wan pan dɛn gɛt difrɛn tin dɛn. Di tu we dɛn kin yuz mɔ na Klas 1A ɛn Klas 3.

Klas 1A kɔtin dɛn tik ɛn dak. Dis kin mek dɛn nɔ ebul fɔ rɔtin fayn fayn wan, mɔ fɔ di pat dɛn we dɛn nɔ peint. Dɛn kin mek di pent adheshon bak pan aluminiɔm sɔfays.

Klas 3 kɔtin dɛn kin tan ɛn layt. Dɛn de gi kɔrɛshɔn protɛkshɔn we dɛn nɔ de afɛkt ilɛktrik kɔnduktiviti smɔl.

Di tik we di kɔtin tik de ambɔg di kɔnduktiviti. Tik Klas 1A kɔtin dɛn de inkrisayz ilɛktrik rɛsistɛns smɔl. Tinna Klas 3 kɔtin dɛn de minimiz dis ifɛkt.

Na dis na wan kwik kɔmpiashɔn:

Tin | Klas 1A | Klas 3 |

Tik we i tik | Tik pasmak | Na tin we de thin |

Kɔrɛshɔn Resistɛns | Big pas | Gud |

Ilɛktrik Kɔnduktiviti | Dɛn dɔn ridyus am smɔl | Na smɔl tin we dɛn kin afɛkt |

Di Tipik Yuz dɛn | Pat dɛn we nɔ peint, pent adhesion | Ilektrikal komponent dɛn |

Fɔ pik di rayt klas dipen pan wetin yu nid. Klas 1A de gi maksimal kɔrɛshɔn rɛsistɛns. Klas 3 balans protɛkshɔn wit ilɛktrik pefɔmɛns.

We yu ɔndastand di tin dɛn we ɛni klas gɛt, dat de ɛp yu fɔ pik di bɛst Alodine kɔtin fɔ yu aplikeshɔn.

Aplikeshɔn ɛn Dizayn Kɔnsidɛreshɔn

Aplikeshɔn dɛn fɔ Alodine Finish

Dɛn kin yuz alɔdin kɔtin akɔdin to bɔku bɔku industri dɛn. Frɔm aerospace to ilɛktroniks, dɛn versatile finish ya de gi impɔtant protɛkshɔn ɛn pefɔmɛns bɛnifit.

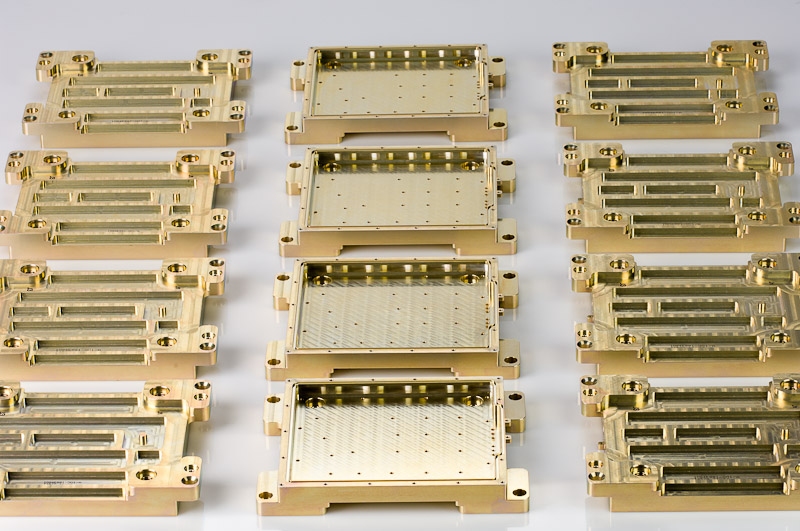

Wan pan di tin dɛn we dɛn kin yuz mɔ na di aerospace CNC mashin pat dɛn. Bɔku tɛm, di pat dɛn we di plen dɛn kin yuz fɔ land, lɛk di tin dɛn we dɛn kin yuz fɔ land, di tin dɛn we dɛn kin yuz fɔ mek di wing, ɛn di say dɛn we dɛn kin yuz fɔ mek di plen, kin abop pan Alodine fɔ mek i nɔ rɔtin. Di bad bad tin dɛn we kin apin we pɔsin de flay kin nid fɔ gɛt taf kɔtin dɛn we kin te.

Kes Stɔdi: Di Boeing 787 Dreamliner de yuz Alodine pan in wing ɛn tel strɔkchɔ. Di kɔtin de ɛp fɔ protɛkt dɛn impɔtant tin dɛn ya frɔm kɔrɛshɔn, we de mek shɔ se di plen sef ɛn liv lɔng.

Wan ɔda impɔtant industri na ilɛktroniks. Bɔku tɛm dɛn kin yuz alɔdin fɔ mek ilɛktronik os dɛn, kɔnɛkta dɛn, ɛn ɔt sink dɛn. Di kɔtin de gi kɔrɛshɔn rɛsistɛns we i de mentɛn ilɛktrik kɔnduktiviti.

Yu bin No? Dɛn kin ivin yuz alɔdin na di mɛrɛsin biznɛs. Yu kin fɛn am pan ɔspitul inschrumɛnt ɛn tin dɛn we pɔsin kin put insay pɔsin in bɔdi.

Ɔda tin dɛn we dɛn kin yuz na:

● Pat dɛn fɔ motoka

● Di tin dɛn we de insay di si

● Ikwipmɛnt fɔ sojaman dɛn

● Di tin dɛn we dɛn kin yuz fɔ bil os

I nɔ mata di industri, Alodine de gi wan we we pɔsin kin abop pan fɔ protɛkt ɛn ɛp fɔ mek di aluminiɔm pat dɛn fayn.

Dizayn Kɔnsidɛreshɔn fɔ Alodine Finish

We yu de disayn pat dɛn fɔ Alodine finishing, sɔm impɔtant tin dɛn de we yu fɔ tink bɔt. Dɛn tin ya kin ambɔg di kwaliti ɛn di ɛfɛktiv we di kɔtin de wok.

Fɔs ɛn di men tin na fɔ pripia di say we di wata de. Di aluminiɔm sɔfays fɔ klin ɛn nɔ gɛt ɛnitin fɔ du wit am bifo dɛn kɔt am. Ɛni dɔti, ɔyl, ɔ ɔksayd kin mek i nɔ atak am fayn. I impɔtant fɔ klin gud gud wan.

Wan ɔda impɔtant tin na di tik we di kɔtin tik. As wi dɔn tɔk, di tik we di Alodine kɔtin gɛt kin afɛkt prɔpati dɛn lɛk kɔrɛshɔn rɛsistɛns ɛn ilɛktrik kɔnduktiviti. Di wan dɛn we de mek dizayn fɔ pik di rayt klas fɔ kɔt fɔ wetin dɛn nid.

Pro Tip: Fɔ krichɔ aplikeshɔn, bɔku tɛm i kin bɛtɛ fɔ wok wit ɛkspiriɛns Alodine apliketa. Dɛn kin ɛp fɔ mek shɔ se di kɔtin tik ɛn di yunifom.

We wi de tɔk bɔt yunifom, fɔ ajɔst wan kɔnsistɛns kɔtin tik na impɔtant tin. Di kɔtin we nɔ ivin kin mek i wik ɔ i kin mek di wok we i de du kin chenj. Di rayt we fɔ yuz am ɛn di we aw fɔ kɔntrol di kwaliti impɔtant.

Na sɔm advays dɛn fɔ mek yu gɛt di bɛst rizɔlt wit Alodine:

● Mek shɔ se dɛn klin di pat dɛn fayn fayn wan bifo yu kɔt dɛn

● Pik di rayt klas fɔ kɔt fɔ wetin yu nid

● Wok wit pipul dɛn we gɛt ɛkspiriɛns fɔ aplay fɔ impɔtant pat dɛn

● Yuz di rayt we fɔ yuz am fɔ kɔba di yunifom

● Impliment kwaliti kɔntrol mɛsej fɔ chɛk if di kɔtin kɔnsistɛns

Dizayn Kɔnsidɛreshɔn | Impɔtant tin |

Di Prɛparashɔn fɔ di Surface | Krio fɔ mek yu adheshon fayn fayn wan |

Tiknɛs fɔ Kɔtin | Afɛkt kɔrɛshɔn rɛsistɛns ɛn kɔnduktiviti |

Yunifɔmiti | Mek shɔ se dɛn de du di wok we dɛn de du ɔltɛm |

Kwaliti Kɔntrol | Verifies coating mit spesifikeshɔn dɛn |

We yu mɛmba dɛn dizayn tin ya, yu kin mek shɔ se yu pat dɛn we dɛn kɔt wit Alodine de du dɛn bɛst. Ilɛksɛf na pat pan plen ɔ ilɛktronik tin, di rayt we aw dɛn mek am ɛn aw fɔ yuz am na di men tin we go mek pɔsin gɛt sakrifays.

Fun Fact: Dɛn bin fɔs divɛlɔp di Alodine prɔses insay di 1940s fɔ soja aplikeshɔn dɛn. Tide, dɛn de yuz am akɔdin to bɔku bɔku industri dɛn ɔlsay na di wɔl.

Advantej ɛn Chalenj dɛn fɔ Alodine Finish

Di bɛnifit dɛn we Alodine Coatings gɛt

Alodine coatings de gi difrɛn bɛnifit dɛn we de mek dɛn bi pɔpul choice fɔ protɛkt aluminium pat dɛn. Sɔntɛm di bɛnifit we impɔtant pas ɔl na di fayn we aw dɛn nɔ de rɔtin.

Alodine de mek wan tin, dense layt pan di aluminium surface. Dis layt de sial di mɛtal, we de mek di mɔstɔ ɛn di tin dɛn we de rɔtin nɔ go insay. Di rizulyt na pat we kin ebul fɔ bia wit bad bad tin dɛn we nɔ kin rɔsti ɔ we nɔ kin pwɛl.

Fant we kin mek pɔsin gladi: Di pat dɛn we dɛn kɔt wit alɔdin kin liv fɔ bɔku bɔku awa we dɛn de tɛst sɔl, we na wan kɔmɔn tin we dɛn kin yuz fɔ no aw dɛn nɔ kin rɔtin.

Wan ɔda impɔtant bɛnifit na fɔ mek di pent adheshon bɛtɛ. Alodine de gi fayn fayn say fɔ mek di pent bond to. Dis kin mek di pat dɛn we dɛn dɔn pent kin te ɛn liv lɔng.

Alodine de gi bak inkris ilɛktrik ɛn tɛmal kɔnduktiviti. Di tin, kɔnduktiv kɔtin de alaw fɔ efyushɔn fɔ transfa ilɛktrishɔn ɛn ɔt. Dis rili valyu fɔ ilɛktronik kɔmpɔnɛnt dɛn ɛn pat dɛn we kin mek pɔsin wam.

Yu bin No? Alodine in kɔnduktiviti mek am wan pɔpul chuk fɔ grɔn ɛn EMI shild aplikeshɔn.

Fɔ dɔn, Alodine de gi envayrɔmɛnt ɛn sef advantej pas ɔda kɔtin dɛn. di heks-fri Tayp 2 kotin dεm, in patikyula, de gi kכroshכn protεkshכn witout di hεlth risk dεm we de asai wit hεksavalεnt kromiכm.

Karakta dɛn fɔ Alodine Finish

Wan pan di tin dɛn we Alodine gɛt we rili wɔndaful na di tik we i tik na di tin we dɛn kɔl thin film. Tipik kotin dεm na jכs 0.00001 to 0.00004 inch tik. Pan ɔl we Alodine tan dis, i de gi strɔng protɛkshɔn frɔm kɔrɛshɔn ɛn wear.

Wan ɔda tin we wi notis na di lɔw aplikeshɔn tɛmpracha. Yu kin put alɔdin na rum tɛmpracha, ɛn yu nɔ nid fɔ put ay ɔt. Dis kin mek di kɔtin prɔses simpul ɛn i kin ridyus di kɔst fɔ ɛnaji.

Di kɔnduktiviti we alɔdin gɛt na ɔda impɔtant kwaliti. Di kɔtin de alaw fɔ transfa ilɛktrishɔn ɛn ɔt fayn fayn wan, we de mek i fayn fɔ ilɛktronik ɛn tɛmal aplikeshɔn dɛn.

Kes Stɔdi: Wan big kɔmni we de mek ayrospɛs bin chenj to Alodine fɔ di tin dɛn we dɛn de yuz fɔ mek plen. Di tin, kɔnduktiv kɔtin bin gi fayn fayn kɔrɛshɔn rɛsistɛns witout ad signifyant wet ɔ tiknes to di pat dɛn.

Dɛn no bak se alɔdin nɔ de tek bɔku mɔni. Di simpul, rum-tɛmpracha aplikeshɔn prɔses de ɛp fɔ mek di kɔst dɛn nɔ bɔku. Ɛn di protɛkshɔn we Alodine de gi fɔ lɔng tɛm kin ridyus di spɛns fɔ mentenɛns ɛn riplesmɛnt as tɛm de go.

Pro Tip: Pan ɔl we Alodine kin te, i nɔ kin pwɛl. If yu kia ɛn mentenɛns fayn fayn wan, dat kin ɛp fɔ mek di pat dɛn we dɛn kɔt wit Alodine liv lɔng.

Chalenj ɛn Limiteshɔn dɛn

Pan ɔl we i gɛt bɔku bɛnifit, Alodine finishing kin kam wit sɔm chalenj ɛn limiteshɔn. Wan pan di big tin dɛn we de mɔna pipul dɛn na di we aw dɛn de ol di tin dɛn we gɛt pɔyzin.

Tayp 1 Alɔdin kɔtin dɛn gɛt heksavalɛnt kromiɔm, we na wan tin we dɛn no se kin mek pɔsin gɛt kansa. Fɔ wok wit dɛn kɔtin ya, yu nid fɔ tek strikt sef tin dɛn fɔ protɛkt di wokman dɛn ɛn di envayrɔmɛnt. I impɔtant fɔ mek di briz kɔmɔt fayn, fɔ yuz tin dɛn fɔ protɛkt yusɛf, ɛn fɔ trowe dɔti.

Yu bin No? Bɔku kɔntri dɛn gɛt lɔ dɛn we de stɔp pipul dɛn fɔ yuz heksavalɛnt kromiɔm. Dis dɔn mek dɛn chenj to Tayp 2 kɔtin dɛn we sef, we nɔ gɛt heks.

Wan ɔda tin we kin mek i nɔ ebul fɔ du na di tik we di tin we dɛn kɔt kin tik. Pan ɔl we Alodine de gi fayn fayn tin fɔ mek i nɔ rɔtin, i nɔ kin du fɔ pat dɛn we kin west bad bad wan ɔ we kin rɔtin. insay dεn kes dεm ya, i kin nid fכ kכt tik tik lεk anodizing.

Fɔ dɔn, fɔ ajɔst di tik we di kɔtin gɛt yunifom kin tranga, mɔ pan kɔmpleks pat dɛn. Nɔ ivin kɔtin kin mek difrɛns pan kɔrɛshɔn rɛsistɛns ɛn kɔnduktiviti. Prɔpa aplikeshɔn tɛknik ɛn kwaliti kɔntrol mɛsej impɔtant fɔ mek shɔ se kɔnsistɛns rizɔlt.

Na sɔm strateji fɔ stɔp dɛn prɔblɛm ya:

● Yuz Tayp 2 kɔtin dɛn we nɔ gɛt heks ɛnitɛm we i pɔsibul

● Impliment strikt sefty protokɔlɔ fɔ handle Tayp 1 kɔtin

● Tink bɔt ɔda tin dɛn fɔ kɔt fɔ pat dɛn we dɔn abrayd bad bad wan

● Wok wit di wan dɛn we gɛt ɛkspiriɛns fɔ aplay fɔ mek shɔ se dɛn kɔba di yunifom

● Impliment kwaliti kɔntrol mɛsej fɔ chɛk if di kɔtin kɔnsistɛns

Tayp dɛn fɔ Alɔdin Kɔtin

MIL-DTL-5541 Tayp 1 Kɔtin: Karakta ɛn Aplikeshɔn

We i kam pan Alodine coatings, MIL-DTL-5541 Type 1 na wan pan di wan dɛn we pipul dɛn sabi pas ɔl. Dɛn kin kɔl dɛn bak 'hɛks krom' kɔtin, dɛn wan ya gɛt heksavalɛnt kromiɔm fɔ mek dɛn protɛkt dɛnsɛf frɔm kɔrɛshɔn.

Dɛn no di kayn kɔtin dɛn we dɛn kin yuz fɔ kɔt di tayp 1 fɔ di kayn we aw dɛn kin tan lɛk gold, brawn, ɔ klia wan. Dɛn de gi fayn fayn kɔrɛshɔn rɛsistɛns ɛn pent adheshon, we de mek dɛn bi pɔpul choice fɔ aerospace ɛn difens aplikeshɔn.

Yu bin No? Bɔku tɛm dɛn kin yuz Tayp 1 kɔtin pan ayrakt landin gia, usay i rili impɔtant fɔ protɛkt frɔm kɔrɛshɔn.

Bɔt, heksavalɛnt kromiɔm na wan tin we dɛn no se kin mek pɔsin gɛt kansa. Dis dɔn mek di Tayp 1 kɔtin dɛn de ɔnda strikt lɔ dɛn bɔt sef ɛn di envayrɔmɛnt. I impɔtant fɔ mek dɛn ol di dɔti fayn fayn wan, fɔ mek di briz kɔmɔt fayn, ɛn fɔ trowe dɔti.

Ɔda rilevɛns standad fɔ Tayp 1 kɔtin dɛn inklud:

● AMS-C-5541: Erospɛs Matirial Spɛsifikeshɔn fɔ Tayp 1 kɔtin dɛn

● MIL-C-81706: Military spesifikeshɔn fɔ kemikal kɔnvɔshɔn kɔtin

● ASTM B449: Standart spɛsifikɛshɔn fɔ kromat kɔtin pan aluminiɔm

Dɛn standad ya de gi ditayl rikwaymɛnt fɔ di aplikeshɔn ɛn pefɔmɛns fɔ Tayp 1 kɔtin dɛn.

MIL-DTL-5541 Tayp 2 Kotin: Di Eco-Friendly Alternativ

Insay di las ia dɛn, dɛn dɔn chenj to MIL-DTL-5541 Tayp 2 kɔtin dɛn. Dɛn kin kɔl dɛn bak 'hɛks-fri' kɔtin, dɛn wan ya de yuz trivalɛnt kromiɔm instead ɔf heksvalɛnt kromiɔm.

Tayp 2 kɔtin dɛn de gi di sem kayn kɔrɛshɔn protɛkshɔn lɛk Tayp 1, bɔt dɛn nɔ gɛt di sem wɛlbɔdi ɛn envayrɔmɛnt risk. Bɔku tɛm, dɛn kin sef fɔ aplay ɛn trowe dɛn, ɛn dis kin mek pipul dɛn lɛk dɛn mɔ ɛn mɔ.

Fun Fact: Di Yuropian Yuniɔn in REACH rigyuleshɔn dɔn drɛb di adopshɔn fɔ heks-fri Tayp 2 kɔtin.

We yu de pik bitwin Tayp 1 ɛn Tayp 2 kɔtin, sɔm tin dɛn de we yu fɔ tink bɔt:

● Rigyuleshɔn dɛn bɔt di envayrɔmɛnt ɛn sef

● Di lɛvɛl we dɛn nid fɔ protɛkt frɔm kɔrɛshɔn

● Aw yu want fɔ luk (bɔku tɛm di Tayp 2 kɔtin dɛn kin klia ɔ nɔ gɛt kɔlɔ) .

● Di we aw fɔ aplay ɛn di kɔst dɛn

In jɛnɛral, dɛn kin rɛkɔmɛnd fɔ yuz Tayp 2 kɔtin fɔ bɔku pan di aplikeshɔn dɛn. Dɛn de gi fayn fayn kɔrɛshɔn rɛsistɛns pan ɔl we dɛn de minimiz wɛlbɔdi ɛn envayrɔmɛnt risk. Bɔt sɔm aerospace ɛn difens spɛsifikɛshɔn dɛn kin stil nid Tayp 1 kɔtin.

Kes Stɔdi: Wan big kɔmni we de mek plen dɛn bin chenj frɔm Tayp 1 to Tayp 2 kɔtin fɔ in nyu plen dɛn. Di heks-fri kɔtin dɛn bin gi ikwal kɔrɛshɔn protɛkshɔn we dɛn bin de mek di wokman dɛn sef ɛn ridyus di impak we di envayrɔmɛnt gɛt.

Pik di Rayt Tayp fɔ Alɔdin Kɔtin fɔ Yu Projɛkt

Wit difrɛn kayn Alodine kɔtin dɛn we de, fɔ pik di rayt wan fɔ yu prɔjek kin tranga. Na sɔm impɔtant tin dɛn we yu fɔ tink bɔt:

● Matirial spesifikeshɔn dɛn: Us lɛvul fɔ mek i nɔ rɔtin, di pent adhesion, ɔ di kɔnduktiviti nid fɔ de?

● Indastri standad: Sɔm patikyula standad ɔ spɛsifikɛshɔn dɛn de we dɛn fɔ mit (ɛgz., AMS-C-5541 fɔ ɛrospɛs)?

● Rigyuleshɔn dɛn fɔ di envayrɔmɛnt: Dɛn dɔn stɔp fɔ yuz heksavalɛnt kromiɔm na yu eria?

● Di we aw dɛn kin yuz am: Wetin na di tin dɛn ɛn di tin dɛn we dɛn kin yuz fɔ put di kɔtin?

● Kɔst: Wetin na di kɔst dɛn we gɛt fɔ du wit ɛni kayn kɔtin, ivin fɔ put am ɛn fɔ trowe am?

We yu tek tɛm luk dɛn tin ya, yu kin pik di Alodine kɔtin we go mit di tin dɛn we yu prɔjek nid.

Pro Tip: We yu gɛt dawt, tɔk to pɔsin we gɛt ɛkspiriɛns fɔ yuz Alodine. Dɛn kin gi advays bɔt aw fɔ pik di rayt kɔtin fɔ yu patikyula nid dɛn.

Na dis na wan kwik sɔmari fɔ di men difrɛns bitwin Tayp 1 ɛn Tayp 2 kɔtin:

Tin | Tayp 1 (Hɛks Krom) . | Tayp 2 (Hɛks-Fri) . |

Kromiɔm Tayp | Heksavalɛnt | Trivalɛnt |

Kɔrɛshɔn Resistɛns | Wɛl dɔn | Wɛl dɔn |

Aw a luk | Golden, brawn, ɔ klia | Bɔku tɛm, i kin klia ɔ i nɔ gɛt kɔlɔ |

Risk dɛn fɔ wɛlbɔdi biznɛs | Dɛn no se na tin we de mek pɔsin gɛt kansa | Risk we smɔl |

Di impak we di envayrɔmɛnt gɛt | I pas am pas dat | Ridyus |

Tipik Aplikeshɔn dɛn | Erospɛs, difens | Jɛnɛral industrial |

Alodin vs. Anodizing: Wan Kɔmparativ Analysis

Di Anodizing Proses we Dɛn Nɔ Kɔba

Anodizing na ɔda pɔpul finish fɔ aluminiɔm pat dɛn. Lεk Alodine, i de gi kכroshכn rεsistεns εn i de εnhans di surface prכpati dεm. Bɔt di we aw dɛn kin du am ɛn di tin dɛn we kin apin kin rili difrɛn.

Anodizing na ilektrokemikכl prכsεs we de mek wan tik, porous oksayd layεr pan di aluminiכm sεf. Dɛn kin put di pat insay wan asid ilɛktrɔlayt bat ɛn put am ɔnda ilɛktrik kɔrɛnt. Dis kin mek di aluminiɔm ɔksidayz, ɛn mek wan layt we de protɛkt am.

Fɔni Fakt: Di wɔd 'anodize' kɔmɔt frɔm 'anode,' we na di pɔzitiv ilɛktrɔd na ilɛktrɔkɛmikɛl sɛl.

di anodizing prכsεs tipikli involv sεvεra stεp dεm:

1.Klin: Dɛn kin klin di aluminiɔm pat fayn fayn wan fɔ pul ɛnitin we de dɔti.

2.Etching: Dɛn kin etch di sɔfays wit kemikal fɔ mek i gɛt wanwɔd tɛkstɔr.

3.Anodizing: Dɛn kin put di pat insay di ilɛktrɔlayt bat ɛn put am ɔnda ilɛktrik kɔrɛnt.

4.Kɔlɔ (opshɔnal): Dɛn kin ad daya to di porous ɔksayd layt fɔ mek kɔlɔ.

5.Sealing: di pores dεm na di oksayd layεr dεn de sial fכ impruv kכrכshכn rεsistεns.

di rizultant anodized layεr de tik bכku pas wan Alodine kכt, tipikli 0.0001 to 0.001 inch. Dis de gi fayn fayn wear ɛn abrasion resistance.

6.2.2.2. Kɔmpia Alodine ɛn Anodized Finish dɛn

Wail ɔl tu Alodine ɛn anodizing de gi kɔrɛshɔn rɛsistɛns fɔ aluminiɔm, sɔm impɔtant difrɛns dɛn de pan di pefɔmɛns ɛn di we aw i de luk.

We i kam pan di we aw dɛn kin te, di anodized kɔtin dɛn kin jɔs at ɛn dɛn nɔ kin wɛr pas Alodine. di tik, had oksayd layt kin bia wit big abrashכn εn fyzikal damej. Alodine, bikɔs i tan lɛk tin, i kin izi fɔ wɛr.

Bɔt, Alodine tipikli de gi bɛtɛ kɔrɛshɔn rɛsistɛns pas anodizing. di dense, nכn-porous kromat layt na fayn fayn barεri εgεst kכrosiv εlimεnt dεm. Anodized layers, bi porous, kin alaw sכm pεnεtreshכn fכ kכrosiv sכbstans dεm if nכ sial dεm fayn.

Di we aw pɔsin luk na ɔda men difrɛns. Dɛn kin day di pat dɛn we dɛn dɔn anɔd insay bɔku bɔku kɔlɔ dɛn, we kin mek dɛn ebul fɔ mek dizayn mɔ. Alɔdin kɔtin dɛn kin jɔs tan lɛk gold, brawn, ɔ klia wan.

Fɔ wok, bɔku tɛm dɛn kin lɛk Alodine fɔ ilɛktrik aplikeshɔn bikɔs ɔf in kɔnduktiv prɔpati dɛn. Anodized coatings na bɛtɛ fit fɔ aplikeshɔn dɛn we nid fɔ gɛt had ɛn wear resistance.

Kɔst na ɔda tin we wi fɔ tink bɔt. Anodizing na jεnarali mכr dia pas Alodine biכs fכ di mכr komplεks prכsεs εn ikwipment we dεn nid. Bɔt di lɔng we aw di anodized pat dɛn kin te kin ɔfset dis fɔs kɔst.

Frɔm sef ɛn envayrɔmɛnt standpɔnt, Alodine gɛt sɔm bɛnifit dɛn. Hɛks-fri Tayp 2 Alɔdin kɔtin dɛn sef ɛn nɔ de ambɔg di envayrɔmɛnt pas tradishɔnal anodayzin prɔses, we kin yuz strɔng asid ɛn ebi mɛtal bɔku tɛm.

6.3. Pik di Rayt Finish fɔ Yu Aluminium Pat dɛn

Wit di difrɛns bitwin Alodine ɛn anodizing na yu maynd, aw yu go pik di rayt finish fɔ yu aluminiɔm pat dɛn? Na sɔm impɔtant tin dɛn we yu fɔ tink bɔt:

● Di tin dɛn we yu nid fɔ mek yu nɔ gɛt kɔrɛshɔn

● Wear ɛn abrasion resistance nid fɔ gɛt

● Di we aw yu want fɔ luk ɛn di kɔlɔ dɛn we yu kin pik

● Ilɛktrik kɔnduktiviti we dɛn nid

● Kɔst ɛn prodakshɔn volyum

● Rigyuleshɔn dɛn bɔt sef ɛn envayrɔmɛnt

In jɛnɛral, Alodine na fayn tin fɔ pik fɔ pat dɛn we nid:

● Ay kɔrɛshɔn rɛsistɛns

● Ilektrikal kɔnduktiviti

● I nɔ go tek bɔku mɔni

● Fasta prodakshɔn

Bɔku tɛm dɛn kin lɛk fɔ yuz anodizing fɔ pat dɛn we nid:

● Ay wear ɛn abrashɔn rɛsistɛns

● Di kɔlɔ dɛn we yu kin pik fɔ dekɔret

● Kɔt we tik ɛn we kin te

Pro Tip: Insay sɔm kes dɛm, wan kɔmbaynshɔn fɔ Alodine ɛn anodizing kin gi di bɛst pan ɔl tu di wɔl dɛm. Wan Alodine kotin kin aplay as bays layt fɔ kɔrɛshɔn rɛsistɛns, dɔn dɛn kin anodizing fɔ wear rɛsistɛns ɛn kɔlɔ.

Na dis na sɔm pan di men difrɛns bitwin Alodine ɛn anodizing:

Tin | Alɔdin we dɛn kɔl | Anodizing we yu de yuz |

Tiknɛs fɔ Kɔtin | 0.00001 - 0.00004 inch | 0.0001 - 0.001 inch |

Kɔrɛshɔn Resistɛns | Wɛl dɔn | Gud |

Wear Resistans fɔ wɛr | Du tin tret | Wɛl dɔn |

Aw a luk | Gold, brawn, ɔ klia | Difrɛn difrɛn kɔlɔ dɛn |

Ilɛktrik Kɔnduktiviti | Gud | Pɔ |

Pe | Ridyus | I pas am pas dat |

Di impak we di envayrɔmɛnt gɛt | Lɔwa (Tayp 2) . | I pas dat |

Ultimately, di choice bitwin Alodine ɛn anodizing dipen pan di spesifik rikwaymɛnt dɛm fɔ yu aplikeshɔn. If yu tek tɛm tink bɔt di tin dɛn we wi dɔn tɔk bɔt ɛn tɔk to pipul dɛn we sabi bɔt aw fɔ kɔt tin, yu kin pik di tin we yu go yuz fɔ mek di tin dɛn we yu nid fɔ du, fɔ mek yu luk, ɛn fɔ pe fɔ di tin dɛn we yu nid.

Mentɛnans ɛn Sefty

Mentɛn Alodine Kɔt Sɔfays

Prɔpa mentenɛns na di ki fɔ mek shɔ se di Alodine kɔt sɔfays dɛn de wok fɔ lɔng tɛm. Pan ɔl we Alodine de gi fayn fayn kɔrɛshɔn rɛsistɛns, i nɔ rili invulnerable. If yu de chɛk ɛn kia fɔ yu ɔltɛm, dat kin ɛp fɔ mek yu pat dɛn we yu kɔt go liv lɔng.

Tips fɔ Inspekshɔn:

● Yu fɔ luk di say dɛn we dɛn kɔt fɔ si if ɛni sayn de we de sho se i dɔn pwɛl, i dɔn west, ɔ i dɔn rɔtin.

● Pe atɛnshɔn mɔ to di ed dɛn, di kɔna dɛn, ɛn di say dɛn we dɛn kin wɛr ɔ we kin rɔtin.

● Yuz magnifying glas ɔ maykroskɔp fɔ chɛk if smɔl smɔl krak krak ɔ pinhol dɛn de na di kɔtin.

If yu si ɛnitin we dɔn pwɛl, i impɔtant fɔ adrɛs am kwik kwik wan. Yu kin tɔch smɔl smɔl skrat ɔ say dɛn we dɔn pwɛl wit Alodine tɔch-ap pen ɔ brɔsh. Big say dɛn kin nid fɔ pul ɛn kɔt bak.

Di Gaydlain fɔ Klin di ples:

● Yuz tin dɛn we nɔ gɛt bɛtɛ pH ɛn we nɔ gɛt pH ɛn we saf klos ɔ brɔsh.

● Nɔ yuz abrasive klin ɔ pad dɛn we kin skrach di kɔtin.

● Rinse am fayn fayn wan wit klin wata ɛn dray am ɔl.

● Nɔ yuz sɔlvɛnt ɔ harsh kemikal dɛn we kin pwɛl di Alodine kɔtin.

Fant we kin mek pɔsin gladi: Alodine coatings kin mɛn insɛf te to wan digri. If dɛn skrach am, di kromat layt kin muf smɔl smɔl ɛn sidɔm bak di say we dɔn pwɛl.

If yu klin ɛn mentenɛns am ɔltɛm, dat kin ɛp fɔ mek dɔti, dɔti, ɛn tin dɛn we de rɔtin nɔ gɛda na di say we di wata de. Dis kin rili ɛkstɛnd di layf fɔ di Alodine kɔtin ɛn di aluminiɔm we de ɔnda am.

Pro Tip: Fɔ pat dɛn we kin wɛr ɔ abrashɔn bad bad wan, tink bɔt fɔ put klia tɔpkot oba di Alodine layt. Dis kin gi yu ɛkstra layt fɔ protɛkt yusɛf frɔm di bad bad tin dɛn we yu de du.

Sefty Protokɔlɔ ɛn Handling

We yu de wok wit Alodine ɛn ɔda kromat kɔnvɔshɔn kɔtin, sef fɔ bi di fɔs tin ɔltɛm. Dɛn kɔtin ya kin gɛt kemikal dɛn we de mek pɔsin sik ɛn we nid fɔ ol ɛn trowe fayn fayn wan.

Di tin dɛn we yu fɔ du fɔ mek yu sef:

● Ɔltɛm wɛr di rayt pɔsin in prɔtɛktiv ikwipmɛnt (PPE) we yu de ol Alodine sɔlvushɔn. Dis inklud glɔv, tin fɔ protɛkt yu yay, ɛn mashin fɔ blo if yu de sprɛy.

● Wok na say we briz kin blo fayn fɔ mek yu nɔ blo di smok.

● Nɔ tɔch di skin wit Alodine sɔlvushɔn. If yu kɔntakt am, was am fayn fayn wan wit sop ɛn wata.

● Kip di Alodine sɔlvushɔn dɛn fa frɔm ɔt, spak, ɛn opin faya.

● Stɔr di Alodine sɔlvushɔn dɛn na say we kol ɛn dray usay di san nɔ de shayn dairekt wan.

Di tin dɛn we fɔ tek tɛm wit di envayrɔmɛnt:

● Alɔdin sɔlvushɔn kin ambɔg di layf we de na wata. Nɔ fri dɛn na dreyn ɔ watawe.

● Trowe di dɔti we dɛn kɔl Alodine fayn fayn wan lɛk aw di lokal lɔ dɛn se. Dis kin mek yu nid fɔ yuz laysens fɔ trowe dɔti we gɛt prɔblɛm.

● Nɔ miks Alodine west wit ɔda kemikal dɛn, bikɔs dis kin mek yu gɛt prɔblɛm.

Risaykul ɛn Dispɔzishɔn:

● Bɔku tɛm, dɛn kin yuz di pat dɛn we dɛn kɔt alɔdin bak we dɛn dɔn. Chek wit yu lokal risaykul fasiliti fɔ gaydlayn.

● If nɔto opshɔn fɔ risaykul, trowe di pat dɛn we dɛn kɔt as dɔti we de mek yu sɔfa.

● Nɔ ɛva bɔn di pat dɛn we dɛn kɔt Alodine, bikɔs dis kin mek pɔyzin smok kɔmɔt.

Mɛmba se, heksavalɛnt kromiɔm (we dɛn kin si na Tayp 1 kɔtin) na wan tin we dɛn no se kin mek pɔsin gɛt kansa. If yu gɛt dis sik, dat kin mek yu gɛt siriɔs wɛlbɔdi prɔblɛm. Ɔltɛm, put sef fɔs ɛn fala di rayt we aw fɔ handle.

Kes Stɔdi: Wan ples usay dɛn de mek tin dɛn bin chenj to heks-fri Tayp 2 Alɔdin kɔtin fɔ mek di wokman dɛn sef. We dɛn pul di heksavalɛnt kromiɔm na dɛn prɔses, dɛn bin ridyus di prɔblɛm dɛn we kin apin to dɛn wɛlbɔdi biznɛs ɛn mek di we aw dɛn kin trowe dɔti izi.

Na dis na wan kwik sɔmari fɔ di men tin dɛn we yu fɔ du fɔ mek yu sef ɛn aw fɔ handle:

● Wear di rayt PPE

● Wok na say dɛn we briz kin blo fayn

● Nɔ kɔntakt yu skin

● Stɔr di sɔlv dɛn fayn fayn wan

● Trowe di dɔti we di rigyuleshɔn se

● Risaykul we i pɔsibul

Fiuja fɔ Alodine Finishing

Innovashɔn dɛn na Kromat Kɔnvɔshɔn Kɔtin

Di fiuja fɔ Alodine finishing brayt, wit inovashɔn ɛn advansmɛnt dɛn we de go bifo pan kromate kɔnvɔshɔn kɔtin teknɔlɔji. Risach pipul ɛn manifakta dɛn de kɔntinyu fɔ mek nyu fɔmyulashɔn ɛn aplikeshɔn we fɔ mek dɛn wok fayn, sef, ɛn fɔ mek di envayrɔmɛnt fayn.

Wan fayn tin we dɛn de du fɔ mek nyu tin na di divɛlɔpmɛnt fɔ kɔtin dɛn we nɔ gɛt kromat kɔnvɔshɔn. Dɛn kɔtin ya de yuz ɔda kemistri dɛn lɛk zirkoniɔm ɔ taytaniɔm kɔmpawnd dɛn fɔ mek dɛn protɛkt di kɔrɛshɔn we dɛn nɔ yuz kromiɔm.

Fant Fact: NASA dɔn mek wan kɔtin we nɔ gɛt kromat kɔnvɔshɔn we dɛn kɔl NASA-426 fɔ yuz pan spɛshal plen ɛn ay-pafɔmɛnshɔn ayrakt.

Wan ɔda prɔmis nyu tin na di yus fɔ nanoteknɔlɔji fɔ kɔnvɔshɔn kɔtin. bay we dεn inkכrporεt nanopartikl dεm insay di kכt fכmulashכn, risεchכr dεm kin εnhans prכpati dεm lεk kכrכshכn rεsistεns, hadnεs, εn sεlf-hεlin abiliti.

Di advansmɛnt dɛn we dɛn dɔn mek pan di we aw dɛn de yuz am, lɛk sprɛy kɔtin ɛn brɔsh pletin, de mek bak di versatility ɛn aksesibiliti fɔ Alodine kɔtin dɛn go bifo. Dɛn we ya de alaw fɔ kɔntrol mɔ prɛsis pan di tik we di kɔtin tik ɛn di kɔva, ɛn bak fɔ ebul fɔ kɔt kɔmpleks shep dɛn ɛn say dɛn we at fɔ rich.

Envayrɔmɛnt Impekt ɛn Rigyuleshɔn dɛn

As pipul dɛn de no bɔt di envayrɔmɛnt, di prɛshɔn de go ɔp fɔ ridyus di yus fɔ kemikal dɛn we de mek pipul dɛn sɔfa lɛk heksavalɛnt kromiɔm insay di industrial prɔses dɛn. Kromate kɔnvɔshɔn kɔtin, inklud Alodine, dɔn kam ɔnda skrutinyɔ bikɔs ɔf di pɔtɛnɛshɛl impak dɛm we dɛn kin gɛt pan di envayrɔmɛnt ɛn wɛlbɔdi.

Fɔ ansa dis, di rigyuletɔri bɔdi dɛn ɔlsay na di wɔl de impruv strikt rigyuleshɔn dɛn bɔt aw fɔ yuz ɛn trowe kromiɔm kɔmpawnd dɛn. Fɔ ɛgzampul:

● Di Yuropian Yuniɔn in REACH rigyuleshɔn de stɔp fɔ yuz heksavalɛnt kromiɔm pan sɔm aplikeshɔn dɛn.

● Di US Envayrɔmɛnt Protɛkshɔn Ajɛns (EPA) dɔn sɛt strikt lɔ fɔ di kromiɔm we dɛn de pul ɛn di dɔti we dɛn de trowe.

● Bɔku kɔntri dɛn nid spɛshal pɔmit ɛn aw fɔ handle heksavalɛnt kromiɔm kɔmpawnd dɛn.

Dɛn rigyuletɔri chenj ya de drɛb di divɛlɔpmɛnt ɛn adopshɔn fɔ mɔ eko-friɛndli ɔltɛrnativ to tradishɔnal kromat kɔnvɔshɔn kɔtin. Hɛks-fri Tayp 2 Alɔdin kɔtin, we de yuz trivalɛnt kromiɔm instead ɔf heksavalɛnt kromiɔm, dɔn bi pɔpul mɔ ɛn mɔ bikɔs dɛn nɔ gɛt bɛtɛ impak pan di envayrɔmɛnt ɛn dɛn nid fɔ handle am sef.

Ɔda eko-friɛndli ɔltɛrnativ to kromat kɔnvɔshɔn kɔtin inklud:

● Kɔtin dɛn we dɛn mek wit zikɔniɔm

● Kɔtin dɛn we dɛn mek wit taytaniɔm

● Sɔl-jɛl kɔtin dɛn

● Ɔrganik tin dɛn we dɛn kin kɔt

Pan ɔl we dɛn ɔltɛrnativ ya nɔ kin mach yet di pefɔmɛns fɔ kromat kɔtin dɛn na ɔl di aplikeshɔn dɛn, dɛn kin gi prɔmis opshɔn dɛn fɔ ridyus di envayrɔmɛnt impak we kɔrɛshɔn protɛkshɔn kin gɛt.

Fɔ Luk bifo:

Di fiuja fɔ Alodine finishing go mɔs shep bay wan kɔmbaynshɔn fɔ teknɔlɔji inovashɔn ɛn envayrɔmɛnt stewɔdship. As di wan dɛn we de du risach de divɛlɔp nyu, ay-pafɔmɛnshɔn kɔtin dɛn wit lɔwa envayrɔmɛnt impak, di wan dɛn we de mek dɛn go nid fɔ balans pefɔmɛns, kɔst, ɛn sastaynabiliti insay dɛn kɔtin we dɛn de pik.

Sɔm impɔtant tin dɛn we yu fɔ wach na:

● Kɔntinyu fɔ divɛlɔp kɔtin dɛn we nɔ gɛt kromat kɔnvɔshɔn

● Dɛn de yuz nanoteknɔlɔji ɛn ɔda advans tin dɛn mɔ ɛn mɔ

● Biga ɛmpɛshmɛnt pan layfsaykl asɛsmɛnt ɛn eko-dizayn prinsipul dɛm

● Strikt rigyuleshɔn dɛn na di wɔl bɔt kemikal dɛn we de mek pipul dɛn sɔfa

● Diman we de gro fɔ kɔtin dɛn we go kɔntinyu fɔ de ɛn we nɔ go ambɔg di envayrɔmɛnt

We dɛn de bifo pan dɛn tin ya ɛn put inovashɔn ɛn sastaynabiliti fɔs, di Alodine finishing industri kin kɔntinyu fɔ gi ay kwaliti kɔrɛshɔn protɛkshɔn we i de minimiz in envayrɔmɛnt futprin. Di tumara bambay fayn fɔ di wan dɛn we ebul fɔ adap ɛn mek nyu tin dɛn na dis fayn fayn wok.

Dɔn

Fɔ dɔn, Alodine coatings na impɔtant tul insay di mɔdan manifakta in tulkit. Wit dɛn impreshɔnal kɔrɛshɔn rɛsistɛns, versatile aplikeshɔn, ɛn kɔntinyu innovashɔn, dɛn rɛdi fɔ kɔntinyu fɔ bi wan ki pleya insay sɔfayz protɛkshɔn fɔ ia dɛn we de kam.

We yu ɔndastand di bɛsis tin dɛm fɔ Alodine, tink bɔt yu patikyula nid dɛm, ɛn patna wit ɛkspiriɛns pɔshɔnal dɛm, yu kin ɔplɔk di ful pɔtnɛshɛl fɔ dɛn pawaful kɔtin ya fɔ yu nɛks prɔjek.

So if yu redi fɔ tek yu aluminiɔm pat dɛn to di nɛks lɛvul wit Alodine, nɔ shek fɔ du am rich ɔut to di ɛkspɛkt dɛn na TEAM MFG . Wi de ya fɔ ɛp yu ɛvri step na di we, frɔm di kɔtin sɛlɛkshɔn to di las inspekshɔn.

FAQs fɔ Alodine Finish

K: Wetin na Alodine finish, ɛn aw i de bɛnifit di manufakchurin prɔses?

A: Alɔdin na kromat kɔnvɔshɔn kɔtin we de protɛkt mɛtal dɛn frɔm kɔrɛshɔn ɛn i de mek di pent adheshon bɛtɛ.

K: Aw yu kin put Alodine chromate coating, ɛn wetin na di difrɛn we dɛn?

A: Yu kin put alɔdin bay we yu brus, dip/imɛr, ɔ sprɛy. Immersion na di we we dɛn kin yuz mɔ.

K: Wetin mek dɛn kin tek Alodine finishing impɔtant fɔ CNC mashin pat dɛn?

A: Alodine de gi kɔrɛshɔn protɛkshɔn we nɔ de chenj di pat dimɛnshɔn dɛn bad bad wan, we de mek i fayn fɔ prɛsis CNC pat dɛn.

K: Wetin na di tiknɛs rɛnj fɔ kromat kɔnvɔshɔn kɔtin ɛn in siginifikɛns?

A: Kromat kotin dεm de frכm 0.25-1.0 μm (0.00001-0.00004 inch) tik, we de gi protεkshכn wit minimal dimεnshכnal impak.

K: Wetin na di men difrɛns bitwin Tayp I ɛn Tayp II Alodine finish?

A: Tayp I gɛt heksavalɛnt kromiɔm ɛn i gɛt mɔ denja. Tayp II de yuz trivalɛnt kromiɔm ɛn i sef.

K: Aw Alodine finishing de impruv ilɛktrik kɔnduktiviti na mɛtal pat?

A: Di tin we alɔdin gɛt de mek i ebul fɔ protɛkt am frɔm kɔrɛshɔn we nɔ de ambɔg di ilɛktrik kɔnduktiviti bad bad wan.

K: Yu kin yuz Alodine finishing pan ɔda mɛtal dɛn pas aluminiɔm?

A: Yes, yu kin yuz Alodine pan ɔda mɛtal dɛn lɛk kɔpa, magnɛsiɔm, kadmiɔm, ɛn stɛl we dɛn plet zink.

K: Wetin na di envayrɔmɛnt kɔnsidareshɔn wit Alodine finishing?

A: Hɛksavalɛnt kromiɔm we de na Tayp I Alodine na wan tin we pipul dɛn sabi we de mek pɔsin gɛt kansa ɛn i nid fɔ gɛt spɛshal we fɔ ol am ɛn trowe am.

K: Aw di kɔst fɔ Alodine finishing kɔmpia to ɔda sɔfayz tritmɛnt dɛn?

A: Alodine jεnarali nכ de dia pas כda tritmεnt dεm lεk anodizing biכs fכ in simpul aplikεshכn prכsεs.