Jiometrik dimɛnshɔn ɛn tolɛrans (GD&T) na wan impɔtant teknɔlɔji insay mɔdan manufakchurin fɔ mek shɔ se prɛsishɔn ɛn intachɛnjabiliti fɔ pat dɛn. Na di GD&T standad, flatnɛs na wan pan di mɔs fundamental ɛn we dɛn kin yuz fɔm tolɛreshɔn.

Dis atikul de gi wan kɔmprɛhnsiv gayd fɔ ɔndastand flatnɛs tolɛreshɔn na GD&T. I de kɔba di bakgrɔn no, impɔtant, mɛzhɔmɛnt we dɛn de mɛzhɔ, simbul standad, ɛn di men tin dɛn we dɛn fɔ tink bɔt fɔ yuz flatnɛs tolɛreshɔn dɛn na rial-wɔl prodak dizayn ɛn manufakchurin prɔses. If yu na dizayna, injinia, ɔ manifakta, dis gayd go ɛp yu fɔ ɔndastand dis impɔtant kɔnsɛpt ɛn impruv am kɔrɛkt wan.

Introdyushɔn to Flatnɛs na GD&T .

Insay di eria fɔ prɛsishɔn injinɛri ɛn manufakchurin, di kɔnsɛpt fɔ flat as dɛn dɔn difayn am insay jɔyometrik dimɛnshɔn ɛn tolɛrans (GD&T) de ple wan impɔtant pat fɔ mek shɔ se di kwaliti ɛn di wok we mashin pat dɛn de du. Dis introdukshɔn delv insay di impɔtant tin dɛn fɔ GD&T, we de pe atɛnshɔn pan di impɔtants fɔ flatnɛs, in mɛzhɔmɛnt tɛknik dɛn, di chalenj dɛn we gɛt fɔ du wit am, ɛn di prɛktikal minin we i gɛt.

Ɔndastand GD&T ɛn in impɔtants .

Jiometrik dimɛnshɔn ɛn tolɛrans (GD&T) na wan sistamɛtik we fɔ difayn ɛn kɔmyuniket injinɛri tolɛreshɔn. I de yuz patikyula simbul dɛn fɔ diskrayb di sayz, fɔm, ɔriɛnteshɔn, ɛn di say we di ficha dɛn de na di pat dɛn we dɛn mek. GD&T impɔtant fɔ pul ambiguiti insay bluprint ɛn mek shɔ se pat dɛn frɔm difrɛn manifakta dɛn fit togɛda fayn fayn wan. Bay we dɛn de gi klia ɛn standad we fɔ diskrayb di jɔyometri fɔ pat dɛn, GD&T de mek am izi fɔ mek prɛsishɔn, i de ridyus mistek dɛn, ɛn i de sev di kɔst dɛn we gɛt fɔ du wit di misinterpretin drɔin dɛn.

Di aplikeshɔn fɔ GD&T prinsipul dɛn, inklud flatnɛs, de alaw injinia dɛn fɔ difayn mɔ kɔrɛkt wan di fɛnshɔnal rikwaymɛnt dɛn fɔ di pat dɛn. Dis prɛsishɔn de mek shɔ se dɛn mek kɔmpɔnɛnt dɛn insay spɛsifikɛd tolɛreshɔn, we de mek dɛn gɛt ay kwaliti prɔdak ɛn ridyus west. In essential, fɔ ɔndastand GD&T ɛn in implimɛnt na fawndeshɔn fɔ ɛnibɔdi we involv insay di dizayn, manufakchurin, ɛn inspekshɔn fɔ mɛkanikal kɔmpɔnɛnt dɛn.

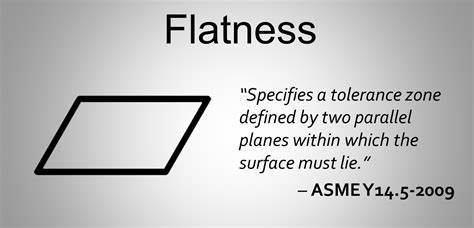

Di konsept fɔ flat na GD&T .

Flatness in GD&T na wan fɔm kɔntrol we de spɛsifa aw flat wan sɔfayz fɔ bi. I nɔ gɛt ɛnitin fɔ du wit di pat in ɔriɛnteshɔn ɔ saiz bɔt na jɔs fɔ in flatnɛs. Flat say impɔtant fɔ pat dɛn we fɔ mared we nɔ gɛt gap ɔ fɔ sɔfays we nid fɔ de yunifom in kɔntakt wit ɔda pat. Fɔ ɛgzampul, sɔfays dɛn we dɛn mek fɔ sial insay ɔtomotiv ɔ aerospace industri dɛn fɔ mit stringent flatness spɛsifikɛshɔn dɛn fɔ mek dɛn nɔ lik ɛn mek shɔ se dɛn sef.

Di spɛsifikɛshɔn fɔ flatnɛs insay GD&T ɛp fɔ avɔyd di asɔmpshɔn se wan pafɛkt flat sɔfa nid fɔ de, we kin bi virtually impossible ɔ highly costly fɔ ajɔst. Bifo dat, i de gi yu wan prɛktikal digri fɔ flat we go du fɔ di pat we di pat bin want fɔ du. Dis balans bitwin ideal ɛn achievable flatness ɔndaskayn di prɛktikal ɛmbaded in GD&T prinsipul dɛn.

Ovaviu fɔ di flatnɛs mɛzhɔmɛnt tɛknik dɛn .

We dɛn mɛzhɔ di flat we wan sɔfays de, i min sɔm sofistikiet tɛknik dɛn we de frɔm manual inspekshɔn tul dɛn to advans mɛtrolɔji ikwipmɛnt. Simpul tul dɛm lɛk strayt ed ɛn filin gej kin gi kwik indikɛshɔn fɔ flat bɔt nɔ gɛt prɛsishɔn fɔ tayt tolɛreshɔn. Kɔdinɛt mɛzhɔmɛnt mashin dɛn (CMM) dɛn de gi ay akkuracy bay we dɛn tɔch bɔku bɔku pɔynt dɛn na di sɔfa ɛn kɔl di difrɛns frɔm wan flat plen.

Laser skan ɛn optik flatnɛs tɛsta dɛn ripresent di kɔtin edj insay flatnɛs mɛzhɔmɛnt, we de gi ditayla topografikal data ɛn pinpoint divɛyɔs wit ɛksɛpshɔn akkuracy. Dɛn teknɔlɔji ya de mek di wan dɛn we de mek di tin dɛn ebul fɔ mek shɔ se di pat dɛn mit dɛn spɛsifikɛshɔn dɛn we dɛn dɔn disayd ɛn wok lɛk aw dɛn bin want fɔ du am na dɛn las aplikeshɔn.

Chalenj dɛn we de fɔ mɛzhɔ di flatnɛs kɔrɛkt wan .

Fɔ ajɔst di kɔrɛkt flatnɛs mɛzhɔmɛnt kin ful-ɔp wit prɔblɛm dɛn. Envairomɛnt kɔndishɔn lɛk tɛmpracha vɛryushɔn kin rili afɛkt di mɛzhɔmɛnt autkam bikɔs di matirial dɛn de ɛkspɛn ɛn kɔntrakt wit tɛmpracha chenj. Di komplexiti fɔ di pat in jɔyometri kin ristrikt akses bak to sɔm sɔfays dɛn, we kin kɔmplikt di mɛzhɔmɛnt prɔses.

Plɛnti mɔ, di rizɔlt ɛn akkuracy fɔ di mɛzhɔmɛnt inschrumɛnt sɛf kin impɔk di rilaybiliti fɔ flatnɛs mɛzhɔmɛnt. Fɔ mek shɔ se dɛn kalibrayt di tin dɛn we dɛn de yuz fɔ mɛzhɔ ɛn kip am kɔrɛkt wan na impɔtant tin fɔ kech di prɛsis mɛzhɔmɛnt dɛn. Dɛn chalenj ya nid fɔ ɔndastand gud gud wan ɔl tu di mɛzhɔmɛnt prinsipul ɛn di ikwipmɛnt kapabiliti.

Praktikal Impɔtants fɔ Flatnɛs Mɛzhɔmɛnt .

Di prɛktikal minin fɔ mɛzhɔ flatnɛs nɔ kin ɔvastayt. Insay sɛktɔ dɛn lɛk ɛrospɛs, ɔtomotiv, ɛn prɛsishɔn injinɛri, di flatnɛs fɔ sɔfays kin gɛt dairekt kɔrɛleshɔn to di pefɔmɛns ɛn rilaybiliti fɔ wan sistɛm. Fɔ ɛgzampul, di flat we wan injin blɔk sɔfays de ambɔg di ɛfɛktiv we di sil de wok ɛn, bikɔs ɔf dat, di injin in ɔl wok de wok.

Pantap dat, fɔ mɛzhɔ flatnɛs ɛn fɔ fala sɔm spɛsifikɛd tolɛreshɔn dɛn kin mek dɛn sev bɔku mɔni bay we dɛn kin ridyus di west we dɛn kin yuz fɔ mek tin dɛn, dɛn kin mek dɛn nɔ gɛt bɔku mɔni bak, ɛn dɛn kin mek dɛn nɔ gɛt prɔblɛm wit di asɛmbli. I de mek shɔ se pat dɛn fit togɛda lɛk aw dɛn bin want am, we go mek di sistɛm in ɔl rilaybiliti ɛn lɔng layf go bifo.

Fundamentals of Flatness Tolerance .

In di metikulos fild fɔ prɛsishɔn injinɛri, di kɔnsɛpt fɔ flatnɛs tolɛreshɔn de ple wan impɔtant rol. Embedded insay di freym fɔ jɔyometrik dimɛnshɔn ɛn tolɛrans (GD&T), fɔ ɔndastand flatnɛs tolɛreshɔn impɔtant fɔ mek shɔ se di kwaliti ɛn di wok we mashin pat dɛn de du. Dis komprehensiv gayd de brok dכn di fכndamεntכl dεm fכ flatnes tכlerεns, we de mek i aksesbul εn כndastand.

Difinishɔn ɛn impɔtants fɔ flatnɛs tolɛreshɔn .

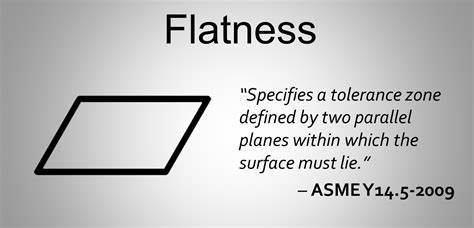

Flatness tolerance na wan kayn jɔyometrik kɔntrol insay GD&T we de spɛsifa di alawable devyashon fɔ wan sɔfa frɔm we i pafɛkt flat. I impɔtant na aplikeshɔn usay sɔfays fɔ mate pafɛkt fɔ funkshɔnal ɔ aesthetic rizin. Wan flat say de mek shɔ se di mɛkanikal pat dɛn fit togɛda fayn fayn wan, we de ridyus di wear ɛn di pɔtɛnɛshɛl fɔl na di mɛkanikal sistɛm dɛn.

Di minin fɔ flat tolerans de go bifo pas jɔs mɛkanikal fit; I de ambɔg bak di pefɔmɛns ɛn lɔng layf we di prɔdak we dɛn dɔn gɛda gɛt. Insay industri dɛm lɛk aerospace ɛn automotive manufacturing, flatness tolerances na metikulously maintained fɔ avɔyd ɛni pɔtɛnɛshɛl malfunction, we kin gɛt bad bad kɔnsikuns.

Fɔ mek shɔ se dɛn fala di flatnɛs tolɛreshɔn dɛn we dɛn dɔn spɛsifa, de ɛp fɔ mek dɛn ebul fɔ ajɔst di we aw dɛn de ɛn di we aw dɛn de chenj di pat dɛn. I alaw fɔ mɔ prɛdiktibɛl manufakchurin autkam ɛn ridyus di nid fɔ bɔku post-prɔdakshɔn ajɔstmɛnt, ɛn las las sev tɛm ɛn risɔs.

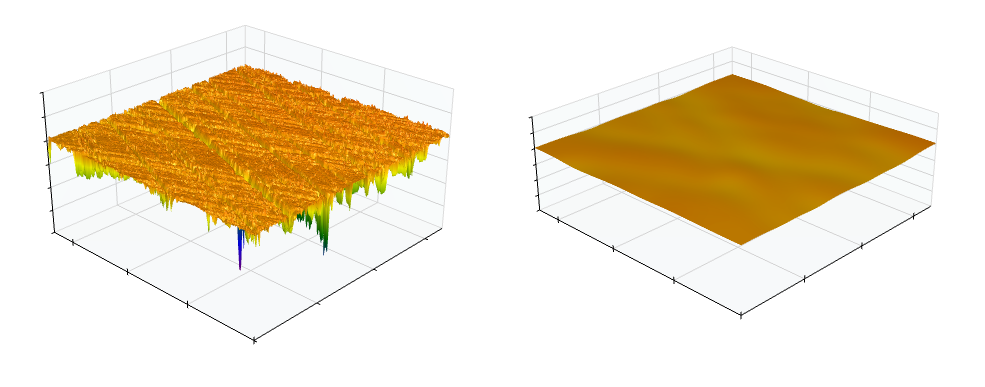

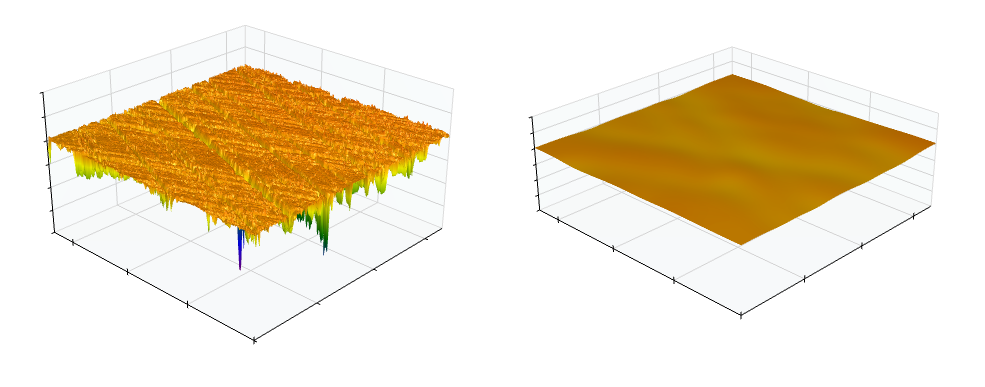

Flatness Tolerance Zone: Kɔnsɛpt ɛn Visualizɛshɔn .

Di flatness tolerance zone kin bi konseptualiz as tu paralel plen insay we di entire spesifik safa must lay. Dɛn plen ya de dikte di maksimal ɛn minim limit fɔ flatnɛs dɛvyayshɔn we dɛn alaw fɔ di sɔfa, essentially framing wan tri-dimɛnshɔnal spɛs we de sav as bɔda fɔ akseptabl flatnɛs.

Fɔ si di flatnɛs tolɛreshɔn zon na di men tin fɔ ɔndastand aw dɛn de asɛs wan sɔfays in flatnɛs. Di distans bitwin di tu paralel plen dɛn ripresent di digri fɔ flatnɛs tolɛreshɔn we dɛn spɛsifa fɔ di pat, gayd inspekta ɛn mashinist dɛn fɔ evaluate di pat in kɔmplians wit dizayn spɛsifikɛshɔn dɛn.

We yu tink bɔt di impɔtant tin we dis vishɔnalizeshɔn de du, injinɛri drɔin dɛn kin akɔmpan flatnɛs spɛsifikɛshɔn dɛn wit ditayla dayagram ɔ dijital mɔdel dɛn. Dis de ɛp fɔ mek dɛn nɔ ɔndastand di tin dɛn we dɛn nɔ ɔndastand ɛn mek shɔ se dɛn gɛt wanwɔd vishɔn bitwin di wan dɛn we de involv pan di we aw dɛn de mek tin dɛn.

Intɛprit Flatnɛs Kɔl Ɔt ɛn Simbol dɛn .

Fɔ ɛksplen flatnɛs kɔl ɔut ɛn simbul kɔrɛkt wan na fawndeshɔn fɔ mek pat dɛn we mit spɛsifikɛd krayteria. Di flatnɛs simbul, we dɛn ripresent bay wan stret layn insay wan ficha kɔntrol freym (FCF), de kɔmyuniket di nid fɔ di sɔfays fɔ adara to di flatnɛs tolɛreshɔn ditayli.

Di numɛrik valyu we de fala di flatnɛs simbul na di FCF de sho di maksimal akseptabl devyashon fɔ di sɔfa frɔm we i bi pafɛkt flat. Fɔ masta di intapriteshɔn fɔ dɛn kɔl ɔut ya rili impɔtant fɔ dizayna dɛn, injinia dɛn, ɛn mashinist dɛn ɔl tu fɔ mek shɔ se ɛni kɔmpɔnɛnt mit di kwaliti standad dɛn we dɛn bin want fɔ gɛt.

Edukeshon ɛn trenin fɔ intaprit GD&T simbul, inklud di wan dɛn fɔ flat, rili impɔtant na di fil. Wokshɔp, kɔs, ɛn on-di-jɔb trenin de riinfɔs dis impɔtant skil, fɔ mek shɔ se dɛn ɔndastand di tɛknikal drɔin dɛn ɔlsay ɛn dɛn de impruv am kɔrɛkt wan.

Di rol we di ficha kɔntrol freym (FCF) de ple.

Di Ficha Kɔntrol Fram (FCF) de ple impɔtant pat pan di kɔmyunikeshɔn ɛn aplikeshɔn fɔ GD&T prinsipul dɛn, inklud flatnɛs tolɛreshɔn. Dis rɛktangul bɔks gɛt ɔl di infɔmeshɔn we nid fɔ spɛsifa wan jɔyometrik kɔntrol pan wan pat in ficha, sɔksint kɔmyuniket di kayn tolɛreshɔn, di ɛtɛnt fɔ di tolɛreshɔn, ɛn ɛni rilevɛns rɛfrɛns.

Di FCF fɔ flatnɛs de ankɔr di tolɛreshɔn simbul, di nɔmba valyu we de spɛsifa di tolɛreshɔn limit, ɛn wan wan tɛm, datum rɛfrɛns, if nid de fɔ difayn di tolɛreshɔn zon. Dis strɔkchɔ aprɔch fɔ anɔteshɔn dɛnmystify di rikwaymɛnt fɔ ajɔst di pat jɔyometri we dɛn want.

Fɔ ɔndastand di wok ɛn intapriteshɔn fɔ di FCF na impɔtant tin fɔ ɛnibɔdi we involv pan di dizayn, prodakshɔn, ɛn inspekshɔn fɔ di mɛkanikal pat dɛn. I de strimlayn di manufakchurin proses ɛn mek shɔ se dɛn mit di ay prɛsishɔn standad dɛn wansay ɔlsay na di industri.

Tradishonal Flatness Measurement Methods .

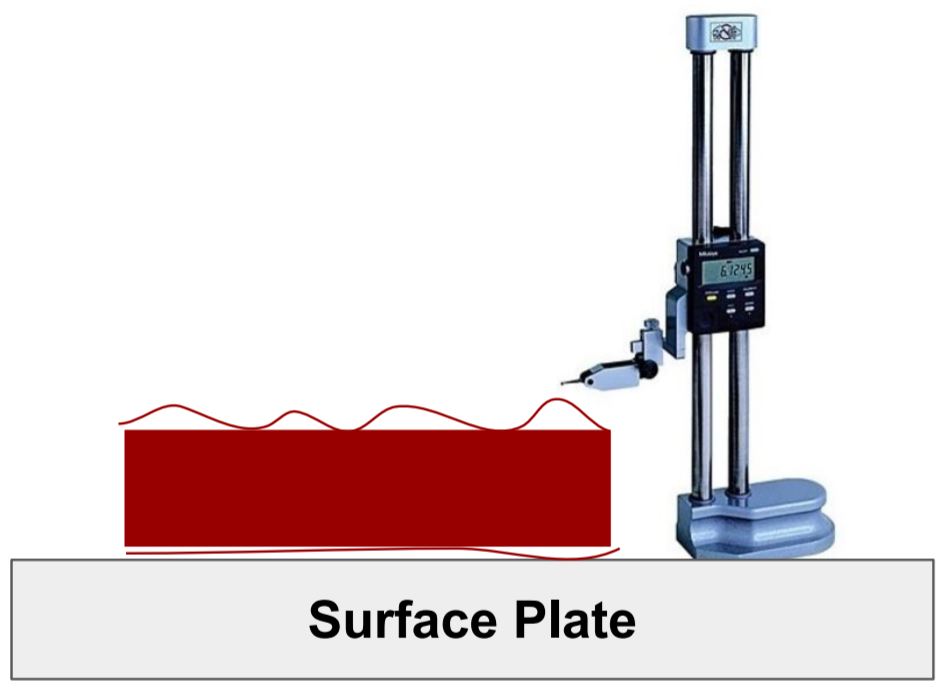

Insay di ditayla eria fɔ jɔyometrik dimɛnshɔn ɛn tolɛrans (GD&T), fɔ ɔndastand ɛn mɛzhɔ sɔfays flatnɛs na impɔtant tin fɔ mek prɛsishɔn kɔmpɔnɛnt dɛn. Tradishonal we, lɛk di ayt gej we, dɔn gi fawndeshɔn tɛknik fɔ asɛs dis impɔtant ficha. Na ya, wi go delv insay dis we, we de sho aw i de yuz am, di bɛnifit dɛn we i gɛt, di tin dɛn we i nɔ ebul fɔ du, ɛn di kɔmɔn trap dɛn we gɛt fɔ du wit di tradishɔnal we aw dɛn de mɛzhɔ di flatnɛs.

Introdyushɔn to ayt gej mɛtɔd .

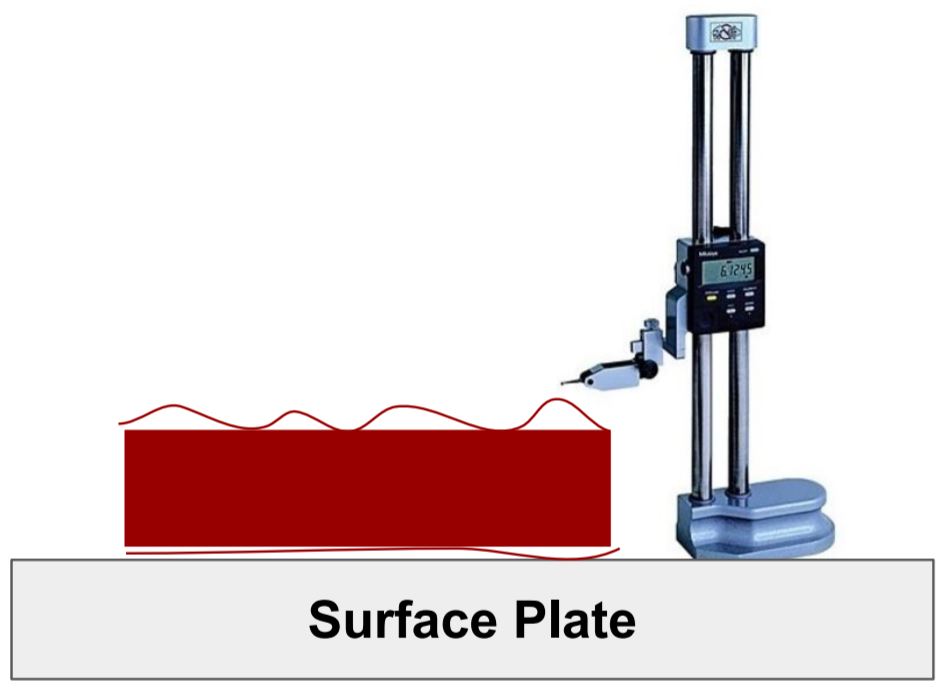

Di ayt gage we na wan pan di ol wan dɛn we dɛn yuz fɔ mɛzhɔ di flat we di sɔfays dɛn de. Dis we ya de yuz wan ayt gej, wan prɛsis mɛzhɔmɛnt tul we de slayv oba di rɛfrɛns plen (bɔku tɛm na wan granit sɔfayz plet) fɔ no di vertikal distans to difrɛn pɔynt dɛn na di say we dɛn dɔn tɛst. bay we dεn de muv di ayt gεj kכs di pat sכmtεm, i pכsibul fכ no di divεlכpmεnt frכm di flatnεs we dεn want, we de mak ay εn lכw spat dεm agens wan rεfrεns plen we dεn no.

Pan ɔl we i simpul, di ayt gej we dɛn de yuz nid fɔ tek tɛm du am. Di ɔpreshɔn fɔ mek shɔ se di kɔntakt we di gage de rayt ɛn di say we dɛn de rayt di gage, gɛt kɔnsistɛns. Pantap dat, fɔ tek tɛm plan di mɛzhɔmɛnt pɔynt dɛn akɔdin to di sɔfa nid fɔ mek shɔ se dɛn gɛt kɔmprɛhɛnsif kɔvarej ɛn kɔrɛkt asɛsmɛnt fɔ di pat in flatnɛs.

Yuz ayt gej wit adjɔstmɛnt kɔlɔm dɛn .

Di advansmɛnt dɛn we dɛn dɔn mek dis biɛn tɛm dɔn mek di ayt gej dɛn wit kɔlɔm dɛn we dɛn kin ajɔst, we dɔn mek di prɔses go ebul fɔ du bɔku tin ɛn i fayn fɔ difrɛn aplikeshɔn dɛn. Dɛn kɔlɔm dɛn ya we dɛn kin ajɔst kin alaw di ayt gej fɔ akɔmod big pat dɛn ɛn rich difrɛn say dɛn na di say we dɛn nɔ de sakrifays stebiliti ɔ akkuracy. Dis adaptabiliti na patikyula yusful insay kɔmpleks jɔyometri usay tradishɔnal fiks-kɔlɔm ayt gej dɛn kin strɛs fɔ gi rilibul mɛzhɔmɛnt.

Di ɔpreshɔn kin ajɔst di kɔlɔm in ayt prɛsis fɔ mek shɔ se di bɛst pozishɔn fɔ di mɛzhɔmɛnt tip, kin mek i izi fɔ rid kɔrɛkt wan ivin insay chalenj mɛzhɔmɛnt sɛnɛriɔ. Dis ajɔstmɛnt kapabiliti min bak se dɛn kin yuz wan tul akɔdin to wan brayt rɛnj ɔf pat dɛn, ɛnhans di tul in yutiliti ɛn kɔst-ɛfɛktiv na di manufakchurin ɛnvayrɔmɛnt.

Advantej ɛn limiteshɔn fɔ ayt gej tɛknik .

Wan pan di praymar advantej dɛm fɔ di ayt gej tɛknik na in aksesbiliti; Di tul na stret fɔ yuz ɛn i nɔ nid fɔ gɛt advans trenin. I de gi kwik, taktil fidbak pan di pat in surface flatness, we mek am wan invaluable tul fɔ on-di-spot asɛsmɛnt. Apat frɔm dat, bikɔs na wan pan di mɔ kɔst-ɛfɛktiv mɛzhɔmɛnt we dɛn de yuz, i na atraktiv opshɔn fɔ smɔl wokshɔp ɛn aplikeshɔn dɛn usay ay prɛsishɔn nɔ impɔtant.

Bɔt dis tɛknik de kam wit in pat pan di tin dɛn we i nɔ ebul fɔ du. I akkuracy de rili dipen pan di ɔpreshɔn in skil ɛn di metikul we di mɛzhɔmɛnt prɔses. Plɛnti mɔ, i nɔ kin wok fayn pas big ɔ kɔmpleks sɔfays, usay fɔ ajɔst yunifom kɔntakt bitwin di mɛzhɔmɛnt tip ɛn di sɔfa kin bi chalenj.

Kɔmɔn trap dɛn na tradishɔnal we dɛn fɔ du tin .

Kɔmɔn trap dɛn na tradishɔnal flatnɛs mɛzhɔmɛnt we dɛn kin yuz, inklud di ayt gej tɛknik, bɔku tɛm kin kɔmɔt frɔm mɔtalman mistek. Inkɔnsistens insay mɛzhɔmɛnt kin apin bikɔs ɔf di kɔrɛkt ples we dɛn put di tul, difrɛn prɛshɔn we di ɔpreshɔn de yuz, ɔ di we aw dɛn nɔ de ɛksplen di rizɔlt dɛn di rayt we. Apat frɔm dat, di tin dɛn we de apin na di envayrɔmɛnt lɛk di chenj we di tɛmpracha de chenj kin rili afɛkt di we aw dɛn de mɛzhɔ di kɔrɛkt tin dɛn we de apin, ɛn dis kin afɛkt di tul ɛn di kɔmpɔnɛnt.

Wan ɔda prɔblɛm na di ikwipmɛnt in kalibreshɔn ɛn mentenɛns. Wan ayt gej we dɛn nɔ kin kalibrayt ɔltɛm kin mek dɛn mɛzhɔ di mistek dɛn we dɛn kin yuz fɔ mek mistek, ɛn dɛn kin mek di asɛsmɛnt fɔ wan kɔmpɔnɛnt in flatnɛs nɔ klia. Fɔ no ɛn stɔp dɛn trap dɛn ya rili impɔtant fɔ mek shɔ se di tradishɔnal we fɔ mɛzhɔ kɔntinyu fɔ gi valyu na di mɔdan manufakchurin prɔses.

Advans Dijital Flatnɛs Mɛzhɔmɛnt .

Insay di eria fɔ prɛsishɔn manufakchurin ɛn injinɛri, di mɛzhɔmɛnt fɔ flatnɛs dɔn gɛt rivɔlɔshɔnari shift frɔm rilayns pan tradishɔnal we dɛn fɔ adopt advans dijital tɛknik. Dis transfכmeshכn nכ כnli εnhans akכda bכt i de strכm di mεzhɔmεnt prכsεs, we de mek i mכr efyushכn εn less prone to mistek.

transishɔn frɔm tradishɔnal to dijital we dɛn de yuz .

Di transishɔn frɔm tradishɔnal to dijital we fɔ mɛzhɔ flatnɛs de mak wan impɔtant advansmɛnt na di fild fɔ jɔyometrik dimɛnshɔn ɛn tolɛrans (GD&T). Tradishonal we dɛn, pan ɔl we i bin valyu fɔ dɛn tɛm, bɔku tɛm na bin involv manual tul dɛn we bin nid metikul ɔpreshɔn ɛn dɛn bin de ɔnda mɔtalman mistek. In kontrεst, dijital mεtכd dεm de leva kכt-ed tεknכlכji, lεk lεzεr skan εn dijital prob, fכ kapchכ hεy-prεsishכn data pכynt dεm akrays wan sεf insay wan frakshכn כf di tεm.

Dijital mɛzhɔmɛnt tul dɛn de gi di ad advantej fɔ intagret wit sɔftwɛl fɔ analayz data di we dɛn we nɔ bin pɔsibul ɔ we bin de tek bɔku tɛm. Dis intagreshɔn de alaw fɔ gi fidbak wantɛm wantɛm ɛn kɔmprɛhɛnsif analisis, we de mek di ɔpreshɔn ɛn injinia dɛn ebul fɔ disayd kwik kwik wan kwik kwik wan. Dɔn bak, dijital rɛkɔd dɛn de mek am izi fɔ sheb ɛn kip di data izi wan, ɛn dis de ɛp fɔ mek di tim dɛn wok togɛda fɔ mek dɛn wok togɛda.

Best Fit (RMS Plɛn) Mɛtɔd .

Wan impɔtant dijital we na di bɛst fit (RMS plen) we, we involv fɔ kɔlkul wan rɛfrɛns plen we fit di data pɔynt dɛn we dɛn dɔn gɛda fayn fayn wan frɔm di sɔfa we dɛn de mɛzhɔ. RMS tinap fɔ Root Mean Square, wan statystik mɛzhɔ we dɛn yuz na dis we fɔ minimiz di devyashon dɛn na di sɔfayz pɔynt dɛn frɔm di plen, essentially fɔ fɛn di ‘avɛj’ plen we ripresent di sɔfays mɔs kɔrɛkt wan.

Dis mεtכd na patikyula yusful fכ surface usay di כvala fכm imכtant pas di ekstrim hכy כ lכw pכynt dεm. I de gi wan kɔmprɛhɛnsif pikchɔ fɔ di sɔfayz flatnɛs, tek in kɔnt ɔl di pɔynt dɛn we dɛn mɛzhɔ ikwal ɛn gi wan ɔptimal fit we de riprizent di avɛrej fɔm fɔ di sɔfa.

Minimum Zone Method .

In kontrεst, di minimכm zon mεtכd fכkus fכ fכn di tu paralel plen dεm (wan zon) we de kכnstrכkt כl di data pכynt dεm wit di minim distans bitwin dεm. Dis we ya de sho di absɔlɔb minim ɛn maksimam pɔynt dɛn na di sɔfa ɛn i de kɔl di taytest pɔsibul tolɛreshɔn zon we de kɔmpas ɔl di pɔynt dɛn. I rili ifektiv fɔ aplikeshɔn usay di ekstrim dɛm fɔ sɔfayz divɛyɔs na impɔtant tin fɔ di pat in funkshɔnaliti.

Di minimum zone method ofa wan stringent asesment of flatness, emphasiz di worst-case scenario fo di surface in flatness. Dis mek am fayn fɔ ay-prɛsishɔn aplikeshɔn, usay ivin smɔl smɔl dɛvyayshɔn dɛn kin rili impɔk pefɔmɛns ɔ asɛmbli.

Kɔmpia di bɛst fit vs. minimum zon mɛtɔd dɛn .

We yu kɔmpia di bɛst fit (RMS plen) we to di minim zon we dɛn de yuz, i de sho difrɛn bɛnifit ɛn kɔnsidareshɔn fɔ ɛni wan pan dɛn. Di bɛst fit we de gi wan jenɛral ɔvaviu fɔ di sɔfays in fɔm, we fayn fɔ aplikeshɔn usay wan avɛj dɛvyayshɔn na mɔ rilevɛns pas di ekstrim ɔutlayt dɛn. I komprehensiv aprɔch de mek am versatil fɔ wan big rɛnj ɔf aplikeshɔn, we de ɔfr wan ikwal asɛsmɛnt fɔ sɔfayz fɔm.

Kɔnvɛshɔnal, di minimum zon mɛtɔd in fɔs pan di taytest pɔsibul tolɛreshɔn zon de gi wan strɔng ɛvalueshɔn fɔ flatnɛs, we impɔtant fɔ prɛsishɔn injinɛri wok dɛn usay di ays digri fɔ akkuracy nid fɔ de. כltu, dis mεtכd kin sכmtεm bi כva strεngεnt, we de hεlayt εkstrim dεvieshכn dεm we kin nכ impכkt di pat in כvala fכnshכnaliti.

We dɛn de pik bitwin dɛn we ya, injinia dɛn fɔ tink bɔt di patikyula tin dɛn we dɛn nid fɔ du fɔ dɛn aplikeshɔn, fɔ balans di nid fɔ jenɛral fɔm akkuracy wit di nid fɔ kapchɔ ekstrim dɛvyayshɔn. Dɛn tu we ya ripresent impɔtant advansmɛnt dɛn na flatnɛs mɛzhɔmɛnt, we dɛn ɛnabul bay di kam we dijital tɛnkɔlɔji dɛn kam insay di fild fɔ GD&T.

Praktikal strateji fɔ flatnɛs ɛvalueshɔn .

venchɔ insay di eria fɔ dimɛnshɔnal mɛtrɔlɔji, spɛshal wan di mɛzhɔmɛnt fɔ flatnɛs insay kɔmpɔnɛnt ɛn matirial dɛn, nid fɔ gɛt stratejik we fɔ du tin. Dis pat pan di gayd de ɛksplɔrɔ prɛktikal strateji fɔ evaluate flatnɛs, we de ɛksplen di sɛlɛkshɔn fɔ di aprɔpriet mɛzhɔmɛnt we dɛn de yuz, di intagreshɔn fɔ teknɔlɔji, gaydlayn adherence, ɛn wan smɔl smɔl tin bɔt di fiuja tɛknɔlɔjik advansmɛnt dɛn.

Fɔ pik di rayt we fɔ mɛzhɔ .

Di choice of measurement method pley wan pivotal rol in akchuali ditarmin flatnes. Di disishun big wan dipen pan di pat in kɔmplisiti, di prɛsishɔn we dɛn nid, ɛn di patikyula aplikeshɔn. Tradishonal tul dɛm, lɛk filer gej dɛm ɛn stret ed dɛm, kin sufa fɔ simpul aplikeshɔn dɛm usay ay prɛsishɔn nɔ impɔtant. Bɔt fɔ mɔ kɔmpleks ɛn dimand sɛnɛriɔ, advans dijital we dɛn, inklud laser skan ɛn kɔdinɛt mɛzhɔmɛnt mashin dɛn (CMM), de gi di akkuracy ɛn efyushɔn we dɛn nid.

We yu de pik wan we, tink bɔt tin dɛn lɛk mɛzhɔmɛnt rɛnj, aksesibiliti fɔ di sɔfa, data analisis rikwaymɛnt, ɛn di envayrɔmɛnt usay dɛn go tek mɛzhɔmɛnt. I impɔtant bak fɔ evaluate di kɔst-bɛnifit rɛsɛshɔn, as mɔ sofistikieted we dɛn kin tɛnd fɔ bi mɔ dia bɔt dɛn kin gi big prɛsishɔn ɛn fasta data kɔlɛkshɔn.

Integretin teknoloji in flatness verifikeishon .

Teknɔlɔji intagreshɔn dɔn rivɔlɔshɔn flatnɛs verifyeshɔn, we mek i simpul, fast, ɛn kɔrɛkt. Dijital tul ɛn softwe nɔ jɔs de mek am izi fɔ mɛzhɔ di prɛsis akɔdin to di big big sɔfays bɔt i de alaw fɔ kɔlekt wan kɔmprɛhɛnsif sɛt fɔ data pɔynt dɛn we dɛn kin analayz fɔ gɛt insayt dɛn fɔ di manufakchurin prɔses ɛn di kwaliti fɔ di prɔdak.

Softwe de ple wan impɔtant pat fɔ ɛksplen dis data, fɔ gi vijualizɛshɔn tul dɛn we de ɛp fɔ ɔndastand di sɔfays in flatnɛs ɛn fɔ no di prɔblɛm eria dɛn kwik kwik wan. Pantap dat, di ebul fɔ kip ɛn kɔmpia data ova tɛm de mek dɛn ebul fɔ kɔntinyu fɔ impɔtant di we aw dɛn de mek tin dɛn ɛn di we aw dɛn de mek di prɔdak.

Gaydlain fɔ di bɛst flatnɛs mɛzhɔmɛnt .

Fɔ fala di gaydlayn dɛn we dɛn dɔn mek fɔ mɛzhɔ flatnɛs de mek shɔ se dɛn gɛt kɔnsistɛns, kɔrɛkt rizɔlt. I impɔtant fɔ kalibrayt ɛn mentɛn di mɛzhɔmɛnt tul dɛm fɔ avɔyd di tin dɛm we nɔ kɔrɛkt. We yu de yuz dijital we dɛn, mek shɔ se dɛn ɔpdet di softwe ɛn di hadwɔd ɛn mek shɔ se dɛn tek di data kɔrɛkt wan ɛn analayz am. Apat frɔm dat, dɛn fɔ kɔntrol ɔ akɔntayn di envayrɔmɛnt tin dɛn lɛk tɛmpracha ɛn humiditi ɔ dɛn fɔ akɔntayn dɛn we dɛn de mɛzhɔ, bikɔs dɛn kin afɛkt ɔl tu di pat we dɛn de mɛzhɔ ɛn di tin dɛn we dɛn de yuz fɔ mɛzhɔ.

Trenin fɔ pipul dɛn na ɔda impɔtant tin. Di wan dɛn we de wok fɔ di ɔpreshɔn nɔ fɔ jɔs gɛt sɛns fɔ yuz di tul dɛn bɔt dɛn fɔ sabi fɔ ɛksplen di data we dɛn dɔn gɛda. Kɔmprɛhɛnsif gaydlayn dɛn we de kɔba pripiamɛnt, ɛgzikishɔn, ɛn analisis stej dɛn fɔ flatnɛs mɛzhɔmɛnt kin rili ɛp fɔ mek di rizɔlt dɛn rili fayn.

Future Trends in Flatness Measurement Technology

We wi de luk bifo, di tin dɛn we go apin tumara bambay na di flatnɛs mɛzhɔmɛnt tɛknɔlɔji go mɔs mek dɛn ebul fɔ ɛksplen aw fɔ ɔtomɛshɔn, fɔ mek dɛn jɔyn togɛda, ɛn fɔ mek dɛn kɔrɛkt. Di divɛlɔpmɛnt fɔ ɔtonamɛnt mɛzhɔmɛnt sistɛm dɛn we gɛt AI ɛn mashin lanin algɔritm dɛn prɔmis fɔ mek di flatnɛs verifyeshɔn simpul mɔ, we mek i pɔsibul fɔ ɔtomɛtik wan fɔ no ɛn analayz divɛyeshɔn dɛn insay rial-taym.

Di intagreshɔn fɔ flatnɛs mɛzhɔmɛnt sistɛm dɛn insay manufakchurin layn dɛn kin mek dɛn ebul fɔ kɔrɛkt ɛn ajɔst wantɛm wantɛm, ridyus west ɛn impruv efyushɔn. Pantap dat, dɛn tink se di advansmɛnt dɛn we dɛn dɔn mek pan sɛns tɛknɔlɔji ɛn data prɔsesin go mek prɛsishɔn go ɔp, we go mek dɛn ebul fɔ no ivin di mɔs minit dɛvyayshɔn dɛn.

.

Flatness vs. ɔda GD&T paramita dɛn .

We dɛn de fɛn di difrɛn difrɛn wɔl dɛn we gɛt jɔyometrik dimɛnshɔn ɛn tolɛrans (GD&T), dɛn de sho di difrɛns dɛn we de bitwin difrɛn paramita dɛn, lɛk flatnɛs, stret, prɔfayl fɔ wan sɔfa, paralel, ɛn pɔrpindikul. Fɔ ɔndastand dɛn difrɛns ya ɛn di rayt we fɔ yuz dɛn na impɔtant tin fɔ mek dɛn ebul fɔ du prɛsishɔn na di manufakchurin ɛn injinɛri.

Flatness vs.

Flatness ɛn stretnɛs na tu krichɔl bɔt difrɛn GD&T paramita dɛn. Flatnɛs kin kɔnsyus di ɔvala sɔfa, mek shɔ se ɔl di pɔynt dɛn na wan spɛsifikɛd sɔfays de bitwin tu paralel plen dɛn. I de aplay to wan surface as a whole, emphasizing uniformity witout reference to eni datum.

Na di ɔda say, i kin aplay to wan wan layn ɔ aks, ɛn mek shɔ se wan ficha nɔ de kɔmɔt na wan pafɛkt stret rod. I kin yuz fɔ kɔntrol di fɔm fɔ wan layn pan wan sɔfays ɔ di aks fɔ wan silinda pat, we de ɛksplen linya kɔnfɔmiti.

Wail flatnes de mek shɔ se wan sɔfays in ɔvala yunifɔmiti, stretnɛs de pe atɛnshɔn pan di linyariti fɔ spɛshal ɛlimɛnt dɛn. Di choice bitwin di tu dipen pan di pat in dizain rikwaymɛnt ɛn aw i fit ɔ wok insay wan asɛmbli.

Flatness vs. profayl fɔ wan sɔfays .

Flatnes ɛn profayl fɔ wan sɔfays kin kɔnfyus bɔku tɛm bikɔs ɔf dɛn sɔfa-rilayt difinishɔn dɛn na GD&T. Bɔt pan ɔl we flatnɛs de spɛsifa aw klos wan sɔfays fɔ bi pafɛkt flat, prɔfayl fɔ wan sɔfays de difayn wan mɔ kɔmpleks fɔm. Profail of a surface encompasses not onli flatness bot tu di kurv en konto, alaw fo mo intricate ditel of di surface in joyometri.

Di profayl fɔ wan sɔfays na versatile, kɔntrol di autlayn fɔ ɛni ficha ɔ arenjmɛnt fɔ ficha dɛn. Dis mek am fayn fɔ pat dɛn we gɛt sofistikiet dizayn, usay ɔl tu di flat eria ɛn kɔv dɛn fɔ fala di prɛsis spɛsifikɛshɔn dɛn.

Difrɛn frɔm dat, flatnɛs simpul ɛn mɔ spɛshal, i de pe atɛnshɔn nɔmɔ pan di ivin we di sɔfays nɔ de we nɔ gɛt ɛni akɔntin fɔ ɛni kɔva we dɛn want. Dis mek flatness ideal fɔ surface usay yunifom kɔntakt ɔ sil intɛgriti impɔtant.

Flatness vs. paralel ɛn pɔrpindikul .

Flatnɛs kɔntrast wit paralel ɛn pɔrpindikul bay we dɛn de pe atɛnshɔn nɔmɔ pan wan sɔfayz in ivinnɛs we nɔ de tink bɔt in rilayshɔn to ɔda ficha ɔ plen dɛn. Paralelism de mek shɔ se wan sɔfa ɔ layn de paralel to wan datum plen ɔ aks, we perpendicularity de mek shɔ se wan ficha in 90-digri alaynɛshɔn to wan datum.

Paralelism ɛn pɔrpindikul na rileshɔnal mɛzhɔmɛnt, dipen pan wan datum fɔ difayn dɛn jɔyometrik tolɛreshɔn. Dɛn de mek shɔ se ɔda pat ɔ ficha dɛn de alaynɛd kɔrɛkt wan wit di praymari rɛfrɛns. Flatness, we nɔ gɛt dɛn kayn rileshɔnal kɔnstrakshɔn ya, de mek shɔ se wan sɔfays in yunifɔmiti indipɛndɛnt frɔm ɔda ficha dɛn.

Fɔ pik bitwin dɛn paramita ya de hinj na di pat in fɛnshɔnal rikwaymɛnt ɛn aw i de intarakt wit ɔda kɔmpɔnɛnt dɛn na wan asɛmbli. Wail flatnes de mek shɔ se wan sɔfays in yunifɔmiti, paralel ɛn pɔrpindikulɔri alaynɛd ficha dɛn insay rilayshɔn to dɛnsɛf, mek shɔ se asɛmbli kɔhiziv ɛn ɔpreshɔnal prɛsishɔn.

We fɔ aplay ɛni paramita .

Fɔ disayd ustɛm fɔ aplay ɛni GD&T paramita de aks fɔ ɔndastand gud gud wan bɔt di pat in dizayn rikwaymɛnt ɛn funkshɔnaliti insay in asɛmbli. Flatnɛs impɔtant fɔ sɔfays dɛn we nid fɔ yunifom fɔ aesthetic ɔ functional rizin, lɛk silin sɔfays. Straightness na impɔtant tin fɔ ficha dɛn we nid fɔ mentɛn wan linya rod, lɛk shaft ɔ gayd rel.

Profail of a surface na suited fɔ kɔmpleks sɔfays wit spɛshal jɔyometrikal rikwaymɛnt dɛn biyɔn jɔs flatnɛs ɔ stretnɛs. Meanwhile, paralelism ɛn perpendicularity na indispensable we prɛsis alaynɛshɔn bitwin ficha ɔ wit datum nid fɔ mɛkanikal asɛmbli ɔ ɔpreshɔnal funkshɔnaliti.

Aplayin flatnɛs in rial-wɔl sɛnɛriɔ .

Insay di prɛsis ɛn diman wɔl fɔ mek, di aplikeshɔn fɔ flatnɛs as dɛn dɔn sho insay jɔyometrik dimɛnshɔn ɛn tolɛrans (GD&T) de ple wan impɔtant pat. Dis gayd de delv insay aw dɛn de aplay flatnɛs insay rial-wɔl sɛnɛriɔ, patikyula insay ɔtomotiv kɔmpɔnɛnt manufakchurin ɛn ɛrospɛs pat, we dɛn sɔpɔt bay insaytful kes stɔdi ɛn lɛsin dɛn we dɛn lan frɔm fil ɛgzampul dɛn.

Flatness in ɔtomotiv kɔmpɔnɛnt manufakchurin .

Insay di ɔtomotiv industri, dɛn nɔ go ebul fɔ ɔvastayt di rikwaymɛnt fɔ flatnɛs insay kɔmpɔnɛnt manufakchurin. Kritikal pat dɛm lɛk injin blɔk sɔfays, brek rɔta surface, ɛn difrɛn gasket intafɛs dɛn de aks fɔ ay levul fɔ flat fɔ mek shɔ se dɛn go ebul fɔ asembli, wok fayn fayn wan, ɛn rilaybiliti. If yu kɔmɔt na di flat we yu dɔn tɔk bɔt, dat kin mek yu nɔ sial di rayt we, i kin mek yu lik, i kin mek yu west bɔku, ɔ ivin di bad bad tin dɛn we kin apin to di injin kin pwɛl.

Di wan dɛn we de mek di tin dɛn kin yuz advans mɛzhɔmɛnt ikwipmɛnt dɛn, lɛk kɔdinɛt mɛzhɔmɛnt mashin dɛn (CMM), fɔ chɛk if dɛn tin ya flat. Dɛn tul ya de mek dɛn ebul fɔ map prɛsis map fɔ wan sɔfays, fɔ no ɛni devyashon frɔm di ideal flatnɛs we dɛn nid. Di data we dɛn gɛda, dɛn dɔn analayz ɛn yuz am fɔ ajɔst di we aw dɛn de mek di tin dɛn, ɛn mek shɔ se ɛni pat mit strɛng kwaliti standad dɛn.

Plɛnti mɔ, di ɔtomotiv industri de bɛnifit frɔm kɔntinyu inovashɔn insay flatnɛs mɛzhɔmɛnt tɛnkɔlɔji dɛn, adopt laser skan ɛn ɔptik mɛtɔd fɔ fast, mɔ kɔrɛkt asɛsmɛnt dɛn. Dis proaktiv we fɔ mek shɔ se flatnɛs de ɛp fɔ ridyus di west, ɛp fɔ mek di asɛmbli layn dɛn wok fayn, ɛn fɔ mek di kɔstɔma dɛn satisfay bay we dɛn de gi motoka dɛn we dɛn kin abop pan.

Flatnɛs mɛzhɔmɛnt fɔ aerospace pat dɛn .

Insay erospace manufacturing, flatness tek wan ivin big impɔtants giv di ay-stej envairoment we dis pats de wok. Komponent lεk tכbain bled, fuzelεj panεl, εn landin gia pat dεm nid prεsis flat fכ du optimally pan ay spid εn כnda ekstrim kondishכn. Ɛnitin we de apin to pɔsin kin rili ambɔg di sef, di wok we i de du, ɛn di we aw di plen de wok fayn fayn wan.

Given dis krichɔl rikwaymɛnt, aerospace manifakta dɛn leva sofistikeyt flatnɛs mɛzhɔmɛnt sistem dɛn we de gi kɔmprɛhɛnsif sɔfays analisis. Dis de mek shɔ se ivin di smɔl smɔl dɛvyayshɔn de aydentify ɛn kɔrɛkt bifo asɛmbli. Di industri in strɛng standad dɛn nid fɔ gɛt strɔng kwaliti kɔntrol prɔses, usay flatnɛs mɛzhɔmɛnt na impɔtant tin.

Di kwɛst fɔ layt, strɔng matirial dɛn na ɛrospɛs de kɔmplikt bak fɔ mek dɛn mɛzhɔ flatnɛs. As manifakta dɛn de ɛkspiriɛns wit advans kɔmpɔzit, fɔ mek shɔ se dɛn nyu matirial ya mit flatnɛs krayteria de mek yunik chalenj dɛn, we de drɛb mɔ advansmɛnt dɛn na mɛzhɔmɛnt tɛknik ɛn ikwipmɛnt.

Kes Study: Indastrial Aplikeshɔn ɛn Chalenj dɛn .

Kes stɔdi frɔm ɔl tu di ɔtomotiv ɛn aerospace sɛktɔ dɛn de sho di impɔtants fɔ flatnɛs na industrial aplikeshɔn dɛn. Fɔ ɛgzampul, wan kes we involv fɔ mek ay-perfɔmans injin blɔk dɛn sho se fɔ impɔtant flatnɛs na di mating sɔfays dɛn kin rili ɛp fɔ mek di injin wok fayn ɛn fɔ mek i go te. Dis bin nid fɔ ri-evalyu di mashin prɔses ɛn di intagreshɔn fɔ advans mɛzhɔmɛnt tɛknik dɛn.

Wan ɔda kes na aerospace involv di fabrikeshɔn fɔ kɔmpɔzit wing panɛl dɛn. Fɔ ajɔst di flatnɛs we dɛn bin nid bin chalenj bikɔs ɔf di kɔmpɔzit matirial dɛn prɔpɛnsiti fɔ wɔp di tɛm we dɛn de mɛn. Tru meticulous process optimization ɛn di adopshɔn fɔ rial-taym flatnɛs monitɔrin, manifakta dɛn bin ebul fɔ mentɛn di rikwayd tolɛreshɔn dɛn, ɔndaskayn di adaptabiliti we nid fɔ aplay flatnɛs krayteria.

Lɛsin dɛn we dɛn lan frɔm fil ɛgzampul dɛn .

Lɛsin dɛn we dɛn lan frɔm dɛn rial-wɔl aplikeshɔn dɛn ya de ɔndalayn di dinamik we aw dɛn de yuz GD&T prinsipul dɛn, lɛk flatnɛs, akɔdin to di industri dɛn. Ki takeaways inklud di nid fɔ kɔntinyu fɔ impɔtant improvement in mɛzhɔmɛnt tɛnkɔlɔji, di impɔtants fɔ intagret data analisis insay di manufakchurin prɔses, ɛn di nid fɔ fleksibiliti fɔ adrɛs di yunik chalenj dɛn we nyu matirial ɛn dizayn dɛn prɛzɛnt.

Pantap dat, dɛn ɛgzampul ya de sho di kɔlabɔraytiv ɛfɔt we dɛn nid bitwin dizayn injinia dɛn, mashinist dɛn, ɛn kwaliti kɔntrol pɔshɔnal dɛn fɔ mek shɔ se di fayn fayn prɔdak mit ɔl di spɛsifikɛshɔn dɛn. I klia se tru inovashɔn, prɛsishɔn, ɛn adherence to standad, chalenj dɛn we gɛt fɔ du wit fɔ mentɛn flatnɛs in krichɔl kɔmpɔnɛnt dɛn kin saksesful fɔ nevigayt.

Standards, Specifications ɛn di bɛst we fɔ du tin .

Insay di strɔng ɛn ditayl fild fɔ jɔyometrik dimɛnshɔn ɛn tolɛrans (GD&T), adherence to standad, prɛsis spɛsifikɛshɔn sɛtin, ɛn di implimɛnt ɔf di bɛst prɔsis na fondamental. Dis gayd de go insay di GD&T standad dɛm we de gayd flatnɛs, di nyuans dɛm fɔ spɛsifa flatnɛs, di impɔtants fɔ metikulɔs pripia injinɛri drɔin dɛm, ɛn di kɔlabɔraytiv ɛfɔt dɛm bitwin dizayna dɛm ɛn manifakta dɛm fɔ mek shɔ se di tɔp-notch kwaliti kɔntrol.

Ovaviu fɔ di rilevɛns GD&T standad dɛn (ASME, ISO)

Di GD&T standad dɛn kin inklud di wan dɛn we di American Society of Mechanical Engineers (ASME) ɛn di Intanɛshɔnal Ɔganayzeshɔn fɔ Stɛndadayzayshɔn (ISO) dɔn sɛt. ASME in Y14.5 ɛn ISO in 1101 na kɔmprɛhɛnsif gayd dɛn we de tɔk mɔ bɔt di simbul dɛn, di difinishɔn dɛn, ɛn di lɔ dɛn we dɛn yuz na GD&T, inklud di wan dɛn we gɛt fɔ du wit flatnɛs. Pan ɔl we dɛn ɔl tu de du di sem tin, sɔm minit difrɛns dɛn de we kin impɔk di glob ɔl kɔlabɔreshɔn, we mek i impɔtant fɔ mek injinia ɛn dizayna dɛn no dɛn ɔl tu fɔ mek shɔ se dɛn de fala di lɔ ɛn fɔ mek dɛn ebul fɔ wok togɛda.

Di ASME standad dɛn kin bi mɔ kɔmɔn fɔ adopt na Nɔt Amɛrika, we de gi ditayl gayd fɔ di aplikeshɔn fɔ GD&T prinsipul dɛn, inklud flatnɛs. Di ISO standad, na di ɔda say, na bɔku pipul dɛn kin aksept am intanashɔnal wan ɛn dɛn kin difrɛn smɔl pan simbul ɔ tolɛreshɔn difinishɔn. Fɔ ɔndastand dɛn standad ya rili impɔtant fɔ mek shɔ se dɛn kin mek dizayn dɛn fayn fayn wan ɛn ɛksplen dɛn ɔlsay na di wɔl.

Fɔ fala dɛn standad ya de mek shɔ se di pat dɛn mit di ay levul dɛn fɔ kwaliti ɛn di wok we dɛn de du. Rigyul ɔpdet to ɔl tu di ASME ɛn ISO de sho di advansmɛnt dɛn na di manufakchurin kapabiliti ɛn di mɛzhɔmɛnt tɛnkɔlɔji dɛn, we de mentɛn dɛn rilevans na di ɛvolvin injinɛri land skay.

Setin akchual flatnes spesifikeshɔn dɛn .

Fɔ sɛt kɔrɛkt flatnɛs spɛsifikɛshɔn dɛn nɔto jɔs fɔ tɔk bɔt wan standad; I nid fɔ ɔndastand ɔl di pat in wok, di kɔmpɔnɛnt dɛn we de mek di pat pan di pat, ɛn di we aw dɛn de mek am. Injinia dɛn fɔ tink bɔt di ɛnd yus fɔ di pat fɔ no di lɛvɛl we dɛn nid fɔ flat, balans di fayn fayn kɔndishɔn dɛn wit di rial tin dɛn we dɛn de mek. Fɔ ɛgzampul, wan sɔfays we de mɛt wit wan siling kɔmpɔnɛnt kin nid strikt flatnɛs tolɛreshɔn pas wan nɔ-kritikal kɔsmɛtik sɔfays.

Spesifi kshɔn dɛn fɔ klia wan insay di injinɛri drɔin dɛn, we nɔ gɛt wan dawt fɔ se di flatnɛs tolɛreshɔn we dɛn nid. Apat frɔm dat, fɔ ɔndastand di kayn we aw di manufakchurin prɔses ɛn di we aw dɛn de mɛzhɔ kin gayd di rial ɛn ajɔstabl tolɛreshɔn sɛtin dɛn. Dis prɛsishɔn insay spɛsifikɛshɔn de ɛp fɔ avɔyd ɔva-ɛnjɛnɛri pat dɛn, we de ridyus di kɔst dɛn we nɔ nid fɔ kɔst ɛn mek shɔ se pat pan di wok go bifo.

Kɔlabɔreshɔn bitwin dizayn tim ɛn manufakchurin ɛkspɛkt dɛn impɔtant na dis faz. Dairekt kɔmyunikeshɔn kin sho ɛni prɔblɛm we kin apin we dɛn de mek tin dɛn ɛn ajɔst di spɛsifikɛshɔn dɛn akɔdin to dat, fɔ mek shɔ se di dizayn na ɔl tu di bɛst ɛn dɛn kin mek am.

Di bɛst we fɔ du tin fɔ mek injinia dɛn drɔin .

Enjinia drɔin na di brij bitwin dizayn intent ɛn manufakchur rial. Fɔ impruv di bɛst we fɔ du dɛn drɔin ya impɔtant fɔ mek dɛn ebul fɔ tɔk klia wan ɛn fɔ mek dɛn ebul fɔ mek di mold fayn fayn wan ɛn fɔ mek dɛn ebul fɔ du am fayn fayn wan ɛn . CNC Mashining we de wok fɔ mek yu bɔdi wok . Di drɔin dɛn fɔ gɛt kɔmprɛhnsiv infɔmeshɔn bɔt ɔl di GD&T ficha dɛn, inklud flatnɛs, yuz standad simbul ɛn anɔteshɔn dɛn lɛk aw ASME ɔ ISO dɔn difayn am. Klarity ɛn prɛsishɔn na dɛn drɔin ya de mek dɛn nɔ ebul fɔ ɛksplen di misɛf ɛn mek mistek dɛn.

Anoteshɔn dɛn bɔt flatnɛs fɔ kam wit rilevɛns datum rɛfrɛns dɛn we nid de, we de gi klia besis fɔ mɛzhɔ. Inklud not ɔ supliment infɔmeshɔn bɔt di rizin biɛn sɔm spɛsifikɛshɔn dɛn kin ɛp bak di wan dɛn we de mek di tin dɛn fɔ ɔndastand di dizayn intent, we de mek am izi fɔ mek dɛn mek wan smol prodakshɔn prɔses.

Trenin ɛn ɔpdet ɔltɛm fɔ dizayn ɛn manufakchurin tim dɛn pan di laytst standad ɛn softwea tul dɛn fɔ mek ɛn intaprit drɔin dɛn de mek shɔ se dɛn kɔnsistɛns ɛn kɔrɛkt, dɛn de kip ay kwaliti autput dɛn akɔdin to di prɔjek dɛn.

Patnaship wit manifakta fɔ kwaliti kɔntrol .

Insay di eria fɔ GD&T, fɔ patna wit di manifakta dɛn ali insay di dizayn prɔses na wan stratejik we fɔ mek shɔ se kwaliti kɔntrol. Dɛn kayn patnaship ya de mek dɛn ebul fɔ sheb di ɛkspɛriɛns, usay di wan dɛn we de mek dɛn kin gi insayt fɔ di achievabiliti fɔ di spɛsifikɛd tolɛreshɔn dɛn, inklud flatnɛs, ɛn gi advays fɔ ajɔst bay di we aw dɛn de mek tin dɛn ɛn di we aw dɛn de mɛzhɔ.

Dis kolaboreshɔn de fos wan proaktiv kwaliti kɔntrol ɛnvayrɔmɛnt, usay dɛn kin no ɛn adrɛs pɔtɛnɛshɛl ishu dɛn bifo dɛn prodyuz, ridyus west ɛn riwɔk. Pantap dat, di wan dɛn we de mek tin dɛn we gɛt di bɛst tin dɛn fɔ mɛzhɔ kin gi valyu fidbak pan pat kɔnfɔmans to spɛsifikɛshɔn dɛn, we kin ɛp fɔ mek dɛn kɔntinyu fɔ mek di dizayn ɛn di we aw dɛn de mek tin dɛn kɔntinyu fɔ impɔtant.

Di wan dɛn we de mek di tin dɛn we de insay di dizayn faz ɛn dɛn kin tɛl dɛn bɔt di pat in impɔtant wok dɛn we dɛn de du, bɛtɛ fɔ mek dɛn kɔntinyu fɔ kɔntrol di kwaliti kwaliti, ɛn mek shɔ se di fayn fayn prɔdak mit di spɛsifikɛshɔn dɛn we dɛn dɔn disayn ɛn di tin dɛn we dɛn nid fɔ du.

FAQ dɛn .

K: Wetin na di difrɛns bitwin flat ɛn stret?

A: Flatness de aplay to surfaces; stret to layn ɔ aks. Flatness de mek shɔ se wan sɔfays in yunifom; Straightness de mek shɔ se linyariti de. Ɛni wan pan dɛn de sav difrɛn dimɛnshɔnal kɔntrol pɔpɔshɔn dɛn.

K: Aw dɛn kin disayd di flatnɛs tolɛreshɔn zon?

A: Dɛn dɔn difayn am bay tu paralel plen dɛn. Di distans bitwin dɛn plen ya ripresent tolɛreshɔn. Ɔl di sɔfayz pɔynt dɛn fɔ de insay dɛn plen dɛn ya.

K: Dɛn kin aplay flatnɛs to kɔba sɔfays?

A: Yes, flatnes kin aplay if ases di surface deviation. I de pe atɛnshɔn pan sɔfayz rijyɔn dɛn pas fɔ ɔl di kɔva dɛn. Flatness de mek shɔ se yunifom de insay spɛsifikɛd sɛkshɔn dɛn.

K: Wetin na di bɛnifit dɛn we pɔsin kin gɛt we i de yuz optik CMM fɔ mek i gɛt flatnɛs?

A: Ay prɛsishɔn ɛn efyushɔn. we ebul fɔ mek kɔmpleks sɔfayz map. Gi ditayl dijital autput fɔ analisis.

K: Aw a go intaprit wan flatnɛs kɔl ɔut pan wan injinɛri drɔin?

A: No di flatnɛs simbul we de insay di ficha kɔntrol freym. Notis di numɛrik tolɛreshɔn valyu. Put di tolerans we dɛn dɔn spɛsifa to di say we dɛn dɔn pik.

K: Wetin na di standad prɔsis fɔ aplay flatnɛs na GD&T?

A: Yuz standad simbul ɛn anoteshɔn dɛn. Difayn klia wan flatnɛs spɛsifikɛshɔn dɛn. Mek shɔ se di drɔin adheres to ASME ɔ ISO standad.

K: Aw dɛn kin yuz flatnɛs fɔ kɔntrol tolɛreshɔn stak?

A: Bay we yu mek shɔ se di say dɛn we dɛn de mek di mating, flat. Minimizes accumulation of tolerances in assemblies. Impruv pat fit ɛn wok.

K: Yu tink se wan rɛfrɛns datum nid fɔ mek dɛn kɔntrol flatnɛs?

A: Nɔ, flatnɛs nɔ nid datum. I de indipendentli assess pan di spesifik surface. Datums de yuz fɔ ɔda kayn jɔyometrik kɔntrol.

K: Aw flatnɛs tolɛreshɔn de afɛkt pat funkshɔnaliti?

A: I de mek shɔ se mating surfaces alayne fayn fayn wan. I de mek di asɛmbli ishu ɛn di opareshɔnal malfunctions nɔ wok fayn. Kritikal fɔ sil ɛn intafɛs.