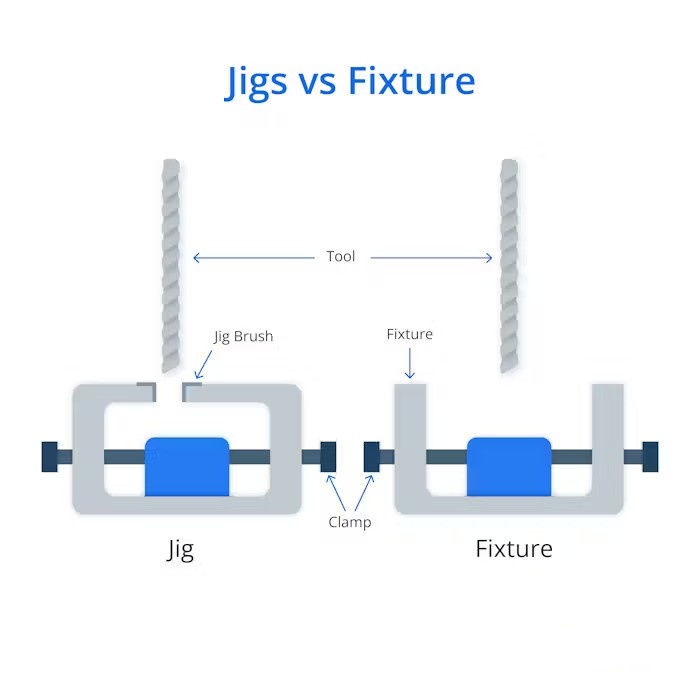

Jigs et fixtures sunt essentiales sunt in vestibulum sed scis quomodo differunt? Utrumque meliorem praecisione et efficientiam, sed non serviunt distincta munera. Jigs Girt Machining Tools, dum fixtures secure workpieces. In roles sunt critica in optimizing productio processibus.

In hoc articulus, ut youll 'definire quid jigs et fixtures sunt, de eorum differentias, et explorarent partes in vestibulum. Te discere de variis typis, materiae usus, et eorum clavem applications per industries sicut automotive et aerospace. Per finem, youll 'animadverto cur haec instrumenta sunt necessaria ad improvidus productio efficientiam et qualitatem.

Quid jigs?

Jigs sunt specialized instrumenta disposito ad augendae praecisione et efficientiam in vestibulum processus. Et serve sicut guiding machinationes ad cutting instrumenta, cursus consistent et accurate eventus trans multiple workpieces.

Detailed explicatione de Jigs

Jigs consistere de pluribus clavis components:

Corpus: Pelagus structuram tenens alias elementa

Locante Elementa: Position workpiece verius

Guiding Elementa: Direct Cutting Tools

Clamping Elementa: Secure Workpiece firmiter

Bushings: dux terebro bits vel alias instrumenta

Haec components opus simul ad creare certa ratio pro repetita machining operationes.

Prima munus de Jigs in vestibulum

Primariter Jigs:

Guide secans Tools pressius

Ut consistent positioning de workpieces

Redigendum setup inter operationes

Minimize humana errore in machining processibus

Auget productio celeritate et efficientiam

Per faciendo haec munera, jigs signanter amplio vestibulum qualis et productivity.

Commune Applications de Jigs

Jigs invenies extensive usus in variis machining operationes:

EXERCITATIO: ensure accurate foraminis placement et profundum

Review: Rector Reamers ad praecise foraminis consummatione

Tapping: facilitate consistent filum creaturae

Odiosis: Direct Tools Tools ad Cylindricum foramine productio

Countersinking: Guide Tools pro creando recessor pertusum

Genera Jigs

Jigs venit in variis formae, singulis disposito specifica vestibulum necessitates. Intelligendo haec genera adjuvat optimize productio processibus.

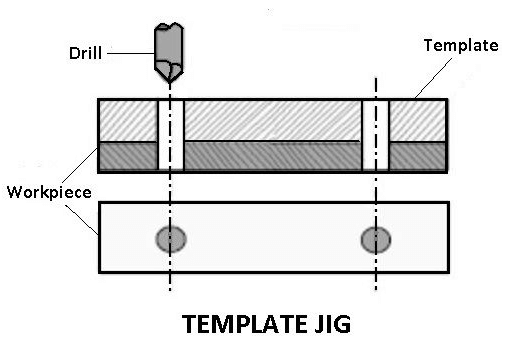

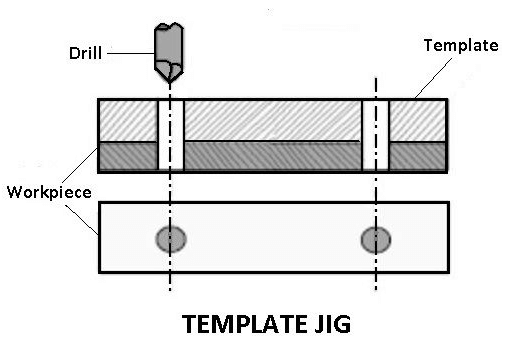

Formula Jigs

Simplici tamen efficax, template Jigs pluma laminis cum foramina servientes ut ducibus. Illi:

Provident basic ductu pro EXERCITATIO Operations

Ensure consistent foraminis collocatione trans plures workpieces

Offer Cost-Efficens Solutions pro Parvus-scale productio

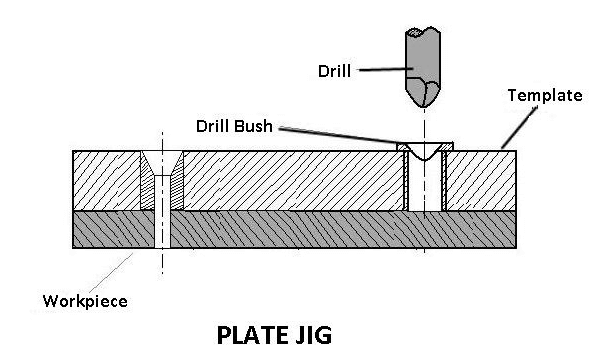

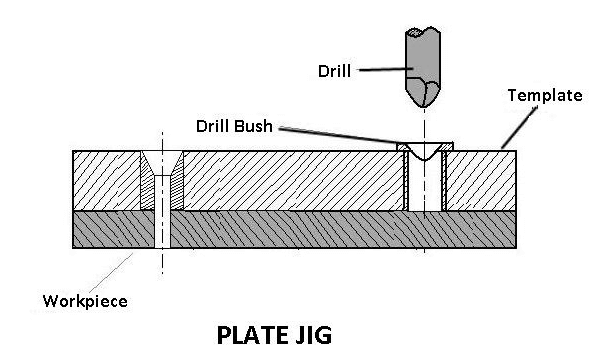

Laminam jigs

Plate Jigs amplio Template consilia per incorporating terebro bushings. Haec Jigs:

Liceat praecise EXERCITATIO magnis partibus

Ponere accurate spacing inter foramina

Augendae diuturnitatem Vivacitas de Jig

Angulus-laminam jigs

Disposito enim angulus EXERCITATIO operationes, angulus-laminam Jigs:

Teneat partes ad propria angulis relative adscendens loca

Enable EXERCITATIO ad praecisa angulos sine complexu setups

Proventus efficientiam in producendo angulis pertusum

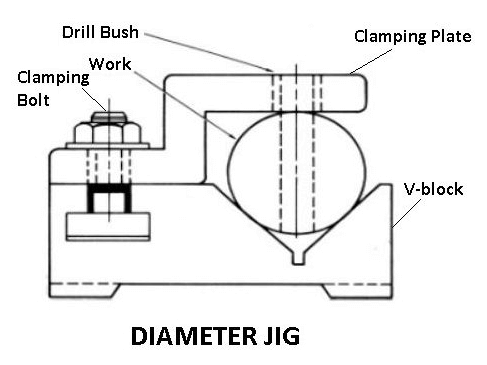

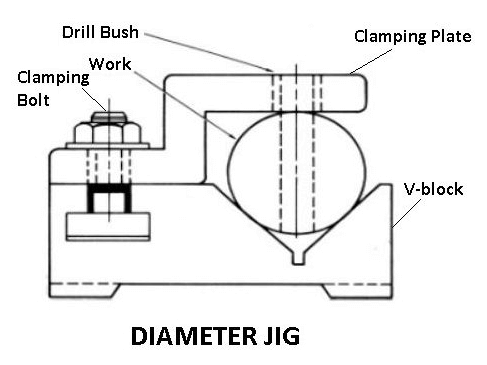

Diametro jigs

Specialized enim cylindrici et sphaerici workpieces, diametro Jigs:

Facilitate EXERCITATIO radialis foramina

Perficite consistency in foraminis placement circa curvam superficiebus

Improve accurate in circularibus component vestibulum

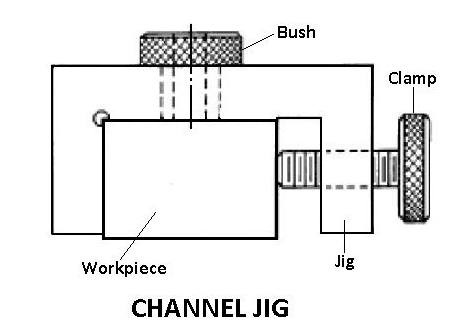

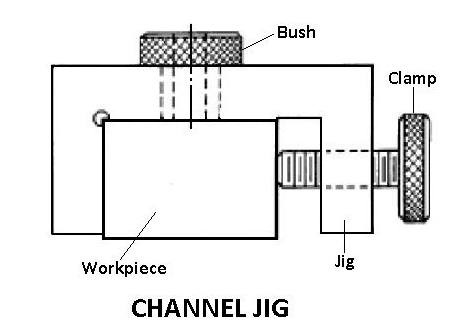

Channel Jigs

Burana channel, sicut crucem-sectionem, haec Jigs:

Patitur facile conveniens components in alveo

Providere secure positioning per Knotled Knob referendo

Dux Tools accuratius per integrated terebro bushings

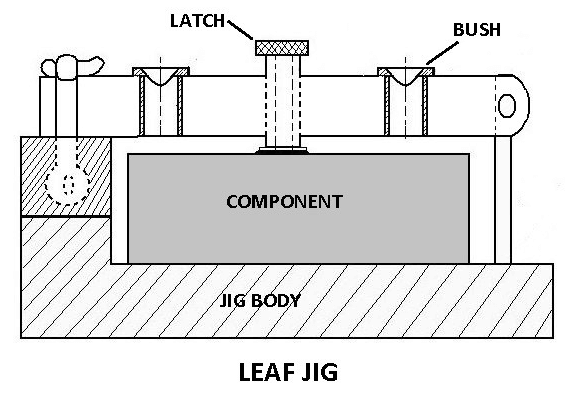

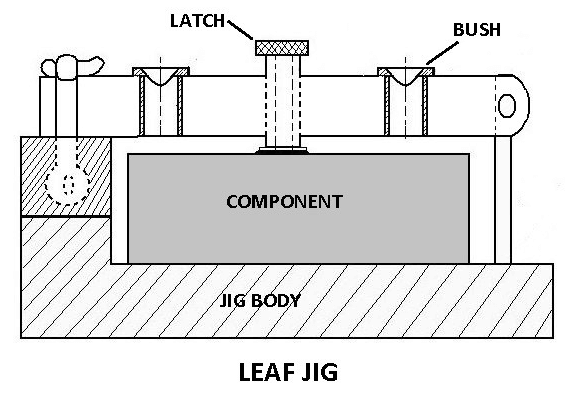

Folium jigs

Folium Jigs Incorporate A CARDINATUS Design pro improved Workflow:

Enable velox loading et unloading workpieces

Redigendum setup inter operationes

Enhance productivity in High-Volume productio environments

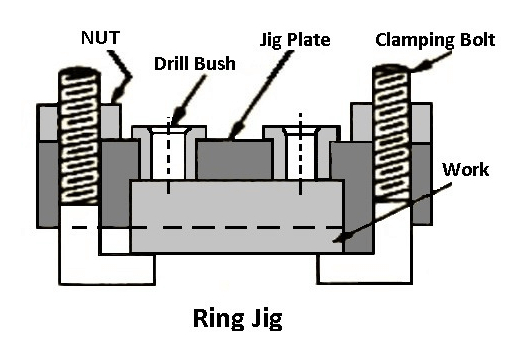

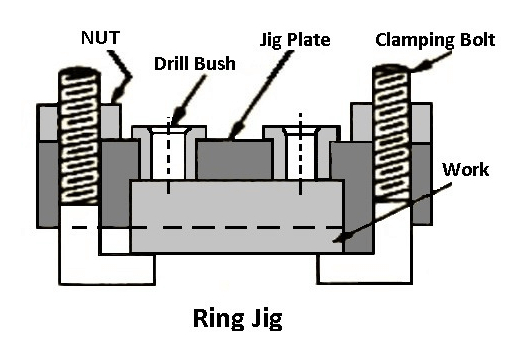

Ring Jigs

Specie disposito circularibus Flanging partes, Orbis Jigs:

Secure opus firmiter ad EXERCITATIO corpus

Tools per pressius loci terebro frutices

Ensure accurate foraminis collocatione in circularis exemplaria

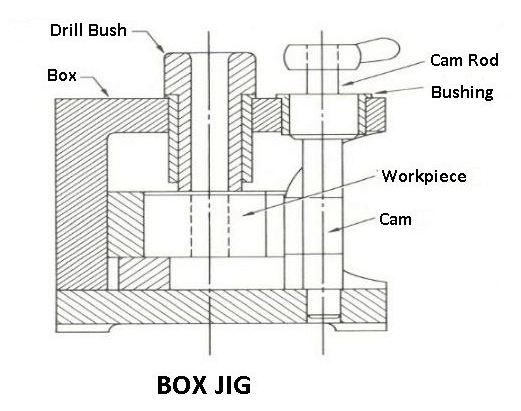

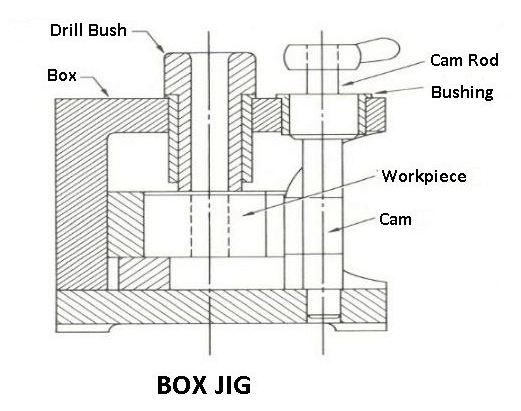

Box Jigs

Versatile et comprehensive, buxum jigs offer:

Multi-angulus machining capabilities in unum setup

Enhanced workpiece stabilitas in operationibus

Melius accurate ad universa partes requiring multiple operationes

Sandwico Jigs

Composita ex multa laminas, Sandwico Jigs providere:

Secure clamping irregulariter informibus workpieces

Flexibilitate in accommodando variis partis magnitudinum

Improved stabilitatem in machining operationes

Trunnion Jigs

Disposito gyratoris positioning, trunnion Jigs:

Patitur workpiece gyrationis pro multi-angle machining

Enhance efficientiam in complexu parte productio

Redigendum setup tempus operationes requiring multiple orientations

Quid fixtures?

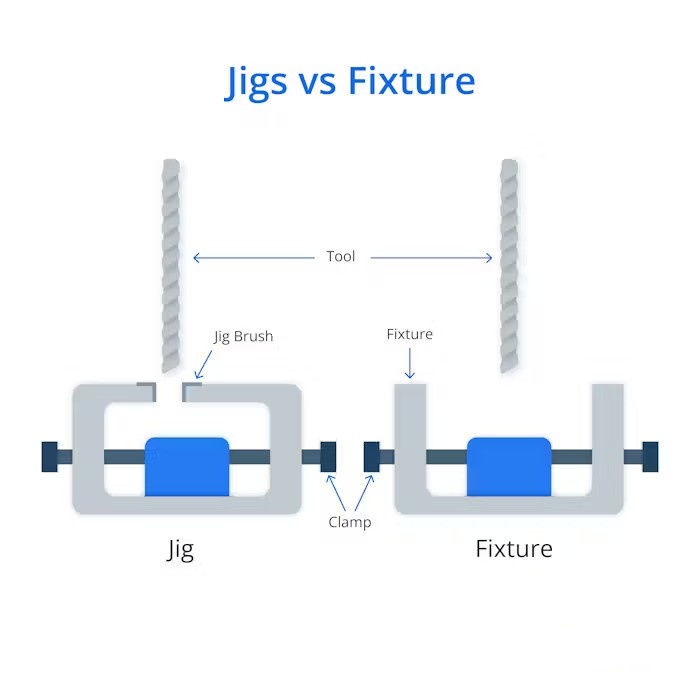

Fixtures sunt critica instrumenta in vestibulum. Tenent et secure workpieces in precise positio per machining operationes. Dissimilis Jigs, fixtures non ducunt ad instrumenta sed ut workpiece manet firmum, permittens accurate cuts et processibus. Sunt essentialia in maintaining consistency, interchangitability, et efficientiam in massa productionem.

Primaria munus fixtures in vestibulum

Pelagus munus a fixture est ut rectam positioning de workpiece ad cutting tool. Per securely tenens workpiece, fixtures auxilium redigendum errores, incremento machining celeritate, et amplio qualis est complevit products. Sunt communiter in automated processus, ubi constantia et repeatability sunt vitalis.

Commune Applications of Fixtures

Fixtures sunt communiter in variis machining operationes, comprehendo:

Milling : sustinet workpiece ad precise milling secat.

Tenet irregularibus components in Lathe operationes.

Dinding : ensures workpiece manet firmum durante molere processibus.

Odiosis , servat partem stabilis pro interno foraminis machining.

Types fixtures

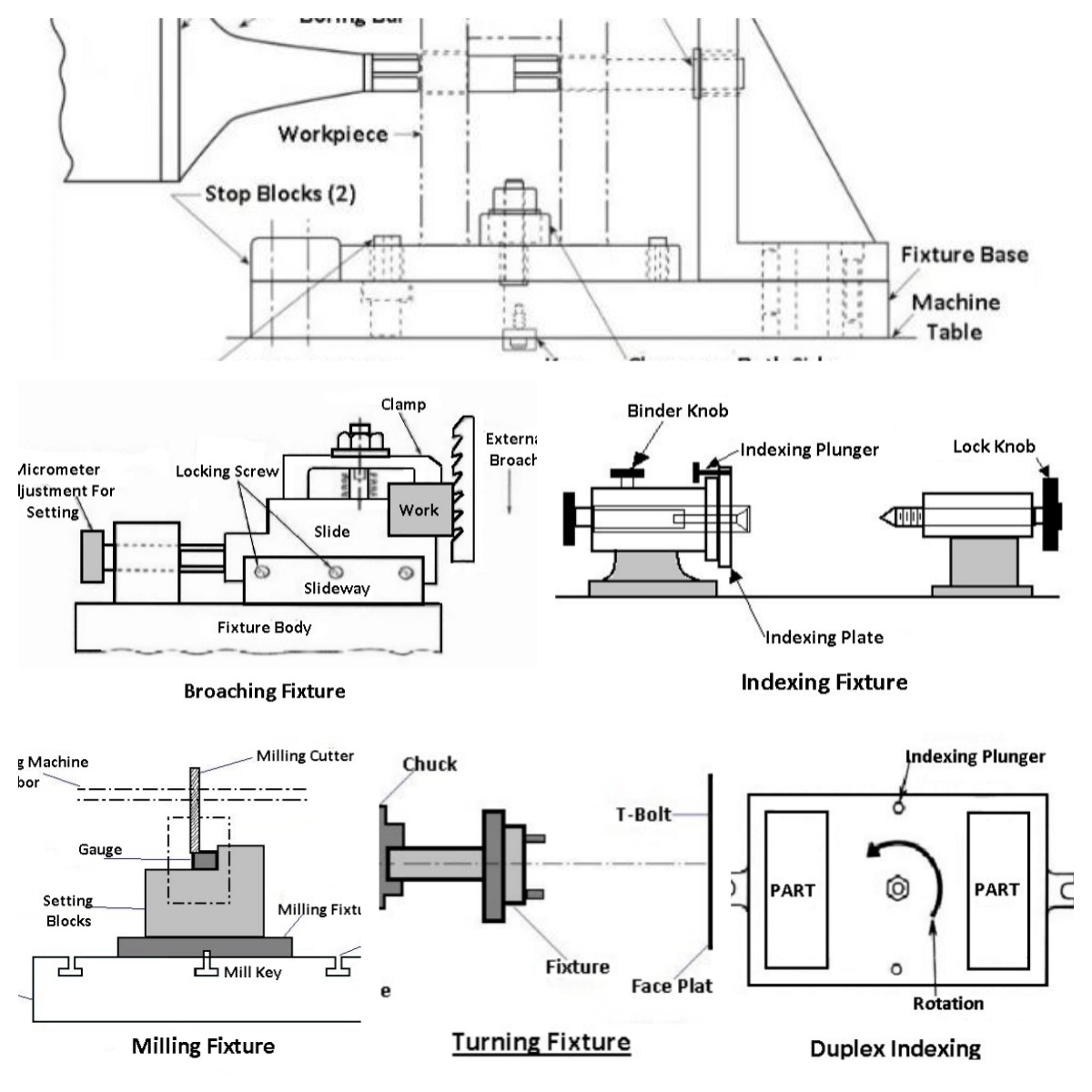

Plures genera fixtures disposito diversis machining operationes

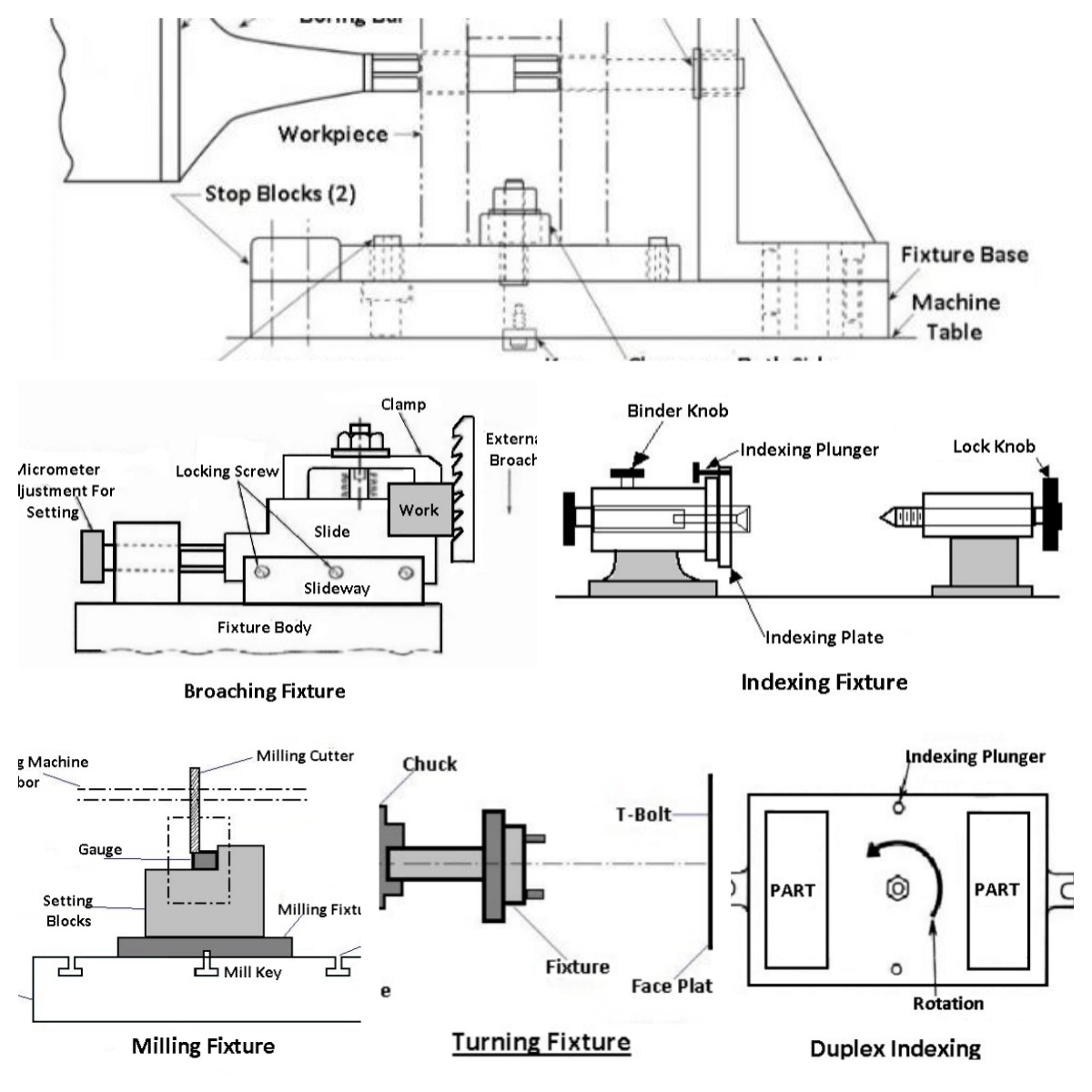

Versus fixtures : solebat habere components in lateris. Hi fixtures curare stabilitatem et obscuratis vibrationem in convertendo operationes.

Fixtures milling , fibulis workpiece ad accurate milling processibus. Et patitur precise positioning et alignment ad relativum ad milling cutter.

EXERCITATIO fixtures : disposito usus in EXERCITATIO velit. Tenent partem securely permittens praecise EXERCITATIO per duce foramina.

Broaching fixtures : tenere workpieces per broaching operationes, usus est ad informationem internum seu externa profiles.

Indexing fixtures : enable uniformis spacing of machining in multiple superficiebus. Sunt instructi indexing machinationes pro praecisione.

Fixtures molere : providere stabilitatem in partes in molere. Magna chucks, Mandrels et vitia communis exempla.

Odiosis fixtures : specie disposito odiosis operationes, tenens workpieces ut accurate foramen loco et profundum.

Tapping fixtures : secure workpieces in internum threading operationes, idealis pro impar-informibus components.

Duplex fixtures : tenere duo idem partes eodem tempore pro duplici machining operationes, augendae productio efficientiam.

Welding fixtures : ne distortio per securely tenens components in loco per Welding processibus.

Conventus fixtures : solebant habere components simul in ecclesia partium, cursus noctis.

Principalis elementa Jigs et fixtures

Jigs et fixtures complectitur complures discrimine components, quisque ludens a vitalis munus in cursus praecisione et efficientiam in vestibulum processus. Intelligendo haec elementa est crucial ad optimal consilio et utendo.

Corpus

Corpus format fundamentum Jigs et fixtures. Non praebet stabile suggestum pro omnibus aliis components. Typically ficti ex durabile materiae sicut mittebant ferrum, ferro, aut aluminium, quod resistit machining viribus dum maintaining rigiditatem. Hoc ensures consistent accurate trans plures workpieces.

Locante elementis

Locando elementa praecise situ workpiece relative ad cutting instrumentum vel apparatus lectum. Et ut includit:

Haec components sunt discrimine ad maintaining repeatability et ensuring partim interchanges in summus volumine productio environments.

Clamping elementa

Clamping elementa secure workpiece firmiter per machining operatio. Non potest esse:

Manual (eg, stupra clamps, Toggle FIGNS)

Powered (eg, hydrau aut pneumatic systems)

Designers debet curare sat habens vim sine distortis workpiece vel intercedente cum tool semitas.

Molere et occasum elementa

Haec elementa duce secans instrumenta in Jigs aut adiuvaret in rectam instrumentum motus in fixtures. Saepe incorporare obfirmatus superficiebus vel replaceable inserit ponere accurate super extenso tempora. Prima munus est ad consequi consistent results trans multiple machining circuitus.

Indexing Elementa

Indexing elementa patitur precise rotationis et repositioning de workpiece ad multi-faceted machining operationes. Illi enable complexu tasks perficitur in unum setup, reducendo pertractatio et improvidus altiore efficientiam.

Positioning elementa

Hi components secure in jig aut fixture ad machina mensam in rectam locum et orientation. Et ut consistent positioning, discrimine ad maintaining parte-ut-pars accurate in productione fugit.

Bushlings

Primarie in Jigs, bushings dirigendis sectiones instrumenta, praecipue in EXERCITATIO operationes. Typically factum ex induretur instrumentum ferro, quod resistunt gerunt et ponere accurate in tempore. Bushings potest fixum, renovabili, aut removeri, permittens facile tortor vel accommodationem ad diversas tool magnitudinum.

| Element | primaria munus in Jigs | prima munus in fixtures |

| Corpus | Sustinet components, Guide Tools | Praebet firmum workpiece platform |

| Locante elementis | Position workpiece ad instrumentum ductu | Ensure praecise workpiece orientation |

| Clamping elementa | Secure workpiece in operationem | Teneat Workpiece adversus sectionem copias |

| Dinding / occasum elementa | Guide tools pro praecisam machining | Adiuvaret in rectam instrumentum motus |

| Indexing Elementa | Permittit multi positio machining | Admitte universa parte productio |

| Positioning elementa | Mass in Mass in JIG | Tutis fixture ad apparatus lectum |

| Bushlings | Guide secans Tools pressius | Non typically usus |

Jigs et fixtures materiae

Discriptis oportet materiam ad Jigs et fixtures est crucial pro ensuring optimal perficientur, Vivacitas et sumptus-efficaciam in vestibulum processus. Quisque materiam offert unique proprietatibus idonea ad propria applications et productio requisita.

Duram ferrum

Duram ferrum stat ex ut premium arbitrium pro summus volumine productio environments. Eius eximia vires et gerunt resistentia facere idealis pro Jigs et fixtures subiecta frequentes usum et altum accentus.

Key commoda:

Superior diuturnitatem sub repetita machining operationes

Maintains dimensional stabilitatem etiam sub gravibus onerat

Optimum pro praecisione applications requiring stricta tolerances

Tamen, eius superiori pretio et pondus ut limit suum usum in certo missionibus.

Ferrum

Circumda Ferrum praestat in applications ubi vibration damping et stabilitatem sunt paramunt. Et proprietatibus faciet in popularibus electio pro magna fixture corpora et bases.

Notabilis features:

Absorbet vibrationum efficaciter, enhancing machining praecisione

Providet optimum scelerisque stabilitatem durante diuturna operationes

Sumptus-effective pro magna-scala fixtures

Et pelagus INCOMMENTUM mendacium in eius susceptibilitatem ad corrosio, necessitating propriis superficie curatio.

Aluminium Alloy

Aluminium Alloys offerre cogens combination de lumine proprietatibus et corrosio resistentia. Haec praecipue idoneam portable jigs fixtures.

Complectuntur includit:

Otium de tractantem et translationem in manual operationes

Naturalis resistentia oxidatio, reducing sustentacionem necessitatibus

Optimum machinabilitatem consuetudinem consilia

Sed non conveniat applications requiring extremum rigiditatem aut gerunt resistentia.

Engineering Plastics

Engineering Plastics praesentem sumptus-effective Africa ad propria figuram et fixture applications. Eorum unicum proprietatibus aperire possibilities in specialioribus vestibulum missionibus.

Key beneficia:

Electrical Vallum proprietates ad applications involving electronic components

Chemical resistentia ad usum in mordive environments

Humilis friction coefficientes, reducing gerunt in workpieces

Quorum limitations includit inferioribus viribus et æstus resistentia comparari metallicis options.

| Materia | corrosio | vi pondus | resistentia | cost | vibration damping |

| Duram ferrum | Altum | Altum | Moderor | Altum | Humilis |

| Ferrum | Altum | Altum | Humilis | Moderor | Altum |

| Aluminium Alloy | Moderor | Humilis | Altum | Moderor | Humilis |

| Engineering Plastics | Humilis | Humilis | Altum | Humilis | Moderor |

Clavem differences inter Jigs et fixtures

Dum utrumque Jigs et fixtures sunt crucial in vestibulum, serviunt diversas partes. Intelligendo haec differentias adjuvat artifices eligere oportet instrumentum ad specifica operationes.

Primarius

Et primaria munus distinguit Jigs et fixtures. Jigs Guide ad Cutting tool ad desideravit locum in workpiece, cursus praecisione operationes sicut EXERCITATIO et percussoque. Fixtures, in alia manu, secure et sustinere workpiece in machining processus ut milling et molere. Et non ducunt ad instrumentum sed ponere in workpiece scriptor orientation.

Pondus et complexionem

Fixtures sunt plerumque graviora et magis universa quam Jigs. Oportet resistere superiorum viribus et vibrationes in machining, faciens eos magis robust. Jigs sunt saepe levius quod praesertim dux Tools et requirere minus materia vires. Haec differentia etiam impingit sumptus, cum fixtures typice magis pretiosa debitum ad complexionem.

Consilio considerations

Fixtures et Jigs eget diversis consilio considerari. Fixtures opus est propter clamping vires, stabilitatem, et vibrationis resistentia tractare gravibus moles onera. Jigs, per contrarium, focus magis in praecisione et accurate, ut eorum primaria munus est gustando instrumenta.

Contactus cum tool

Jigs venit in directum contactus cum instrumentum ad dirigi viam, saepe uti bushings vel templates ut accurate. Fixtures autem non tangere instrumentum. Tantum tenere workpiece confidenter permittens instrumentum movere gratis per machining processus.

Affectum ad machina

Jigs sunt saepe handheld vel leviter fixum in apparatus, secundum operationem. Contra, fixtures firmiter coniuncta apparatus mensa usura fibulis vel seras sustinere viribus exercetur durante operationibus sicut milling vel conversus.

| Clavem difference | jig | fixture |

| Primarius | Ducat ad Cutting tool | Tenet et sustinet workpiece |

| Pondus et complexionem | Levius, minus complex | Gravius, magis universa |

| Design Focus | Praecisione, tool ductu | Stabilitatem, clamping vires |

| Contact tool | Venit in contactum cum tool | Non contact ad tool |

| Apparatus affectum | Handheld aut leviter fixum | Firmiter coniuncta apparatus |

Beneficia per usura Jigs et fixtures in vestibulum

| beneficium | impulsum in vestibulum |

| Auctus productivity | Reduces manual adjustments crescit throughput |

| Melius qualis et accurate | Ensures consistent positioning, amplio complevit uber species |

| Redegit pretium | Moderorum labore et materia costs, reduces exiguo et rework |

| Accurate Mors Principium | Praebet praecisione in tool placement in machining |

| AUGRESSUS | Producit identical partes cum minimal variation |

| Wasotage | Reduces materia vastum et exiguo |

| AUGRATUS | Secure clamping reduces periculo accidentium |

| Reducitur manpower necessitates | Automates workolding, reducendo operatoris requisitis |

| Breviori productio cycle | Simplifies setup, reduces praeparatio tempore |

| Multi-statione machining | Dat multiple processibus in eodem apparatus, amplio utendo |

| Inferius inspectionem costs | Ensures consistent qualis, reducendo opus crebris inspectionibus |

| Automation faciliorem | Supports automated et digital faciens processus |

Fixture consilium consilio

Efficens Jig et Fixture Design est crucial ad optimizing vestibulum processus. Per adhaerens ad clavis consilio principiis, engineers potest creare instrumenta, quod augendae praecisione, efficientiam et operator salutem.

Et noctis et coacto

Perfectus Gratia diei Gratia diei ethnim accurate in machining operationes. Tamen, super-constringining potest inducere erroribus. Designers debet rursus a statera, utens minimum necessaria locating puncta in licita tolerances. Accedens maintains praecisione dum permittens levi variationes in workpiece dimensiones.

Operational efficientiam

Simplifying consilia et prioritizing una-utebatur operatio cum fieri potest significantly amplio efficientiam. Hoc approach reduces operator lassitudine et minimizes potentiale ad errores in setup et usu. Intuitive Designs etiam pauci numero disciplina tempus ad novum operators.

Minimizing humana interventu

Automation in Jig et Fixture Design reduces opus manual interventu in machining processibus. Hoc non solum amplio constantia sed etiam aucta salute per servatione operators a potentia ancipitia periculum areas per operationem.

Errore deprehendatur

Geometries ut highlight misalignment culpa est crucial ad qualis imperium. His consilio features patitur operators celeriter identify et rectam exitibus antequam consequuntur in defectivis partibus. Visual Indicatores aut physica sistit potest servire hanc rem efficaciter.

Processus integration

Coordinatio cum toto vestibulum processus fluxus est. Designers considerans quomodo ad JIG aut fixture vices in latior productio linea, comprehendo:

Holistic accedat ensures lenis transitionum inter gradus et optimizes altiore efficientiam.

Material Electio

Eligendo ius materia est critica ad jig et fixture perficientur. Factors considerare includit:

Design Genus

Ut comprehensive consideratione omnium consilio facies, engineers debetis sequentibus puncta

Have nos effectum optimal noctis sine-constringens?

Potest et JIG aut fixture esse operated cum una parte?

Est humanum interventus minimized per machining processus?

Vtrum Design Highlight potentiale misalignment errores?

Ut bene facit hoc consilium integrate cum altiore vestibulum fluxus?

Est lectus materia meliorem pro nostra propria application?

Products Modi enim Jigs et Fixtures

Eligendo ius vestibulum modum ad jigs et fixtures est critica ad normam perficientur et sumptus-efficaciam. Methodus lectus pendeat ex factores sicut productio volumine, materia requisita et geometric multiplicitate. Hic sunt tria communis modi solebant producere Jigs et fixtures in vestibulum.

Cnc machining

Cnc machining est vulgaris methodo ad producendo Jigs et fixtures cum praecisione et diuturnitatem sunt paramunt. Est maxime idoneam ad humilis-volumine productionem ubi quisque genus necessitates ad occursum stricte dimensiva tolerances. CNC machining permittit manufacturers ad variis materiae ut ferro, aluminium et summus viribus Alloys. Processus tradit partibus alto accurate faciens idealis applications requirere consuetudinem Jigs aut fixtures cum intricatus consilia.

Key beneficia CNC Machining:

Princeps praecisione et stricta tolerances

Idoneam complex partes consuetudo features

Operatur cum amplis materiae

3D printing

3D printing est revisinized productio de jigs et fixtures, praesertim pro humilis-productio fugit vel universa geometries, quae difficile vel pretiosi apparatus. Eam dat celeri prototyping et customization ad inferiores sumptus. 3D printing est saepe propter producendo fixtures cum intricatus internum structurae, lightweight components, aut qui postulantes velox referendo. Dum non semper par fortitudo traditum materiae, offert significant flexibilitate in consilio.

Key beneficia de 3D printing:

Sumptus effective humilis volumine consuetudinem geometries

Citius productio tempora prototypes parva batches

Permittit enim complexu, Lightweight Design

Celeri iniectio CUMATIUM

Nam summus volumine productio de Jigs et fixtures, celeri iniectio CUMATIUM est maluit modum. Est specimen ad producendo millia partium ex ipsum-gradu Thermoplasticas. Processus ensures utraque parte consistent qualitatem et dimensionem. Sumptus per partem decrescit volumine augetur, faciens idoneam magnam scale vestibulum. Celeri iniectio CUMATIUM adhibetur ad fixtures quod requirere fortitudinem, diuturnitatem, et resistentia ad induendum.

Key beneficia de celeri iniectio CUMATIUM:

Agentibus ad altus-volumine productio

Consistent qualis et dimensional accurate

Idoneam partium ex durabile Thermoplastics

Applications de Jigs et fixtures in variis industries

Jigs et fixtures sunt essentiales sunt in vestibulum processus per plures industries. Et meliorem accurate, efficientiam, et productionem celeritatem, faciens ea vitalis est summus qualitas vestibulum. Infra sunt key industries qui confidunt in Jigs et fixtures.

Automotive industria

In automotive sector, jigs et fixtures ludere a discrimine partes in conventu lineas et vestibulum components. Et curare precise noctis durante welding, EXERCITATIO et machining processibus. Fixtures tenere in locum repeatable et accurate vestibulum, conlatis ad massa productionem vehiculorum partes.

Key Applications:

Vehiculum corpus Welding et Conventus

EXERCITATIO et machining de engine partes

Aligning components ad altum praecisione

Aerospace industria

Aerospace vestibulum postulat maxime princeps campester of accurate et praecisione, quod jigs et fixtures auxilium consequi. Fixtures subsidium machining de complexu partes, cum Jigs adiuvaret in precise EXERCITATIO et rivendo aircraft components. Hanc salutem et reliability aircraft constructione.

Key Applications:

Riveting aircraft tabulas et structurae

Machining de Turbine Lamina et Engine components

Gratia diei et alignment Critical

Electronics vestibulum

In electronics vestibulum, jigs et fixtures sunt ad positionem delicata components et secure in solidatoris et ecclesia. Haec instrumenta auxilium ponere consistency in massa productionem dum ne damnum ad sensitivo electronic partes.

Key Applications:

SOLDERERING CONSECRATIO CIRCUS Tabula

Tenens delicata components in loco

Certa in Gratias ALIGNMENT COMMENTUM

LIBRATIO

Woodworking utitur Jigs ad secans, EXERCITATIO et effingens lignum materiae. Fixtures providere stabilitatem durante machining processus, ensuring accurate cuts et consistent results. Haec instrumenta sunt maxime momenti in creando supellectilem, cabinetry et alia praecisione lignum products.

Key Applications:

Dovetail cutting in cabinetry

Guiding Tools pro EXERCITATIO et shing

Clamping pro subtilitate joinery

Metalla

Jigs et fixtures sunt integralis ad metalworking operationes, de milling et conversus ad stridor. Et auxilium tenere metallum partes in loco in secans, effingens et consummatione processibus, cursus consistent quale et reducendo productio est.

Key Applications:

Machining partes in letibus et mola

Certain molere et consummatione

Multi statione metallum fabricam

Fingere vestibulum

Moliaretur vestibulum requirit praecisione, praesertim cum producendo complexu iniectio formae. Fixtures tenere workpiece stabilis in milling vel conversus processus, cum Jigs ensure exigere tool collocatione ad secandum complex figuris.

Key Applications:

Creando Fingit ad plastic iniectio

Subtilitas Machining de Intricate Finge Details

Clamping per instrumentum iter creaturae

Medical fabrica vestibulum

Medical fabrica vestibulum postulat restrictius qualitas imperium et altum praecisione. Jigs et fixtures auxilium ensure components convenerunt accurate, praesertim cogitationes requiring tolerances et munditiam.

Key Applications:

Aligning et congregantibus chirurgicam Tools

Tenens parva partes ad Cleanroom machining

Accuratio ecclesiam implantabilia cogitationes

Consumer Electronics Manufacturing

In dolor electronics, Jigs et fixtures ensure ieiunium et accurate ecclesiam parva, summus volumine products ut Smartphones, tabulas et Laptops. Haec Tools Streamline productio lineas et amplio uber constantiam.

Key Applications:

Precising Placement parva components

Conventus linea fixtures ad summus celeritas productio

Positioning instrumenta pro fabrica armamentis et screen installation

| Industry | Key Applications |

| Eget | Welding, EXERCITATIO, Engine Pars Machining |

| Aerospace | Riveting, Turbine Machining, Structural Gratia diei |

| Electronics | Circuit Board Soldering, pars collocatione |

| LIBRATIO | Dovetail secans, effingens, EXERCITATIO |

| Metalla | Milling, conversus, molere |

| Fingere vestibulum | Molde creaturae, Machining Intricate Details |

| Medical fabrica vestibulum | CRECTIMA conventus, Cleanroom Machining |

| Consumer Electronics | Summus celeritas ecclesia, pars alignment |

Conclusio

Jigs et fixtures ludere a crucial munus in modern vestibulum, enhancing praecisione, efficientiam et productivity. Ex Guiding Tools ad securitatem workpieces, haec cogitationes streamline res per varios machining processibus. Per intellegendum eorum genera, materiae, consilio considerationes et vestibulum modos, fabrum can optimize productio workflows. Utrum usus Cnn machining vel 3D printing, diligenter consilium et exsequendam Jigs et fixtures significantly amplio uber qualis et redigendum productio costs, faciens ea necessaria instrumenta in hodiernae competitive vestibulum landscape.