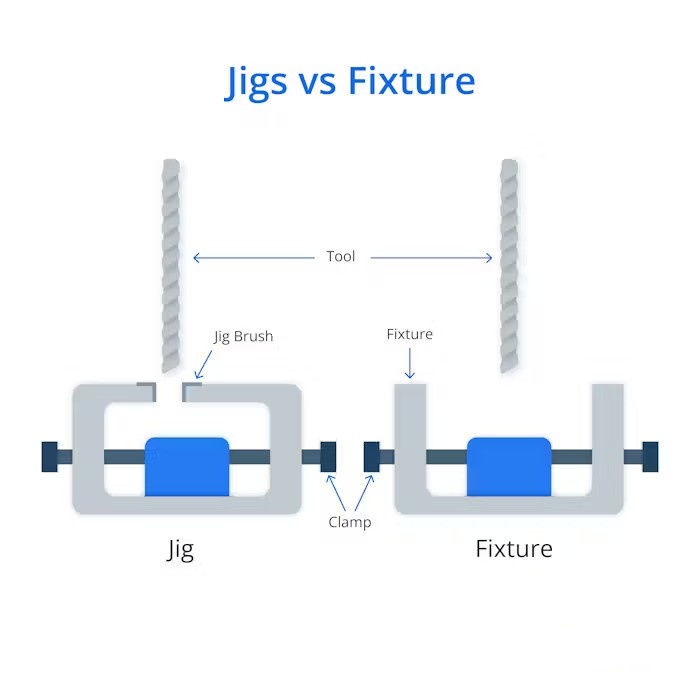

Jigw ni fɛnw ye baarakɛminɛn nafamaw ye fɛn dilanni na, nka yala i b’a dɔn u tɛ kelen ye cogo min na wa? U fila bɛɛ bɛ tiɲɛni ni baarakɛcogo ɲuman ɲɛ, o bɛɛ n’a ta, u bɛ baara kɛ cogo danfaralenw na. Jigs bɛ masinw ɲɛminɛ baarakɛminɛnw na, ka sɔrɔ fiɲɛw bɛ baarakɛminɛnw lakana. U jɔyɔrɔw ka bon kosɛbɛ sɛnɛfɛnw dilanni taabolo ɲuman na.

Nin barokun in kɔnɔ, an bɛna jiginni ni fɛnw ye minnu ye, an bɛna olu ɲɛfɔ, ka baro kɛ u danfara kan, ani k’u jɔyɔrɔw sɛgɛsɛgɛ fɛn dilanni na. Aw bɛna kunnafoni sɔrɔ suguya caman kan, fɛn minnu bɛ kɛ, ani u ka baarakɛcogo jɔnjɔnw iziniw kɔnɔ i n’a fɔ mobili ni aerospace. A laban na, aw bɛna a ye mun na nin baarakɛminɛn ninnu nafa ka bon kosɛbɛ walasa ka fɛn dilanni nafa n’a kɛcogo ɲɛ.

Jigw ye mun ye?

Jigw ye baarakɛminɛn kɛrɛnkɛrɛnnenw ye minnu dabɔra walasa ka fɛn dilanni taabolo tigitigi ni a kɛcogo ɲuman sabati. U bɛ kɛ bilasirali fɛɛrɛw ye tigɛminɛnw na, ka sɔrɔw kɛ minnu bɛ bɛn ani minnu bɛ kɛ cogo bɛnnen na baarakɛminɛn caman kɔnɔ.

Jigs ɲɛfɔli dafalen .

Jigw bɛ Kɛ yɔrɔ koloma damadɔw ye:

Farikolo: Jɛkuluba min bɛ fɛn wɛrɛw minɛ .

Yɔrɔw sɔrɔli: jɔyɔrɔ baarakɛminɛn tigitigi .

Guiding Elements: Tigɛlan tilennenw .

CLAMPING ELEMENTS: Baarakɛminɛn min bɛ lakana kosɛbɛ .

Bushings: Guide Drill Bits walima baarakɛminɛn wɛrɛw .

O yɔrɔw bɛ baara kɛ ɲɔgɔn fɛ walasa ka fɛɛrɛ dɔ sigi sen kan min bɛ se ka da a kan walasa ka segin-ka-bɔnye kɛ.

Jigw ka baara fɔlɔ ye fɛn dilanni na .

Jigs fɔlɔ:

Guide tigɛminɛnw tigitigi .

Aw ye aw jija ka baarakɛminɛnw sigicogo sabati cogo basigilen na .

Setup waati dɔgɔya baarakɛtaw ni ɲɔgɔn cɛ .

Adamadenw ka filiw dɔgɔya masinko taabolo la .

Aw bɛ dɔ fara sɛnɛfɛnw bɔli teliya kan ani u ka baarakɛcogo ɲuman kan .

Ni an bɛ o baara ninnu kɛ, jiginniw bɛ fɛn dilanni cogoya n’a baarakɛcogo ɲɛ kosɛbɛ.

JIGS ka baarakɛcogo minnu bɛ kɛ tuma caman na .

Jigw bɛ baara caman sɔrɔ masinko baara suguya caman na:

Drilling: Aw bɛ a lajɛ ni dingɛ bilali ni a juguman bɛ tiɲɛ .

Reaming: Guide reamers for precise hole finishing .

Tapping: Ka jiri dacogo nɔgɔya

Boring: Direct boring outils for cylindrical hole production .

counterSinking: Guide baarakɛminɛnw walasa ka dingɛw dilan minnu bɛ don .

Jigs suguyaw .

Jigw bɛ sɔrɔ cogoya caman na, u kelen-kelen bɛɛ dabɔra fɛn dilanni mago kɛrɛnkɛrɛnnenw kama. Nin suguya ninnu faamuyali bɛ dɛmɛ don ka sɛnɛ kɛcogo ɲɛ.

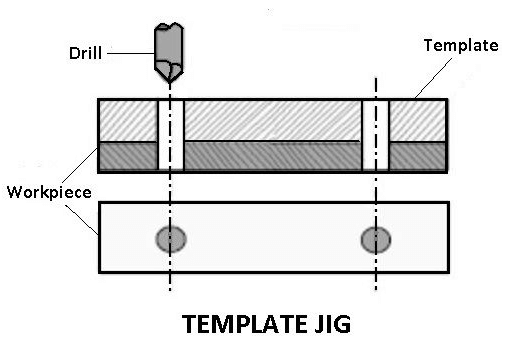

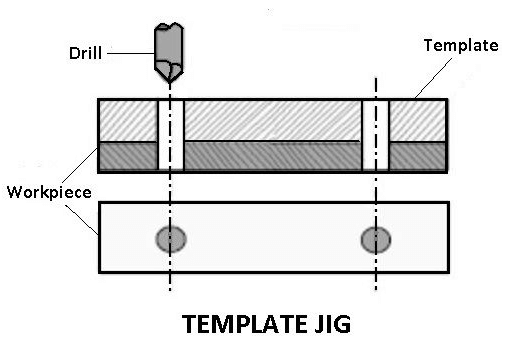

Jigs modèle .

Jigw nɔgɔmanw, minnu bɛ nɔ bɔ, olu bɛ ni platiw ye minnu bɛ kɛ ni dingɛw ye minnu bɛ kɛ ɲɛminɛbagaw ye. Olu:

Aw ye bilasirali jɔnjɔnw di jirituru baara ma .

Aw ye aw jija ka dingɛw bila cogo basigilen na baarakɛminɛn caman cɛ .

Aw bɛ furaw di minnu musaka ka dɔgɔ, ka ɲɛsin fɛn misɛnninw dilanni ma .

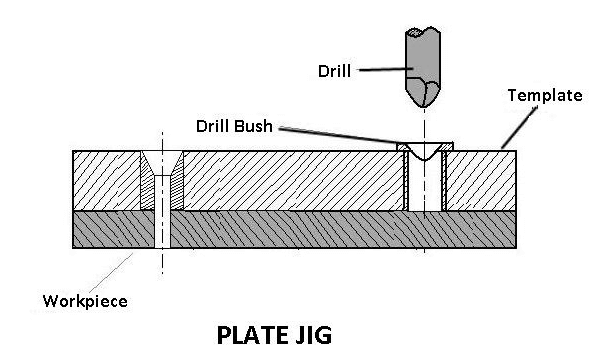

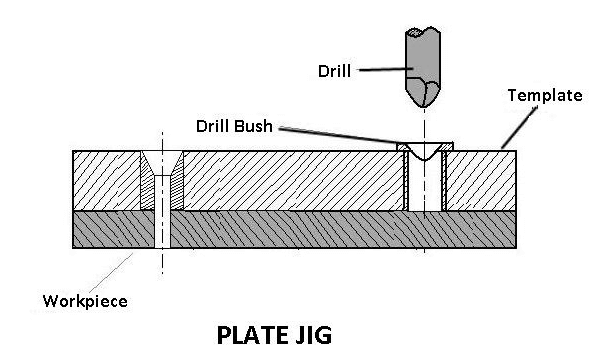

Jigs plate .

Plate jigw bɛ ɲɛ ka ɲɛsin template designs ma ni drill bushings donli ye. Nin jigw:

Aw bɛ a to a yɔrɔbaw ka kɛ tigitigi .

Aw bɛ yɔrɔ janya tigitigi mara dingɛw ni ɲɔgɔn cɛ .

Jig ka mɛnni kuntaalajan bonya .

Jigs angle-plate .

A dabɔra jiriforo baara kama, a bɛ se ka kɛ yɔrɔ ye min bɛ se ka kɛ fɛn ye:

Aw bɛ yɔrɔw minɛ ni u bɛ kɛ yɔrɔ kɛrɛnkɛrɛnnenw na ka kɛɲɛ ni u sigiyɔrɔw ye .

Aw bɛ se ka forow kɛ yɔrɔ tigitigiw la ni setup complexes tɛ .

Dɔ fara baarakɛcogo ɲuman kan dingɛw kɔnɔ minnu bɛ kɛ kɛrɛw la .

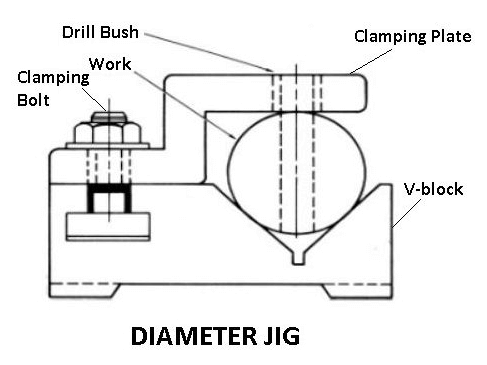

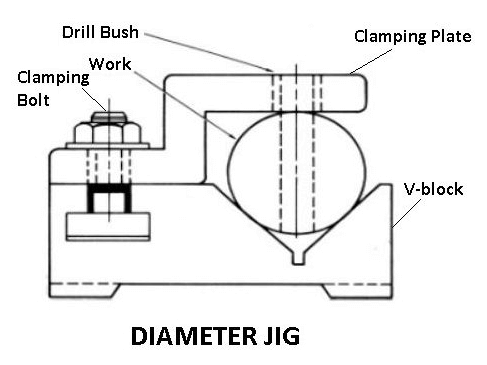

Jigs diamètre .

A kɛrɛnkɛrɛnnen don baarakɛminɛnw na minnu bɛ kɛ silinda la walima minnu bɛ kɛ ni spherical ye, olu ye jigw ye:

Nɔgɔya la , n' o ye ka radial holes drilling kɛ .

Aw ye aw jija ka bɛn dingɛ bilali ma yɔrɔ kurulenw lamini na .

Aw bɛ tiɲɛni ɲɛ ka ɲɛ sigida laminiw dilanni na .

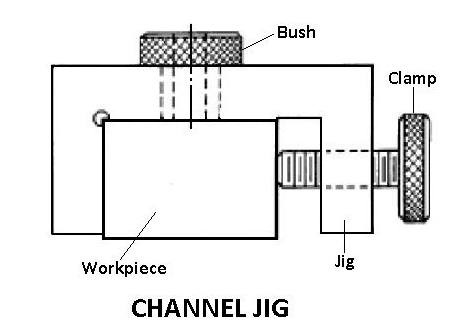

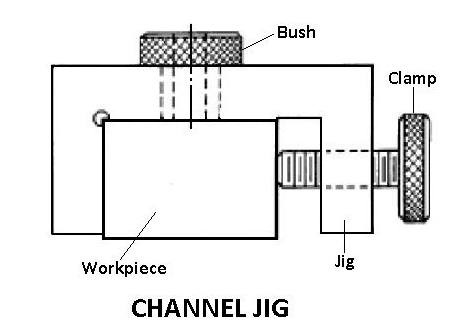

Jigs kanal .

O jiginniw bɛ i n’a fɔ kanal dɔ, olu bɛ sɔrɔ yen:

Aw bɛ a to a ka don nɔgɔya la kanal kɔnɔ .

Aw bɛ jɔyɔrɔ lakananen di nɛgɛbere ladilancogo la .

Guide baarakɛminɛnw tigitigi fɛ drill bushings intégrés fɛ .

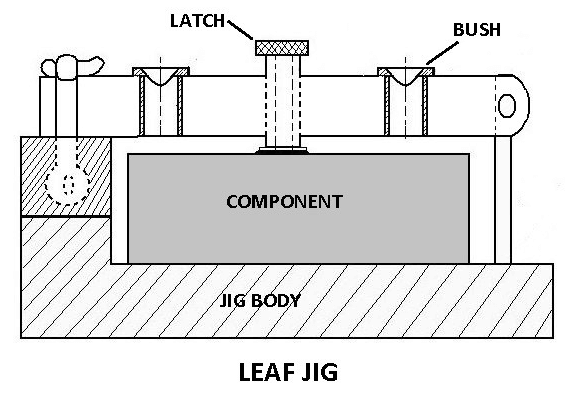

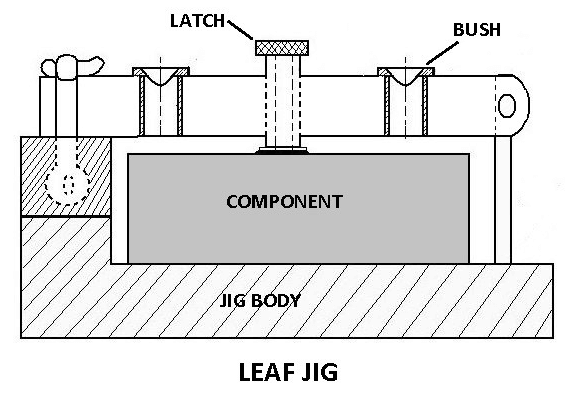

Jigs furabuluw .

Leaf jiginniw bɛ dilan ni fɛn ye min bɛ kɛ ka baara kɛ ka ɲɛ:

Aw bɛ se ka baarakɛminɛnw doni teliya ani ka u bɔ .

Setup waati dɔgɔya baarakɛtaw ni ɲɔgɔn cɛ .

Ka baarakɛcogo ɲɛ sɔrɔ yiriwali sigidaw la minnu ka ca kosɛbɛ .

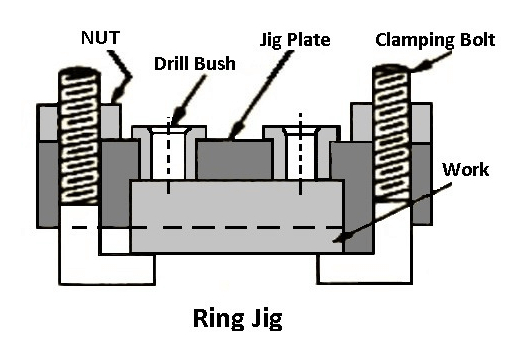

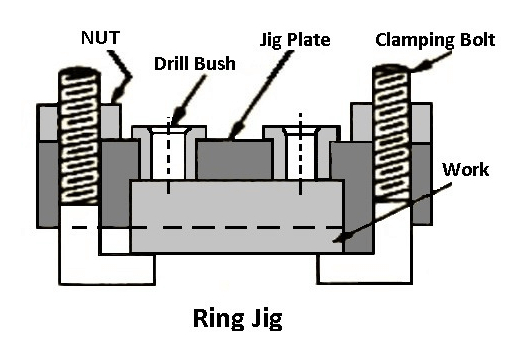

Jigs ring .

A dabɔra kɛrɛnkɛrɛnnenya la ka ɲɛsin yɔrɔw ma minnu bɛ se ka wuli ka bɔ ɲɔgɔn na, n’o ye ring jigs ye:

Baara lakananenba ka ɲɛsin drill farikolo ma .

Guide baarakɛminɛnw ka tɛmɛ drill bugunw kan minnu bɛ sigi tigitigi .

Aw bɛ a lajɛ ni dingɛ bilali tigitigi bɛ kɛ cogo la min bɛ kɛ ni circulaire ye .

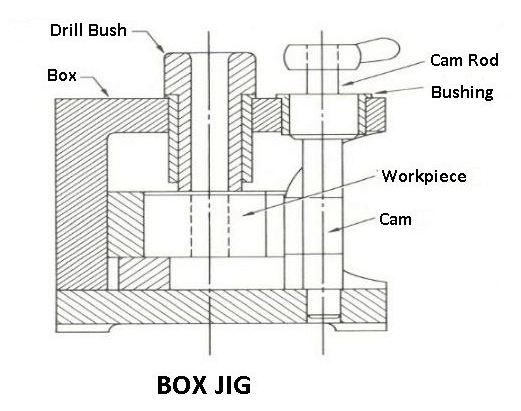

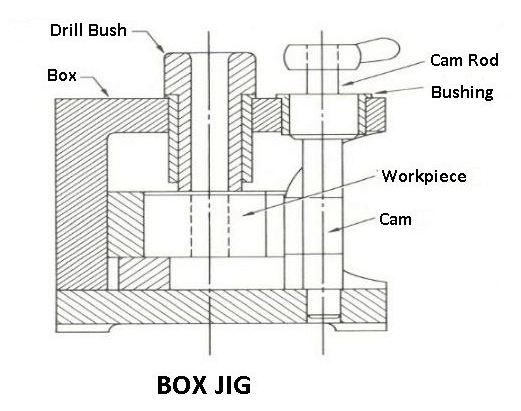

Jigs Box .

A bɛ se ka kɛ fɛn caman ye ani a bɛ se ka kɛ fɛn bɛɛ ye, Box Jigs bɛ o dilan:

Multi-angle machining seko bɛ setup kelen kɔnɔ .

Baara kɛtuma na, baarakɛminɛnw sabatili min bɛ bonya .

Tiɲɛni ɲɛnabɔlen yɔrɔ gɛlɛnw na minnu bɛ baara caman wajibiya .

Sandwich jigs .

A bɛ kɛ ni tasa caman ye, sandwich jigs bɛ:

Baarakɛminɛnw minnu cogoya tɛ kelen ye, olu sirili lakananen .

Flexibilité dans les part sizes de part hakɛ suguya caman .

sabatili ɲɛnabɔlen masinw ka baarakɛtaw senfɛ .

Jigs trunnion .

A dabɔra ka ɲɛsin jiginni ma, trunnion jigs:

A to baarakɛminɛnw ka wuli ka kɛ masin ye .

Ka baara kɛcogo ɲɛ ka ɲɛsin a yɔrɔw dilanni ma minnu ka gɛlɛn .

Setup waati dɔgɔya baarakɛtaw la minnu bɛ ɲɛsin ɲɛjirali caman ma .

Fixtures ye mun ye?

Fɛn minnu bɛ kɛ ka fɛnw labɛn, olu ye baarakɛminɛn nafamaw ye fɛn dilanni na. U bɛ baarakɛminɛnw minɛ ani k’u lakana cogo tigitigi la masinko baara senfɛ. A tɛ i n’a fɔ jiginni, fiɲɛbɔlanw tɛ baarakɛminɛnw ɲɛminɛ nka u bɛ a lajɛ ko baarakɛminɛn bɛ to a cogo la, o bɛ sira di tigɛcogo ni taabolo tigitigiw ma. U nafa ka bon kosɛbɛ bɛnkanw sabatili la, ɲɔgɔn falen-falen, ani baarakɛcogo ɲuman na.

Fɛn minnu bɛ kɛ ka fɛnw dilan, olu ka baara fɔlɔ .

Fɛn min bɛ kɛ ka fɛn dɔ jɔ, o ka baara kunba ye ka baarakɛminɛn dɔ jɔcogo ɲuman sɔrɔ ka kɛɲɛ ni tigɛminɛn ye. Ni baarakɛminɛn minɛna ka ɲɛ, fɛnw bɛ se ka kɛ sababu ye ka filiw dɔgɔya, ka dɔ fara masinw teliya kan, ani ka fɛn dilannenw cogoya ɲɛ. U bɛ kɛ ka caya otomatiki walew la, yɔrɔ minnu na bɛnkan ni segin-ka-bɔnye nafa ka bon kosɛbɛ.

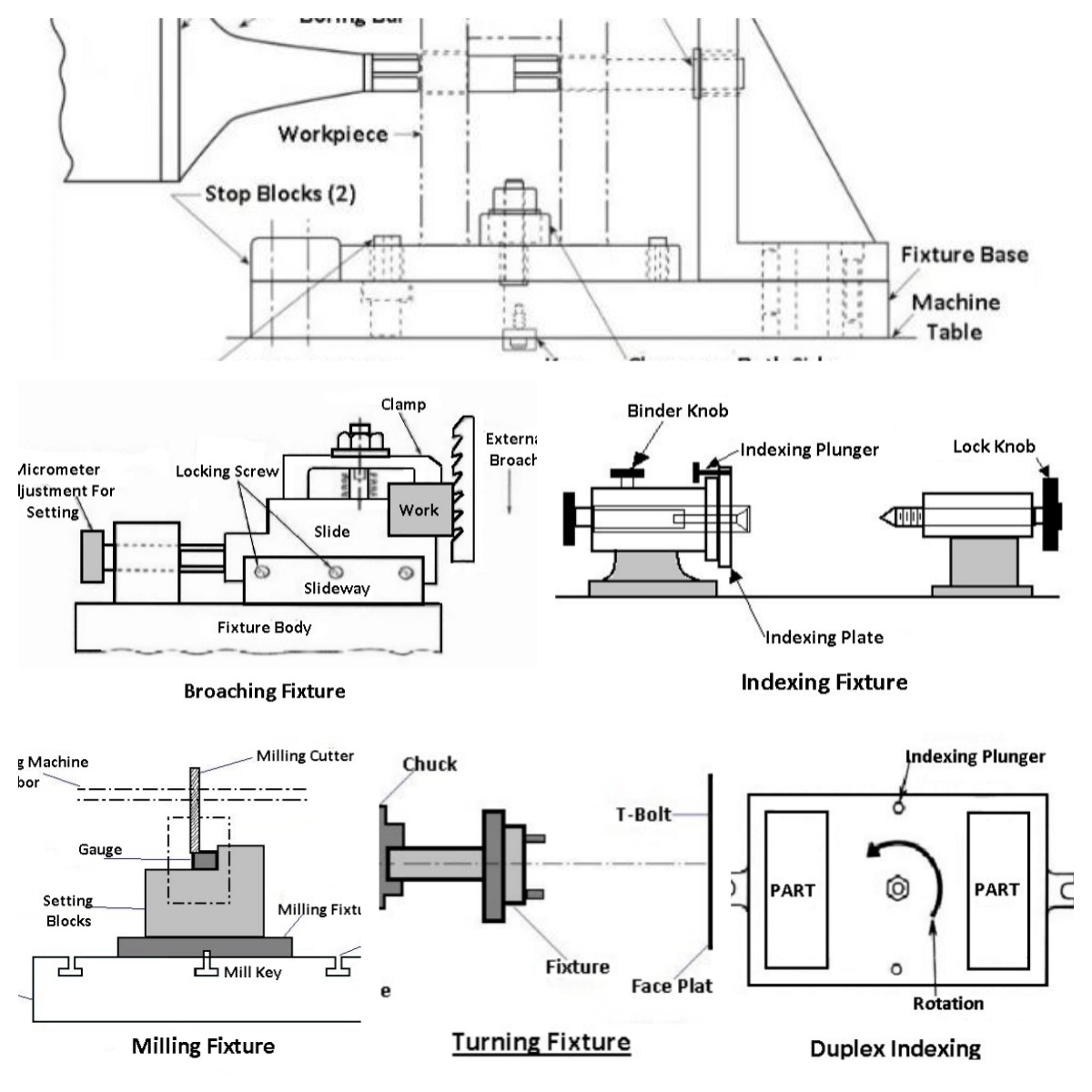

Fixtures ka baarakɛcogo minnu bɛ kɛ tuma caman na .

Fɛn minnu bɛ kɛ ka fɛnw labɛn, olu bɛ kɛ ka caya masinw dilanni baara suguya caman na, i n’a fɔ:

MILLING : A bɛ baarakɛminɛn dɛmɛ ka ɲɛsin mansin tigɛcogo tigitigiw ma.

Turning : A bɛ fɛnw mara minnu tɛ kɛ cogo la lathe operations waati la.

Grinding : A b’a to baarakɛminɛn ka to a cogo la sɔgɔli waatiw la.

Boring : A bɛ yɔrɔ to a ka jɔ kɔnɔna dingɛw dilanni na.

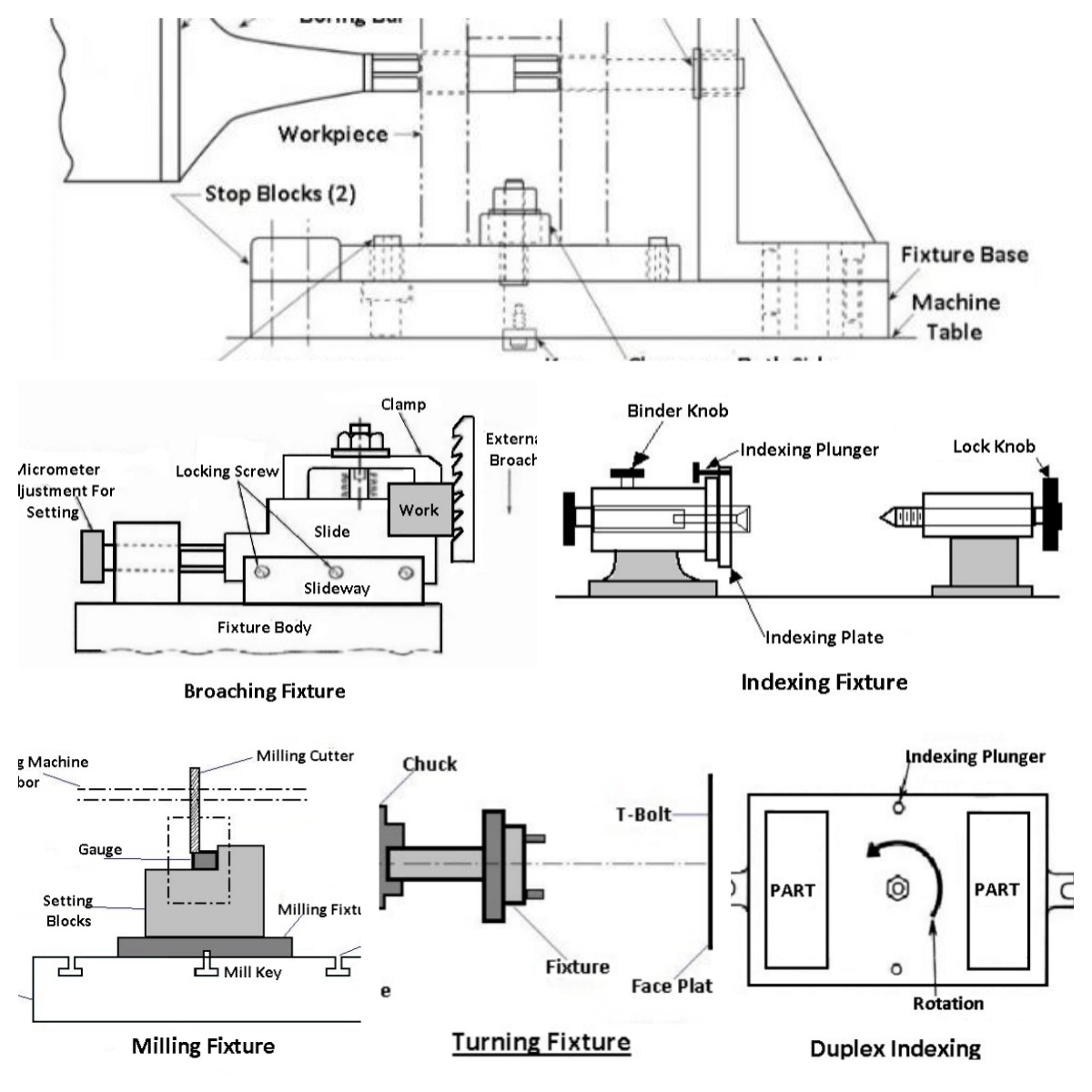

Fixtures suguyaw .

Fixture suguya damadɔ bɛ yen minnu dabɔra masinw ka baara suguya caman kama:

Yɛlɛma minnu bɛ kɛ : A bɛ kɛ ka yɔrɔw minɛ tour kan. O fɛnw bɛ sabati ani ka yɛrɛyɛrɛli dɔgɔya jiginni baarakɛtaw senfɛ.

Milling fixtures : A bɛ baarakɛminɛn siri walasa ka mansin kɛcogo tigitigiw sɔrɔ. U bɛ sira Di jɔyɔrɔ ni ɲɔgɔndɛmɛ tigitigi ma ka kɛɲɛ ni sɔgɔlilan tigɛlan ye.

Drilling fixtures : A dabɔra ka baara kɛ ni drilling machines ye. U bɛ o yɔrɔ minɛ ka ɲɛ ka sɔrɔ ka a to a ka se ka fɛnw sɔgɔ tigitigi ka tɛmɛ bilasirali dingɛw fɛ.

Broaching fixtures : Aw bɛ baarakɛminɛnw minɛ broaching baara waatiw la, minnu bɛ kɛ ka kɔnɔna walima kɛnɛma profiles (profil)w labɛn.

Indexing fixtures : A bɛ se ka kɛ sababu ye ka masinw ni ɲɔgɔn cɛ janya kɛ cogo kelen na yɔrɔ caman na. U bɛ ni index (sɛgɛsɛgɛli) fɛɛrɛw ye walasa ka u ɲɛfɔ ka ɲɛ.

Fixtures de grinding : Aw bɛ sabatili di yɔrɔw ma sɔgɔli waati. Magɛnni chucks, mandrels ani vices ye misaliw ye minnu bɛ sɔrɔ tuma caman na.

Boring fixtures : A dabɔra kɛrɛnkɛrɛnnenya la baarakɛcogo sɛgɛnnenw kama, ka baarakɛminɛnw minɛ walasa ka dingɛ jɔcogo n’a juguman sɔrɔ.

Tapping fixtures : Baarakɛminɛn minnu bɛ lakana kɔnɔna na, olu ye fɛnw ye minnu bɛ kɛ ka fɛnw siri ɲɔgɔn na, minnu ka ɲi kosɛbɛ fɛnw na minnu bɛ kɛ cogo la min tɛ fɛn ye.

Duplex fixtures : ka yɔrɔ fila minɛ ɲɔgɔn fɛ waati kelen na masin fila baara kama, ka dɔ fara sɛnɛfɛnw dilanni nafa kan.

Welding fixtures : Aw bɛ fɛnw tiɲɛni bali ni u yɔrɔw bɛ u jɔyɔrɔ la ka ɲɛ welding waatiw la.

Assembly fixtures : A bɛ kɛ ka yɔrɔw minɛ ɲɔgɔn na yɔrɔw lajɛ waati la, ka a jira ko a bɛ bɛn tigitigi.

Jigw ni fɛnw jɔyɔrɔba .

Jigw ni fɛnw bɛ kɛ fɛn nafama caman ye, u kelen-kelen bɛɛ jɔyɔrɔ ka bon kosɛbɛ walasa ka tiɲɛni ni baarakɛcogo ɲuman sabati fɛn dilanni waatiw la. Nin fɛn ninnu faamuyali nafa ka bon kosɛbɛ dilancogo ɲuman ni baarakɛcogo ɲuman na.

Farikolo

Farikolo bɛ kɛ jiginni ni fɛnw jɔli jusigilan ye. A bɛ plateforme sabatilen di yɔrɔ tɔw bɛɛ ma. A ka c’a la, a dilannen don ni fɛnw ye minnu bɛ mɛn i n’a fɔ nɛgɛ, nɛgɛ, walima aliminiyɔmu, a bɛ masina fanga muɲu k’a sɔrɔ a bɛ gɛlɛya mara. O bɛ kɛ sababu ye ka tiɲɛni sabatilen kɛ baarakɛminɛn caman kɔnɔ.

Yɔrɔw sɔrɔli .

Fɛnw sɔrɔli bɛ baarakɛminɛn bila tigitigi ka kɛɲɛ ni tigɛminɛn walima masin dilan ye. U bɛ se ka kɛ:

Pins .

V-Blocks .

Surfaces custom-shapes .

O yɔrɔw nafa ka bon kosɛbɛ walasa ka segin-ka-bɔnyew sabati ani ka yɔrɔ caman ɲɔgɔn falen-falen sabati fɛn dilanni sigidaw la minnu ka ca kosɛbɛ.

Elements clamping .

Klankolonyalanw bɛ baarakɛminɛn siri kosɛbɛ masinko baara bɛɛ la. U bɛ se ka kɛ:

Manuel (misali la, sirilanw, toggle clamps) .

fanga bɛ min na (misali la, jibolisiraw walima pneumatiques) .

Dilanbagaw ka kan k’a lajɛ ni fanga bɛrɛ bɛ u la k’a sɔrɔ u ma baarakɛminɛn tiɲɛ walima ka baarakɛminɛnw siraw tiɲɛ.

fɛnw sɔgɔli ni u sigicogo .

O fɛnw bɛ tigɛminɛnw ɲɛminɛ jiginni na walima ka dɛmɛ don baarakɛminɛnw lamagacogo ɲuman na fiɲɛbɔlanw kama. Tuma caman na, u bɛ yɔrɔ gɛlɛnw walima fɛn minnu bɛ se ka bila u nɔ na, olu don u kɔnɔ walasa ka tiɲɛni mara waati janw kɔnɔ. U ka baara fɔlɔ ye ka sɔrɔw sɔrɔ minnu bɛ bɛn ɲɔgɔn ma masinw ka sɛgɛsɛgɛli caman na.

Index (Dɔgɔya) fɛnw .

Index (daɲɛw) yɔrɔw bɛ sira Di baarakɛminɛn in wulicogo tigitigi ma walima a jɔyɔrɔ kura ma masinko baara la min ɲɛsinnen bɛ fɛn caman ma. U bɛ kɛ sababu ye baara gɛlɛnw ka se ka kɛ sigicogo kelen kɔnɔ, ka dɔ bɔ u minɛ waati la ani ka baarakɛcogo bɛɛ lajɛlen ɲɛ.

Yɔrɔw jɔyɔrɔ .

O yɔrɔw bɛ jig walima fixture siri masin tabali la yɔrɔ ni a ɲɛsincogo ɲuman na. U bɛ jɔyɔrɔfalen sabati, min nafa ka bon kosɛbɛ walasa ka yɔrɔ kelen-kelen bɛɛ ka tiɲɛni mara fɛn dilanni boliw la.

Bushings .

A bɛ kɛ fɔlɔ jiginni na, bushings guide tigɛminɛnw, kɛrɛnkɛrɛnnenya la drilling baara la. A ka c’a la, u bɛ dilan ni baarakɛminɛn nɛgɛ gɛlɛnw ye, u bɛ sɛgɛn kɛlɛ ani ka tiɲɛni mara waati kɔnɔ. Busiw bɛ se ka jɔ, ka se ka segin u cogo kɔrɔ la, walima ka bɔ, minnu bɛ se ka kɛ sababu ye ka fɛn dɔw bila u nɔ na walima ka u ladilan nɔgɔya la baarakɛminɛnw hakɛ danfaralenw na.

| Element | fɔlɔ baarakɛcogo Jigs | baara fɔlɔ la fixtures kɔnɔ . |

| Farikolo | A bɛ yɔrɔw dɛmɛ, ka baarakɛminɛnw ɲɛminɛ . | A bɛ baarakɛminɛn sabatilen di . |

| Yɔrɔw sɔrɔli . | Baarakɛminɛn min bɛ kɛ ka baarakɛminɛnw ɲɛminɛ . | Aw ye aw jija ka baarakɛminɛnw ɲɛsincogo tigitigiw sɔrɔ . |

| Elements clamping . | Baara kɛtuma na . | Aw bɛ baarakɛminɛn minɛ ka ɲɛsin tigɛ fanga ma . |

| fɛnw sɔgɔli/setting . | Guide baarakɛminɛnw ka ɲɛsin masinw ma tigitigi . | Aw bɛ dɛmɛ don baarakɛminɛnw lamagacogo ɲuman na . |

| Index (Dɔgɔya) fɛnw . | A to multi-position machining . | A bɛ se ka kɛ sababu ye ka yɔrɔ dɔw labɛn . |

| Yɔrɔw jɔyɔrɔ . | Jig align kan masin tabali kan . | Secure fixture à machine bed . |

| Bushings . | Guide tigɛminɛnw tigitigi . | A tɛ kɛ cogoya la . |

Jigw ni fɛnw jɔli fɛnw .

Fɛn bɛnnenw sugandili jiginniw ni fɛnw labɛnni na, o nafa ka bon kosɛbɛ walasa ka baara kɛcogo ɲuman, ɲɛnamaya jan, ani musakabɔcogo ɲuman sɔrɔ fɛn dilanni taabolo la. Fɛn kelen-kelen bɛɛ bɛ fɛn kɛrɛnkɛrɛnnenw di minnu bɛ bɛn baarakɛcogo kɛrɛnkɛrɛnnenw ma ani fɛn dilanni wajibiyalenw ma.

Nɛgɛ gɛlɛn .

Nɛgɛ gɛlɛn bɛ bɔ kɛnɛ kan i n’a fɔ sugandili ɲuman sigidaw la minnu ka ca kosɛbɛ. A fanga danfaralen ani a sɛgɛnbaliya b’a to a ka ɲi jiginni ni fɛnw ma minnu bɛ kɛ ka caya ani minnu bɛ degunba lase mɔgɔ ma.

Nafa jɔnjɔnw:

Superieur durabilité de repetitif machinisation operations .

A bɛ dimension stabilité mara hali doni girinmanw kɔrɔ .

A ka ɲi kosɛbɛ ka ɲɛsin baarakɛcogo ɲuman ma min bɛ muɲuli gɛlɛnw de wajibiya .

Nka, a musaka ni a girinya ka bon, o bɛ se ka dan sigi a baara la cogo dɔw la.

Nɛgɛ min bɛ kɛ ka fɛnw kɛ .

Nɛgɛ min bɛ bɔ, o ka fisa ni fɛnw ye minnu bɛ kɛ yɔrɔ minnu na, yɛrɛyɛrɛ damping ani stabilité de ye fɛn bɛɛ la belebele ye. A ka nafa minnu bɛ a la, olu b’a Kɛ sugandili ye min ka di mɔgɔw ye fixture farikolow ni basiw la.

Fɛn kɛrɛnkɛrɛnnenw:

A bɛ yɛrɛyɛrɛw minɛ ka ɲɛ, ka masinw ka tiɲɛni bonya .

A bɛ funteni sabatili ɲuman di baara janw senfɛ .

A musaka ka dɔgɔ ni fɛnw ye minnu bɛ se ka kɛ fɛnw ye minnu bɛ se ka kɛ .

A nafa fɔlɔ bɛ sɔrɔ a ka se ka sɔgɔsɔgɔ, o bɛ kɛ sababu ye ka kɛnɛya furakɛli ɲuman kɛ.

Aluminiyɔmu aliman .

Aluminiyɔmu bɔgɔlanw bɛ fɛn nɔgɔmanw ni nɔgɔw faralen ɲɔgɔn kan cogo la min bɛ mɔgɔ bila ka miiri. O jogo ninnu b’a to u bɛnnen don kɛrɛnkɛrɛnnenya la jiginni ni fɛnw ma minnu bɛ se ka ta.

Nafa minnu bɛ yen olu ye:

A minɛcogo n’a taali nɔgɔya bololabaarakɛlaw ka baarakɛtaw la .

Oksidan ka se ka oksidan sɔrɔ, ka dɔ bɔ ladonni magow la .

Machinabilité excellent pour les designs personnalisés .

Nka, a bɛ se ka kɛ ko u man ɲi baarakɛcogo la min bɛ gɛlɛya kojugu walima ka se ka sɛgɛn.

Plastiques en étérieure .

Ɛntɛrinɛti plastikiw bɛ fɛɛrɛ wɛrɛ jira min musaka ka dɔgɔ jiginni ni fɛnw labɛnni baara kɛrɛnkɛrɛnnenw kama. U ka nafolo kɛrɛnkɛrɛnnenw bɛ se ka kɛ sababu ye ka fɛn dilanni kɛrɛnkɛrɛnnenw kɛ.

Nafa jɔnjɔnw:

Kuranko gɛlɛyaw baarakɛcogo la minnu bɛ tali kɛ ɛntɛrinɛti yɔrɔw la .

kemikaliw ka se ka baara kɛ ni u ye sigidaw la .

Coefficients de friction low , ka sɛgɛnw dɔgɔya baarakɛminɛnw kan .

U dantigɛliw ye fanga dɔgɔyali ni funteni dɔgɔyali ye n’i y’a suma ni nɛgɛ sugandiliw ye.

| Matériel | fanga | girinya | resistance | cost | vibration damping . |

| Nɛgɛ gɛlɛn . | Jamanjan | Jamanjan | Ka bɛrɛbɛn | Jamanjan | Fɛ́gɛn |

| Nɛgɛ min bɛ kɛ ka fɛnw kɛ . | Jamanjan | Jamanjan | Fɛ́gɛn | Ka bɛrɛbɛn | Jamanjan |

| Aluminiyɔmu aliman . | Ka bɛrɛbɛn | Fɛ́gɛn | Jamanjan | Ka bɛrɛbɛn | Fɛ́gɛn |

| Plastiques en étérieure . | Fɛ́gɛn | Fɛ́gɛn | Jamanjan | Fɛ́gɛn | Ka bɛrɛbɛn |

Danfaraba minnu bɛ jiginniw ni fɛnw cɛ .

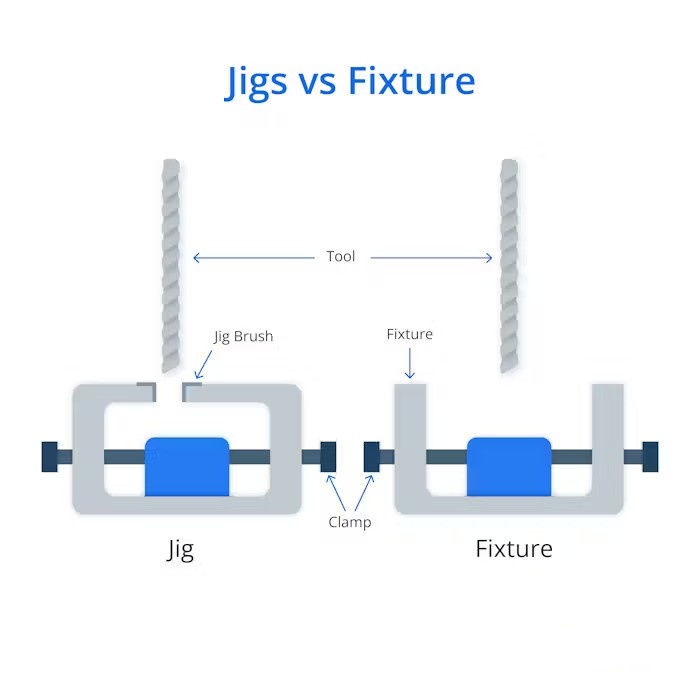

Hali ni jiginni ni fɛnw bɛɛ ye fɛn ye min nafa ka bon kosɛbɛ fɛn dilanni na, u bɛ jɔyɔrɔ wɛrɛw ta. O danfara ninnu faamuyali bɛ dilanbagaw dɛmɛ ka baarakɛminɛn bɛnnen sugandi baara kɛrɛnkɛrɛnnenw kama.

Baarakɛcogo fɔlɔ .

Baara fɔlɔ bɛ jigw ni fixtures danfara. Jigw bɛ tigɛminɛn bilasira ka taa yɔrɔ ɲininen na baarakɛminɛn kan, ka baarakɛcogo ɲuman sabati i n’a fɔ sɔgɔli ni sɔgɔli. Faan wɛrɛ fɛ, fɛnw bɛ se ka kɛ ka baarakɛminɛnw lakana ani k’u dɛmɛ masinko waatiw la i n’a fɔ sɔgɔli ni sɔgɔli. U tɛ baarakɛminɛn ɲɛminɛ nka u bɛ baarakɛminɛn in ɲɛsincogo mara.

girinya ni gɛlɛya .

A ka c’a la, fiɲɛw ka gɛlɛn ani u ka gɛlɛn ka tɛmɛ jiginni kan. U ka kan ka fanga sanfɛtaw ni yɛrɛyɛrɛw muɲu masinw senfɛ, o b’a to u barika ka bon. A ka c’a la, jiginniw ka nɔgɔn bawo u bɛ baarakɛminɛnw ɲɛminɛ fɔlɔ, wa u tɛ fɛnw fanga dɔgɔya. O danfara in fana bɛ nɔ bila musaka la, ni a ka c’a la, fɛnw sɔngɔ ka gɛlɛn k’a sababu kɛ u ka gɛlɛya ye.

Dilanko jateminɛw .

Fixtures ani jigs bɛ dilancogo jateminɛ suguya wɛrɛw de wajibiya. Fɛn minnu bɛ kɛ ka fɛnw siri, olu ka kan ka jate minɛ fanga la, u sabatili la, ani u yɛrɛyɛrɛli la walasa ka masina doni girinmanw minɛ. Jigw, o ni ɲɔgɔn cɛ, u bɛ sinsin kosɛbɛ tigitigiya ni tiɲɛni kan, bawo u jɔyɔrɔ fɔlɔ ye baarakɛminɛnw ɲɛminɛcogo ye.

Contact ni baarakɛminɛn ye .

Jigw bɛ na ɲɔgɔn sɔrɔ ni baarakɛminɛn ye walasa k’a sira ɲɛminɛ, tuma caman na, u bɛ baara kɛ ni bushings walima templates ye walasa ka a dɔn ko a bɛ se ka kɛ. Nka, fiɲɛw tɛ maga baarakɛminɛn na. U bɛ baarakɛminɛn minɛ ka ɲɛ dɔrɔn, o b’a to baarakɛminɛn bɛ se ka taa a yɛrɛ ma masinko waati la.

nɔrɔli masin na .

A ka ca a la, jiginniw bɛ kɛ bolo la walima u bɛ siri nɔgɔya la masin kan, ka kɛɲɛ ni baara ye. O ni ɲɔgɔn cɛ, fɛnw bɛ siri kosɛbɛ masin tabali la ni sirilanw walima bololanɛgɛw ye walasa ka fanga minnu bɛ kɛ baarakɛtaw senfɛ i n’a fɔ sɔgɔli walima tigɛli.

| Danfaraba min bɛ yen | Jig | fixture . |

| Baarakɛcogo fɔlɔ . | A bɛ tigɛminɛn ɲɛminɛ . | A bɛ baarakɛminɛn minɛ ani k' a dɛmɛ . |

| girinya ni gɛlɛya . | A ka nɔgɔn, a ka gɛlɛn kosɛbɛ . | A ka gɛlɛn, a ka gɛlɛn kosɛbɛ . |

| Design Focus . | Tiɲɛni, baarakɛminɛnw ɲɛminɛcogo . | sabatili, fanga sirili . |

| Baarakɛminɛn minnu bɛ sɔrɔ . | bɛ na ni baarakɛminɛn ye . | A tɛ kuma baarakɛminɛn kan . |

| Masina nɔrɔli . | Bololabaarakɛlaw ka bolo kan walima a bɛ se ka jɔ nɔgɔya la . | A sirilen bɛ masin na kosɛbɛ . |

Nafa minnu bɛ sɔrɔ baara kɛli la ni jigw ni fɛnw ye minnu bɛ

| se | ka kɛ fɛn dilanni na . |

| dɔ farala baarakɛcogo kan . | A bɛ dɔ bɔ bololabaara la, ka dɔ fara baarakɛcogo kan . |

| A ka ɲi ani a ka tiɲɛni . | A bɛ a jira ko a jɔyɔrɔ bɛ to ka kɛ, a bɛ fɛn dilannenw cogoya ɲɛ ka taa a fɛ . |

| A musaka dɔgɔyara . | A bɛ baarakɛlaw ni fɛnw musakaw dɔgɔya, ka dɔ bɔ fɛn tiɲɛnenw na ani ka baara kɛ kokura . |

| Baarakɛminɛnw bilasirali tigitigi . | A bɛ baarakɛminɛnw bilacogo ɲɛfɔ ka ɲɛ masinw dilanni waati la . |

| Dɔ farala ɲɔgɔn falen-falen kan . | A bɛ yɔrɔ kelenw dilan ni fɛn caman ɲɔgɔnna ye . |

| Tiɲɛni min bɛ dɔgɔya . | A bɛ dɔ bɔ fɛnw tiɲɛni ni u tiɲɛni na . |

| Lakana caya . | Lakandali sirili bɛ dɔ bɔ kasaara farati la . |

| Baarakɛlaw ka magoɲɛfɛnw dɔgɔyali . | A bɛ baara kɛ ni otomatiki ye, ka baarakɛlaw ka ɲininiw dɔgɔya . |

| A ka baara kɛcogo surun . | Setup nɔgɔya, a bɛ labɛnni waati dɔgɔya . |

| Machining multi-station . | A bɛ kɛ sababu ye ka taabolo caman kɛ masin kelen kan, ka baarakɛcogo ɲɛ . |

| sɛgɛsɛgɛli musakaw dɔgɔyali . | A bɛ a to a ka kɛ cogo la min bɛ to ka kɛ, ka dɔ bɔ a mago la ka sɛgɛsɛgɛli kɛ tuma caman . |

| A bɛ otomatiki nɔgɔya . | A bɛ dɛmɛ don otomatiki ni nizɛri fɛn dilanni taabolo la . |

Jig ni fixture design jateminɛw .

Jig ni fixture dilancogo ɲuman nafa ka bon kosɛbɛ walasa ka fɛn dilanni taabolo ɲumanw kɛ. Ni u bɛ tugu dilancogo sariyakolo jɔnjɔnw na, ɛntɛrinɛti injiniyɛriw bɛ se ka baarakɛminɛnw dilan minnu bɛ fɛnw dilan minnu bɛ se ka kɛ fɛn ye min bɛ se ka kɛ ka ɲɛ, ka baara kɛ ka ɲɛ, ani ka baarakɛlaw lakana.

Alignment ani Constraint .

Alignment dafalen bɛ a to a bɛ se ka kɛ ko a bɛ se ka kɛ ko a bɛ se ka kɛ ko a bɛ se ka kɛ ko a bɛ se ka kɛ ko a bɛ se ka kɛ ko a bɛ se ka kɛ ko a bɛ se ka kɛ ko a bɛ se ka kɛ ko a bɛ se ka kɛ ko a bɛ se ka kɛ ko a bɛ se ka kɛ ko a bɛ se ka kɛ. Nka, fɛn minnu bɛ ɲɔgɔn sɔsɔ kojugu, olu bɛ se ka filiw don. Dilanbagaw ka kan ka balansi sɔrɔ, ka baara kɛ ni yɔrɔ sɔrɔyɔrɔw ye minnu ka kan ka kɛ, minnu ka kan ka kɛ muɲuli ye. O fɛɛrɛ in bɛ tiɲɛni mara ka sɔrɔ ka sira di fɛn dɔw ma minnu bɛ se ka ɲɔgɔn falen dɔɔnin baarakɛminɛnw hakɛw la.

Baarakɛcogo ɲuman .

Dilancogo nɔgɔyali ani ka bolo kelen baara bila jɔyɔrɔ fɔlɔ la ni a bɛ se ka kɛ, o bɛ baara kɛcogo ɲɛ kosɛbɛ. O fɛɛrɛ in bɛ baarakɛlaw ka sɛgɛn dɔgɔya ani ka filiw seko dɔgɔya sigili ni baara kɛtuma na. Intuitive designs fana bɛ dɔ bɔ degeliw waati la baarakɛla kuraw ye.

Hadamadenw ka donko dɔgɔyali .

Otomatiki min bɛ jig ni fixture design la, o bɛ dɔ bɔ bololabaara la masinko waatiw la. O tɛ kɛ sababu ye ka bɛnkan dɔrɔn ɲɛ, nka a bɛ lakana sabati fana, ka baarakɛlaw yɔrɔ janya yɔrɔw la minnu bɛ se ka kɛ farati ye baara kɛtuma na.

filiw dɔnni .

Jateminɛw tali minnu bɛ bɛnkanbaliya filiw jira, o nafa ka bon kosɛbɛ jogoɲini na. O dilanfɛnw bɛ baarakɛlaw bila ka kow dɔn joona ani k’u latilen sani u ka kɛ sababu ye ka yɔrɔ tiɲɛnenw sɔrɔ. Ɲɛjiralanw walima farikolo jɔyɔrɔw bɛ se ka baara kɛ ka ɲɛ.

Taabolow ka ɲɔgɔnfaamu .

Baarakɛɲɔgɔnya ni fɛn dilanni taabolo bɛɛ ye, o nafa ka bon. Dilanbagaw ka kan ka jateminɛ kɛ cogo min na jig walima fixture bɛ bɛn fɛn dilanni sira ma min ka bon, o la:

Nin fɛɛrɛ bɛɛjɛfanga in bɛ wuliliko nɔgɔya taabolow ni ɲɔgɔn cɛ ani ka baarakɛcogo bɛɛ lajɛlen ɲɛnabɔ.

Material Selection .

Fɛn ɲuman sugandili nafa ka bon jiginni ni fixture baarakɛcogo la. Fɛn minnu ka kan ka jateminɛ, olu ye:

Dilancogo sɛgɛsɛgɛli sɛbɛn .

Walasa ka dilancogo fan bɛɛ jateminɛ ka ɲɛ, ɛntɛrinɛti injiniyɛriw ka kan ka nin hakilina ninnu ɲɛnabɔ:

Yala an ye ɲɔgɔndan ɲuman sɔrɔ k’a sɔrɔ an ma dankari kojugu wa?

Yala jig walima fixture bɛ se ka baara kɛ ni bolo kelen ye wa?

Yala hadamadenw ka dɛmɛ bɛ dɔgɔya masinko waati la wa?

Yala o dilancogo bɛ filiw jira minnu bɛ se ka kɛ ɲɔgɔn fɛ wa?

Nin dilan in bɛ don ɲɔgɔn na cogo di ni an ka fɛn dilanni taabolo bɛɛ ye?

Yala fɛn sugandilenw ka ɲi an ka baarakɛcogo kɛrɛnkɛrɛnnen na wa?

Jigw ni fɛnw dilanni fɛɛrɛw .

Jigw ni fɛnw dilanni fɛɛrɛ ɲuman sugandili nafa ka bon kosɛbɛ walasa u ka baara kɛcogo n’u musaka dɔgɔyali. Fɛɛrɛ min sugandira, o bɛ bɔ fɛnw na i n’a fɔ fɛn dilanni hakɛ, fɛnw wajibiyalenw, ani jateminɛcogo gɛlɛya. Fɛɛrɛ saba filɛ nin ye minnu bɛ kɛ ka jiginni ni fɛnw labɛn fɛn dilanni na.

CNC Machining .

CNC masin ye fɛɛrɛ ye min ka di mɔgɔw ye ka jiginni ni fɛnw labɛn ni u bɛ tiɲɛ ani ka u muɲu. A bɛnnen don kɛrɛnkɛrɛnnenya la fɛn dilanni ma min ka dɔgɔ, yɔrɔ min na, fɛn kelen-kelen bɛɛ mago bɛ ka muɲuli gɛlɛnw kunbɛn. CNC masinw bɛ se ka kɛ sababu ye ka fɛn suguya caman kɛ i n’a fɔ nɛgɛ, aliminiyɔmu, ani fɛn minnu fanga ka bon. O kɛcogo bɛ yɔrɔw di minnu bɛ tiɲɛ kosɛbɛ, o b’a to a ka ɲi baarakɛminɛnw ma minnu bɛ jiginni walima fɛnw labɛn minnu dilannen don ni fɛn gɛlɛnw ye.

CNC masinw nafa jɔnjɔnw:

A ka fisa ni tolerances tight ye .

A bɛnnen don yɔrɔ gɛlɛnw ma minnu bɛ ni ladamu ye .

A bɛ baara kɛ ni fɛn caman ye .

3D sɛbɛnni .

3D sɛbɛnni ye fɛn caman sɛmɛntiya jigw ni fɛnw dilanni na, kɛrɛnkɛrɛnnenya la, boliw la minnu bɛ kɛ ka dɔgɔya walima jateminɛ gɛlɛnw na minnu ka gɛlɛn walima minnu musaka ka bon masin na. A bɛ kɛ sababu ye ka prototyping teliya ani ka customisation kɛ ni musaka dɔgɔman ye. 3D sɛbɛnni bɛ kɛ tuma caman na walasa ka fɛnw dilan minnu kɔnɔna fɛnw ka gɛlɛn, fɛn nɔgɔmanw, walima minnu bɛ ladilan teliya la. Hali n’a bɛ se ka kɛ a tɛ bɛn tuma bɛɛ laadalafɛnw fanga ma, a bɛ fɛn caman sɛmɛntiya a dilanni na.

3D sɛbɛnni nafa jɔnjɔnw:

A musaka ka dɔgɔ ni jateminɛ kɛlenw ye minnu ka dɔgɔ walima minnu bɛ kɛ ka kɛɲɛ ni mɔgɔw sago ye .

Prototypes ni Batch misɛnninw bɔli waati teliya .

A bɛ sira di dilancogo gɛlɛnw ma minnu ka nɔgɔn .

pikiri teliya la .

Jigw ni fɛnw dilanni hakɛ caman sɔrɔli kama, pikiri teliya ye fɛɛrɛ ye min ka fisa. A ka ɲi kosɛbɛ walasa ka yɔrɔ ba caman dilan ka bɔ thermoplastique engineering la. O kɛcogo in b’a to a yɔrɔ kelen-kelen bɛɛ bɛ bɛn a jogo ni a bonya ma. A yɔrɔ kelen musaka bɛ dɔgɔya ni a hakɛ bɛ caya, o b’a to a bɛnnen don fɛn dilanni na. Pikiri dilanni teliya bɛ kɛ ka fɛnw labɛn minnu bɛ fanga, muɲuli, ani ka se ka sɛgɛn.

Nafa jɔnjɔnw bɛ sɔrɔ pikiri teliya la:

A bɛ baara kɛ ka ɲɛ ka ɲɛsin fɛn caman dilanni ma .

Jogo ɲuman ni a hakɛ tiɲɛni bɛ kɛ cogo kelen na .

A bɛnnen don yɔrɔw ma minnu dilannen don ni thermoplastiques sabatilenw ye .

Jigw ni fɛnw bilali baara la izini suguya caman kɔnɔ .

Jigw ni fɛnw ye baarakɛminɛn nafamaw ye fɛn dilanni taabolo la izini caman kɔnɔ. U bɛ tiɲɛni, baarakɛcogo ɲuman ani fɛn dilanni teliya ɲɛ, o b’a to u nafa ka bon kosɛbɛ fɛn dilanni na min ka ɲi kosɛbɛ. Nin ye izini jɔnjɔnw ye minnu bɛ tali kɛ jiginni ni fɛnw labɛnni na.

Mobili industrie .

Mobiliko siratigɛ la, jiginni ni fɛnw jɔyɔrɔw jɔyɔrɔ ka bon kosɛbɛ fɛnw lajɛyɔrɔw la ani fɛn dilanni yɔrɔw la. U bɛ ɲɔgɔndɛmɛ tigitigi Sɔrɔ welding (sɔgɔli), drilling (dɔgɔyali), ani machining (masinw) kɛcogo la. Fixtures bɛ yɔrɔ dɔw minɛ u nɔ na walasa u ka se ka segin u cogo kɔrɔ la ani ka u kɛ cogo bɛnnen na, o bɛ kɛ sababu ye ka mobili yɔrɔw dilan jamaba la.

Aplikasi jɔnjɔnw:

Mobili farikolo sɔgɔli ni a lajɛ .

Motɛri yɔrɔw sɔgɔli ni u masin .

A bɛ yɔrɔw labɛn walasa ka u ɲɛfɔ ka ɲɛ kosɛbɛ .

Aerospace industrie .

Aerospace dilanni bɛ tiɲɛni ni tiɲɛni hakɛ caman ɲini, jiginni ni fɛnw bɛ dɛmɛ ka minnu sɔrɔ. Fɛn minnu bɛ kɛ, olu bɛ dɛmɛ don yɔrɔ gɛlɛnw dilanni na, ka sɔrɔ jiginni bɛ dɛmɛ don awiyɔn yɔrɔw sɔgɔli ni u sɔgɔli tigitigi la. O bɛ lakana ni dannaya sabati awiyɔnw jɔli la.

Aplikasi jɔnjɔnw:

Panneau de panneau riveux et structures .

turbine blades ni moteur yɔrɔw masina .

Assemblées critiques (Assemblies kɔrɔfɔlenw) sinsinni .

Elektronikiw dilanni .

Elektronikiw dilanni na, jiginni ni fɛnw bɛ kɛ ka fɛn nɔgɔlenw bila u jɔyɔrɔ la ani k’u lakana solder walima u lajɛtuma na. O baarakɛminɛnw bɛ dɛmɛ ka bɛnkan sabati jamanadenw ka sɔrɔ la ka sɔrɔ ka tiɲɛniw bali ɛntɛrinɛti yɔrɔ gɛlɛnw na.

Aplikasi jɔnjɔnw:

Solder ani assembling circuit boards .

Minɛn nɔgɔlenw minɛni u nɔ na .

A bɛ se ka kɛ ko a bɛ se ka kɛ ka fɛnw lajɛ.

Woodworking .

Woodworking bɛ baara kɛ ni jig ye walasa ka jiriw tigɛ, ka u sɔgɔ, ani ka u cogoya. Fɛn minnu bɛ kɛ ka fɛnw labɛn, olu bɛ sabatili di masinw kɛcogo la, ka tigɛcogo tigitigiw ni u sɔrɔcogo basigilenw sabati. O baarakɛminɛnw nafa ka bon kosɛbɛ minɛnw, kabiniw, ani jiri fɛn wɛrɛw dilanni na minnu bɛ se ka kɛ.

Aplikasi jɔnjɔnw:

Dovetail tigɛ ka ɲɛsin kabini ma .

Guiding Tools for Drilling and Shape .

Clamping ka ɲɛsin precision joinery ma .

Metalworking .

Jigw ni fɛnw ye fɛnw ye minnu bɛ kɛ ka nɛgɛ baara kɛ, k’a ta sɔgɔli la ani ka wuli ka taa u sɔgɔ. U bɛ dɛmɛ ka nɛgɛ yɔrɔw minɛ u nɔ na tigɛcogo, u cogoya ani u finidoncogo waatiw la, o bɛ kɛ sababu ye ka jogo ɲuman sabati ani ka dɔ bɔ a dilanni waati la.

Aplikasi jɔnjɔnw:

Masiniw bɛ kɛ tourw ni mansinw kan .

Récision Grinding and Finishing .

Station Multi-Station Metal Fabrication .

Mold Manufacturing .

Nɔgɔ dilanni bɛ a ɲini ka ɲɛ, kɛrɛnkɛrɛnnenya la ni pikirijikɛlan gɛlɛnw bɛ bɔ. Fɛn minnu bɛ kɛ ka fɛnw labɛn, olu bɛ baarakɛminɛn minɛ ka jɔ a sɔgɔli walima a jiginni waati la, ka sɔrɔ jiginniw bɛ baarakɛminɛnw bila tigitigi cogoya gɛlɛnw tigɛcogo la.

Aplikasi jɔnjɔnw:

Moliw dilanni plastiki pikiri kama .

Machining précision de la details intricate .

Klamping tool sira dabɔli waati .

Dɔgɔtɔrɔso minɛnw dilanni .

Dɔgɔtɔrɔso minɛnw dilanni bɛ jogoɲini gɛlɛn ni tiɲɛniba de wajibiya. Jigw ni fɛnw bɛ dɛmɛ ka yɔrɔw lajɛ ka ɲɛ, kɛrɛnkɛrɛnnenya la, minɛn minnu bɛ muɲuli ni saniya tigitigiw wajibiya.

Aplikasi jɔnjɔnw:

Opereli baarakɛminɛnw bɛ ɲɔgɔn sɔrɔ ani k’u lajɛ ɲɔgɔn fɛ .

Yɔrɔ fitininw minɛni saniyaso kɔnɔ masinw na .

Fɛn minnu bɛ se ka don fɛnw na minnu bɛ se ka don u kɔnɔ, olu lajɛlen .

Consumer Electronics dilanni .

Ɛntɛrinɛti kan, jiginni ni fɛnw bɛ se ka kɛ sababu ye ka fɛn misɛnniw, fɛn caman, i n’a fɔ telefɔni seleke naani, tablɛtiw ani ɔridinatɛriw lajɛ teliya la ani cogo bɛnnen na. O baarakɛminɛnw bɛ fɛnw dilanni siraw labɛn ka ɲɛ ani ka fɛn dilannenw cogoya ɲɛ.

Aplikasi jɔnjɔnw:

A yɔrɔ fitininw bilali tigitigi .

Assemblée Line Fixtures (Layidu minnu bɛ kɛ ka mɔgɔw lajɛ teliya la) .

Fɛn minnu bɛ kɛ ka minɛnw bila ani ka u bila u ka ɛkran kan .

| Industrie | applications . |

| Mobili . | welding, drilling, moteur part machining . |

| Aerospace . | riveting, turbine machining, structurel alignment . |

| Elektroniki . | Circuit Board Soldering, Component Placement . |

| Woodworking . | Dovetail tigɛ, a cogoya, a sɔgɔli . |

| Metalworking . | Milling, turning, grinding . |

| Mold Manufacturing . | Mold Creation, Machining Intricate Details . |

| Dɔgɔtɔrɔso minɛnw dilanni . | Assemblée précision, machining cleanroom . |

| Electronics consommateurs . | A lajɛ teliya la, a yɔrɔw labɛncogo . |

Kuncɛli

Jigiw ni fɛnw jɔyɔrɔw jɔyɔrɔ ka bon kosɛbɛ bi fɛn dilanni na, ka fɛnw tiɲɛni, u ka baarakɛcogo ɲuman ani u ka baarakɛcogo ɲɛ. K’a ta baarakɛminɛnw bilasirali la ka se baarakɛminɛnw lakanani ma, o minɛnw bɛ baarakɛcogo ɲɛnabɔ masinko taabolo suguya caman na. Ni u ye u suguyaw, u ka fɛnw, u ka dilancogo jateminɛ, ani u ka fɛn dilanni fɛɛrɛw faamuya, ɛntɛrinɛti injiniyɛriw bɛ se ka baara kɛcogo ɲɛ. A kɛra CNC masinko ye wo, a kɛra 3D sɛbɛnni ye wo, jiginni ni fɛnw dilanni n’u waleyacogo ɲuman bɛ fɛn dilannenw cogoya ɲɛ kosɛbɛ ani ka dɔ bɔ u dilanni musakaw la, o b’a to u nafa ka bon kosɛbɛ bi fɛn dilanni na, min bɛ kɛ ni ɲɔgɔndan ye.