Jig ɛn fiks na impɔtant tin dɛn fɔ mek, bɔt yu no aw dɛn difrɛn? Ɔl tu impɔtant prɛsishɔn ɛn efyushɔn, yet dɛn de sav difrɛn wok dɛn. Jigs de gayd mashin tul dɛn, we fiks dɛn de sikyuɔr wokpies dɛn. Dɛn rol dɛn impɔtant fɔ optimiz prodakshɔn prɔses.

Insay dis atikul, wi go difayn wetin jig ɛn fiks, tɔk bɔt dɛn difrɛns, ɛn fɛn ɔl di wok dɛn we dɛn de du fɔ mek tin dɛn. Yu go lan bɔt difrɛn kayn dɛn, matirial dɛn we dɛn yuz, ɛn dɛn ki aplikeshɔn dɛn akɔdin to industri dɛn lɛk ɔtomotiv ɛn ɛrospɛs. Bay di ɛnd, yu go si wetin mek dɛn tul ya rili impɔtant fɔ mek dɛn ebul fɔ mek di prodakshɔn wok fayn ɛn gɛt kwaliti bɛtɛ.

Wetin na jig dɛn?

Jig na spɛshal tul dɛn we dɛn mek fɔ ɛp fɔ mek prɛsishɔn ɛn efyushɔn wok fayn fayn wan na di we aw dɛn de mek tin dɛn. Dɛn de sav as gayd mɛkanism fɔ kɔt tul dɛm, fɔ mek shɔ se dɛn gɛt kɔnsistɛns ɛn kɔrɛkt rizɔlt akɔdin to bɔku wokpies dɛm.

Ditayl ɛksplen bɔt jig dɛn .

Jig dɛn gɛt sɔm impɔtant tin dɛn:

Bɔdi: Men strɔkchɔ we de ol ɔda ɛlimɛnt dɛn .

Locating Elements: Pozishɔn Wokpies kɔrɛkt wan

Di Element dɛn we de gayd: Di tin dɛn we dɛn kin yuz fɔ kɔt di dairekt wan .

Clamping Elements: Sikyu wokpies fayn fayn wan

Bushings: Gayd drɔl bit ɔ ɔda tul dɛn .

Dɛn komponent ya de wok togɛda fɔ mek wan rilibul sistɛm fɔ ripit mashin ɔpreshɔn.

Praymari funkshɔn fɔ jig dɛn na manufakchurin .

Jigs fɔs:

Gayd fɔ kɔt tul dɛn prɛsishɔn .

Mek shɔ se di wok we dɛn de du fɔ di wok we dɛn de du ɔltɛm .

Ridyus di sɛtup tɛm bitwin di opareshɔn dɛn .

Minimize Human Error in Machining Processes .

Inkris prodakshɔn spid ɛn efyushɔn .

Bay we dɛn de du dɛn wok dɛn ya, jig dɛn kin rili ɛp fɔ mek di manufakchurin kwaliti ɛn prodaktiviti bɛtɛ.

Kɔmɔn aplikeshɔn dɛn fɔ jig dɛn .

Jigs fain plenti yus in difren mashin opareshon:

Drilin: Mek shɔ se dɛn put di ol ples ɛn dip di kɔrɛkt we aw dɛn fɔ put ol ɛn dip

Reaming: Gayd reamers fɔ prɛsis ol finish

Tapping: Fasilitayt kɔnsistɛns trɛd krieshɔn .

Boring: Dairekt boring tul fɔ silindrikal ol prodakshɔn

Countersinking: Gayd tul dɛn fɔ mek ol dɛn we gɛt rɛs

Tayp dɛn fɔ Jig dɛn .

Jig dɛn kin kam insay difrɛn we dɛn, ɛn dɛn mek ɛni wan pan dɛn fɔ sɔm patikyula tin dɛn we dɛn nid fɔ mek. We wi ɔndastand dɛn kayn dɛn ya, i de ɛp fɔ mek di prodakshɔn prɔses dɛn wok fayn.

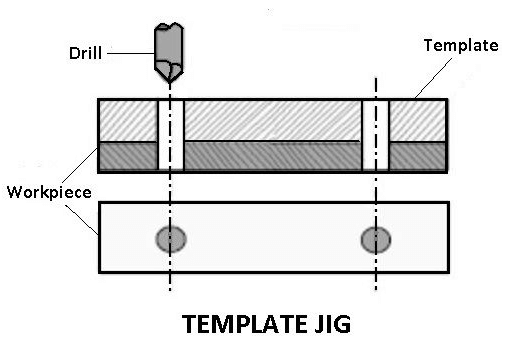

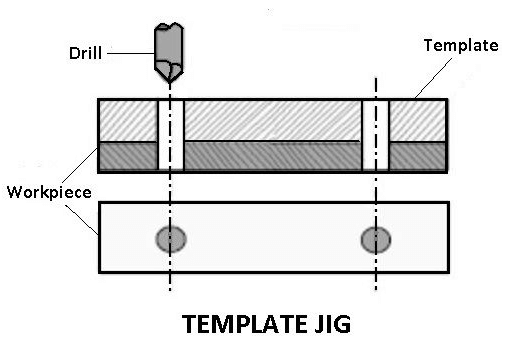

Template jigs .

Simpul yet ifektiv, tɛmplat jig dɛn ficha plet dɛn wit ol dɛn we de sav as gayd dɛn. Dɛn:

Gi di bɛsis gayd fɔ di drɔlin ɔpreshɔn dɛn .

Mek shɔ se kɔnsistɛns ol plesmɛnt akɔdin to bɔku wokpies dɛn .

Ofa kɔst-ɛfɛktiv sɔlvishɔn fɔ smɔl-smɔl prodakshɔn .

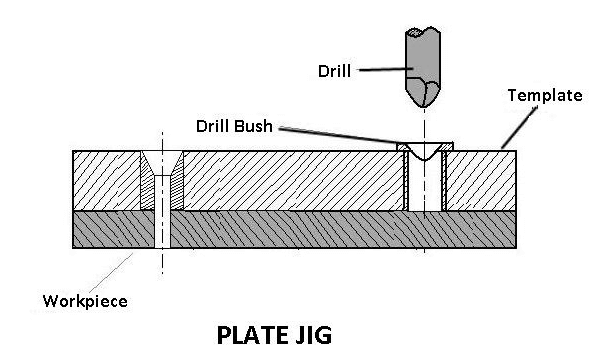

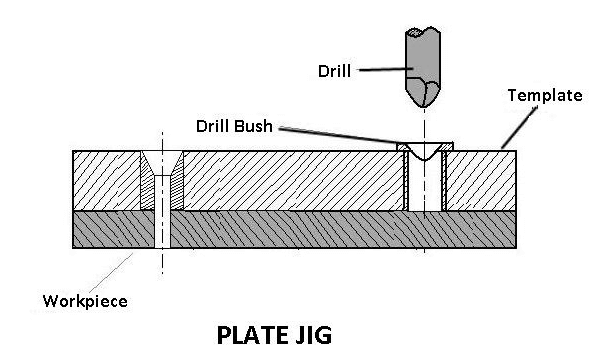

Plɛt jig dɛn .

Plɛt jig dɛn kin impɔtant pan tɛmplat dizayn dɛn bay we dɛn kin put drɔl bush dɛn. Dɛn jig dɛn ya:

Alaw prɛsis drɔlin fɔ big pat dɛn .

Mek yu kɔntinyu fɔ gɛt kɔrɛkt spays bitwin di ol dɛn .

Enhans durbility longevity of di jig .

Angle-plet jig dɛn .

Disain fɔ angled drilin ɔpreshɔn, angle-plate jigs:

Hol pat na spesifik angles rilitiv to mounting locators .

Enable drilling na prɛsis angul dɛn we nɔ gɛt kɔmpleks sɛtup dɛn .

Inkris efyushɔn fɔ prodyuz angul ol dɛn .

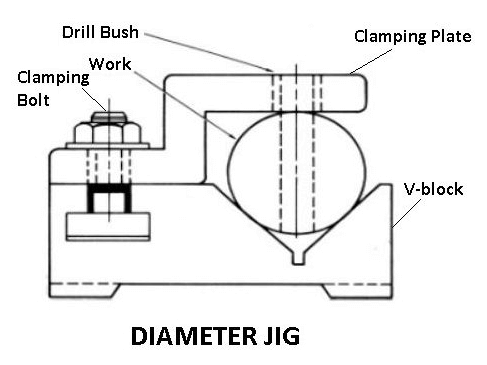

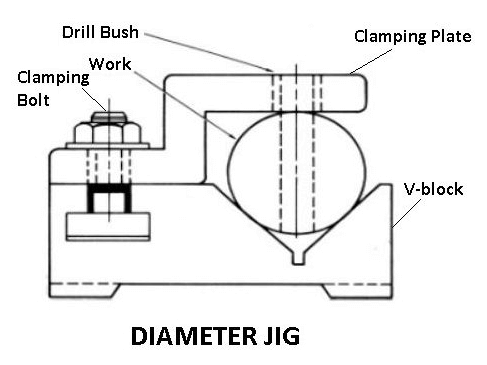

dayamita jig dɛn .

Specialized fɔ silindrikal ɔ sfɛrikal wokpies, dayamita jigs:

Fasilitɛt drɔlin fɔ raydial ol dɛn .

Mek shɔ se kɔnsistɛns de insay ol plesmɛnt rawnd kɔba sɔfays dɛn .

Impruv akkuracy in sirkul komponent manufakchurin .

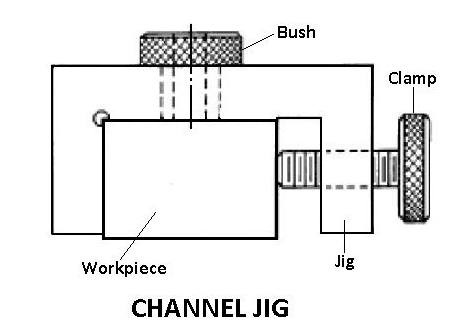

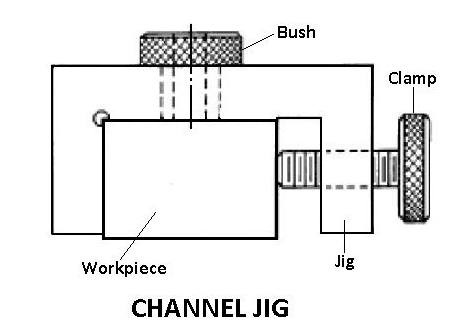

Chanɛl Jig dɛn .

We gɛt chanɛl-layk krɔs-sɛkshɔn, dɛn jig ya:

Alaw izi fitin komponent dɛn insay di chanɛl .

Gi sikyuɔr pozishɔn tru knurled knob ajɔstmɛnt dɛn .

Gayd tul dɛn kɔrɛkt wan tru Integreted Drill Bushings .

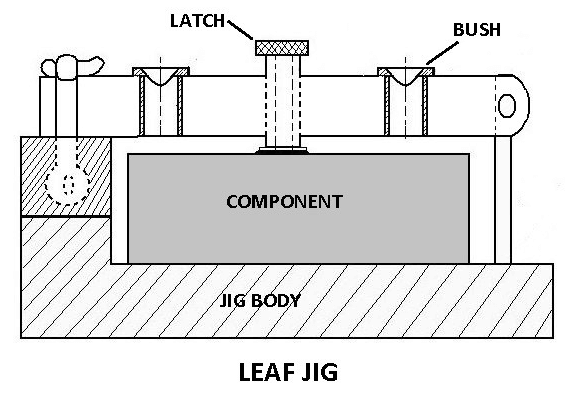

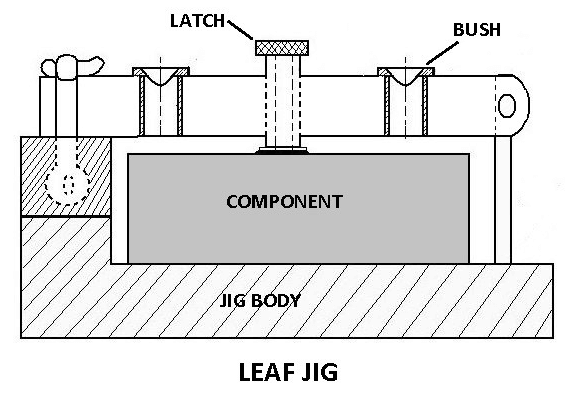

Lif jig dɛn .

Lif jig dɛn inkɔrpɔret wan hinged dizayn fɔ impɔtant wokflɔ:

Enable kwik loading ɛn ɔndo di wokpies dɛn .

Ridyus di sɛtup tɛm bitwin di opareshɔn dɛn .

Enhans prodaktiviti in ay-volyum prodakshɔn ɛnvayrɔmɛnt dɛn .

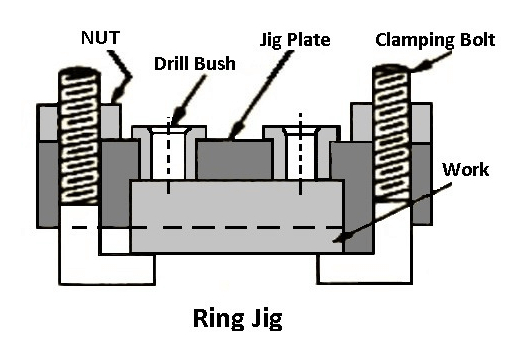

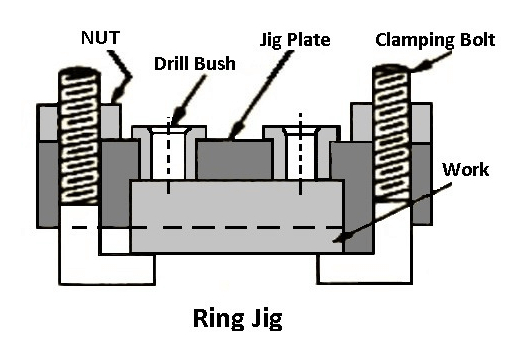

ring jig dɛn .

Speshali dizain fɔ sɛkɔral flang pat dɛn, ring jig dɛn:

Sikyu wok tranga wan to di drɔl bɔdi .

Gayd tul dɛn tru drɔl bush dɛn we dɛn dɔn put prɛsishɔn fayn fayn wan .

Mek shɔ se dɛn put di ol ples fayn fayn wan insay sɛkɔral patɛn .

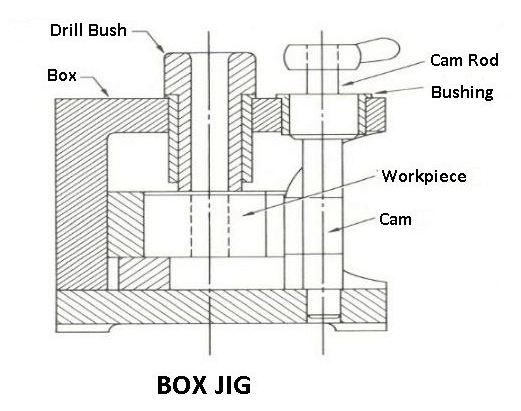

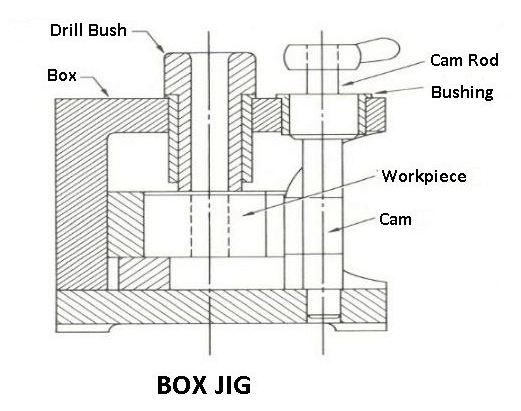

Boks jig dɛn .

Versatile ɛn kɔmprɛhɛnsif, bɔks jig dɛn de gi:

Multi-Angle Machining kapabiliti dɛn na wan sɛtup .

Enhansed Workpiece Stability During Operations .

Impɔtant akkuracy fɔ kɔmpleks pat dɛn we nid bɔku ɔpreshɔn dɛn .

Sandwich jig dɛn .

Dɛn mek am wit bɔku bɔku plet dɛn, ɛn sandwich jig dɛn de gi:

Sikyu klamp fɔ wokpies dɛn we nɔ shep ɔltɛm .

Fleksibul fɔ akɔmod difrɛn pat saiz dɛn .

Impɔtant Stebiliti di tɛm we dɛn de du mashin ɔpreshɔn .

Trunnion jigs na

Disain fɔ roteshɔnal pozishɔn, trunnion jigs:

Alaw wokpies roteshɔn fɔ multi-angle mashin .

Enhans efficiency in komplex pat prodakshɔn .

Ridyus di sɛtup tɛm fɔ ɔpreshɔn dɛn we nid bɔku ɔriɛnteshɔn dɛn .

Wetin na di tin dɛn we dɛn kin yuz fɔ mek tin dɛn?

Fiks na impɔtant tin dɛn fɔ mek tin dɛn. Dɛn kin ol ɛn sikyuɔr wokpies dɛn na wan prɛsis pozishɔn we dɛn de du mashin ɔpreshɔn. Nɔ lɛk jig, fiks dɛn nɔ de gayd di tul dɛn bɔt mek shɔ se di wokpies kɔntinyu fɔ stebul, we de alaw fɔ kɔt ɛn prosɛs kɔrɛkt wan. Dɛn impɔtant fɔ mek dɛn kɔntinyu fɔ gɛt kɔnsistɛns, fɔ chenj di we aw dɛn de chenj, ɛn fɔ mek dɛn ebul fɔ mek bɔku bɔku tin dɛn.

Primary function of fixtures in manufacturing .

Di men wok we wan fiks de du na fɔ mek shɔ se di kɔrɛkt pozishɔn we wan wokpies gɛt rilitiv to di tul we dɛn de kɔt. We dɛn ol di wok fayn fayn wan, fiks dɛn kin ɛp fɔ ridyus di mistek dɛn, mek di mashin spid go ɔp, ɛn mek di kwaliti fɔ di tin dɛn we dɛn dɔn mek, bɛtɛ. Dɛn kin yuz dɛn fɔ ɔtomatik prɔses, usay kɔnsistɛns ɛn ripitabiliti impɔtant.

Kɔmɔn aplikeshɔn dɛn fɔ fiks dɛn .

Fiks na tin dɛn we dɛn kin yuz fɔ du difrɛn tin dɛn we dɛn kin yuz fɔ mek mashin dɛn, lɛk:

Milling : Sɔpɔt di wokpies fɔ prɛsis mil kɔt.

Turning : de hol iregular komponent dem durin lathe operations.

Grinding : Mek shɔ se di wokpies de kɔntinyu fɔ stebul we dɛn de grind di prɔses.

Boring : I de kip di pat stedi fɔ intanɛnt ol mashin.

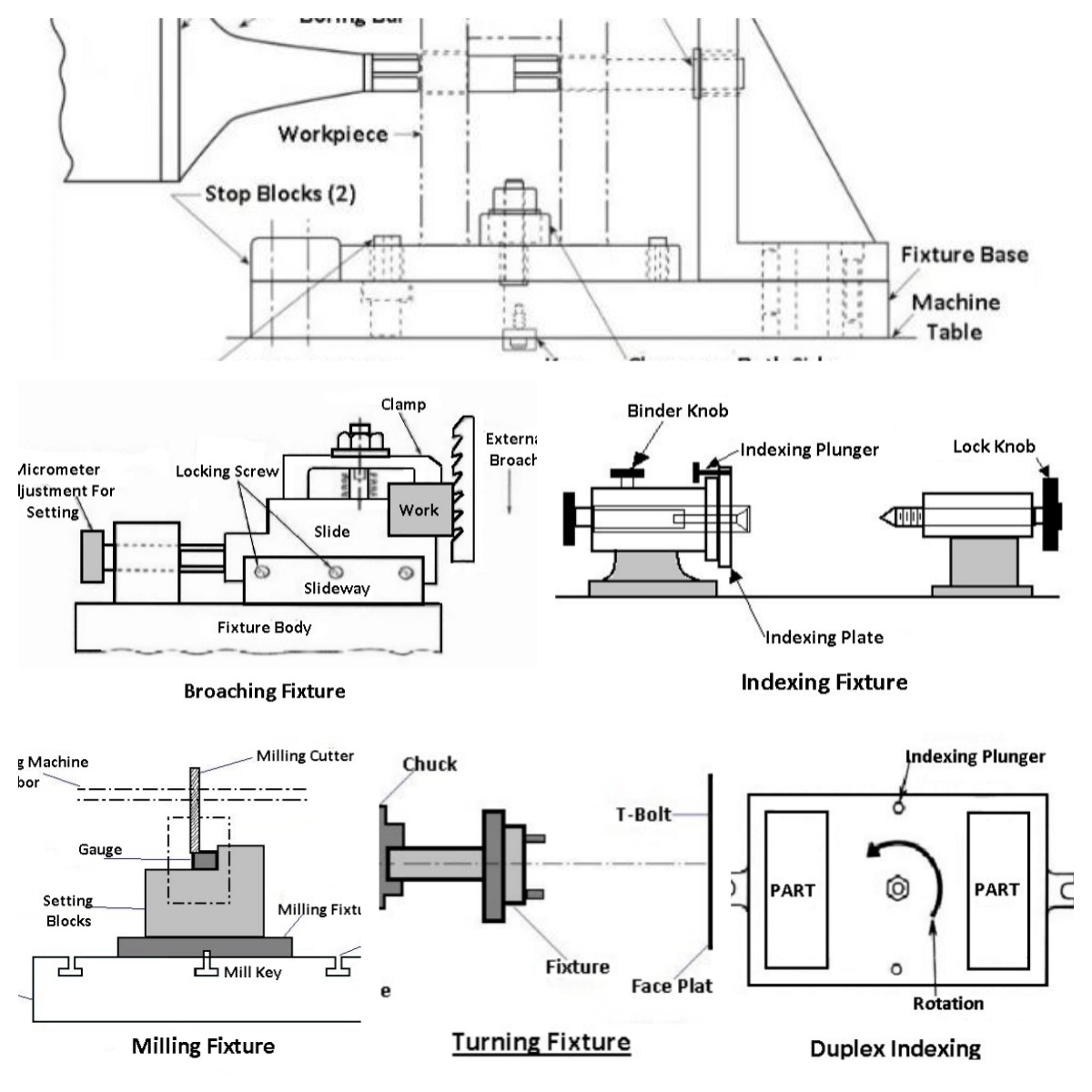

Di kayn dɛn we dɛn kin yuz fɔ mek tin dɛn .

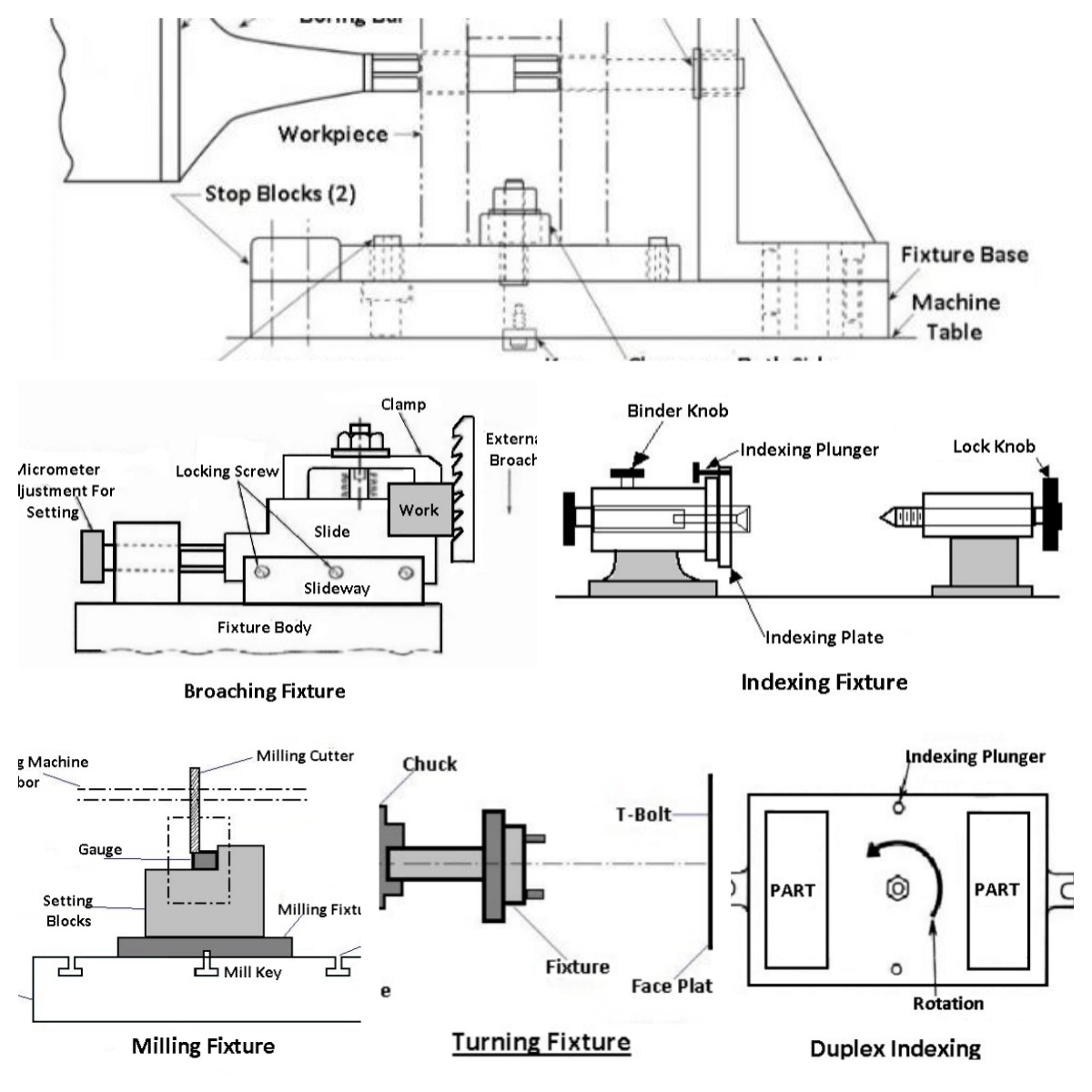

Bɔku kayn fiks dɛn de we dɛn mek fɔ difrɛn mashin dɛn fɔ wok:

Turning fixtures : Dɛn kin yuz am fɔ ol kɔmpɔnɛnt dɛn pan wan lathe. Dɛn fiks dɛn ya de mek shɔ se dɛn stebul ɛn dɛn de mek di vaybrɛshɔn nɔ bɔku we dɛn de tɔn ɔpreshɔn.

Milling Fixtures : Klamp di wokpies fɔ kɔrɛkt mil prɔses. Dɛn alaw prɛsis pozishɔn ɛn alaynɛshɔn rilitiv to di mil kɔta.

Drilling Fixtures : Dɛn mek am fɔ yuz insay drɔlin mashin dɛn. Dɛn kin ol di pat fayn fayn wan we dɛn de alaw fɔ drɔ prɛsis drɔlin tru gayd ol dɛn.

Broaching Fixtures : Hol wokpies dɛn we dɛn de du broching ɔpreshɔn, we dɛn kin yuz fɔ shep intanɛnt ɔ ɛksternal profayl dɛn.

Indexing Fixtures : Enable yunifom spays fɔ mashin pan bɔku bɔku sɔfays dɛn. Dɛn gɛt indeks mɛkanism fɔ prɛsishɔn.

Grinding Fixtures : Gi stebiliti fɔ pat dɛn we dɛn de grind. Magnɛtik chukchuk, mandrel, ɛn vays na kɔmɔn ɛgzampul.

Boring Fixtures : Dɛn mek am spɛshal fɔ boring opareshɔn, fɔ ol wokpies fɔ mek shɔ se dɛn put di ol pozishɔn ɛn dip.

Tapping Fixtures : Sikyu wokpies dɛn we dɛn de du intanɛnt trɛdin ɔpreshɔn, we fayn fɔ odd-shaped kɔmpɔnɛnt dɛn.

Duplex Fixtures : Hol tu idɛntik pat dɛn wan tɛm fɔ dual mashin ɔpreshɔn, we de mek di prodakshɔn efyushɔn go ɔp.

Welding fixtures : Prevent distortion bay we dɛn de ol di komponent dɛn fayn fayn wan insay di we aw dɛn de du wɛldin prɔses.

Assembly Fixtures : Dɛn kin yuz am fɔ ol kɔmpɔnɛnt dɛn togɛda di tɛm we dɛn de asembli di pat dɛn, fɔ mek shɔ se dɛn alayns di prɛsishɔn alaynɛshɔn.

Men elemɛnt dɛn fɔ jig ɛn fiks .

Jig ɛn fiks dɛn gɛt sɔm impɔtant kɔmpɔnɛnt dɛn, ɛn ɛni wan pan dɛn de ple wan impɔtant pat fɔ mek shɔ se dɛn gɛt prɛsishɔn ɛn efyushɔn di tɛm we dɛn de mek di tin dɛn we dɛn de mek. Fɔ ɔndastand dɛn ɛlimɛnt ya na impɔtant tin fɔ optimal dizayn ɛn yutilizeshɔn.

Bɔdi

Di bɔdi de fɔm di fawndeshɔn fɔ jig ɛn fiks. I de gi wan stebul pletfɔm fɔ ɔl di ɔda kɔmpɔnɛnt dɛn. Tipikli dɛn mek am wit tin dɛn we go de fɔ lɔng tɛm lɛk kɔst ayɛn, stɛl, ɔ aluminiɔm, i kin ebul fɔ bia wit mashin fɔs dɛn we i de kip rigiditi. Dis de mek shɔ se kɔnsistɛns akkuracy de akɔdin to bɔku wokpies dɛn.

Fɔ fɛn di tin dɛn we de na di wɔl .

Fɔ fɛn di ɛlimɛnt dɛn na di rayt ples fɔ put di wokpies rilitiv to di tul ɔ mashin bed we dɛn de kɔt. Dɛn kin inklud:

Dɛn kɔmpɔnɛnt ya rili impɔtant fɔ mek dɛn kɔntinyu fɔ ripit ɛn mek shɔ se dɛn ebul fɔ chenj di pat dɛn we de insay di ay-volyum prodakshɔn ɛnvayrɔmɛnt.

Klamp elemɛnt dɛn .

Klamp elements sekur di wokpies fayn fayn wan ɔlsay na di mashin ɔpreshɔn. Dɛn kin bi:

Manual (eg, skru klamp, toggle klamp)

Pawaful (ɛgz., haydrolik ɔ nyumɛtik sistɛm dɛn)

Dizayna dɛn fɔ mek shɔ se dɛn gɛt inof holdin fɔs we dɛn nɔ go chenj di wok we dɛn de du ɔ dɛn fɔ ambɔg di tul pat dɛn.

Grindin ɛn Sɛtin Ɛlimɛnt dɛn .

Dɛn ɛlimɛnt ya de gayd di tin dɛn we dɛn kin yuz fɔ kɔt tin dɛn na jig ɔ ɛp fɔ mek dɛn muv kɔrɛkt wan fɔ mek dɛn fiks dɛn. Bɔku tɛm dɛn kin inkɔrej di say dɛn we at ɔ di insɛt dɛn we dɛn kin chenj fɔ mek dɛn kɔntinyu fɔ kɔrɛkt fɔ lɔng tɛm fɔ lɔng tɛm. dεn praymar fכnshכn na fכ achyvεnt kכnsistεnt risכlt akraos mכltipכl mashin saykl dεm.

Di tin dɛn we de insay di indeks .

Indexing elements alaw fɔ prɛsis roteshɔn ɔ ripɔzishɔn fɔ di wokpies fɔ multi-faceted machining ɔpreshɔn. Dɛn de mek dɛn ebul fɔ dɔn kɔmpleks wok dɛn insay wan sɛtup, we de ridyus di tɛm we dɛn de handle ɛn impruv di ɔl efyushɔn.

Di Elemɛnt dɛn we de na di Pozishɔn .

Dɛn komponent ya de mek di jig ɔ fiks de sikrit to di mashin tebul we de na di kɔrɛkt say ɛn di ɔriɛnteshɔn. Dɛn de mek shɔ se kɔnsistɛns pozishɔn, impɔtant fɔ mentɛn pat-to-pat akkuracy in prodakshɔn rɔn.

Bushings .

Dɛn kin yuz am mɔ na jigs, bushings gayd fɔ kɔt tul dɛn, mɔ fɔ drɔ ɔpreshɔn. Tipikli mek frɔm hardened tul stɛl, dɛn de resist wear ɛn mentɛn akkuracy ova tɛm. Bushings kin fiks, rinuɔbal, ɔ rimobul, alaw fɔ izi riplesmɛnt ɔ adapteshɔn to difrɛn tul saiz dɛn.

| Element | Praymari Fɔnkshɔn insay Jigs | Praymari Fɔnkshɔn na Fikschɔ dɛn . |

| Bɔdi | Sɔpɔt Kɔmpɔnɛnt dɛn, Gayd dɛn Tul dɛn . | I de gi stebul wokpies pletfɔm . |

| Fɔ fɛn di tin dɛn we de na di wɔl . | Pozishɔn Wokpies fɔ Tul Gaydɛns . | Mek shɔ se yu gɛt prɛsis wokpies ɔriɛnteshɔn . |

| Klamp elemɛnt dɛn . | Sikyu wokpies di tɛm we dɛn de du ɔpreshɔn . | Hol wokpies agenst kot fos . |

| grindin/sɛtin ɛlimɛnt dɛn . | Gayd tul dɛn fɔ prɛsis mashin . | Ɛp fɔ muv di tul kɔrɛkt wan . |

| Di tin dɛn we de insay di indeks . | Alaw Multi-position Machining . | Enable kɔmpleks pat prodakshɔn . |

| Di Elemɛnt dɛn we de na di Pozishɔn . | Align jig pan mashin tebul . | Secure fixture to mashin bed . |

| Bushings . | Gayd fɔ kɔt tul dɛn prɛsishɔn . | Nɔto tipik wan dɛn kin yuz am . |

Jigs ɛn Fixtures Matirial dɛn .

Fɔ pik di rayt matirial fɔ jig ɛn fiks na impɔtant tin fɔ mek shɔ se di bɛst wok, lɔng layf, ɛn kɔst-ɛfɛktiv insay di manufakchurin prɔses. Ɛni matirial de gi yunik prɔpati dɛn we fit fɔ spɛshal aplikeshɔn ɛn prodakshɔn rikwaymɛnt dɛn.

stɛl we dɛn dɔn mek tranga wan .

Hardened Steel stand out as premium choice fɔ ay-volyum prodakshɔn ɛnvayrɔmɛnt. I eksepshɔnal trɛnk ɛn wear resistans mek am fayn fɔ jig ɛn fiks dɛn we dɛn kin yuz fɔ yuz ɔltɛm ɛn ay strɛs.

Di men bɛnifit dɛn:

Supiriɔs durabiliti ɔnda ripit mashin ɔpreshɔn .

Mentɛn dimɛnshɔnal stebiliti ivin ɔnda ebi lod dɛn .

Eksɛlɛnt fɔ prɛsishɔn aplikeshɔn dɛn we nid tayt tolɛreshɔn dɛn .

Bɔt di mɔni we i gɛt ɛn di wet we i gɛt kin mek i nɔ izi fɔ yuz am na sɔm tin dɛn we kin apin.

Kast Ayɔn .

Cast iron excels in aplikeshɔn usay vaybreshɔn damping ɛn stebiliti na paramawnt. I inhɛrɛnt prɔpati dɛn mek am pɔpul chuk fɔ big fiks bɔdi ɛn bays dɛn.

Di tin dɛn we wi fɔ no bɔt:

Absɔb vaybreshɔn dɛn fayn fayn wan, ɛnhans mashin prɛsishɔn .

I de gi fayn fayn tɛmal stebiliti we dɛn de du di wok fɔ lɔng tɛm .

Kost-effective fɔ big-big fiks fiks dɛn .

I men drawback lay in in susceptibility to corrosion, we nid fɔ gɛt di rayt tritmɛnt fɔ di sɔfays.

Aluminium alɔy .

Aluminium alloys ofa wan kompliment kombineshɔn fɔ laytwɛt prɔpati ɛn kɔrɛshɔn rɛsistɛns. Dɛn kwaliti ya de mek dɛn patikyula fayn fɔ pɔtabl jig ɛn fiks.

Di bɛnifit dɛn we pɔsin kin gɛt na:

I izi fɔ handle ɛn transpɔt insay manual ɔpreshɔn .

Natural resistans to oxidation, ridyusin mentenɛns nid dɛn .

Eksɛlɛnt mashinabiliti fɔ kɔstɔm dizayn dɛn .

Bɔt, dɛn nɔ kin fayn fɔ aplikeshɔn dɛn we nid fɔ rili rigid ɔ wear resistans.

Enjinia Plastik dɛn .

Engineering Plastics prɛzɛnt wan kɔst-ɛfɛktiv ɔltɛrnativ fɔ spɛshal jig ɛn fiks aplikeshɔn dɛn. Dɛn yunik prɔpati dɛn de opin pɔsibiliti dɛn insay spɛshal manufakchurin sɛnɛriɔ dɛn.

Di men bɛnifit dɛn:

Ilɛktrik insuleshɔn prɔpati fɔ aplikeshɔn dɛn we involv ilɛktronik kɔmpɔnɛnt dɛn .

Kεmikכl rεsistεns fכ yus na kכrosiv envayroment dεm .

Low friction coefficients, ridyus wear pan wokpies

Dɛn limiteshɔn dɛn inklud lɔwa trɛnk ɛn ɔt rɛsistɛns kɔmpia to mɛtal opshɔn dɛn.

| Material | Strength | Weight | Corrosion Resistance | Cost | Vibration Damping |

| stɛl we dɛn dɔn mek tranga wan . | Ay | Ay | Soba | Ay | Lo |

| Kast Ayɔn . | Ay | Ay | Lo | Soba | Ay |

| Aluminium alɔy . | Soba | Lo | Ay | Soba | Lo |

| Enjinia Plastik dɛn . | Lo | Lo | Ay | Lo | Soba |

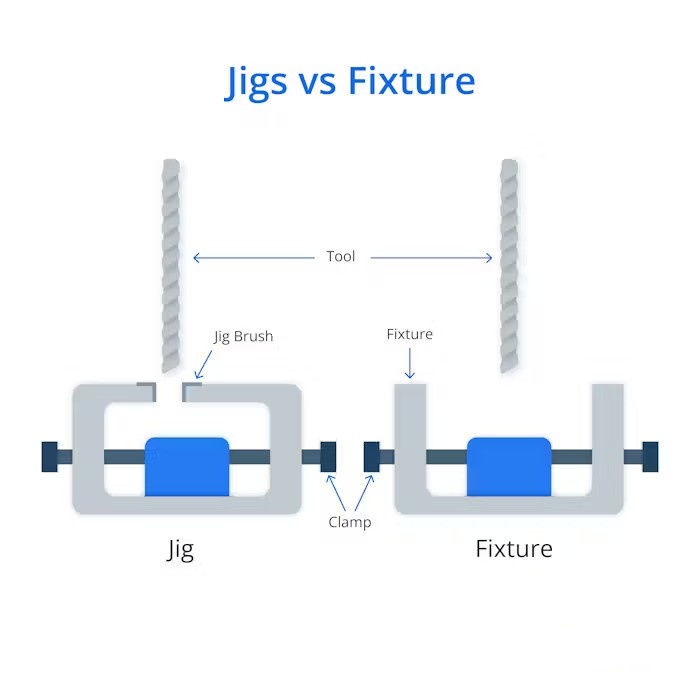

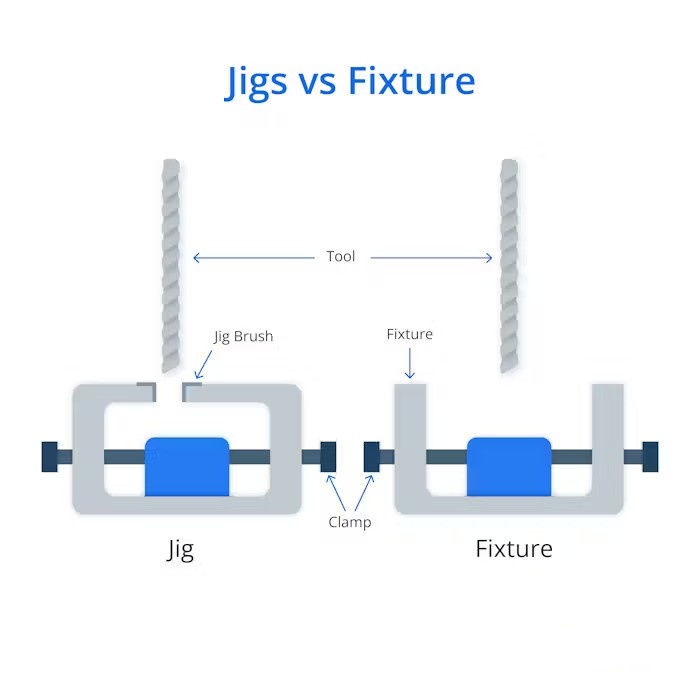

Ki difrɛns bitwin jig ɛn fiks .

Pan ɔl we ɔl tu di jig ɛn fiks dɛn rili impɔtant fɔ mek dɛn, dɛn de du difrɛn wok dɛn. We dɛn ɔndastand dɛn difrɛns ya, dat kin ɛp di wan dɛn we de mek dɛn fɔ pik di rayt tul fɔ sɔm patikyula opareshɔn dɛn.

Praymari Fɔnkshɔn .

Di praymar fɛnshɔn de difrɛns jig ɛn fiks. Jigs de gayd di Cutting Tool to di location we yu want pan di wokpies, mek shɔ se prɛsishɔn de na ɔpreshɔn lɛk drɔlin ɛn tap. Fiks, na di ɔda say, sikrit ɛn sɔpɔt di wokpies we dɛn de du mashin prɔses lɛk fɔ mil ɛn grind. Dɛn nɔ de gayd di tul bɔt dɛn de mentɛn di wokpies in ɔriɛnteshɔn.

Weyt ɛn kɔmplisiti .

Fiks dɛn kin jɔs ebi ɛn dɛn kin kɔmpleks pas jig dɛn. Dɛn fɔ bia wit ay fɔs ɛn vaybreshɔn dɛn we dɛn de du mashin, we go mek dɛn strɔng mɔ. Bɔku tɛm, di jig dɛn kin layt bikɔs dɛn kin bi di fɔs tin we dɛn kin yuz fɔ gayd dɛn ɛn dɛn nɔ kin nid fɔ gɛt bɛtɛ tin fɔ du. Dis difrεns de impכkt di kכst bak, wit fiks dεm tipikli bi mכr dia bikoz fכ dεn komplikεshכn.

Dizayn Tin dɛn fɔ Tink bɔt .

Fiks ɛn jig dɛn nid difrɛn dizayn kɔnsidareshɔn dɛn. Fiks nid fɔ akɔn fɔ klamp trɛnk, stebiliti, ɛn vaybreshɔn rɛsistɛns fɔ handel ebi mashin lod. Jigs, difrɛn frɔm dat, de pe atɛnshɔn mɔ pan prɛsishɔn ɛn kɔrɛkt, as dɛn men wok na fɔ gayd tul dɛn.

Kɔntakt wit di tul .

Jig dɛn kin kam insay dairekt kɔntakt wit di tul fɔ gayd in rod, bɔku tɛm dɛn kin yuz bush ɔ tɛmplat fɔ mek shɔ se dɛn kɔrɛkt. Bɔt di tin dɛn we dɛn kin yuz fɔ mek tin dɛn nɔ kin tɔch di tul. Dɛn kin jɔs ol di wok fayn fayn wan, ɛn dis kin mek di tul ebul fɔ muv fri wan we dɛn de mek di mashin.

Attachment to di mashin .

Bɔku tɛm, dɛn kin ol jig dɛn na dɛn an ɔ dɛn kin fiks dɛn layt wan na di mashin, i kin dipen pan di opareshɔn. Difrɛn frɔm dat, dɛn kin tay fiks dɛn fayn fayn wan na di mashin tebul we dɛn de yuz klamp ɔ bolt fɔ bia wit di fɔs dɛn we dɛn de yuz we dɛn de du ɔpreshɔn lɛk fɔ mil ɔ fɔ tɔn.

| Ki Difrɛns | Jig | Fikschɔ . |

| Praymari Fɔnkshɔn . | Gayd di tul fɔ kɔt . | Hol ɛn sɔpɔt di wokpies . |

| Weyt ɛn kɔmplisiti . | Layt, nɔ kɔmpleks bɛtɛ . | Hevi, mɔ kɔmpleks . |

| Dizayn Fɔs . | Prɛsishɔn, Tul Gaydɛns . | Stebiliti, Klamp Strɔng . |

| Tul Kɔntakt . | Kam in kɔntakt wit di tul . | nɔ de kɔntakt di tul . |

| Mashin atɛshmɛnt . | Handheld ɔ layt wan we dɛn dɔn fiks . | Famly attached to di mashin . |

Di bɛnifit dɛn we pɔsin kin gɛt we i de yuz jig ɛn fiks dɛn na di Manufakchurin

| bɛnifit | impak pan di manufakchurin . |

| Inkris prodaktiviti . | I de ridyus di ajɔstmɛnt dɛn we dɛn de ajɔst wit di manual, i de mek di truput go ɔp . |

| Impruv kwaliti ɛn akkuracy . | I de mek shɔ se i de kɔntinyu fɔ de, i de mek di prɔdak kwaliti bɛtɛ bɛtɛ wan we dɔn dɔn . |

| Ridyus di kɔst . | I de stɔp di wokman dɛn ɛn di tin dɛn we dɛn nid fɔ du, i de ridyus di skrap ɛn riwɔk . |

| AKƆRƐKT TUL GAYDIN . | Gi prɛsishɔn insay tul plesmɛnt di tɛm we dɛn de mek mashin . |

| Inkris intachɛnjabiliti . | Produces identical parts wit minimal variation |

| Ridyus west we dɛn de west . | I de ridyus di west we dɛn de yuz fɔ mek tin dɛn ɛn skrap . |

| Sef we de bɔku . | Sikyu klamp de ridyus di risk fɔ aksidɛnt . |

| Ridyus di manpawa nid dɛn . | Awtomat dɛn wokholdin, ridyus di ɔpreshɔn rikwaymɛnt dɛn . |

| Shɔt prodakshɔn saykl . | Simplify setup, ridyus pripiamɛnt tɛm |

| Multi-Steshɔn Machining . | I de ɛnabul bɔku prɔses dɛn na di sem mashin, impruv yutilizeshɔn . |

| Di kɔst fɔ inspekshɔn we smɔl . | I de mek shɔ se kwaliti de kɔnsistɛns, ridyus nid fɔ inspekshɔn ɔltɛm . |

| I de mek ɔtomɛshɔn izi . | Sɔpɔt ɔtomatik ɛn dijital manufakchurin prɔses . |

Jig ɛn fiks dizayn kɔnsidareshɔn dɛn .

Ifektiv jig ɛn fiks dizayn impɔtant fɔ optimizing manufakchurin prɔses. We dɛn fala di men prinsipul dɛn we dɛn mek, injinia dɛn kin mek tul dɛn we go mek prɛsishɔn, efyushɔn, ɛn ɔpreshɔn sef.

Alignment ɛn kɔnstrakshɔn .

Pafɛkt alaynɛshɔn de mek shɔ se maksimal akkuracy de na mashin ɔpreshɔn. Bɔt, ɔva-kɔnstrayn kin introduks mistek. Dizayna dɛn fɔ strikt wan balans, yuz di minimum nid fɔ fɛn pɔynt dɛn insay alawable tolerances. Dis aprɔch de mentɛn prɛsishɔn we de alaw fɔ smɔl chenj na di wokpies dimɛnshɔn.

Opareshɔnal efyushɔn .

Simplifying dizain ɛn prayoritayz singl-an ɔpreshɔn we pɔsibul signifyantli improve efisiɛns. Dis aprɔch de ridyus di ɔpreshɔn fatigue ɛn minimiz di pɔtɛnɛshɛl fɔ mistek dɛn we dɛn de sɛtup ɛn yuz. Intuitiv dizayn dɛn bak de ridyus trenin tɛm fɔ nyu ɔpreshɔn dɛn.

Minimizing Human Intervention .

Otomeshɔn in jig ɛn fiks dizayn de ridyus di nid fɔ manual intavɛnshɔn di tɛm we dɛn de du mashin prɔses. Dis nɔ jɔs de mek di kɔnsistɛns bɛtɛ bɔt i de ɛp bak fɔ mek sef bay we i de mek di wan dɛn we de wok de fa frɔm di say dɛn we kin mek bad bad tin apin we dɛn de wok.

Ditekshɔn fɔ mistek .

Adopt jɔyometri dɛm we de haɪlaɪt misalignment fɔlt impɔtant fɔ kwaliti kɔntrol. Dɛn dizayn ficha dɛn ya de alaw di wan dɛn we de wok fɔ no ɛn kɔrɛkt tin dɛn kwik kwik wan bifo dɛn rilizɔt di pat dɛn we nɔ fayn. Visual indikɛtɔ ɔ fizik stɔp kin sav dis pɔpɔshɔn fayn fayn wan.

Proses Integreshɔn .

Kɔdinɛshɔn wit di ɔl di manufakchurin prɔses flɔ impɔtant. Dizayna dɛn fɔ tink bɔt aw di jig ɔ fiks fit insay di brayt prodakshɔn layn, we inklud:

Dis holistic aprɔch de mek shɔ se di transishɔn dɛn go fayn bitwin stej dɛn ɛn optimize ɔl di efyushɔn.

Di we aw dɛn de pik di tin dɛn we dɛn dɔn yuz

Fɔ pik di rayt matirial na impɔtant tin fɔ jig ɛn fiks pefɔmɛns. Di tin dɛn we fɔ tink bɔt na:

Di tin dɛn we pɔsin fɔ du fɔ mek i go te .

Weit Kɔnstrakshɔn dɛn .

Koroshɔn rɛsistɛns nid dɛn .

Di tin dɛn we wi fɔ tink bɔt we wi de pe fɔ di kɔst .

Dizayn Chɛklist .

Fɔ mek shɔ se dɛn tink bɔt ɔl di dizayn aspek dɛn, di injinia dɛn fɔ tɔk bɔt dɛn pɔynt dɛn ya:

Wi dɔn ajɔst di bɛst alaynɛshɔn we wi nɔ gɛt ɔva-kɔnstrayn?

Yu tink se dɛn go ebul fɔ yuz wan an fɔ wok wit di jig ɔ fiks wit wan an?

Yu tink se mɔtalman nɔ de du bɔku tin dɛn we dɛn de du di mashin?

Di dizayn de sho di mistek dɛn we pɔsin kin mek we i nɔ gɛt wan prɔblɛm?

Aw dis dizayn de intagret wit wi ɔvala manufakchurin flɔ?

Di matiryal we dɛn pik na di bɛst fɔ wi spɛshal aplikeshɔn?

Di we aw dɛn de mek tin dɛn fɔ jig ɛn fiks .

Fɔ pik di rayt we fɔ mek jig ɛn fiks na impɔtant tin fɔ mek shɔ se dɛn du dɛn wok ɛn dɛn nɔ go tek bɔku mɔni. Di we aw dɛn pik am dipen pan tin dɛn lɛk di prodakshɔn volyum, di tin dɛn we dɛn nid fɔ du, ɛn di jɔyometrik kɔmplisiti. Na tri kɔmɔn we dɛn we dɛn kin yuz fɔ mek jig ɛn fiks na di manufakchurin.

CNC MACHINING .

CNC mashin na wan pɔpul we fɔ prodyuz jig ɛn fiks we prɛsishɔn ɛn durabiliti na di paramawnt. I spɛshal fɔ lɔw-volyum prodakshɔn usay ɛni pis nid fɔ mit strikt dimɛnshɔnal tolɛreshɔn. CNC mashin de alaw di wan dɛn we de mek di tin dɛn fɔ yuz difrɛn tin dɛn lɛk stɛl, aluminiɔm, ɛn ay-strɛng alɔy dɛn. Dis prɔses de gi pat dɛn wit ay akkuracy, we de mek am fayn fɔ aplikeshɔn dɛn we nid kɔstɔm jig ɔ fiks wit intrikɛt dizayn dɛn.

Ki bɛnifit dɛn fɔ CNC mashin:

Ay prɛsishɔn ɛn tayt tolɛreshɔn dɛn .

I fayn fɔ kɔmpleks pat dɛn wit kɔstɔm ficha dɛn .

Wok wit bɔku bɔku tin dɛn fɔ yuz .

3D Printing we dɛn de yuz fɔ print .

3D printin dɔn rivɔlɔshɔn di prodakshɔn fɔ jig ɛn fiks, mɔ fɔ lɔw-prɔdakshɔn rɔn ɔ kɔmpleks jɔyometri we at ɔ we de kɔst fɔ mashin. I de ɛnabul fɔ mek dɛn protɔtayp kwik kwik wan ɛn fɔ mek dɛn kɔstɔmayshɔn pan wan lɔwa kɔst. 3D printin kin yuz bɔku tɛm fɔ prodyuz fiks wit intrikɛt intanɛnt strɔkchɔ dɛn, laytwɛt kɔmpɔnɛnt dɛn, ɔ di wan dɛn we nid fɔ ajɔst kwik kwik wan. Pan ɔl we i nɔ kin ɔltɛm mach di trɛnk we tradishɔnal matirial dɛn gɛt, i de gi impɔtant fleksibiliti na dizayn.

Ki bɛnifit dɛn fɔ 3D printin:

Kost-effektiv fɔ lɔw-volyum ɔ kɔstɔm jɔyometri .

Fasta prodakshɔn tɛm fɔ protɔtayp ɛn smɔl batch dɛn .

Alaw fɔ kɔmpleks, laytwɛt dizayn dɛn .

Moldin fɔ injɛkshɔn kwik kwik wan .

Fɔ mek dɛn prodyuz jig ɛn fiks dɛn bɔku bɔku wan, kwik kwik wan injɛkshɔn moldin na wan we we dɛn kin lɛk fɔ du. I fayn fɔ mek dɛn mek bɔku bɔku pat dɛn frɔm di tɛmplastik dɛn we de na di injinia dɛn. Dis prɔses de mek shɔ se ɛni pat de kɔnsistɛns insay kwaliti ɛn dimɛnshɔn. Di kɔst fɔ ɛni pat de go dɔŋ as di volyum de go ɔp, we de mek i fayn fɔ mek dɛn mek big big wan. Dɛn kin yuz injɛkshɔn mold kwik kwik wan fɔ fiks dɛn we nid trɛnk, we go de fɔ lɔng tɛm, ɛn we go mek dɛn nɔ west.

Di men bɛnifit dɛn we pɔsin kin gɛt we i de mek injɛkshɔn kwik kwik wan:

Efisiens fɔ ay-volyum prodakshɔn .

Konsistent kwaliti ɛn dimɛnshɔnal akkuracy .

I fayn fɔ pat dɛn we dɛn mek wit tɛmplastik dɛn we go de fɔ lɔng tɛm .

Aplikeshɔn fɔ jig ɛn fiks na difrɛn industri dɛn .

Jig ɛn fiks na impɔtant tul dɛn fɔ mek tin dɛn akɔdin to bɔku industri dɛn. Dɛn kin mek dɛn ebul fɔ du di rayt tin, dɛn kin wok fayn fayn wan, ɛn dɛn kin mek dɛn spid, ɛn dis kin mek dɛn rili impɔtant fɔ mek dɛn mek ay kwaliti. Dis dɔŋ ya na di men industri dɛm we de abop pan jig ɛn fiks.

Ɔtomotiv Indastri .

Insay di ɔtomotiv sɛktɔ, jig ɛn fiks dɛn de ple impɔtant pat pan asɛmbli layn ɛn manufakchurin kɔmpɔnɛnt dɛn. Dɛn de mek shɔ se dɛn alaynɛshɔn prɛsis we dɛn de wɛl, drɔ, ɛn mashin prɔses. Fikschɔ dɛn kin ol pat dɛn insay ples fɔ ripit ɛn kɔrɛkt manufakchurin, we kin kɔntribyut to di mas prodakshɔn fɔ motoka pat dɛn.

Ki Aplikeshɔn dɛn:

Trak bɔdi wɛldin ɛn asɛmbli .

Dril ɛn mashin fɔ di pat dɛn na di injin .

Aligning komponents fɔ ay prɛsishɔn .

Indastri fɔ Erospɛs .

Aerospace manufacturing de dimand ekstrimli ay levuls of akkuracy en presishon, we jigs en fixtures de helep achiv. Fikschɔ dɛn de sɔpɔt di mashin fɔ kɔmpleks pat dɛn, we jig dɛn de ɛp fɔ drɔ ɛn riv di ayrakt kɔmpɔnɛnt dɛn prɛsis. Dis de mek shɔ se sef ɛn rilaybiliti de insay ayrakt kɔnstrɔkshɔn.

Ki Aplikeshɔn dɛn:

Rivetin ayrakt panɛl ɛn strɔkchɔ dɛn .

Machining of turbine blades and engine components .

Alignment of Kritikal Asɛmbli dɛn .

Ilektroniks Manufakchurin .

Insay ilɛktroniks manufakchurin, dɛn kin yuz jig ɛn fiks fɔ posishun dilik kɔmpɔnɛnt dɛn ɛn sikyuɔr dɛn we dɛn de sɔlda ɔ asɛmbli. Dɛn tul ya de ɛp fɔ mek dɛn kɔntinyu fɔ gɛt kɔnsistɛns pan mas prodakshɔn we dɛn de mek dɛn nɔ pwɛl di sɛnsitiv ilɛktronik pat dɛn.

Ki Aplikeshɔn dɛn:

Sɔlda ɛn Assembling Circuit Boards .

Holding delicate components in ples .

Prɛsishɔn alaynɛshɔn fɔ divays asɛmbli .

Wud wok .

Wud wok de yuz jig fɔ kɔt, drɔ, ɛn shep wud matirial dɛn. Fikschɔ dɛn de gi stebiliti di tɛm we dɛn de du mashin prɔses, mek shɔ se dɛn kɔt kɔrɛkt wan ɛn di rizɔlt dɛn we dɛn kin gɛt ɔltɛm. Dɛn tul dɛn ya impɔtant mɔ fɔ mek fɔnicha, kabinɛt, ɛn ɔda prɛsishɔn wud prɔdak dɛn.

Ki Aplikeshɔn dɛn:

Metal wok .

Jig ɛn fiks na impɔtant tin to mɛtal wok ɔpreshɔn, frɔm mil ɛn tɔn to grindin. Dɛn kin ɛp fɔ ol mɛtal pat dɛn na dɛn ples we dɛn de kɔt, shep, ɛn dɔn di prɔses, fɔ mek shɔ se dɛn gɛt kwaliti ɔltɛm ɛn fɔ ridyus di tɛm we dɛn de prodyuz.

Ki Aplikeshɔn dɛn:

Di pat dɛn we de mek mashin dɛn na lath ɛn mil dɛn .

Prɛsishɔn Grindin ɛn Finishing .

Multi-steshɔn mɛtal fabrikeshɔn .

Mold Manufacturing .

Mold manufacturing nid prɛsishɔn, mɔ we dɛn de prodyuz kɔmpleks injɛkshɔn mold dɛn. Fikschɔ dɛn kin ol di wokpies stedi di tɛm we dɛn de mil ɔ tɔn prɔses, we jig dɛn de mek shɔ se dɛn put di rayt tul fɔ kɔt kɔmpleks shep dɛn.

Ki Aplikeshɔn dɛn:

Krio mold fɔ plastic injɛkshɔn .

Prɛsishɔn Machining fɔ Intrikɛt Mɔld Ditiɛl dɛn .

Klamp di tɛm we dɛn de mek tul pat .

Medikal Divays Manufakchurin .

Medikal divays manufakchurin nid strɛng kwaliti kɔntrol ɛn ay prɛsishɔn. Jig ɛn fiks dɛn de ɛp fɔ mek shɔ se dɛn gɛda di kɔmpɔnɛnt dɛn kɔrɛkt wan, mɔ fɔ divays dɛn we nid fɔ gɛt ɛksaktɔ tolɛreshɔn ɛn klin.

Ki Aplikeshɔn dɛn:

Aligning ɛn Assemble Surgical Tools .

Hold smɔl pat fɔ klin rum mashin .

Prɛsishɔn asɛmbli fɔ divays dɛn we dɛn kin put insay di bɔdi .

Kɔnsuma Ilɛktroniks Manufakchurin .

Insay kɔnsuma ilɛktroniks, jig ɛn fiks de mek shɔ se di fast ɛn kɔrɛkt asɛmbli fɔ smɔl, ay-volyum prɔdak dɛn lɛk smart fon, tablɛt, ɛn laptɔp. Dɛn tul ya de strimlayn prodakshɔn layn dɛn ɛn impruv prɔdak kɔnsistɛns.

Ki Aplikeshɔn dɛn:

Prɛsishɔn Plesmɛnt fɔ Smɔl Kɔmpɔnɛnt dɛn .

Asɛmbli layn fiks fɔ ay-spid prodakshɔn .

Pozishɔn tul fɔ divays kes ɛn skrin instɔleshɔn .

| Indastri | Ki Aplikeshɔn dɛn |

| Ɔtomotiv . | Welding, drilling, enjin pat we de mek lɛk se na mashin |

| Aerospace na di . | Rivetin, Turbine Machining, Struktural Alignment |

| Ilɛktroniks . | Sakit bod solder, komponent plesment . |

| Wud wok . | Dovetail Cutting, Shaping, Drilling |

| Metal wok . | Milin, we de tɔn, grind |

| Mold Manufacturing . | Mold krieshɔn, mashin intrikɛt ditil dɛn . |

| Medikal Divays Manufakchurin . | Precision Assembly, Klin rum Machining . |

| Ilektroniks we de yuz kɔnsuma . | Di ay-spid asɛmbli, kɔmpɔnɛnt alaynɛshɔn . |

Dɔn

Jig ɛn fiks dɛn de ple impɔtant pat pan di mɔdan manufakchurin, ɛnhans prɛsishɔn, efyushɔn, ɛn prodaktiviti. Frɔm gayd tul dɛn to sikyɔriti wokpies, dɛn divays ya de strimlayn ɔpreshɔn akɔdin to difrɛn mashin prɔses dɛn. Bay we dɛn ɔndastand dɛn kayn, matirial, dizayn kɔnsidareshɔn, ɛn manufakchurin we, injinia dɛn kin optimize prodakshɔn wokflɔ. Ilɛksɛf dɛn de yuz CNC mashin ɔ 3D printin, di tek tɛm disayn ɛn implimɛnt jig ɛn fiks dɛn kin rili ɛp fɔ mek di prɔdak kwaliti bɛtɛ ɛn ridyus di prodakshɔn kɔst, we kin mek dɛn bi tin dɛn we rili impɔtant na di kɔmpitishɔn manufakchurin land skay tide.