In today’s competitive market, the durability and longevity of a product play a critical role in consumer satisfaction and brand reputation. Customers increasingly expect products that not only perform well but also stand the test of time under regular use. In this context, the choice of material is paramount. ABS plastic, known for its toughness and versatility, has emerged as a preferred material for manufacturers aiming to improve product lifespan while balancing cost and performance.

ABS plastic’s unique combination of mechanical strength, impact resistance, and environmental resilience makes it an ideal candidate for molded components that require long-lasting durability.

One of the foremost reasons ABS plastic is favored for durable molded components is its impressive mechanical strength and impact resistance. ABS is a tough thermoplastic polymer that absorbs and distributes shock effectively without cracking or breaking. This property is particularly important for products subjected to frequent handling, accidental drops, or mechanical stresses.

When molded correctly, ABS components maintain structural integrity even under repeated impacts and flexing. This makes it suitable for applications such as tool housings, protective gear, and automotive interior parts, where resilience to physical force is essential. The polymer’s toughness reduces the likelihood of fractures and failures that would otherwise shorten the product’s usable life.

In addition to raw impact resistance, ABS’s ability to maintain shape and strength under stress contributes to product reliability. Components molded from ABS resist deformation and warping, which ensures that mechanical assemblies continue to fit and function properly over time. This structural stability is vital for products requiring precision and consistent performance.

Durability isn’t just about withstanding shocks; it also involves resisting the gradual wear and tear products experience through daily use. ABS plastic exhibits excellent resistance to chemical exposure and abrasion, two major factors that degrade materials over time.

In many consumer and industrial environments, molded components come into contact with cleaning agents, oils, or other chemicals that could degrade inferior plastics. ABS’s chemical resistance helps prevent surface degradation, discoloration, and loss of mechanical properties. This ensures that products maintain their appearance and functionality over extended periods.

Furthermore, ABS demonstrates robust resistance to temperature variations and moisture. Products exposed to varying climates or indoor/outdoor conditions benefit from ABS’s ability to retain performance despite humidity changes or temperature cycling. Unlike some plastics that become brittle in cold or soften in heat, ABS remains stable within a broad temperature range, reducing the risk of cracks or distortion.

Abrasion resistance also plays a role in preserving product lifespan, especially for components subject to friction or contact with rough surfaces. ABS withstands scratching and surface wear better than many competing materials, preserving both the component’s look and strength. This makes ABS a smart choice for parts such as electronic device housings, automotive trims, and industrial casings.

ABS plastic’s durability has been proven across numerous industries and applications. Tool housings for power drills and garden equipment are often made from ABS, as the material absorbs shocks from drops and rough handling while protecting internal components.

In electronics, ABS is a common choice for shells and enclosures that safeguard delicate circuit boards and displays. These components require toughness to endure daily transport, use, and occasional impacts. ABS’s resistance to chemical and temperature stress also ensures the electronics stay protected from environmental damage.

Automotive interior parts such as dashboard panels, trim pieces, and console housings benefit from ABS’s strength and aesthetic qualities. These components must endure temperature fluctuations, UV exposure, and frequent contact without cracking or fading.

In industrial settings, ABS is used for protective gear and machine components that demand long service lives under harsh conditions. Its combination of mechanical strength and environmental resilience helps maintain product integrity, reducing maintenance and replacement costs.

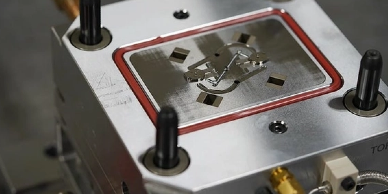

Injection molding stands out as the preferred manufacturing method for producing durable ABS plastic components, especially when high performance and longevity are essential. This process provides manufacturers with exceptional control over part design and production parameters, allowing them to optimize the strength and durability of ABS molded parts while minimizing waste and cost.

One of the key advantages of injection molding ABS plastic is the ability to integrate specific design features that enhance mechanical performance and resist wear. For instance, ribs—thin, raised sections incorporated into the part—serve to increase stiffness without adding significant weight. By strategically placing ribs in areas prone to bending or flexing, manufacturers can significantly improve the structural integrity of ABS components, helping them withstand repeated use and external forces without cracking or warping.

Similarly, bosses—small cylindrical protrusions used as mounting points or for screw inserts—can be molded directly into ABS parts. These features provide robust connection points, ensuring secure assembly while preventing stress concentrations that might otherwise cause damage during operation. Gussets, triangular reinforcements at junctions, also help distribute loads evenly, further strengthening vulnerable sections of the molded component. The careful integration of ribs, bosses, and gussets during the injection molding process ensures that ABS plastic parts maintain their shape and functionality under demanding conditions, greatly extending their service life.

Beyond structural reinforcements, injection molding with ABS enables the creation of hybrid or multi-material parts through overmolding techniques. Overmolding involves molding a secondary material over or around a primary ABS substrate to enhance product functionality. For example, combining ABS with softer thermoplastics or elastomers can add ergonomic features such as improved grip surfaces, shock absorption, or sealing properties. This hybrid design approach allows manufacturers to leverage the toughness and rigidity of ABS while incorporating the flexibility and cushioning benefits of complementary materials, creating parts that are both durable and user-friendly.

Moreover, injection molding offers precise control over wall thickness, which is critical in achieving durable ABS components. Optimized wall thickness ensures that parts cool evenly, preventing internal stresses that can lead to warping, shrinkage, or cracking. Uniform cooling also reduces cycle times and improves dimensional accuracy, resulting in consistent, high-quality parts across large production runs. By tailoring wall thickness and cooling parameters specifically for ABS plastic, manufacturers can produce components with excellent mechanical properties and superior surface finishes that resist degradation over time.

Another durability advantage provided by injection molding is the ability to incorporate molded-in colors and surface textures directly into ABS parts. Molded-in color eliminates the need for additional painting or coating steps, which can wear off or chip with use. The color becomes an integral part of the ABS component, maintaining aesthetic appeal throughout the product’s lifespan. Similarly, textured surfaces can be molded to improve grip, reduce glare, or hide scratches, enhancing both the functional and visual durability of ABS products.

ABS plastic stands out as a highly durable, cost-effective material that supports extended product lifespan across a wide range of applications. Its excellent mechanical strength, impact resistance, chemical and abrasion resistance, combined with its suitability for precision injection molding, make it a top choice for manufacturers aiming to deliver reliable, long-lasting products.

By choosing ABS plastic and leveraging advanced injection molding design strategies, companies can enhance product durability, reduce maintenance costs, and improve customer satisfaction. For manufacturers seeking expert solutions in durable ABS plastic molded components, partnering with a professional injection molding company ensures access to high-quality production capabilities tailored to specific needs.

Team Rapid MFG Co., Ltd. specializes in plastic injection molding services, providing custom ABS solutions designed for durability and performance. To explore how ABS molded components can improve your product lifespan, visit www.team-mfg.com or contact their team for professional guidance and manufacturing expertise.

TEAM MFG is a rapid manufacturing company who specializes in ODM and OEM starts in 2017.