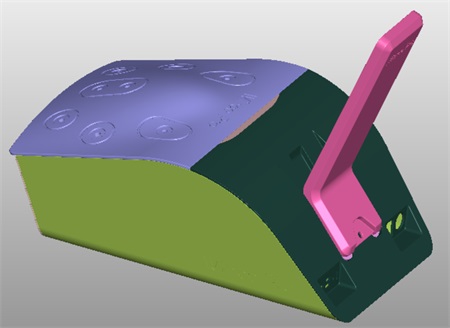

Project: Medical Device

Process Involved: CNC Machining, 3D Printing, Vacuum Casting, Painting, Silk Printing

Order Quantities: 20 Units

Lead-Time: 25 Calendar Days

A medical company in Spain develops a new device for better medical treatment. Before moving forward to mass production, they need 20 units rapid prototypes quickly to test the assembly and function. It is a medical device that includes 15 PCS total plastic/metal parts.

We had a long meeting witht the customer via video call. We clearly learn about all the requirements of the project, we know QTY/per part, material and expected finish etc. The customers tell us how these parts assembled/function, and what details need to be paid attention. In order to avoid mistake, we make a BOM, and to do list.

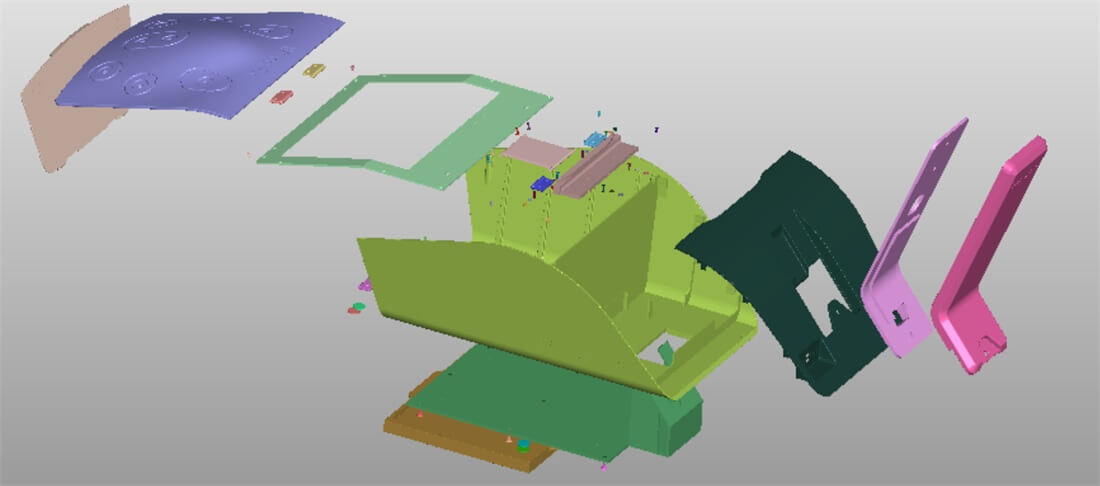

According to the device’s function and application, we suggested the manufacturing progress as follow:

- 4 parts made by CNC

- 11 parts made by 3D printing & vacuum casting

- 3 parts need silk printing.

- Assemble all these parts together.

As these processes are very suitable for this project, here are our summary of the processes:

| Feature | CNC Machining | 3D Printing | Vacuum Casting |

|---|---|---|---|

| Process | Subtractive (cutting) | Additive (layer by layer) | Replication with silicone molds |

| Materials | Metals, plastics | Plastics, resins, some metals | Polyurethane, rubber-like plastics |

| Precision | Very high (±0.01 mm) | Moderate to high (depends on tech) | Good (close to injection molding) |

| Surface Finish | Smooth, machining marks possible | Layered surface, needs post-work | Smooth, mold-dependent |

| Lead Time | Days–weeks | Hours–days | 1–2 weeks |

| Volume | Low to high | Single to low | Low (10–50 pcs) |

| Cost Efficiency | High for precision, medium runs | Low cost for prototypes | Very cost-effective for small batch |

| Best For | Strong functional parts, metals | Concept models, complex designs | Small-batch plastics, bridge tooling |

Settling down the progress, we started with the first unit parts built. We timely reported to the customer about the manufacturing process by email. Once all these first parts build, we started with assembly, we marked down all the potential issues during assembly and feedback solutions to our customer to improve design for following production.

Customer was happy with the first unit parts, TEAM MFG started with the following production. All these 20 units parts were build within 25 calendar days.

“TEAM MFG exceeded our expectations on our prototype development project. They were great at confirming quantities, materials, and key design checkpoints with us—especially the clip assemblies. Their workflow, splitting the job across CNC, 3D printing, vacuum casting, and silk printing, proved efficient and precise. The first unit provided valuable feedback that smoothed out downstream production, and all 20 units were delivered in just 25 calendar days. Highly professional and highly responsive.

”

--- Nir, Project Leader

TEAM MFG is a rapid manufacturing company who specializes in OEM from product development to mass production. The company was established in 2017, we offer a series of rapid manufacturing services such as rapid prototyping services, CNC machining services, injection molding services, and pressure die casting services to help with your low to high volume manufacturing needs.

TEAM MFG warmly invite you to visit our facilities and be our guests in Zhongshan, China. We are only 90 minutes from Hong Kong by ferry, and easily accessible from Shenzhen and Guangzhou by taxi. Send us an Email Now!

content is empty!

TEAM MFG is a rapid manufacturing company who specializes in ODM and OEM starts in 2017.