Aluminum extrusion turns a simple metal billet into almost any cross-sectional shape you can imagine. It's the reason your smartphone stays cool, your car stays light, and your office building stands tall. Yet most engineers underestimate how much design freedom this process actually offers.

This guide breaks down everything you need to know about extrusion aluminum—from the process itself to choosing the right profiles for your project.

What we'll cover:

● What is aluminum extrusion and how it works

● Common aluminum extrusion shapes and profiles

● Custom aluminum extrusions for specialized applications

● Heatsinks, frames, and enclosures

● How to cut, machine, and finish extruded parts

● Finding the right aluminum extrusion manufacturers

If you're sourcing custom aluminum extrusion parts,Team MFG offers end-to-end manufacturing support. From prototype to mass production, we handle CNC machining, finishing, and global delivery, all under one roof.

Aluminum extrusion is a manufacturing process that forces heated aluminum alloy through a steel die to create objects with a specific cross-sectional profile. Think of it like squeezing toothpaste from a tube. The aluminum comes out in the exact shape of the die opening and maintains that shape along its entire length.

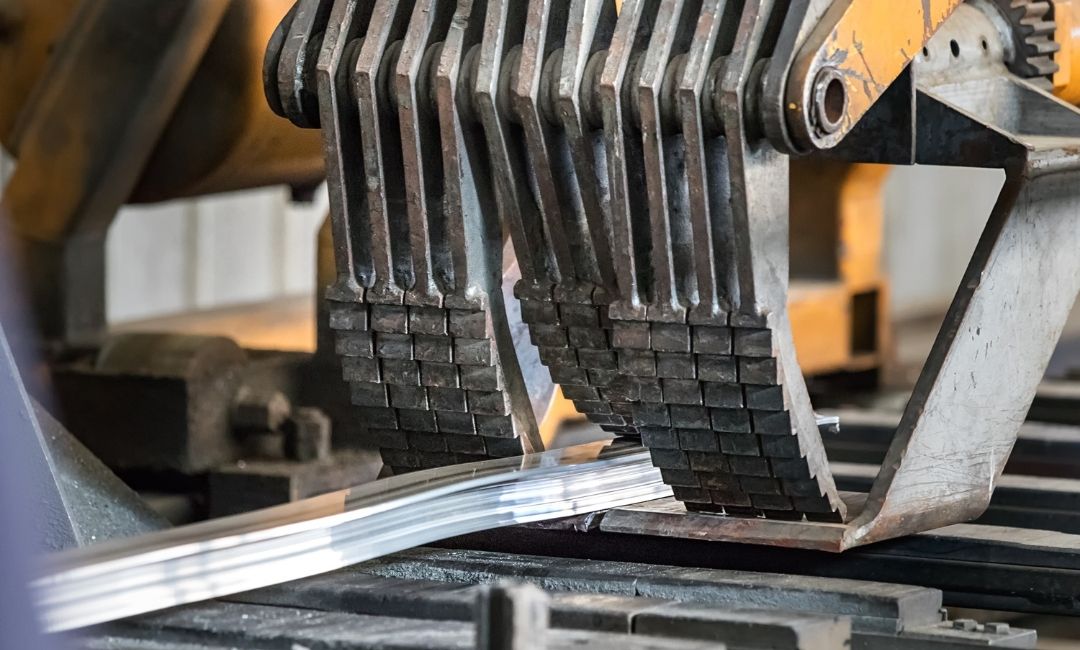

The process begins when a powerful hydraulic ram pushes the aluminum through the die, and it emerges from the die opening in the same shape as the die.Hydraulic presses can exert anywhere from 100 to 15,000 tons of pressure, which is enough force to crush about 50 pickup trucks.

What makes this process special? You can create almost any cross-sectional shape imaginable. Solid bars. Hollow tubes. Complex profiles with internal channels. If you can design it, extrusion can likely produce it.

The aluminum extrusion process follows a precise sequence of steps. Each one affects the quality, strength, and dimensional accuracy of your final part.

First, a round-shaped die is machined from H13 steel. Before extrusion, the die must be preheated to between 450-500 degrees Celsius to help maximize its life and ensure even metal flow.

An aluminum billet (the raw material) is heated to approximately 350°C to 500°C, achieving the malleability required for extrusion. The billet stays solid but becomes soft enough to flow through the die under pressure.

With the billet lubricated and loaded into the extrusion press, the hydraulic ram pushes the aluminum into the container. As pressure is applied, the billet material expands to fill the walls of the container and then squeezes through the die opening.

As it moves along the runout table, the profile is "quenched," or uniformly cooled by a water bath or by fans above the table. Cooling method depends on the alloy and profile complexity.

Each profile is mechanically gripped on both ends and pulled until the extrusion has straightened out fully and matches the intended specifications. This also work-hardens the metal for improved strength.

After stretching, the extrusions are transferred to the saw table and cut to pre-specified lengths, generally between 8 and 21 feet long. After sawing, they can be moved to an aging oven to be aged to the T5 or T6 temper.

The aluminum extrusion die is the heart of the process. It determines your profile's shape, tolerances, and surface quality.

An aluminum extrusion die is essentially a steel disk containing a carefully designed opening that determines the cross-sectional shape of the extruded profile. Dies are machined from H13 tool steel and heat-treated to withstand extreme pressure and temperature.

There are three main die types:

Die Type | Description | Best For |

Solid Die | No enclosed voids or openings | Rods, bars, angles, channels |

Hollow Die | One or more internal cavities | Tubes, window frames, structural members |

Semi-Hollow Die | Partially enclosed voids | C-channels, complex architectural profiles |

While the upfront investment in an aluminum extrusion die may look expensive, shorter lead times and overall lower production costs make it a clear winner for many product applications.

Pro Tip: A critically important characteristic of extrusion dies is that the effective bearing length controls the metal flow through the die. The longer the bearing length, the greater the resistance to the flow of aluminum. A good aluminum extrusion design accounts for this to ensure uniform metal flow across the entire profile.

Not all aluminum alloys extrude equally. The 6000 series dominates the extrusion industry because it offers the best balance of strength, corrosion resistance, and workability.

The two most popular choices are 6061 and 6063:

Property | 6061 Aluminum | 6063 Aluminum |

Nickname | Structural Aluminum | Architectural Aluminum |

Tensile Strength (T6) | 42,000 psi minimum | 28,000 psi minimum |

Hardness (Brinell) | ~95 HB | ~73 HB |

Surface Finish | Good | Excellent |

Corrosion Resistance | Good | Better |

Extrudability | Good | Excellent |

Alloy 6063 is the most popular aluminum alloy for extrusions. It offers slightly better corrosion resistance and a very appealing surface finish that is exceptional for anodizing.

Aluminum 6063 is somewhat more ideal for the extrusion process, but 6061 is typically stronger. So, if strength is the determining factor for an application, 6061 may be the optimal choice between the two.

When to choose 6061:

● Structural and load-bearing applications

● Aerospace components

● Bicycle frames and automotive parts

● Applications requiring maximum strength

When to choose 6063:

● Architectural trim and window frames

● Decorative applications requiring anodizing

● Complex profiles with fine details

● Applications prioritizing corrosion resistance

The aluminum extrusion process looks straightforward on paper. In practice, dozens of variables affect your final part quality: billet temperature, ram speed, die design, cooling rates, and post-processing steps.

An experienced aluminum extrusion supplier or aluminum extrusion factory understands how to optimize each variable for your specific alloy, profile, and application. They can also advise on design modifications that reduce tooling costs or improve extrudability.

TEAM MFG provides complete manufacturing support for custom aluminum extrusion projects. From rapid prototyping to mass production, our engineering team helps optimize your aluminum extrusion design for manufacturability, cost, and performance. We handle secondary operations like aluminum extrusion, CNC machining, surface finishing, and assembly under one roof.

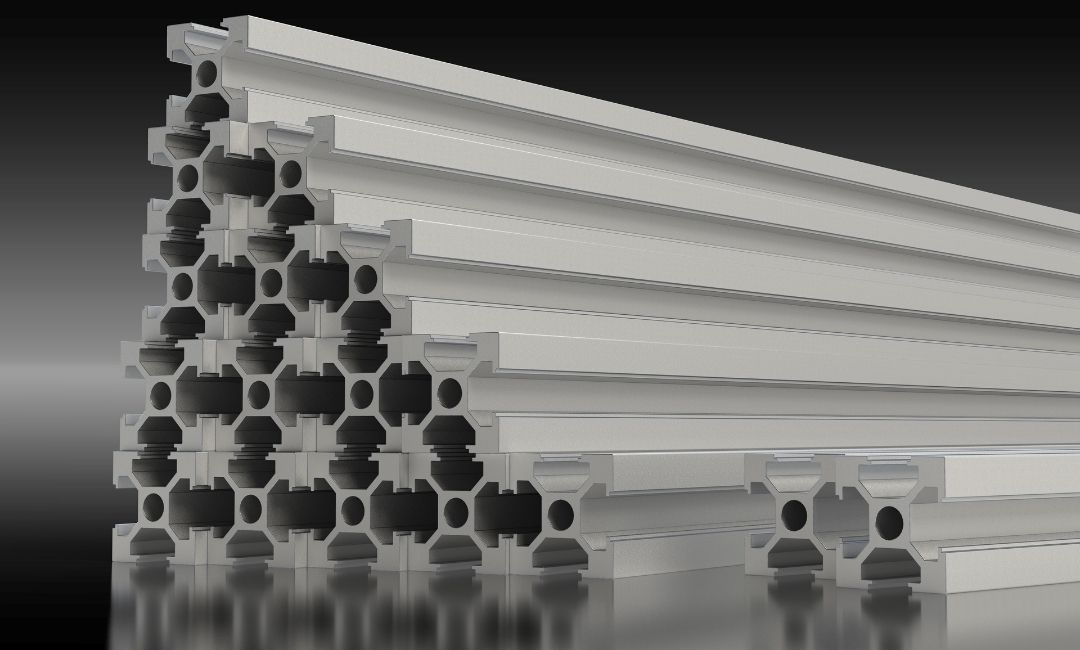

The beauty of aluminum extrusion lies in its versatility. You can create virtually any cross-sectional shape, from simple rods to complex multi-void profiles with intricate internal channels.

Standard aluminum extrusion profiles such as angles, square and round tubes, T-profiles, U-profiles, Z-shapes, and channels are readily available from reputable aluminum extrusion manufacturers. But these are just the starting point.

Solid Profiles

Solid profiles have no enclosed cavities and are ideal for applications requiring strength and simplicity. Examples include rods, bars, angles, and channels. They're the most economical to produce because they use simpler dies.

Hollow Profiles

Hollow profiles feature one or more enclosed voids. Square or rectangular tubes are commonly used in industrial automation and structural frameworks, offering lightweight strength with internal space for wiring or fluid channels.

Semi-Hollow Profiles

Semi-hollow profiles have partially enclosed voids and offer a balance between strength and lightweight design, making them suitable for applications in 3D printing, furniture design, and automated systems.

Beyond basic shapes, aluminum extrusion profiles fall into functional categories based on their intended use:

Profile Category | Characteristics | Common Applications |

Standard | Pre-set dimensions, universal compatibility | Modular workstations, conveyor systems, enclosures |

Structural | Load-bearing, high-strength (often 6061 alloy) | Industrial automation, machinery frames |

Decorative | Aesthetic finishes, smooth surfaces | Furniture, interior architecture |

Thermal Break | Insulating materials between sections | Climate-controlled enclosures, window systems |

I-shaped extrusions are standard aluminum extrusion profiles for use in ceiling and floor joists. They're available in a variety of shape and size configurations, including traditional I-beams and uneven or tapered iterations.

U-shaped channels provide a reliable option for a variety of applications, including protective covers, rims, railing, and brackets.

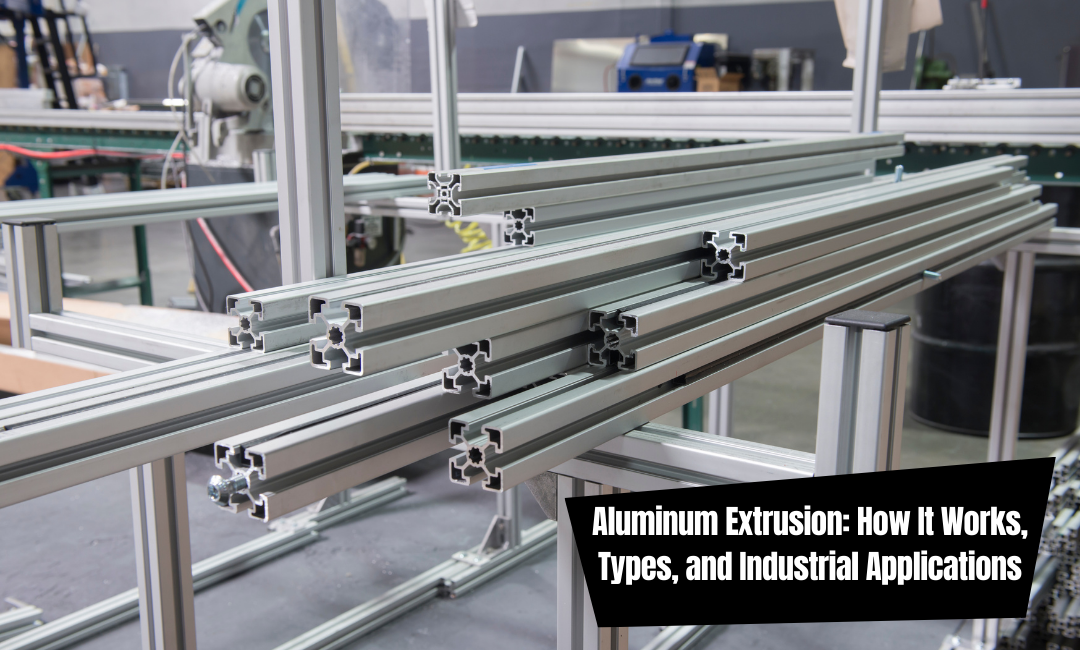

One of the most popular aluminum extrusion frame designs is the T-slot system. T-slot aluminum extrusion is a modular structural material with a precision-engineered profile shaped like a "T". These extrusions are known for their strength, lightweight properties, and flexibility, making them ideal for custom frames, enclosures, machine guards, workstations, and more.

What makes T-slot framing so popular?

● No welding required. The T-slot channel allows for fast and easy assembly using compatible connectors, eliminating the need for welding.

● Infinitely reconfigurable. Their groove-based modular design allows easy assembly, customization, and reconfiguration without welding or specialized tools.

● Plug-and-play components. Most aluminum T-slot extrusions and their counterparts or fittings are plug-and-play.

Modular aluminum framing systems can function in countless different ways in numerous industries. They can be assembled to construct carts, safety enclosures, worktables, test engineering frames, shelving, office furniture, and point-of-purchase display frames.

Pro Tip: T-slot connections rely on friction to hold systems together. For applications with vibration or dynamic loads, consider adding gussets or using mechanical locking connectors to prevent loosening over time.

When standard profiles don't cut it, custom aluminum extrusions step in. These are profiles designed from scratch to meet the exact requirements of your application.

Custom extrusions can be designed to meet specific requirements, allowing for unique shapes, sizes, and complex geometries that standard extrusions cannot provide.

The real power of custom profiles lies in integration. Custom profiles can incorporate specific features such as grooves, channels, screw ports, and more, reducing the need for additional machining or assembly.

Here's what custom aluminum extrusions offer:

● Design flexibility. Create any cross-sectional shape your application demands.

● Reduced assembly. Integrate multiple functions into a single profile.

● Material efficiency. By designing extrusions to precise specifications, material waste is minimized, leading to cost savings and more efficient use of resources.

● Weight optimization. Custom extrusions can be designed to achieve the required strength with minimal material, resulting in lighter components.

Aluminum heatsink extrusion is one of the most common custom applications. Extruded metal heat sinks are among the lowest cost, widest used heat spreaders in electronics thermal management. Besides their affordability, extruded heat sinks are lightweight, readily cut to size and shape, and capable of high levels of cooling.

Why aluminum for heatsinks?

Aluminum boasts superior thermal conductivity compared to other commonly used materials. This property enables efficient heat transfer from the heat-generating component to the heat sink, allowing for rapid dissipation.

Extruded heat sinks can be designed with very thin, and thus more, fins than other sink types. They can be extruded with aspect ratios of around 8:1, which can greatly optimize heat sink performance.

Common applications for aluminum heatsink extrusions include:

● Electronics: CPUs, GPUs, voltage regulators, power transistors

● LED lighting: Aluminum extrusion heat sinks provide an effective cooling solution for LED lighting fixtures, ensuring optimal thermal management.

● Automotive: Aluminum extrusion heat sinks are utilized in automotive applications such as engine control units (ECUs), power modules, and lighting systems.

● Industrial equipment: Power electronics, motor drives, control systems

An aluminum extrusion enclosure provides a protective housing for electronic components. Extruded aluminum enclosures provide exceptional protection for PCBs and other electronic components. Designed with internal slots, these aluminum extrusion cases allow standard 0.063" PCBs to slide securely into place without the need for screws.

Why choose extruded enclosures over other options?

● Built-in EMI shielding. Extruded aluminum alloy housings and other metal enclosures offer inherent EMI/RFI attenuation, making them an excellent choice for protecting sensitive electronics.

● Integrated heat dissipation. Their grooved exterior enhances heat dissipation.

● PCB mounting simplicity. Internal slots eliminate the need for standoffs or mounting hardware.

● Customizable lengths. Cut to any length from a single extrusion profile.

Stylishly designed aluminum enclosures with aluminum extrusion are suitable to be used for FA control boxes, network devices, measuring instruments, and audio amplifiers.

Finding the right custom aluminum extrusion manufacturers can make or break your project. Here's what to look for:

● Engineering support. Companies that specialize in the customization of aluminum extrusion profiles are at the forefront of technological innovation. They embrace cutting-edge technologies in extrusion and fabrication processes, enabling them to produce highly specialized and complex profiles with accuracy and efficiency.

● Die design expertise. The die determines everything. Experienced manufacturers optimize die design for metal flow, surface finish, and dimensional accuracy.

● Secondary operations. Most custom profiles need additional work: CNC machining, drilling, tapping, surface finishing, or assembly.

TEAM MFG works with custom aluminum extrusion projects from design through production. Our engineering team reviews your aluminum extrusion design for manufacturability, suggests optimizations, and handles all secondary operations, including aluminum extrusion CNC machining, anodizing, and assembly. Whether you need a specialized heatsink profile or a complex structural frame, we deliver complete parts ready for your production line.

These three applications represent the bread and butter of aluminum extrusion. Each takes advantage of aluminum's unique properties in different ways.

Most extruded heat sinks are made from aluminum alloys, mainly from the 6000 alloy series. These alloys are easy to extrude and machine, are weldable, and can be hardened. The extrusion process allows manufacturers to create complex fin geometries that maximize surface area for heat dissipation.

The aluminum extrusion process starts with heating a solid billet of aluminum alloy and forcing it through a precision-engineered steel die using a high-tonnage hydraulic press. This creates consistent fin spacing and density across the entire profile length.

T-slot aluminum extrusion frames dominate industrial applications. Modular aluminum framing systems can function in countless different ways. They can be assembled to construct carts, safety enclosures, worktables, test engineering frames, shelving, office furniture, and point-of-purchase display frames.

The modular design eliminates welding. You bolt components together and reconfigure as needed.

Extruded aluminum enclosures provide exceptional protection for PCBs and other electronic components. Internal slots allow circuit boards to slide directly into place without additional mounting hardware.

Extruded aluminum alloy housings offer inherent EMI/RFI attenuation, making them an excellent choice for protecting sensitive electronics.

Raw extrusions rarely ship directly to end-use. Most require secondary operations to become finished parts.

How to cut aluminum extrusion depends on your volume and precision requirements:

Method | Best For | Precision |

Miter saw (carbide blade) | Workshop/DIY cuts | Good |

Cold saw | Production runs | Very good |

CNC saw | High-volume, tight tolerances | Excellent |

Bandsaw | Thick profiles, angles | Good |

The professional method requires specialized tools such as a miter saw or circular saw with a non-ferrous metal cutting blade. The impact on the precision and quality of cuts is significant, with the professional method allowing for more accurate cuts with minimal chipping or damage to the aluminum.

Pro Tip: A little cutting oil on the blade can reduce heat and wear. It also helps give a cleaner edge.

Aluminum extrusion CNC machining adds features that extrusion alone cannot create: holes, threads, pockets, and complex geometries. CNC operations transform a basic profile into a production-ready component.

Two finishes dominate the industry:

● Anodizing creates a hard, corrosion-resistant oxide layer. The resulting surface is perfect for adding dyes, and the finishing service provider can recycle the chemicals in the electrolytic bath for future anodizing projects.

● Powder coating offers unlimited color options. Powder-coated surfaces are far more resistant to abrasions and impacts than wet-painted surfaces. There is no chance of blistering or running with powder coatings.

Choosing the wrong aluminum extrusion supplier costs more than money. It costs time, quality, and project momentum.

Selecting the ideal aluminum extrusion manufacturer requires evaluating technical expertise, communication responsiveness, design support capabilities, verified quality systems, and their commitment to being a reliable long-term partner beyond the initial quote.

Certifications matter. ISO 9001 certification means an aluminum extrusion manufacturer has established and follows effective processes. It signifies a structured approach to managing quality across the organization, from initial inquiry to final delivery.

Key questions to ask:

● What press sizes and tonnages do they operate?

● Can they handle your required alloy and temper?

● Do they offer secondary operations in-house?

● What are their standard lead times?

● Can they support prototype-to-production scaling?

Partnering with an aluminum extrusion manufacturer offering these services in-house reduces the number of suppliers you need to manage. It means better quality control and a smoother path from raw material to finished part.

Team MFG operates as your single-source aluminum extrusion factory for custom projects. We handle die design, extrusion sourcing, CNC machining, surface finishing, and assembly under one roof.

Our ISO 9001 certified facility delivers from 1 piece to 1,000,000+ parts with a 99.9% on-time delivery rate. Whether you need rapid prototypes or mass production, our engineering team optimizes your project for cost, quality, and speed.

Aluminum extrusion offers unmatched design flexibility, from simple angles to complex heatsink profiles. The right alloy, die design, and finishing process determine whether your parts perform as expected or fall short.

Key takeaways:

● Aluminum extrusion forces heated aluminum through a steel die to create consistent cross-sectional profiles

● 6063 aluminum excels at complex shapes and surface finishes; 6061 delivers superior strength for structural applications

● T-slot frames enable modular, weld-free assembly for workstations, enclosures, and machine guards

● Custom profiles integrate multiple functions into single parts, reducing assembly and material waste

● Anodizing provides hard, corrosion-resistant surfaces; powder coating offers unlimited color options

● Choose manufacturers with ISO 9001 certification, in-house secondary operations, and engineering support

Team MFG simplifies custom aluminum extrusion from concept to delivery. Our engineering team reviews your design for manufacturability, coordinates die production, and handles all secondary operations, including CNC machining and finishing.

With 12+ years of experience serving clients across 73 countries, we deliver prototype-to-production support with the quality control and on-time delivery your project demands.

The aluminum extrusion process follows six main steps: die preparation and preheating, billet heating to 350-500°C, extrusion through the die using hydraulic pressure, quenching (cooling) on the runout table, stretching to straighten the profile, and cutting to specified lengths, followed by aging.

Common examples include T-slot framing for workstations, window and door frames, heatsinks for electronics cooling, LED light housings, solar panel frames, curtain wall systems, and automotive trim pieces. Any aluminum product with a consistent cross-sectional shape likely started as an extrusion.

Aluminum extrusions appear across virtually every industry: construction (window frames, curtain walls), automotive (trim, structural components), electronics (heatsinks, enclosures), aerospace (aircraft structures), industrial automation (machine frames, guards), solar energy (panel mounting systems), and consumer goods (furniture, appliances).

The raw material is an aluminum billet, a solid cylindrical log cut from cast aluminum alloy. Most extrusions use 6000-series alloys, primarily 6063 and 6061, which contain aluminum alloyed with magnesium and silicon. These alloys offer the ideal balance of extrudability, strength, and corrosion resistance.

Five common aluminum applications include beverage cans, aircraft components, automotive body panels, building facades and window frames, and electronic device housings. Aluminum's lightweight strength, corrosion resistance, and recyclability make it ideal for transportation, construction, packaging, electronics, and consumer products.

TEAM MFG is a rapid manufacturing company who specializes in ODM and OEM starts in 2017.