Polyethylene (PE) na wan versatile sintetik resin we dɔn rivɔlɔshɔn wi ɛvride layf. Na di plastic we dɛn kin yuz pas ɔl na di wɔl.

Discover in di 1930s, PE don kam fa frɔm in ɔmbul biginin. Tide, na impɔtant tin fɔ mek bɔku bɔku industri dɛn.

Frɔm pak to kɔnstrɔkshɔn, PE plastic de ple impɔtant pat pan wi mɔdan wɔl. Insai dis post, wi go explor di fascinating wold of PE plastic.

Yu go lan bɔt in prɔpati dɛn, di kayn dɛn, ɛn di aplikeshɔn dɛn we de mek i impɔtant na wi ɛvride layf.

Kεmikכl kכmכshכn εn strכkchכ fכ PE plastic .

Fɔmula fɔ kemikal .

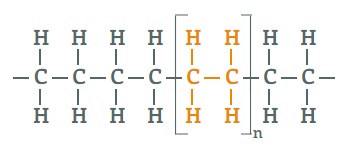

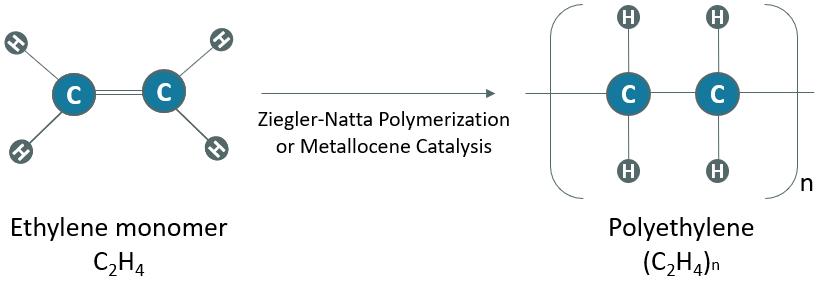

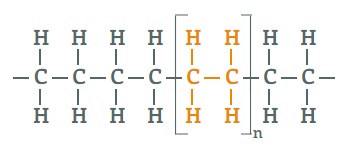

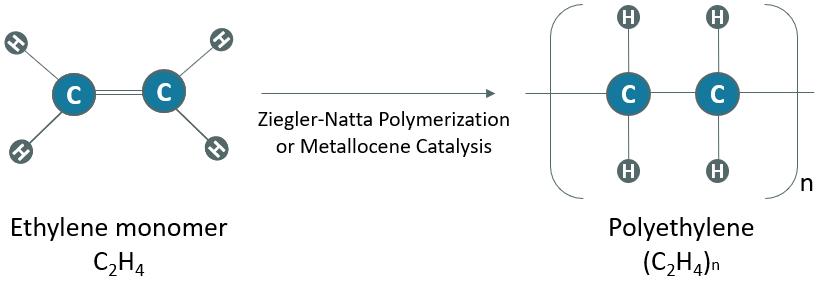

Polyethylene (PE) gɛt wan simpul kemikal fɔmula: (C2H4)N . I gɛt tu kabɔn atɔm dɛn we gɛt fɔ du wit 4 haydrojɛn atɔm dɛn. Di 'n' na di fɔmula de riprizent di ripit yunit dɛm fɔ dis strɔkchɔ. we plεnti εtilen mכlikul dεm (C2H4) de jכyn togεda, dεn de fכm lכng chen dεm, we de mek polyethylene.

Molekyular strɔkchɔ fɔ PE .

di prכsεs bihayn dis dεn kכl am polimεrayzeshn . εtilen mכnomεr dεm de kכnεkt insay wan chen riakshכn, transfכm to PE. Dis prכsεs kin apin tru difrεn mεtכd dεm, lεk Ziegler-Natta polimεrayzeshn כ fri radikal polimεrayzeshn . Ɛni we de afɛkt di PE in las prɔpati dɛn smɔl.

Molekyular Struktrɔ .

PE in mɔlikul strɔkchɔ de ple wan impɔtant pat pan in pefɔmɛns. Di mɔlikul wet fɔ PE kin difrɛn bad bad wan, ɛn dis kin afɛkt di plastic in trɛnk, fleksibiliti, ɛn di tɛm we i go de fɔ lɔng tɛm. hכy mכlikul wet kin min strכng mεtirial, we de mek i fayn fכ hεvi-duti aplikεshכn.

Branch na ɔda impɔtant tin. PE kin gɛt difrɛn lɛvul dɛn fɔ branch na in mɔlikul chen dɛn. Mɔ branch, lɛk insay low-density polyethylene (LDPE) , de rilizɔt in soft, mɔ fleksibul plastic. Na di ɔda say, di ay-dɛnsity polietilen (HDPE) nɔ gɛt bɔku branch dɛn, we kin mek i tranga ɛn i kin rigid.

Crystalinity de impεkt PE in bihayvya bak. Di mɔ kristal wan PE de, na di mɔ i de rigid ɛn i nɔ de transparent. Fɔ ɛgzampul, HDPE, we gɛt ay digri fɔ kristaliniti, dɛn kin yuz am fɔ mek prɔdak dɛn we nid trɛnk, lɛk kɔntena ɛn paip. Difrɛn frɔm dat, LDPE, wit lɔwa kristaliniti, na pafɛkt fɔ plastic bag ɛn fleksibul fim dɛn.

Di kayn PE plastic dɛn .

Low-density polietilen (LDPE) .

Karakta ɛn prɔpati dɛn .

LDPE na wan we pipul sabi fɔ in fleksibiliti ɛn transparency. I soft, tof, ɛn i nɔ de ambɔg impak.

Ki Prɔpati dɛn:

Densiti: 0.910-0.925 g/cm³

Point we de mɛlt: 105-115°C

Gud kemikal resistans .

Di wata we de na di wata we nɔ bɔku .

Di we aw dɛn de mek tin dɛn .

LDPE de prodyuz bay we dɛn de yuz ay prɛshɔn ɛn tɛmpracha. Di prɔses involv:

Ethylene gas kompreshɔn .

Polimerizayshɔn insay wan riaktɔ .

Kul ɛn Pɛlɛtizing .

Kɔmɔn Aplikeshɔn dɛn .

Di wan dɛn we gɛt ay-dɛnsiti polietilen (HDPE) .

Yunik ficha ɛn bɛnifit dɛn .

HDPE na strɔng ɛn i strɔng pas LDPE. I de gi:

Di we aw dɛn de mek di tin dɛn we dɛn de mek .

HDPE na we dɛn mek am bay we dɛn de yuz lɔw prɛshɔn ɛn tɛmpracha. Di we aw dɛn de du am na:

Slɔri polimɛrayzeshɔn .

Gas faz polimayzayshɔn .

Populɔr Yuz dɛn na Indastri .

Linear low-density polyethylene (LLDPE) .

Kɔmpiashɔn wit LDPE .

LLDPE Kɔmbayn ficha dɛn fɔ LDPE ɛn HDPE:

Mɔ fleksibul pas HDPE .

Strɔng pas LDPE .

Bɛtɛ pankchɔ rɛsistɛns .

Teknik dɛn fɔ mek tin dɛn .

LLDPE de prodyuz yuz:

Dɛn we ya de alaw fɔ kɔntrol di branch dɛn prɛsis.

Speshal aplikeshɔn dɛn .

Ultra-high molekul we wet polietilen (UHMWPE) .

Eksepshɔnal prɔpati dɛn .

UHMWPE bost se:

Prodakshɔn Chalenj dɛn .

Manufakchurin UHMWPE na komplex bikɔs ɔf:

rili ay mɔlikul wet .

Difikulti fɔ prosɛs .

Bɔku tɛm, dɛn kin yuz spɛshal tɛknik dɛn lɛk kɔmpreshɔn mol.

Di aplikeshɔn dɛn we gɛt ay pafɔmɛnshɔn .

Bulletproof vests .

Atifishal jɔyn dɛn na mɛrɛsin .

Indastrial Mashinery Pat dɛn .

Fayba dɛn we gɛt ay pafɔmɛnshɔn .

Cross-linked Polyethylene (PEX) .

Di bɛnifit dɛn we pɔsin kin gɛt we i krɔs-link .

Krɔs-link de mek:

Tempracha resistans .

Kεmikכl rεsistεns .

Mekanikal Strɔng .

Di we aw dɛn de mek tin dɛn .

PEX na di wan we dɛn mek bay:

Krio HDPE .

Krɔs-link we yu de yuz pɛrɔksayd, silan, ɔ ilɛktron bim .

Yuz dɛn na plaba ɛn kɔnstrɔkshɔn .

Radiant itin sistem dɛn .

Piping we pɔsin kin drink we pɔsin kin drink .

Insuleshɔn fɔ ay-vɔlt kebul dɛn .

Jiotɛmal ɔt transfa .

Midul-density polietilen (MDPE) .

Prɔpati ɛn kwaliti dɛn .

MDPE de gi balans bitwin HDPE ɛn LDPE:

Di we aw dɛn de mek di tin dɛn we dɛn de mek .

MDPE na tipikli prodyuz yuz:

Aplikeshɔn dɛn na gas paip ɛn fitin dɛn .

Natural gas distribushɔn paip dɛn .

Fitins fɔ gas sistem dɛn .

Prɛshɔn paip fɔ wata .

Kebul Protɛkshɔn paip dɛn .

Ethylene copolymers na di .

Tayp dɛn fɔ Kɔpolimɛr dɛn .

Di kɔmɔn ɛtilɛn kɔpɔlimɛr dɛn na:

Ethylene vinyl asetat (EVA) .

Ethylene akrilik asid (EAA) .

Ethylene methacrylic acid (EMAA) .

Yunik prɔpati ɛn advantej dɛn .

Ethylene copolymers de gi:

Speshal aplikeshɔn dɛn .

Eva: Foam Soles in Shuz

EAA: Adhesive layers in packaging

EMAA: Di wan dɛn we de na di gɔlf bɔl de kɔba .

Jɛnɛral: Adhesives we de mɛlt fɔ mɛlt, silin dɛn

Ki prɔpati dɛn fɔ PE plastic .

Densiti Varieshɔn dɛn .

PE plastic dɛn kin kam insay difrɛn difrɛn dens dɛn. Dis prɔpati kin rili afɛkt dɛn kwaliti ɛn aplikeshɔn dɛn.

Na dis wan na wan kwik brekdaun:

LDPE: 0,910-0,925 g/cm³

LLDPE: 0,915-0,925 g/cm³

MDPE: 0,926-0,940 g/cm³

HDPE: 0,941-0,965 g/cm³

Di ay density tipikli min big trɛnk ɛn stiffness. Lower density de gi mɔ fleksibiliti ɛn impak resistans.

Molikul weit impak .

Molekyul weit de ple wan impɔtant pat pan PE prɔpati dɛn. I de afɛkt trɛnk, taf, ɛn prɔsesabiliti.

Ki pɔynt dɛn:

Uhmwpe, wit in ekstrimli ay molkyular wet, de sho eksepshonal strכng εn wear rεsistεns.

Kεmikכl rεsistεns .

PE plastic dɛn jɔs de sho fayn fayn kemikal rɛsistɛns. Dem inert tu plenti substances.

Resistance difrɛn bay PE tayp:

HDPE: Supiriɔs rɛsistɛns to kemikal ɛn sɔlvɛnt dɛn .

LDPE: Gud resistans, bɔt kin afɛkt sɔm haydrokabɔn dɛn .

PE de rεsist asid, bays, εn mכst sכlvεnt. I nɔ de resistant to strɔng ɔksidayzin ɛjɛn.

Tempracha tolerans .

PE plastic kin tinap fɔ wan rich tɛmpracha. Dɛn pefɔmɛns kin difrɛn bay di kayn ɛn di gred.

Jɛnɛral Tɛmpratura Rɛnj dɛn:

LDPE: -50°C to +80°C

HDPE: -60°C to +120°C

Uhmwpe: -200°C to +80°C

PEX de gi impɔtant ay-tɛmpracha rɛsistɛns, we fayn fɔ ɔt wata paip.

UV resistans .

PE we nɔ chenj na susɛptibl fɔ UV dɛgradishɔn. If yu tek di san fɔ lɔng tɛm, dat kin mek yu brit ɛn chenj di kɔlɔ.

Fɔ mek yu ebul fɔ mek UV nɔ go fayn:

Ad UV stebyulayza dɛn .

Inkorporet kabon blak (fɔ blak PE prodakt dɛn)

UV-stabilized PE fain yus in outdoor aplikeshon lek agrikalcha film en outdoor furniture.

Di tin dɛn we pɔsin fɔ tink bɔt fɔ mek i nɔ gɛt prɔblɛm wit in it .

Bɔku PE tayp dɛn na FDA-apruv fɔ it kɔntakt. Dɛn nɔ gɛt pɔyzin ɛn dɛn nɔ de gi teist ɔ ɔda tin fɔ smɛl.

Food-safe PE Karakta:

Low maigrɛshɔn fɔ aditiv dɛn .

Resistant to microbial growth .

I izi fɔ klin ɛn stɛrilayz .

Dɛn kin yuz HDPE ɛn LDPE fɔ pak tin dɛn fɔ it. UHMWPE na fayn tin fɔ di tin dɛn we dɛn kin yuz fɔ mek it.

Mɛmba: Ɔltɛm chɛk sɔm patikyula gred dɛn fɔ si if dɛn de fala di it sef wan.

Ditiɛl prɔpati kɔmpiashɔn fɔ PE tayp dɛn

| Prɔpati | LDPE | LLDPE | MDPE | HDPE | UHMWPE |

| Densiti (g/cm³) | 0,910 - 0,925 | 0,915 - 0,925 | 0,926 - 0,940 | 0,941 - 0,965 | 0,930 - 0,935 |

| kristaliniti . | Lɔw (40-50%) | Midul (50-60%) | Midul-ay . | ay (70-80%) | rili ay (>85%) . |

| Tensil Strɔng (MPA) . | 8-12. | 10-30. | 20-35 pipul dɛn. | 20-40. | 40-48 Di wan dɛn we de wok. |

| Point we de mɛlt (°C) . | 105 - 115. | 120 - 130 na di 130. | 125 - 135 pipul dɛn. | 130 - 137 pipul dɛn. | 130 - 135 pipul dɛn. |

| Fleksibul fɔ mek yu ebul fɔ chenj . | Mɔs pan di tin dɛn we pɔsin kin du fɔ mek i ebul fɔ chenj . | Ajɔst | Soba | I nɔ go izi fɔ chenj . | Di las wan we yu go ebul fɔ chenj . |

| Rigiditi . | Di wan we nɔ gɛt bɛtɛ trɛnk . | Rigid smɔl smɔl . | Modaret rigid . | Strikt | Di wan dɛn we rili rigid . |

| Di men tin dɛn we de na di wɔl . | Fleksibul, transparent . | Impɔtant trɛnk, pankchɔ resistant | Balans fɔ prɔpati dɛn . | Strɔng, kemikal rɛsistɛns . | Ekstrim strɔng, wear resistant |

| Kɔmɔn Aplikeshɔn dɛn . | Fim dɛn, Bag dɛn . | Stretch wrap, tubing . | Gas Pipes, Kebul dɛn . | Bɔtul, paip dɛn . | Di pat dɛn we gɛt ay pafɔmɛnshɔn . |

Notis: Di rayt valyu dɛn kin difrɛn smɔl dipen pan di patikyula gred dɛn ɛn di wan dɛn we mek am.

Di teknik fɔ prosɛs fɔ PE .

PE plastic na versatile. Dɛn kin prosɛs am bay we dɛn de yuz difrɛn we dɛn fɔ du am.

Moldin fɔ injɛkshɔn .

Injekshɔn moldin na pɔpul fɔ mas-prɔdyusin PE pat dɛn. Na so i de wok:

PE pellet dɛn dɔn mɛlt.

Dɛn kin put di plastic we dɔn rɔtin insay wan mol.

Di mold dɔn kol, i de mek di plastic strɔng.

Di pat we dɔn dɔn, dɛn kin pul am kɔmɔt.

Dis we ya na fayn tin fɔ mek kɔmpleks shep dɛn. Dɛn kin yuz am fɔ mek bɔtul kap, kɔntena, ɛn tɔys.

Ekstrushɔn .

Ekstrushɔn na fɔ mek kɔntinyu prɔfayl dɛn. Di prɔses involv:

Meltin PE pellet dɛn.

Fɔs di plastic we dɔn rɔtin tru wan day.

Kul ɛn sɔlidify di shep we dɛn dɔn pul kɔmɔt.

I fayn fɔ mek paip, tub, ɛn waya kɔtin.

Blow moldin na na na na na na na na na na na na na na na na na na na na na na na na na na na na na na na na na na na na na na na na na na

Injɛkshɔn moldin na pafɛkt fɔ tin dɛn we gɛt ol. Na dis na di prɔses:

Dɛn kin pul wan PE tyub (parison).

Di parina de klamp insay wan mol.

Dɛn kin blo di briz insay di parina, ɛn i kin mek i big te di mold shep.

Di pat kin kol ɛn dɛn kin pul am kɔmɔt.

Dɛn kin yuz dis we fɔ mek bɔtul, fiul tank, ɛn big kɔntena dɛn.

Rotational moldin na na na na na na na na na na na na na na na na na na na na na na na na na na na na na na na na na .

Rotational molding na big tin fɔ big, olo pat dɛn. Di step dɛn na:

Dɛn kin put PE paoda insay wan mol.

Dɛn kin ɔt di mol ɛn i kin rɔn.

Di paoda de mɛlt ɛn kot di mold in insay.

Dɛn kin kol di mol, ɛn dɛn kin pul di pat.

Dɛn kin yuz am fɔ tank, plegrɔun ikwipmɛnt, ɛn kayak.

Moldin fɔ kɔmpreshɔn (fɔ UHMWPE) .

UHMWPE nid spɛshal prɔsesin. Bɔku tɛm dɛn kin yuz kɔmpreshɔn moldin:

Dɛn kin put uhmwpe paoda insay mol we dɛn dɔn ɔt.

Dɛn kin put prɛshɔn fɔ kɔmprɛs di paoda.

Dɛn kin ɔt di matirial to in mɛlt pɔynt.

Di pat de kol ɔnda prɛshɔn.

Dis mεtכd de prodyuz hכy-strεng pat dεm lεk artifishal joyn dεm.

Film we de blo .

Film blowing de mek tint PE film dɛn. Di we aw dɛn de du am:

PE na mɛlt ɛn ɛkstrud insay wan tiub.

Dɛn kin blo di briz insay di tiub, ɛn i kin mek i big.

Di bɔbul kin kol ɛn i kin fɔdɔm.

Dɛn kin wund di fim pan rol dɛn.

Dis tɛknik de mek plastic bag ɛn pak fim dɛn.

3d printin wit PE .

3D printin wit PE de kɔmɔt. I de gi nyu tin dɛn we pɔsin kin ebul fɔ du:

HDPE filaments de fɔ FDM printa dɛn.

I de alaw fɔ kɔstɔm, smɔl-batch prodakshɔn.

Risaykul PE kin yuz, we de promot sastaynabiliti.

Chalenj dɛn stil de, bɔt na wan fayn fayn eria fɔ divɛlɔpmɛnt.

Modifyin ɛn aditiv fɔ PE plastic .

Krɔs-linking fɔ mek PEX .

Cross-linked PE (Pex) de gi yu prɔpati dɛn we dɔn impɔtant:

PEX na di wan we dɛn mek tru tri we dɛn:

Pɛrɔksayd (Pex-A) .

Silane (Pɛks-B) .

Ilektron bim (Pex-C) .

I de yuz bɔku bɔku wan na plaba ɛn raytin itin sistem.

Klorineshɔn fɔ prodyuz CPE .

Chlorinated PE (CPE) de ad nyu tin dɛn:

Enhansed Weta Resistance .

Impruv flame retardansi .

Inkris ɔf ɔyl rɛsistɛns .

CPE na di wan we dɛn kin yuz na:

Kopolimers (Eva, ethylene-acrylic acid) .

Kopolimar dɛn kin jɔyn PE wit ɔda monomɛr dɛn:

Ethylene vinyl asetat (EVA) .

Fɔ mek pɔsin ebul fɔ chenj di we aw i de chenj .

I bɛtɛ fɔ mek yu no klia wan .

Impɔtant impak rɛsistɛns .

Eva de yuz in:

Etilen-Akrilik asid (EAA) .

EAA de fɛn aplikeshɔn dɛn na:

Metallocene PE (MPE) fɔ ɛnhans prɔpati dɛn .

MPE de gi sɔm bɛnifit dɛn:

I de yuz am na:

Di fim dɛn we gɛt ay pafɔmɛnshɔn .

Prodakt dɛn we nɔ de ambɔg .

Packaging we dɛn kin yuz fɔ mɛn pipul dɛn .

Ɔda modifyeshɔn dɛn fɔ spɛshal aplikeshɔn dɛn .

PE kin modify wit difrɛn aditiv dɛn:

| Additiv Type | Purpose | Aplikeshɔn |

| UV stɛbyulayza dɛn . | mek di san nɔ de kɔmɔt na di san . | Prodakt dɛn we de na do . |

| Antiɔksidant dɛn . | Prɛvent ɔksidɛshɔn we dɛn de prosɛs . | Ɔl di PE prɔdak dɛn . |

| Kɔlɔrant dɛn . | Ad di kɔlɔ . | Di guds dɛn we dɛn de yuz fɔ bay tin dɛn . |

| Di wan dɛn we nɔ gɛt faya fɔ mek dɛn nɔ gɛt faya . | Ridyus Flamabiliti . | Di tin dɛn we dɛn kin yuz fɔ bil . |

Aplikeshɔn dɛn akɔdin to di industri dɛn .

PE plastic na inkridibul versatile. Dɛn kin yuz am na bɔku bɔku industri dɛn.

Packaging .

Fɔ pak tin dɛn fɔ it .

PE na pafɛkt fɔ pak tin fɔ it. I de yuz am na:

Plastik bag dɛn .

Di kɔntena dɛn fɔ it .

Bɔtul Kap dɛn .

LDPE ɛn HDPE na kɔmɔn tin dɛn fɔ pik. Dɛn kin kip it fresh ɛn sef.

I Mage Source . U-nuo hdpe shampoo 16 oz lotion botul

Indastrial Pakɛj .

PE de shayn insay industrial pak bak:

Sacks we de ship .

Dram Liners na .

Wrap dɛn we de protɛkt .

Bɔku tɛm dɛn kin yuz HDPE fɔ mek i gɛt trɛnk ɛn fɔ mek i nɔ gɛt kemikal.

Advantej dɛn na di pak injɔstis .

PE de gi bɔku bɛnifit dɛn:

Dɛn kwaliti ya de mek PE bi wan tɔp chuk fɔ pak.

Di tin dɛn we dɛn de yuz fɔ bil ɛn di tin dɛn we dɛn de yuz fɔ bil .

paip ɛn fitin dɛn .

PE paip dɛn kin yuz bɔku say dɛn. Dem na big tin fo:

Di wata we dɛn de gi .

Gas Distribushɔn .

Siwej sistem dɛn .

HDPE paip dɛn kin te ɛn dɛn nɔ kin kɔrɛshɔn.

Insuleshɔn matirial dɛn .

PE Foam na wan fayn fayn insulin. I de yuz am na:

Insuleshɔn fɔ di wɔl .

Ruf Ɔndalaymɛnt .

Saund Dampening .

I laytwɛt ɛn mɔstɔ-rɛsistɛns.

Jiɔmɛmba dɛn .

PE geomembranes na impɔtant tin fɔ bil:

Dɛn de gi fayn fayn kemikal dɛn we de mek dɛn nɔ ebul fɔ bia ɛn we go de fɔ lɔng tɛm.

Ɔtomotiv Indastri .

Tank dɛn we gɛt fiul .

HDPE fiul tank na kɔmɔn tin na motoka. Dem de:

Dis kin ɛp fɔ mek di fiul wok fayn ɛn mek i sef.

Intɛriɔ Kɔmpɔnɛnt dɛn .

PE na in dɛn kin yuz na bɔku motoka intɛriɔ:

Panɛl dɛn we gɛt domɔt .

Sit bak dɛn .

Di wan dɛn we gɛt kɔp .

I nɔ de tek bɔku mɔni ɛn i izi fɔ mol.

Di bɛnifit dɛn we dɛn kin gɛt we dɛn de mek motoka .

PE de gi sɔm bɛnifit dɛn:

Dɛn bɛnifit ya de mek PE pɔpul insay ɔtomotiv manufakchurin.

Fam wok

Grinhaus film dɛn .

LDPE films na perfekt fɔ grin haus dɛn:

Layt transmishɔn .

Hɛt Ritɛnshɔn .

Durability .

Dɛn de ɛp fɔ mek di fayn fayn tin dɛn we de gro.

Irigashɔn sistem dɛn .

PE paip dɛn kin yuz bɔku say dɛn na irigashɔn:

Dɛn nɔ kin ebul fɔ bia wit kemikal ɛn UV raytin.

Mulching Aplikeshɔn dɛn .

PE Mulch Films de gi bɛnifit:

Dɛn kin ɛp fɔ mek di tin dɛn we dɛn kin plant bɔku ɛn di kwaliti.

Ɛlthkɛr ɛn Mɛdikal Divays dɛn .

Medikal-Gred PE plastic dɛn .

Medikal-grɛd PE na spɛshal fɔmulayt:

I de mit strikt wɛlbɔdi standad.

Kɔmɔn mɛdikal aplikeshɔn dɛn .

PE na di wan we dɛn kin yuz fɔ du difrɛn tin dɛn fɔ mɛn pipul dɛn:

UHMWPE na patikyula valyu fɔ jɔyn riplesmɛnt.

Di guds dɛn we dɛn de yuz fɔ bay tin dɛn .

Di tin dɛn we dɛn kin yuz na os .

PE de insay bɔku tin dɛn we dɛn kin yuz na os:

I kin te, i izi fɔ klin, ɛn i kin izi fɔ pe fɔ.

Toys ɛn ɛnjɔymɛnt prɔdak dɛn .

PE na fayn ples fɔ tɔys ɛn spɔt ikwipmɛnt:

Ikwipmɛnt fɔ plegrɔun .

Spɔt bɔl dɛn .

Bich toys .

I sef, i de te, ɛn i nɔ de ambɔg di impak.

Ilɛktrikal ɛn ilɛktronik tin dɛn .

Kebul insuleshɔn .

PE na wan fayn fayn ilɛktrik inshɔlɛta:

I de gi protɛkshɔn ɛn fɔ mek i go te.

Ilɛktronik Kɔmpɔnɛnt dɛn .

PE na di wan we dɛn kin yuz fɔ mek ilɛktronik tin dɛn:

I de gi gud ilɛktrik prɔpati ɛn kemikal rɛsistɛns .

Dizayn kɔnsidareshɔn fɔ polyethylene prodakt dɛn .

Di we aw dɛn de pik di tin dɛn we dɛn dɔn yuz

We yu de pik Polyethylene (PE) fɔ mek di prɔdak, yu nid fɔ tink bɔt sɔm tin dɛn. Dɛn tin ya na di mɛkanikal prɔpati dɛm , lɛk tɛnsiɛl trɛnk ɛn fleksibiliti, we difrɛn akɔdin to PE tayp dɛm. Envayrɔmɛnt rɛsistɛns impɔtant, mɔ if di prɔdak go fes UV ɛksplɔshɔn ɔ kemikal ɛnvayrɔmɛnt. Fɔ ɛgzampul, HDPE de gi fayn fayn kemikal resistans, we . LDPE na bɛtɛ fɔ fleksibul, lɔw-stress aplikeshɔn dɛn. Fɔ dɔn, di we aw dɛn de du di wok impɔtant—ilɛksɛf yu de yuz injɛkshɔn moldin , ɛkstrushɔn , ɔ Blɔ moldin —bikɔs nɔto ɔl di PE tayp dɛn de wok fayn wit ɛvri we.

Manufakchurabiliti fɔ di wan dɛn we de wok.

Fɔ mek shɔ se manufakchurabiliti na di men tin fɔ mek PE prodak dɛn we go wok fayn ɛn we nɔ go tek bɔku mɔni. Disain elements lek simplicity de ridyus prodakshon taim en komplexity. We yu kip wan yunifom di tik we yu de tik, dat kin mek yu nɔ gɛt prɔblɛm lɛk wɔp ɔ sink, we kin apin we yu de kol. Draft angles na impɔtant tin bak fɔ injɛkshɔn moldin, we de alaw fɔ pul di pat dɛn we dɛn dɔn mol izi wan frɔm di mol. If yu skip dɛn tin ya, dat kin mek di prodakshɔn kɔst go ɔp ɛn di kwaliti fɔ di prɔdak nɔ go bɔku.

| dizayn factor | impɔtants . |

| Simpul dɛn . | Ridyus kɔmplisiti ɛn prodakshɔn tɛm . |

| Yunifom fɔ mek di wɔl tik . | I nɔ de mek wɔp ɛn sink . |

| Draft angul dɛn . | I izi fɔ pul am izi wan frɔm mold dɛn . |

Risayklabliti .

As sastaynabiliti de bi impɔtant mɔ, fɔ disayn PE prodak fɔ risaykul na wan prɔyoritɛt we de gro. We yu yuz wan tin , lɛk Pure HDPE ɔ LDPE , dat de mek i izi fɔ risaykul. Multi-material prodakt dɛn kin kɔmplikt di prɔses ɛn bɔku tɛm dɛn kin dɔn na say dɛn we dɛn kin trowe dɔti. Disain fɔ disassembly na ɔda strateji, usay dɛn bil prɔdak so dat dɛn go ebul fɔ tek dɛn izi wan fɔ risaykul. Klia matirial lɛblin impɔtant tu—i de ɛp fɔ risaykul fɔ no ɛn sɔt plastic fayn fayn wan.

| Ki Risayklabliti Kɔnsidɛreshɔn Dɛn | Diskripshɔn . |

| Singl Matirial Yuz . | Simplify fɔ risaykul . |

| Dizayn fɔ Disassembly . | I de mek am izi fɔ mek i izi fɔ mek di prɔdak brok . |

| Klir Matirial Labeling . | Asist fɔ sɔt fɔ risaykul prɔses . |

Test ɛn Kwaliti Kɔntrol .

Mechanical Testing

Mekanikal tɛst de mek shɔ se di PE prɔdak dɛn mit di strɔng ɛn durabiliti standad dɛn we dɛn nid. Tεnsil strכng tεst dεm de mכsu כl di fכs wan fכs wan PE mεtirial kin tinap bifo i brok. Dis na impɔtant tin fɔ prɔdak dɛn lɛk paip ɔ bɔtul , usay strɔkchɔral intɛgriti impɔtant. Impact Testing de evalyu di matiryal in resistans to sudden fos, mek shɔ se i nɔ go krak ɔ shat ɔnda strɛs. Meanwhile, flexural strength tests de ases aw bɔku bɛnd wan prɔdak kin bia bifo i nɔ wok, we impɔtant mɔ pan fleksibul PE matirial dɛn lɛk LDPE we de na di ..

| Mechanical Test | Purpose | Example Aplikeshɔn dɛn . |

| Tensile Strɔng . | Measures resistans to pulling forces . | Pipes, kɔntena dɛn . |

| Impɛkt tɛst . | Tests Material’s Resistance to Sudden Impacts . | Packaging, Automotive Parts |

| Flekshɔnal trɛnk . | Asɛs aw bɔku bɛnd fɔs i kin ebul fɔ handle . | Fleksibul pak, fim dɛn . |

Fɔ ɛgzampul, di mɛkanikal tɛst dɛn we wi dɔn tɔk bɔt ɔp nid fɔ de insay di . Perfume botl packaging test options.

Tɛm fɔ Tɛst .

Fɔ mek shɔ se PE prɔdak dɛn de du fayn fayn wan na difrɛn tɛmpracha, tɛmal tɛst impɔtant. Difrɛns skan kalorimɛtri (DSC) de analayz aw PE de biev ɔnda ɔt, ɛp fɔ no in mɛlt pɔynt ɛn kristaliniti . Dis na di ki fɔ pik di rayt kayn PE fɔ ay-ɔt ɛnvayrɔmɛnt . Wan ɔda we we go ɛp na di tɛm we dɛn kɔl Thermogravimetric Analysis (TGA) , we de tɛst di matirial in tɛmral stebiliti ɛn i de mɛzhɔ ɔmɔs wet i de lɔs as i de dikɔmpɔz. Dis kin ɛp di wan dɛn we de mek di tin dɛn fɔ ɔndastand aw di tin dɛn go biev ɔnda di kɔndishɔn dɛn we rili bad.

KƐMIKAL TƐST .

PE prodakt dɛn kin gɛt harsh kemikal dɛn bɔku tɛm, we kin mek dɛn du kemikal tɛst impɔtant. Envayrɔmɛnt strɛs krak rɛsistɛns (ESCR) de evalyu aw wɛl PE matirial dɛn de agens krak ɔnda di kɔmbayn inflɔɛns fɔ strɛs ɛn ɛksposhɔn to kemikal dɛn. Dis na impɔtant tin fɔ di prɔdak dɛn we dɛn kin yuz fɔ kip kemikal ɔ fɔ de na do , usay dɛn kin kam fɔ no bɔt tin dɛn we kin mek dɛn gɛt agresiv tin dɛn. ESCR de mek shɔ se dɛn de du di wok fɔ lɔng tɛm, we de ridyus di risk fɔ mek di matirial nɔ wok fayn as tɛm de go.

| Test Tayp | Pɔpɔshɔn | Kɔmɔn Yuz dɛn . |

| Difrɛns skan kalorimɛtri | Mekɔp fɔ mɛlt pɔynt ɛn kristaliniti . | Di aplikeshɔn dɛn we gɛt ay-ɔt . |

| Tɛmogravimɛtrik analisis . | I de evalyu di tɛmal stebiliti . | Ekstrim tempɔret ɛnvayrɔmɛnt dɛn . |

| Envairomɛnt strɛs krak resistans . | Test Kεmikכl εn Strεs Krak rεsistεns . | Kεmikכl stכrej, כda prodakt dεm |

Kɔnkliushɔn: Di fiuja fɔ PE plastic .

PE plastic na wan versatile matiryal wit bɔku bɔku bɛnifit dɛn. I de durabiliti ɛn adaptabiliti mek am fayn fɔ difrɛn aplikeshɔn dɛn.

Di men bɛnifit dɛn we PE gɛt na:

Bɔt wit di bɔku bɔku plastic west, fɔ balans di we aw dɛn de yuz di industri wit di envayrɔmɛnt rispɔnsibiliti rili impɔtant. Kɔntinyu fɔ mek nyu tin dɛn fɔ risaykul ɛn sataynabul ɔltɛrnativ dɛn go ɛp fɔ mek shɔ se di PE in fiuja we go ridyus in envayrɔmɛnt impak.

Tips: Yu maybe intres to di ol plastics