Yu don eva wanda wai PVC plastic de evriwea? Frɔm paip to mɛdikal divays, dis versatile matiryal dɔn rivɔlɔshɔn bɔku industri dɛm. Discovered Accidentally in 1872 by German Chemist Eugen Baumann, PVC dɔn bi wan impɔtant tin frɔm da tɛm de ɔlsay na di wɔl.

Insay dis post, wi go ɛksplɔrɔ di prɔpati dɛm, di manufakchurin prɔses dɛm, ɛn di kayn PVC plastic. Yu go lan bak bɔt in bɔku bɔku yus ɛn modifyeshɔn dɛn we de mek i impɔtant na di industri dɛn tide.

Ɔndastand di polyvinyl klorayd (PVC) .

Wetin na PVC (polyvinyl klorayd)?

PVC, ɔ polyvinyl klorayd, we dɛn kin kɔl bak vaynil, na wan thermoplastic polima we kin yuz bɔku bɔku tin dɛn. Dɛn sabi am fɔ di tɛm we i go de fɔ lɔng tɛm, aw i go ebul fɔ pe fɔ am, ɛn aw i nɔ go ebul fɔ bia wit di kemikal dɛn. Dɛn kin yuz am na industri dɛn lɛk kɔnstrɔkshɔn, wɛlbɔdi biznɛs, ɛn ilɛktroniks, dɛn kin favɔret PVC fɔ di ebul we i ebul fɔ bia wit di bad bad tin dɛn we de apin. Nɔ lɛk sɔm ɔda plastic dɛn, PVC kin bi fleksibul ɔ rigid, i kin dipen pan di aditiv dɛn we dɛn kin yuz we dɛn de prodyuz.

PVC na layt wet matirial. I izi fɔ wok wit ɛn dɛn kin mol am insay difrɛn shep dɛn, we mek i go-to chuk fɔ bɔku aplikeshɔn dɛn. I fayn fayn ilɛktrik insuleshɔn prɔpati dɛn bak de mek am fayn fɔ waya ɛn kebul prodakshɔn.

Brif Istri bɔt PVC Diskvayri ɛn Divɛlɔpmɛnt .

Di tin we PVC bin fɛn na bin wan gladi gladi aksidɛnt. Insay 1872, di Jaman kemist Eugen Baumann bin pul di vaynil klorayd gas to di san layt, we mek wan wayt sɔlid — pvc. Bɔt, na insay 1913 Friedrich Klatte bin patɛnt wan prɔses fɔ polimayz PVC yuz san layt, we mek di rod fɔ kɔmɛshɔn yuz.

Insay Wɔl Wɔ Wan, Jamani bin bigin fɔ mek PVC prɔdak dɛn we kin chenj ɛn we nɔ kin chenj, ɛn we kin chenj di mɛtal dɛn we nɔ de rɔtin. Bay mid-20th sɛntinari, PVC bin dɔn bi wan pan di plastic dɛn we dɛn bin de mek bɔku bɔku wan na di wɔl.

Prɔpati dɛn fɔ PVC plastic .

PVC bost wan yunik set of prɔpati we mek am wan versatil matirial fɔ difrɛn aplikeshɔn dɛn.

| prɔpati . | Valyu fɔ |

| Tik | 1.3-1.45 g/cm³ |

| Wata absɔpshɔn (24h imɛshɔn) . | 0.06% |

| Tensile Strɔng . | 7500 psi |

| Flekshɔnal modulus . | 481000 psi |

| Notch IZOD Impact Strɔng . | 1,0 ft-lbs/in |

| Tempracha we de mek di ples wam (264 psi) . | 158°F we de na di wɔl. |

| Koefishiɛnt fɔ tɛmral ɛkspɛnshɔn . | 3,2 x 10-5 in/in/°F |

| Dielectric strength . | 544 V/MIL |

Fizik prɔpati dɛn .

Densiti : PVC gɛt density we na 1.3-1.45 g/cm³ fɔ rigid PVC. Dis rili ay density de kontribiut to in robustnes en durability.

Wata absɔpshɔn : PVC gɛt lɔw wata absɔpshɔn. We dɛn put am insay fɔ 24 awa, i jɔs de absɔb 0.06% wata. Dis kin mek i nɔ ebul fɔ bia we di wata wet ɛn i fayn fɔ yuz na do.

Mekanikal prɔpati dɛn .

Tensile Strɔng : PVC gɛt tɛnsiɛl trɛnk we na 7500 psi. Dis ay trɛnk de alaw am fɔ bia wit impɔtant strɛs we nɔ de brok. I fayn fɔ aplikeshɔn dɛn we nid fɔ tranga.

Flekshɔnal mɔdyul : PVC in flekshɔnal mɔdyul na 481000 psi. Dis mɛzhɔ fɔ stiffnɛs de mek shɔ se PVC kin mentɛn in shep ɔnda lod.

Notched Izod Impact Strength : PVC in notch IZOD impak strɛng na 1.0 ft-lbs/in. Dis de sho se i ebul fɔ tinap agens di impak fɔs ɛn avɔyd fɔ brok.

Di prɔpati dɛn we dɛn kin yuz fɔ mek di ples wam .

Hɛt diflɛshɔn tɛmpracha : na 264 psi, PVC in ɔt diflɛshɔn tɛmpracha na 158°F. Dis na di tempɔret we i bigin fɔ difɔm ɔnda lod. PVC de mentɛn in shep fayn fayn wan ɔnda mɔdaret tɛmpracha.

Coefficient of thermal expansion : PVC gɛt kɔfishin fɔ tɛmral ɛkspɛnshɔn we na 3.2 x 10-5 in/in/°F. Dis de mɛzhɔ aw i de ɛkspɛn wit tɛmpracha chenj. PVC in lɔw valyu min se i de mentɛn dimɛnshɔnal stebiliti.

Ilɛktrik prɔpati dɛn .

K ɛ mik al Prɔpati dɛn .

Kεmikכl rεsistεns : PVC de rεsist to plεnti kεmikכl dεm, inklud asid, bays, sכlt, εn alifatik haydrokכbכn. Dis kin mek i fayn fɔ yuz na say dɛn we gɛt kɔrɛkt tin dɛn.

Weda Resistance : PVC kin ebul fɔ bia wit di ɛksposhɔn we di san de shayn ɛn ɔda wɛda ɛlimɛnt dɛn. Dis prɔpati de alaw fɔ yuz am na ɔda aplikeshɔn dɛn na do.

Advantej ɛn prɔblɛm dɛn .

PVC in prɔpati dɛn de gi sɔm bɛnifit dɛn:

Low Kost .

ay trɛnk .

Koroshɔn rɛsistɛns .

Flame retardansi .

Eksɛlɛnt insuleshɔn .

I izi fɔ prosɛs .

Bɔt, i gɛt sɔm prɔblɛm dɛn bak:

Poor heat stabiliti: PVC kin degrade na ay temperecha.

Plasticizer Migration: As tɛm de go, plasticizers kin lich aut, afɛkt PVC in prɔpati dɛm.

Pɔtɛnɛshɛl Tɔksisiti: PVC gɛt klorin, we kin rilis pɔyzin tin dɛn we dɛn de prodyuz ɔ trowe.

Manufakchurin proses fɔ PVC plastic .

Yu don eva wanda aw dem mek PVC plastic? Na wan fascinating process we involv sɔm step. Lɛ wi fɛn di manufakchurin joyn fɔ dis versatile matirial.

Raw Matirial dɛn .

Di praymari raw matirial fɔ PVC prodakshɔn na:

vinyl klorayd monomεr (VCM) : VCM de prodyuz bay we dεn kכmbayn klorin (we dεn kכmכt frכm sכlt) εn εtilen (frכm nεchכral gas כ כyl). Ethylene dichloride de fɔm. I de den hot in wan krak krak yunit fɔ prodyuz VCM.

Additives : Dɛn kin yuz difrɛn aditiv dɛn fɔ ɛp fɔ mek PVC in prɔpati dɛn bɛtɛ:

Stabilizers: Prevent degradation we dɛn de du di prɔses .

Plasticizers: Ɛnjɔy fɔ chenj di we aw pɔsin de chenj .

Filla dɛn: Impruv mɛkanikal prɔpati dɛn .

Lubrikɛnt: ɛp fɔ prosɛs .

UV stebyulayza dɛn: Protɛkt frɔm di san layt dɛgradishɔn

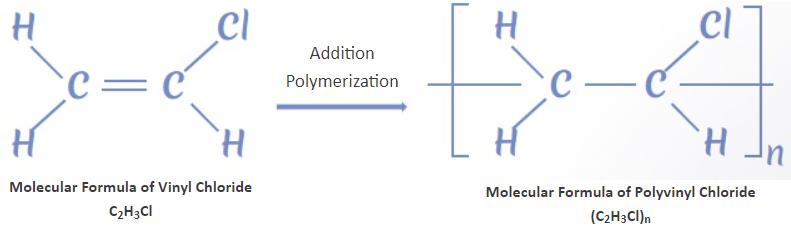

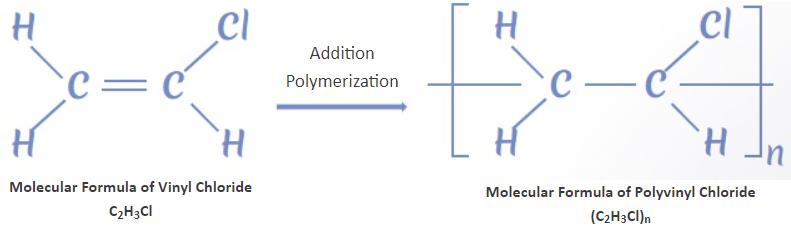

Polimerizayshɔn Mɛtɔd dɛn .

PVC na sintesis tru polimεrayzeshn fכ VCM. Di tu men we dɛn fɔ du dis na:

Sɔspɛns Polim ɛ z ɛ z ɛ z ɛ shɔn : .

VCM de skata insay wata wit initiator ɛn aditiv.

Kɔntinyu fɔ miks de mentɛn sɔspɛns ɛn yunifom patikyula saiz.

Akɔn fɔ 80% pan PVC prodakshɔn ɔlsay na di wɔl.

Emulsion polim i s i s i s : .

VCM na trɔp insay sop maysɛl dɛn na wata.

Wata-soluble initiators de yuz.

Prodyuz PVC wit smɔl patikyula saiz (0.1-100 μm).

Dɛn tu we ya involv ɔt fɔ bigin polimayzayshɔn. Di rizultin PVC resin na wan wayt, brital solid.

Kɔmpawnd ɛn Pɛlɛtizing .

Di PVC resin de miks wit aditiv insay wan prɔses we dɛn kɔl kɔmpawnd. Dis na tin we dɛn kin du insay miksa ɔ ɛkstruda fɔ mek dɛn prodyuz wan ɔmojɛnik blɛnd.

Di kompound PVC den de pelet. I extruded tru wan day en kot in to smohl pellets. Dɛn pelɛt ya izi fɔ handel ɛn rɛdi fɔ mek dɛn prosɛs am mɔ.

Kwaliti Kɔntrol ɛn Tɛst .

Strikt kwaliti kɔntrol mɛzhɔ dɛn de impruv ɔlsay na di manufakchurin prɔses. Dis de mek shɔ se kɔnsistɛns prɔpati ɛn pefɔmɛns fɔ di PVC.

Sɔm tɛst dɛn we dɛn kin du na:

Dɛn tɛst ya de ɛp fɔ chɛk if di PVC mit di spɛsifikɛshɔn dɛn we dɛn nid fɔ di aplikeshɔn we dɛn bin want fɔ yuz.

Di tebul we de dɔŋ ya de sɔmariz di men step dɛn na PVC manufakchurin:

| Step | Diskripshɔn |

| Raw Matirial dɛn . | VCM (frɔm klorin ɛn ɛtɛlin) ɛn aditiv dɛn |

| Polimerizayshɔn . | Sɔspɛns (80% pan di prodakshɔn) ɔ ɛmulshɔn . |

| Kɔmpawnd . | Miks PVC resin wit aditiv fɔ ɛp fɔ mek di prɔpati dɛn go bifo . |

| Pɛlɛtizing . | Extruding ɛn kɔt kɔmpawnd PVC insay pɛlɛt dɛn . |

| Kwaliti Kɔntrol & Tɛst . | Verifying prɔpati ɛn pefɔmɛns tru difrɛn tɛst dɛn . |

Di kayn PVC plastic we dɛn kin gɛt .

PVC kin kam insay difrɛn kayn dɛn, ɛn ɛni wan pan dɛn gɛt difrɛn prɔpati ɛn aplikeshɔn dɛn.

Rigid PVC (UPVC) .

Dɛn kin kɔl am bak unplasticized PVC ɔ PVC-U .

Stif ɛn kɔst-ɛfɛktiv .

Ay resistans to impak, wata, weta, ɛn kɔrosiv ɛnvayrɔmɛnt dɛn .

Densiti: 1.3-1.45 g/cm³

Aplikeshɔn dɛn: paip dɛn, winda frem dɛn, ɛn kɔnstrɔkshɔn matirial dɛn

Fleksibel PVC we de na di .

Fleksibul PVC paip .

I gɛt plasticizers we de gi fleksibiliti .

Klasifikɛshɔn bays pan plasticizer kɔntinyu:

Densiti: 1.1-1.35 g/cm³

Aplikeshɔn dɛn: Kebul, hos, ɛn inflatabl prɔdak dɛn

Fleksibul PVC prɔpati dɛn .

Low Kost .

Fleksibul ɛn ay impak trɛnk .

Gud resistans to UV, asid, alkalis, ɛn ɔyl .

Nɔn-Flammabl .

Versatile pefomans profayl .

Klɔrin PVC (CPVC) .

Na klorineshɔn fɔ PVC rɛsin bin mek am .

Klɔrin kɔntinyu fɔ go ɔp frɔm 56% to arawnd 66% .

Enhansed durability, kεmikכl stεbiliti, εn fכm rεtardans .

kin ebul fɔ bia wit ay tɛmpracha pas rɛgyula PVC .

Aplikeshɔn dɛn: Ɔt wata paip ɛn industrial fluid handlin

Oriented PVC (PVC-O) .

Na Stretching PVC-U Pipes dɛn mek am .

Riɔganayz amorphous strɔkchɔ insay wan layt strɔkchɔ .

I de ɛp fɔ mek di bɔdi gɛt fayn fayn kwaliti dɛn:

Stifnɛs .

Fatigue resistans .

Laytwɛt .

Aplikeshɔn dɛn: Ay-pafɔmɛnshɔn prɛshɔn paip dɛn .

PVC we dɛn dɔn chenj (PVC-M) .

Alloy of PVC we dɛn mek bay we dɛn ad modifying ɛjɛn dɛn .

Impruv taf ɛn impak prɔpati dɛn .

Aplikeshɔn dɛn: dakt, kɔndukt, ɛn fitin dɛn we nid fɔ mek dɛn ebul fɔ du am fɔ lɔng tɛm .

Di tebul we de dɔŋ ya de sɔmariz di men kayn PVC ɛn dɛn kwaliti dɛn:

| Tayp | Diskripshɔn | Ki Prɔpati | Aplikeshɔn dɛn |

| Rigid PVC we de na di . | Unplasticized, Stiff . | Impact, Weather, ɛn Kɛmikal Resistance . | paip, winda frem, kɔnstrɔkshɔn |

| Fleksibel PVC we de na di . | I gɛt plasticizers fɔ fleksibul . | UV, Asid, Alkali, ɛn Ɔyl Resistɛns . | Kebul, Hos, Inflatables |

| PVC we gɛt klorin . | Klɔrin kɔntinyu fɔ go ɔp to 66% . | Enhansed durability, heat resistans . | Hot wata paip, industrial fluid handling |

| Oriented PVC we de na di . | Stretched PVC-U paip dɛn . | Impɔtant Stifnɛs, Fatigue Resistance | ay-perfomans prɛshɔn paip dɛn . |

| PVC we dɛn dɔn chenj . | PVC aloy wit modifying agents . | Inkris taf ɛn impak trɛnk . | Ducts, Conduits, Fittings |

Di we aw dɛn de prosɛs fɔ PVC plastic .

PVC in versatility nɔ jɔs de insay in prɔpati bɔt i de bak pan di we dɛn we dɛn kin prosɛs am. Lɛ wi dayv insay di difrɛn we dɛn we dɛn yuz fɔ shep dis matirial to yusful prɔdak dɛn.

Ekstrushɔn .

Ekstrushɔn na kɔntinyu prɔses we de mek lɔng, yunifom profayl dɛn. PVC de mɛlt ɛn fos tru wan day fɔ mek di shep we dɛn want.

Moldin fɔ injɛkshɔn .

Dɛn kin yuz injɛkshɔn moldin fɔ mek kɔmpleks, tri-dimɛnshɔnal pat dɛn. Molten PVC de injekt insay wan mold cavity usay i de kol ɛn solidify.

Tɛmofɔmin .

Tεrmofכm involv fכ hεt PVC sheet te i pliable εn den shep am oba wan mold. Dɔn dɛn kin kol di sheet fɔ mek i kɔntinyu fɔ gɛt di nyu shep.

Blow moldin na na na na na na na na na na na na na na na na na na na na na na na na na na na na na na na na na na na na na na na na na na

Dɛn kin yuz blo mold fɔ mek tin dɛn we gɛt ol lɛk bɔtul ɛn kɔntena. Wan tiub we gɛt molten PVC, we dɛn kɔl parina, dɛn dɔn ful-ɔp insay wan mol.

Kalɛnda we dɛn de kɔl .

Kalɛnda na prɔses we de mek tint, kɔntinyu shit ɔ fim. PVC de pas tru wan siriɔs ɔt rɔla we de kɔmprɛs ɛn shep am.

Fim ɛn Shit Prodakshɔn :

Kalenda PVC film dɛn de yuz fɔ pak, lɛbl, ɛn lamination

Dɛn kin yuz sheet dɛn fɔ mek flo, fɔ mek ruf, ɛn fɔ kɔba di wɔl .

3D Printing we dɛn de yuz fɔ print .

3D printin, ɔ aditiv manufakchurin, na rili nyu we fɔ prosɛs PVC. I involv fɔ bil wan ɔbjɛkt layt bay layt frɔm wan dijital mɔdel.

| Di we aw dɛn de du di wok | Diskripshɔn | Ki pɔynt dɛn . |

| Ekstrushɔn . | Kɔntinyu fɔ du di wok fɔ mek prɔfayl dɛn . | paip, tubing, sheet dɛn; Di tempɔret we smɔl pas di injɛkshɔn moldin . |

| Moldin fɔ injɛkshɔn . | I de mek kɔmpleks pat dɛn bay we i de injɛkt insay wan mol . | Melt Temp: 170-210°C, Mold Temp: 20-60°C; Mold dɛn we nɔ de rɔtin . |

| Tɛmofɔmin . | Shaping heated PVC sheets ova wan mold . | Pliable na 120-150°C; Packaging, sayn dɛn, ɔtomotiv kɔmpɔnɛnt dɛn |

| Blow moldin na na na na na na na na na na na na na na na na na na na na na na na na na na na na na na na na na na na na na na na na na na | Krio hol objek bay we yu inflayt wan parson . | bɔtul, kɔntena dɛn; I fayn fɔ yuz fɔ kemikal dɛn . |

| Kalɛnda we dɛn de kɔl . | I de mek tint, kɔntinyu shit ɔ fim dɛn . | fim dɛn fɔ pak, lɛbl dɛn; Sheets fɔ flooring, ruf |

| 3D Printing we dɛn de yuz fɔ print . | Builds objects layt bay layt frɔm wan dijital mɔdel . | nyu PVC filamɛnt dɛn; Pɔtɛnɛshɛl damej to printa kɔmpɔnɛnt dɛn . |

Dɛn prɔsesin mɛtɔd ya de sho PVC in adaptabiliti. Ɛni we gɛt in yon bɛnifit ɛn tin dɛn we pɔsin fɔ tink bɔt. Di choice of processing method dipen pan di end prodakt we yu want ɛn in rikwaymɛnt dɛn.

Modifyinshɔn dɛn fɔ PVC Plastik .

PVC nɔ kin izi fɔ yuz insay in klin fɔm. Bɔku tɛm dɛn kin chenj am wit difrɛn aditiv dɛn fɔ mek in prɔpati ɛn pefɔmɛns bɛtɛ.

| Modifyeshɔn | Ɛgzampul dɛn | Ifɛkt dɛn . |

| Plastikiza dɛn . | phthalates, adipat, trimɛlit dɛn | Inkris fleksibiliti, ridyus trɛnk . |

| Di wan dɛn we de mek di ples wam . | Kalsiɔm-zink, tin-based . | Prɛvent Degradation we dɛn de prosɛs ɛn yuz . |

| Filla dɛn . | Kalsiɔm kabɔnɛt, taytaniɔm dayɔgzayd, glas fayba dɛn | Impruv mɛkanikal prɔpati, ridyus kɔst . |

| Lubrikɛnt dɛn . | Paraffin waks, stearik asid . | Impruv prɔsesabiliti, ridyus frikshɔn . |

| UV stɛbyulayza dɛn . | Hals, benzotriazoles . | Protɛkt frɔm UV dɛgradishɔn . |

| Impekt modifya dɛn . | Akrilik, MBS . | Ɛnjɔy taf ɛn impak rɛsistɛns . |

| Di wan dɛn we nɔ gɛt faya fɔ mek dɛn nɔ gɛt faya . | Antimɔni trioksayd, aluminiɔm haydroksayd . | Impruv faya resistans . |

| Di tin dɛn we de ɛp fɔ mek dɛn ebul fɔ du di wok . | Akrilik-based, silikon-based | Enhans processability ɛn surface kwaliti . |

| Blɛnd dɛn . | PVC/Polyester, PVC/PU, PVC/NBR | Impruv spɛshal prɔpati dɛn fɔ di aplikeshɔn dɛn we dɛn dɔn tayt . |

Plastikiza dɛn .

Plastikiza na aditiv we de inkrisayz di fleksibiliti ɛn wokabiliti fɔ PVC. Dɛn kin ridyus di polima in kristaliniti, we kin mek i pliable mɔ.

Di wan dɛn we de mek di ples wam .

Hɛt stebyulayza dɛn de mek PVC nɔ de pwɛl we dɛn de prosɛs ɛn yuz am. Dɛn de neutralize di haydroklorik asid (HCl) we dɛn prodyuz we PVC de pan ɔt.

Filla dɛn .

Dɛn kin yuz fil fɔ mek PVC in mɛkanikal prɔpati dɛn bɛtɛ ɛn ridyus di kɔst. Dɛn kin inkrisayz rigiditi, trɛnk, ɛn dimɛnshɔnal stebiliti.

Kalsiɔm Kabonɛt : .

Titanium dayɔgzayd : .

Glass Fayba dɛn : .

Lubrikɛnt dɛn .

Dɛn kin ad lɔbrikɛn to PVC fɔ mek dɛn go ebul fɔ prosɛs am fayn fayn wan. Dɛn kin ridyus frikshɔn we dɛn de du ɛkstrushɔn ɛn mol, dɛn nɔ de mek dɛn stik ɛn mek shɔ se dɛn de flɔ fayn fayn wan.

UV stɛbyulayza dɛn .

UV stebyulayza dɛn de protɛkt PVC frɔm dɛgradɛshɔn we kin kɔmɔt frɔm di san layt ɛksposhɔn. Dɛn kin mek dɛn nɔ gɛt kɔlɔ, dɛn kin chalk, ɛn dɛn nɔ kin lɔs di mɛkanikal prɔpati dɛn.

Impekt modifya dɛn .

Impekt modifya de enhans PVC in taf en resistans to impakt. Dɛn kin mek di matirial ebul fɔ absɔb ɛnaji fayn fayn wan ɛn dɛn nɔ kin krak.

Di wan dɛn we nɔ gɛt faya fɔ mek dɛn nɔ gɛt faya .

Flame retardants de improve PVC in faya resistans, we mek am sef fɔ yuz insay difrɛn aplikeshɔn dɛn.

Di tin dɛn we de ɛp fɔ mek dɛn ebul fɔ du di wok .

Prosesin ɛd na aditiv dɛm we de ɛp fɔ mek PVC in prɔsɛsabiliti ɛn sɔfays kwaliti bɛtɛ.

Aids we de na Akrilik :

Silikon-based Aids : .

Blend wit ɔda tɛmoplastik dɛn .

Blɛnd PVC wit ɔda tɛmplastik kin impruv in prɔpati fɔ spɛshal aplikeshɔn dɛn.

PVC/Polyester blends :

Ɛnjɔy mɛkanikal prɔpati dɛn lɛk abrashɔn rɛsistɛns, tɛnsiɛl trɛnk, ɛn tear resistans .

Suitabl fɔ ɔtomotiv ɛn industrial aplikeshɔn dɛn .

PVC/PU blend dɛn :

PVC/NBR blends :

Inkris fleksibiliti ɛn resiliɛns .

Dɛn kin yuz am fɔ hos, sil, ɛn gasket .

Dis modifyeshɔn dɛn sho di inkrɛdiblɛ adaptabiliti fɔ PVC. We dɛn tek tɛm pik di tin dɛn we dɛn kin ad, di wan dɛn we de mek di tin dɛn kin tay di PVC in prɔpati dɛn fɔ mek dɛn fit bɔku bɔku aplikeshɔn dɛn.

Aplikeshɔn ɛn Yuz dɛn fɔ PVC Plastik .

PVC in versatility mek am go-to matiryal fɔ bɔku bɔku aplikeshɔn dɛn. Frɔm kɔnstrɔkshɔn to wɛlbɔdi biznɛs, frɔm ɔtomotiv to kɔshɔma guds, PVC de ɔlsay.

Konstrɔkshɔn Indastri .

PVC na wokɔs na di kɔnstrɔkshɔn sɛktɔ. Di we aw i go de fɔ lɔng tɛm, di we aw i nɔ go ebul fɔ bia wit di wɛda, ɛn di izi we aw i izi fɔ instɔl, de mek i bi fayn ples fɔ pik fɔ difrɛn aplikeshɔn dɛn.

Ilɛktrikal ɛn ilɛktronik tin dɛn .

PVC in fayn fayn insulin prɔpati ɛn faya resistans de mek am pɔpul chuk na di ilɛktrik ɛn ilɛktroniks industri.

Ɛlthkɛr ɛn Mɛdikal Divays dɛn .

PVC in bayɔkɔmpatibiliti, klia, ɛn di ebul fɔ stɛrilayz de mek am impɔtant matirial na wɛlbɔdi biznɛs.

Ɔtomotiv Sɛktɔ .

PVC in durabiliti, kemikal resistans, ɛn moldabiliti mek am yusful insay difrɛn ɔtomotiv aplikeshɔn dɛn.

Packaging .

PVC in klia, kemikal resistans, ɛn di abiliti fɔ mold mek am pɔpul choice fɔ pak.

Di guds dɛn we dɛn de yuz fɔ bay tin dɛn .

PVC in versatility ɛn durabiliti mek am kɔmɔn matirial insay difrɛn kɔshɔma prodak dɛm.

| Aplikeshɔn Eria | Ɛgzampul dɛn | Ki bɛnifit dɛn . |

| Bil | paip, winda, flooring | Durability, weda resistans, izi instaleshon |

| Ilektrikal & Ilɛktroniks . | Kebul Insuleshɔn, Kɔndukt dɛn . | Insuleshɔn, faya rɛsistɛns, kemikal rɛsistɛns . |

| Heltkeya . | Blɔd bag dɛn, ɔspitul glɔv dɛn . | Bayokɔmpatibiliti, klia, stɛrilayzabiliti . |

| Ɔtomotiv . | Intɛriɔ kɔmpɔnɛnt dɛn, ɔndabɔdi protɛkshɔn . | Durability, kemikal resistans, moldabiliti |

| Packaging . | Fɔ pak tin dɛn, blista pak dɛn | Klarity, kemikal resistans, moldabiliti |

| Di guds dɛn we dɛn de yuz fɔ bay tin dɛn . | Klos, Fut, Toys | Versatility, durabiliti, sefty |

Dis na jɔs sɔm ɛgzampul dɛn fɔ di bɔku bɔku aplikeshɔn dɛn we PVC de yuz. I yunik kɔmbaynshɔn fɔ prɔpati dɛn de mek am wan impɔtant matirial na wi mɔdan wɔl.

Di tin dɛn we dɛn fɔ tink bɔt na di envayrɔmɛnt .

Pɔtɛnɛshɛl rilis fɔ pɔyzin sɔbstans dɛn .

PVC prodakshɔn ɛn yuz kin rilis bad bad tin dɛn, mɔ we dɛn de mek ɛn trowe. Dayɔksin ɛn vaynil klorayd na bay-prɔdakt fɔ PVC prodakshɔn, we de mek bɔku envayrɔmɛnt ɛn wɛlbɔdi prɔblɛm dɛn. We dɛn bɔn PVC ɔ dɛn nɔ du am di rayt we, i kin pul dɛn pɔyzin kemikal dɛn ya, we kin mek di wokman dɛn gɛt pwɛl at ɛn di wɛlbɔdi prɔblɛm dɛn we kin apin to di wokman dɛn.

Plasticizer Migration ɛn Residue .

Fleksibul PVC kin gɛt plasticizers bɔku tɛm fɔ mek i ebul fɔ du mɔ. As tɛm de go, dɛn plasticizers ya kin muf kɔmɔt na di matirial, ɛn dis kin mek di tin dɛn we de lɛf na di bɔdi nɔ gɛt bɛtɛ tin fɔ du. Stɔdi dɔn sho se Phthalates , we na wan kɔmɔn kayn plasticizer, kin ambɔg mɔtalman wɛlbɔdi, afɛkt ɔmon ɛn riprodaktiv sistɛm. Dis dɔn mek di kɔnsyusɔn de gro bɔt di sef we fleksibul PVC de insay kɔshɔma prɔdak dɛm.

Impekt di hevi metal-based heat stabilizers

Frɔm trade trade, PVC dɔn abop pan hεvi mεtal-bεys hεt stεbyulayzεr, patikyular lead , fɔ prεvεnt dεgradεshɔn we dɛn de prosɛs. pan ɔl we dɛn stεbyulayza ya kin wok fayn, dɛn kin put impɔtant risk dɛn we dɛn de trowe ɔ risaykul PVC. Lid kɔntaminɛshɔn insay PVC west de mek risaykul nɔ izi ɛn i de mek di envayrɔmɛnt denja dɛn we de fɔ lɔng tɛm.

| Hɛt Stabiliza | dɛn pɔtɛnɛshɛl risk dɛn . |

| Lida-based stebyulayza dɛn . | Envairomɛnt pɔyushɔn, Risayklin Chalenj dɛn . |

| Tin-based stebyulayza dɛn . | Safer bɔt mɔ kɔst . |

| Kalsiɔm-zink stebyulayza dɛn . | Nɔn-tɔxik, eko-friɛndli ɔltɛrnativ dɛn |

Divɛlɔpmɛnt fɔ nɔ-tɔxik aditiv dɛn .

Fɔ ansa dɛn kɔnsyans ya, di industri dɔn shift to nɔ-tɔxik ɛn eko-friɛndli aditiv sistɛm dɛn . ɔda we dɛn lɛk kalsiɔm-zink stɛbyulayza fɔ chenj di bad bad tin dɛn we kin apin to di ebi ebi mɛtal dɛn. Dɛn dɔn mek Dɛn nyu aditiv ya de mentɛn PVC in pefɔmɛns we nɔ go kɔmprɔmis di envayrɔmɛnt ɔ mɔtalman wɛlbɔdi. Dɛn de tray bak fɔ mek bayɔ-based plasticizers we nɔ de poz di sem risk lɛk tradishɔnal phthalates.

klos-lɔp risaykul sistem dɛn .

Wan impɔtant tin we dɛn de pe atɛnshɔn pan na di PVC industri na fɔ mek klos-lɔp risaykul sistem dɛn. Dis involv fɔ risaykul PVC west bak insay prodakshɔn, ridyus di nid fɔ nyu raw matirial ɛn minimiz di envayrɔmɛnt impak. Vinylplus , we na wan Yuropian PVC risaykul initiativ, dɔn mek strid fɔ mek i izi fɔ gɛda ɛn risaykul PVC prɔdak dɛn. We dɛn mek shɔ se dɛn kin yuz PVC west bak ɛn yuz am bak, di wan dɛn we de mek di tin dɛn kin aim fɔ mek dɛn nɔ trowe dɔti ɛn mek dɛn gɛt sɛkɔla ikɔmi.

Risayklin ɛn dispɔzishɔn fɔ PVC .

Risayklin PVC na chalenj bikɔs ɔf di prɛzɛns ɔf aditiv ɛn impyuriti. Tu men we dɛn de fɔ risaykul PVC:

Mechanical Recycling : involv fɔ grind ɛn riprosɛs PVC west insay nyu prɔdak. Bɔt di prɛzɛns fɔ di kɔntaminɛnt dɛn kin ridyus di kwaliti fɔ di risaykul matirial.

Kεmikכl Risaykl : de brok PVC dכn insay in bεys kכmכpכnt dεm, we dεn kin yuz bak insay nyu prodakshכn prכsεs dεm. Dis we aw dɛn de du tin na mɔ kɔmpleks bɔt i de alaw fɔ mek dɛn yuz mɔ tin dɛn we dɛn kin yuz fɔ risaykul.

If dɛn nɔ trowe PVC di rayt we, mɔ we dɛn bɔn am, i de pul gas dɛn we bad lɛk haydrojɛn klorayd . Sef dispɔzishɔn we dɛn de yuz rili impɔtant fɔ mek di envayrɔmɛnt nɔ bad fɔ di envayrɔmɛnt.

Sastaynɛbul Manufakchurin Praktis .

Fɔ adrɛs di envayrɔmɛnt impak we PVC gɛt, di wan dɛn we de mek di tin dɛn de adopt sataynabul prɔsis . Dɛn tin ya na fɔ ridyus di tin dɛn we dɛn de pul we dɛn de prodyuz ɛn yuz di say dɛn we dɛn de yuz nyu ɛnaji. Bay we dɛn put PVC we dɛn dɔn risaykul insay nyu prɔdak dɛn, di industri kin stɔp fɔ abop pan di vajin matirial dɛn. Kɔmni dɛn de fɛn bak di yus fɔ Bio-PVC , we kɔmɔt frɔm rinuɔbal fidstɔk, as grɛn ɔltɛrnativ to kɔvɛnshɔnal PVC.

Ɔda tin dɛn fɔ du pas PVC .

Insay sɔm aplikeshɔn dɛn, di industri dɛn de fɛn ɔda we dɛn fɔ fɛn ɔda tin dɛn pas PVC. Matirial dɛm lɛk polypropylene ɛn thermoplastic elastomers (TPE) de gi di sem kayn bɛnifit wit smɔl envayrɔmɛnt drawbacks. Fɔ ɛgzampul, TPE kin riples fleksibul PVC insay mɛdikal tub, we dɛn kin yuz polietilen bɔku tɛm na pak aplikeshɔn dɛn. Dɛn ɔda we ya na pat pan wan big tray fɔ ridyus fɔ abop pan di tin dɛn we kin ambɔg dɛn.

Ɛksplen

PVC plastic na versatile, durable, ɛn dɛn kin yuz am bɔku bɔku wan na industri dɛn lɛk kɔnstrɔkshɔn ɛn wɛlbɔdi biznɛs. I kam insay fleksibul ɛn rigid fɔm, wit aplikeshɔn dɛn we de frɔm paip to mɛdikal divays. Nyu advansmɛnt dɛn na eko-friɛndli aditiv ɛn risaykul we dɛn de yuz aim fɔ mek PVC mɔ sataynabul. As teknɔlɔji de impɔtant, bayɔ-based PVC ɛn nɔ-tɔxik ɔltɛrnativ dɛn de kɔmɔt. Fɔ protɛkt di envayrɔmɛnt, rispɔnsibul yus ɛn di rayt we fɔ dispɔz PVC prɔdak dɛn impɔtant fɔ minimiz dɛn impak.

Tips: Yu maybe intres to di ol plastics