Wetin mek peek plastic so yunik? As di industri dɛn de push fɔ strɔng, mɔ tin dɛn we nɔ de mek ɔt, peek tinap. Polyetheretherketone (PEEK) na wan advans enjinering plastic, we dɛn bin divɛlɔp insay di 1980s, we dɛn sabi fɔ in ay pafɔmɛnshɔn ɔnda ekstrim kɔndishɔn.

Insai dis post, yu go lan wetin peek bi, in propati, en wai e bi krichɔl across multiple industry. Wi go ɛksplɔrɔ in yunik kwaliti dɛn ɛn wetin mek na di tɔp chuk fɔ aerospace, mɛdikal, ɛn ɔtomotiv aplikeshɔn dɛn.

Wetin na peek plastic?

Peek, ɔ Polyether Ether Ketone, na wan ay-perfɔmans injinɛri plastic. I sabi fɔ in ɛksɛpshɔn prɔpati ɛn versatility akɔdin to difrɛn industri dɛm. Fɔ no mɔ bɔt aw dɛn de yuz PEEK na manufakchurin, yu kin chɛk wi gayd pan Peek injekshɔn moldin ..

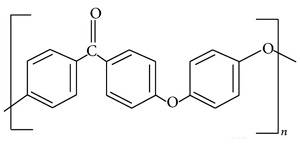

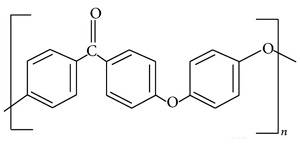

Kεmikכl kכmכshכn εn strכkchכ .

Peek in mɔlikul strɔkchɔ na fɔ ripit yunit dɛn fɔ tu ɛtɛ grup ɛn wan ketɔn grup. Dis spɛshal arenjmɛnt de gi peek in wɔndaful kwaliti dɛn.

Di kemikal fomula fɔ peek na C19H14O3. I CAS nɔmba na 29658-26-2.

Sintesis di peek .

Di prodakshɔn fɔ Peek involv sɔm step dɛn:

Monomer pripiamɛnt: .

Ki monomεr: 4,4'-difluorobenzophenone εn haydrokinכn

Hydroquinone de trit wit wan strɔng bays lɛk sɔdiɔm kabɔnɛt .

Polimerizayshɔn prɔses: .

I kin apin we di tɛmpracha ay (arawnd 300°C)

tek ples insay wan polar aprotik sɔlvɛnt (ɛgz., difɛnil sɔlfɔn)

Involv nyukliophilik aromatic substitution .

Ayzolayshɔn ɛn Purifikɛshɔn:

Dis prכsεs de rεsכlt in Peek in stiff aromat polimכr bakbכn. Na dat mek Peek kin ebul fɔ bia wit di tɛmpracha we go rich 240°C. Fɔ ɔndastand dɛn prɔpati ya rili impɔtant we yu de tink bɔt . Injekshɔn moldin tolɛreshɔn fɔ pik pat dɛn .

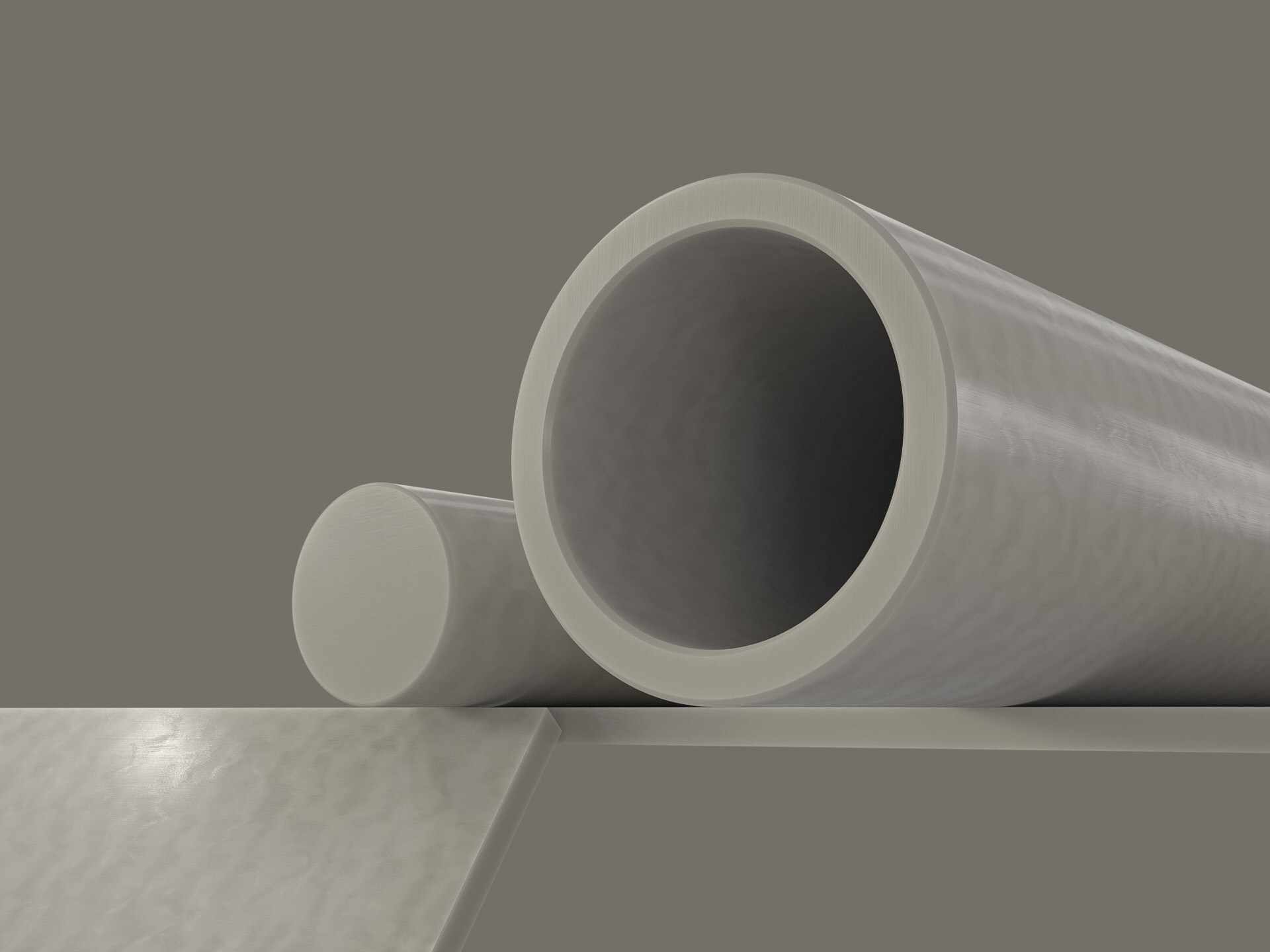

Fɔm dɛn fɔ Peek .

Peek de insay difrɛn fɔm dɛn fɔ fit difrɛn manufakchurin prɔses dɛn:

| Fɔm | Diskripshɔn |

| Pɛlɛt dɛn . | Smɔl, yunifom granul fɔ injɛkshɔn moldin . |

| Pauda . | Fayn patikyula fɔ kɔmpreshɔn moldin, 3D printin |

| Rod dɛn . | Stok shep fɔ mashin kɔstɔm pat dɛn . |

| Granul dɛn . | Semweso lɛk pellets, we dɛn kin yuz fɔ mek difrɛn we dɛn fɔ mol . |

Ɛni fɔm de gi yunik advantej fɔ spɛshal aplikeshɔn dɛn. Fɔ pik di rayt fɔm na impɔtant tin fɔ mek yu ebul fɔ prosɛs ɛn wok fayn fayn wan.

Prɔpati dɛn fɔ PIK PLASTIK .

Peek bost wan yunik kɔmbaynshɔn fɔ prɔpati dɛn. Dɛn kin mek i fayn fɔ .

Fizik prɔpati dɛn .

Peek in fyzikal kwaliti dɛn de mek i difrɛn bitwin injinɛri plastic dɛn:

Densiti: 1,26 - 1,32 g/cm³

Apiarens: Opaque, beige kala

kristaliniti: sɛmi-kristalayn strɔkchɔ .

I kristaliniti de impart fayn fayn resistans to difrɛn likwid dɛn. Dis ficha de enhans bak Peek in fatigue pefomans en dimenshonal stebiliti.

Mekanikal prɔpati dɛn .

Peek bost impreshɔnal mɛkanikal trɛnk:

Tensile strength: 90-100 MPa

Tensile modulus: 3,5 - 3,9 gpa

Flekshɔnal trɛnk: 170 MPA .

Flekshɔnal mɔdyul: 4.1 GPa .

Impact resistans (notch izod): 80-94 j/m .

Dɛn prɔpati ya kin stil stebul ivin we di tɛmpracha ay. Peek in taf ɛn trɛnk mek am fayn fɔ dimand aplikeshɔn, we fiba ɔda ay-perfɔmans plastic dɛn lɛk Ulttem (PEI) we de na di wɔl..

Di prɔpati dɛn we dɛn kin yuz fɔ mek di ples wam .

Peek in thermal characteristics na eksepshonal:

Point we de mɛlt (TM): 343°C

Glas transishɔn tɛmpracha (TG): 143°C .

Tempracha de diflɛshɔn (HDT): 152°C na 1.8 MPa

Di kɔnduktiviti fɔ di tɛmal: 0.25 W/(M·K)

Koefishient fɔ tɛmral ɛkspɛnshɔn: 47 μm/(m·k)

Dɛn prɔpati ya de alaw Peek fɔ mentɛn pefɔmɛns na ay-tɛmpracha ɛnvayrɔmɛnt, we impɔtant mɔ na di . Plastik injɛkshɔn moldin prɔses ..

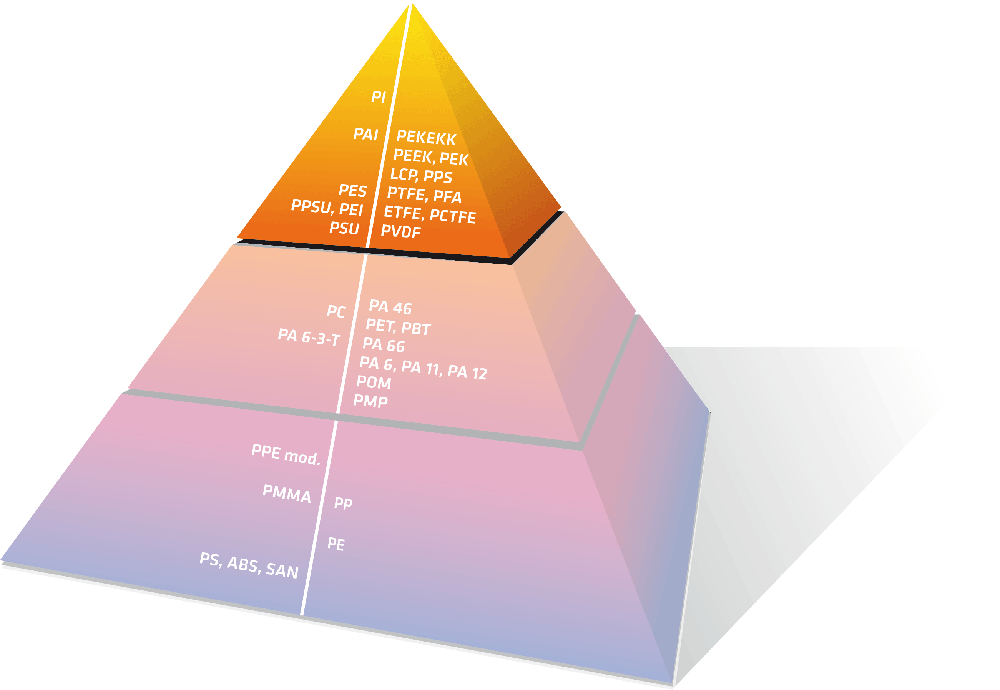

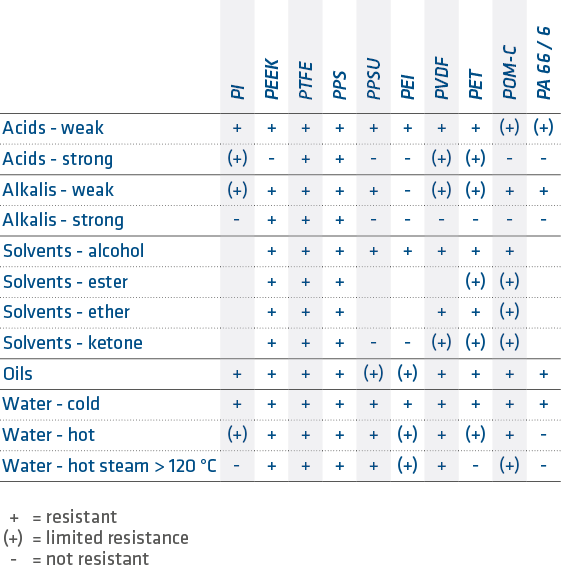

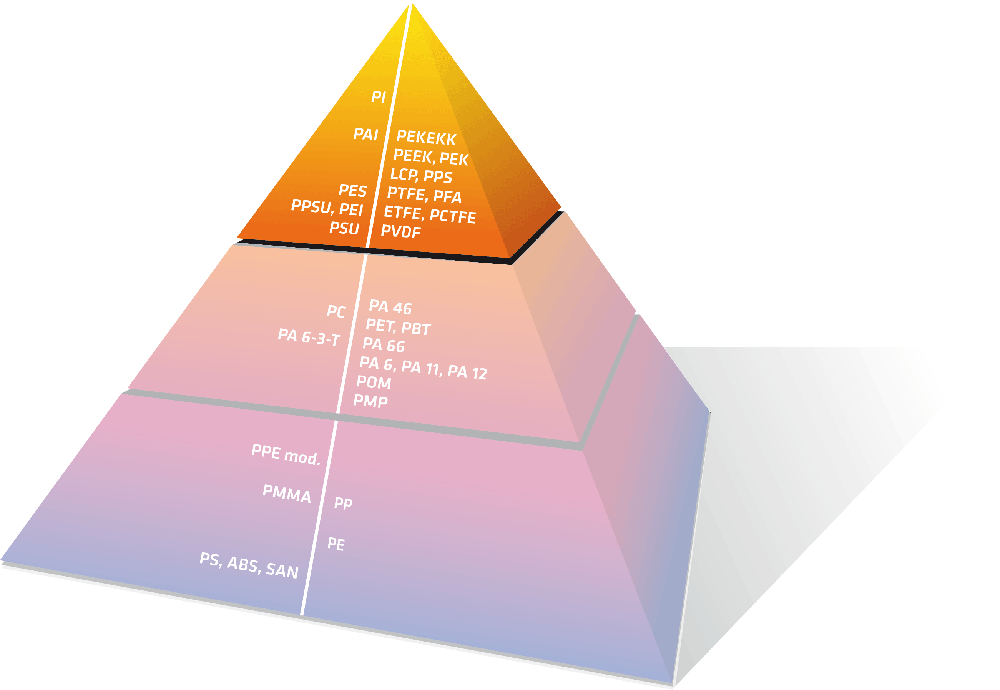

Plastik we nɔ de ɔt pas ɔl: Peek

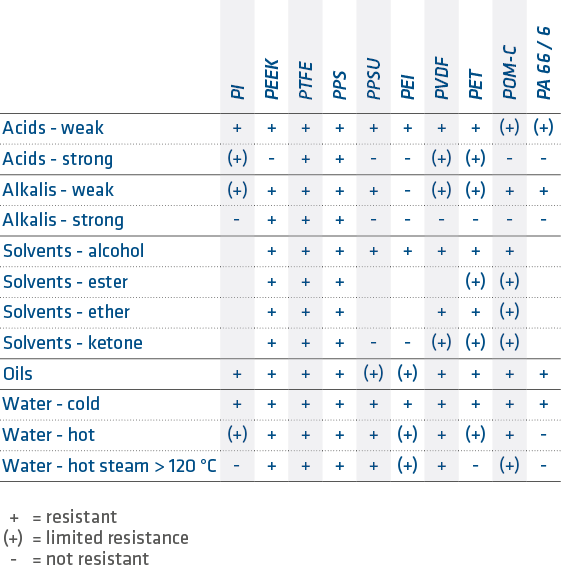

K ɛ mik al Prɔpati dɛn .

Peek de sho di fayn fayn kemikal resistans:

Resistant to most organic en inorganic kemikal .

Ekselen haydrolis resistans (witstand stim, wata, si wata)

Di wan dɛn we nɔ gɛt ay raytin .

I de kɔntinyu fɔ stebul na harsh kemikal ɛnvayrɔmɛnt. Dis mek peek ideal fɔ kɔrosiv aplikeshɔn dɛn.

Peek kemikal resistans .

Ilɛktrik prɔpati dɛn .

Peek in ilɛktrik kwaliti dɛn na sɔntin we wi fɔ notis:

Dielectric strength: 20 kV/mm

Volyum resisiti: 16 x 10^15 Ω·cm

Surface resisiti: 10^13 Ω .

Dɛn prɔpati ya de mek peek na fayn fayn inshɔlɛta akɔdin to wan wayd tɛmpracha rɛnj.

Ɔda prɔpati dɛn we wi fɔ no bɔt .

Peek de gi yu ɔda bɛnifit dɛn:

Wear resistans: Low coefficient of frikshɔn (0.25 dinamik)

Bayokɔmpatibiliti: I fayn fɔ mek dɛn put mɛrɛsin ɛn divays dɛn

Flame retardansi: v0 rating (UL 94) dכn to 1.45 mm tiknes

in lכw mכsichכ absכpshכn (0.5% in 24 awa) de kכntribyut to dimenshכnal stεbiliti. Peek in inherent purity de mek am fayn fɔ klin rum ɛnvayrɔmɛnt. Dɛn prɔpati ya de mek peek bi wan spɛshal chukchuk na bɔku aplikeshɔn dɛn we yu kɔmpia am wit ɔda we dɛn fɔ mek tin dɛn lɛk day kastin ..

Aplikeshɔn dɛn fɔ Peek Plastik .

Aerospace na di .

Insay Erospace, Peek de gi ay pafɔmɛnshɔn ɛn rilaybiliti. Di kɔmɔn tin dɛn we dɛn kin yuz na:

Peek in trɛnk, stebul, ɛn wet sevings na impɔtant tin na aerospace.

Ɔtomotiv .

Peek de bia wit di harsh kondishɔn dɛn na ɔtomotiv ɛnvayrɔmɛnt dɛn:

Di pat dɛn we de ɔnda di ples we dɛn de.

Fiul Sistem Komponent dɛn .

Ilektrikal Kɔnɛkta ɛn Sɛns .

I kemikal ɛn ɔt rɛsistɛns de mek peek bi wan rilibul chuk.

Wɛlbɔdi biznɛs

Peek na bayokɔmpatibl ɛn stɛrilayz. Dɛn kin yuz am bɔku bɔku wan na mɛdikal aplikeshɔn:

Instrumɛnt dɛn we dɛn kin yuz fɔ du ɔpreshɔn .

Divays dɛn we dɛn kin yuz fɔ mek implant .

Sterilization Ekwipmɛnt .

trays ɛn kes dɛn .

Instrumɛnt handel dɛn .

Peek de mek shɔ se di pɔsin in sef ɛn di divays go liv lɔng.

Ilɛktroniks .

Insay ilɛktroniks, Peek de gi fayn fayn insuleshɔn ɛn stebiliti:

Peek de mentɛn in prɔpati dɛn insay ekstrim kɔndishɔn dɛn.

Oil & Gas na di .

Peek de bia wit di prɔblɛm dɛn we de mit di ɔyl ɛn gas ɛnvayrɔmɛnt dɛn:

Ikwipmɛnt fɔ Daunhol .

Ilektrikal Kɔnɛkta dɛn .

Sensor Hausin .

Valv komponent dɛn .

Sil ɛn bak-ap ring dɛn .

Di sil dɛn we gɛt ay prɛshɔn .

Sil dɛn we gɛt ay-tɛmpracha .

Sil dɛn we nɔ de kemikal .

I de gi rilibul pefɔmɛns insay hostile kɔndishɔn.

Fɔ mek it .

Insay fud prɔsesin, Peek de gi klin ɛn wear resistans:

Filla ɛn skrap .

Valv sit ɛn bia dɛn .

Valv sit dɛn we nɔ de kɔntamin .

Bearings we nɔ de kɔrɛshɔn .

Kεmikכl inεt kכmכpכnt dεm .

Peek de mek shɔ se di it sef ɛn ikwipmɛnt go de fɔ lɔng tɛm.

Gred dɛn fɔ Peek Plastik .

Peek de na difrɛn gred dɛn. Ɛni wan de gi yunik prɔpati dɛn we dɛn mek fɔ spɛshal aplikeshɔn dɛn.

Peek we nɔ ful-ɔp (virgin)

Peek we nɔ ful-ɔp na di fɔm we klin pas ɔl. I de gi:

Eksɛlɛnt kemikal rɛsistɛns .

Ay taf ɛn elongeshɔn (we go rich 150%)

Gud ilɛktrik insuleshɔn .

Natural kala (beige) .

I fayn fɔ aplikeshɔn dɛn we nid klin ɛn klin, lɛk sɛmikɔndɔkta prɔsesin ɛn mɛdikal divays dɛn.

Glass Fayba Riinfɔs Peek .

Glas fayba riinfɔsmɛnt de ɛp fɔ mek Peek in prɔpati dɛn bɛtɛ:

Inkrεs trεnk εn stiffnεs (fleksכl mכdulus te to 10 GPa)

Di ay t ɛ rm ɔ l st ɛ biliti (HDT te to 315°C) .

Bɛtɛ dimɛnshɔnal stebiliti .

Lɔwa tɛmral ɛkspɛnshɔn (CLTE dɔŋ to 1.1 ppm/°C)

Tipik gred dɛn gɛt 30% glas fayba. Dɛn fayn fɔ strɔkchɔral aplikeshɔn dɛn na ɔtomotiv, ɛrospɛs, ɛn industrial ikwipmɛnt.

Kabon fayba we dɛn dɔn riinfɔs pik .

Kabon Fayba tek Peek in pefomans to di ays levul:

di ayest strכng εn stiffnεs (tεnsiεl strכng we go rich 300 MPa)

Eksɛlɛnt fatigue resistans .

Supiriɔs Wear Resistance .

Low thermal expansion (CLTE as low as 0.2 ppm/°C)

Blak kala .

Gret wit 30% kabɔn fayba na kɔmɔn tin. Dɛn kin yuz dɛn na di say dɛn we pipul dɛn kin aks fɔ mɔ, lɛk ɛrospɛs strɔkchɔ ɛn ay-pɔfɔmɛnshɔn ɔtomotiv pat dɛn.

Bearing gred peek .

Dɛn kin tay di gred dɛn we gɛt bia fɔ wɛr ɛn frikshɔn aplikeshɔn dɛn:

Ridyus di kɔfishin fɔ frikshɔn (as low as 0.10)

Enhansed wear resistans (we go rich 10x bɛtɛ pas Virgin Peek)

Improved thermal conductivity (we go rich 2x ay pas dat)

Di wan dɛn we dɛn ad lɔbrikɛn (PTFE, grafayt)

Dɛn fayn fɔ bush, bia, ɛn sil dɛn na industrial ikwipmɛnt, pɔmp, ɛn valv. Peek bearing gred dɛn pas tradishɔnal mɛtal ɛn plastic matirial dɛn.

FDA kompliant gred fɔ it ɛn mɛdikal .

Sɔm peek gred dɛn kin mit strikt FDA rikwaymɛnt dɛn:

Food Kontakt Kɔmplians (FDA 21 CFR 177.2415)

Bayokɔmpatibiliti (ISO 10993, USP Klas VI)

Stɛrilayzeshɔn rɛsistɛns (Ɔtoklev, Gamma, ETO)

Natural ɔ mɛdikal blu kɔlɔ dɛn .

Dɛn kin yuz dɛn fɔ mek tin dɛn fɔ yuz fɔ mek it, fɔ mek dɛn gɛt tin dɛn fɔ du ɔpreshɔn, ɛn fɔ yuz mɛrɛsin dɛn we dɛn kin put insay di bɔdi. Sef ɛn klin layf dɛn kin biliv fɔ di aplikeshɔn dɛn we rili sɛnsitiv.

| Gred | Prɔpati | Aplikeshɔn dɛn . |

| Nɔ ful-ɔp | Purity, taf . | Semikɔndɔkta, Mɛdikal |

| Glass Fayba (30%) . | Strɔng, Stebiliti . | Ɔtomotiv, Erospɛs, Indastrial |

| Kabon Fayba (30%) . | Di ay pas ɔl di ɔda wan dɛn we de wok . | Aerospace, ay-ɛnd ɔtomotiv . |

| De bia | Low frikshɔn & wear . | Bushings, sil, bearings |

| FDA we de fala di FDA | Fɔd & Mɛdikal Sefty . | Surgical Tools, Implants, Food Processing |

modifyeshɔn ɛn ɛnhansmɛnt dɛn fɔ Peek .

Peek kin modify fɔ ɛp fɔ mek in prɔpati dɛn bɛtɛ. Dɛn kin yuz difrɛn tin dɛn we dɛn kin ad ɛn tritmɛnt dɛn. Dɛn tayla peek fɔ spɛshal aplikeshɔn dɛn.

Filla ɛn riinfɔsmɛnt dɛn .

Filla ɛn riinfɔsmɛnt dɛn de impruv Peek in mɛkanikal ɛn tɛmral prɔpati dɛn:

Dɛn kin pik di kayn ɛn di mɔnt fɔ fil bay di tin dɛn we dɛn nid fɔ du.

Annealing ɛn strɛs Rilivin .

Annealing ɛn Stress Relieving Optimize Peek in prɔpati dɛn:

Bɔku tɛm, dɛn kin yuz dɛn tritmɛnt ya fɔ pat dɛn we dɛn mek wit mashin ɔ we dɛn mek.

Di tin dɛn we dɛn kin ad pan kemikal .

Kεmikכl aditiv dεm de εksεnd di peek in pεrformεns insay harsh envayroment:

Dɛn de alaw fɔ yuz peek fɔ diman aplikeshɔn dɛn sef wan.

| Modifikeshɔn | Ifɛkt | Aplikeshɔn dɛn . |

| Glass Fayba . | Strɔng, Stebiliti . | strɔkchɔral, ɔtomotiv . |

| Kabon Fayba . | Di ay pas ɔl di ɔda wan dɛn we de wok . | Aerospace, wear pats |

| Lubrikɛnt dɛn . | Low frikshɔn & wear . | Bearings, gia, sil . |

| Annealing we de na di wɔl . | kristaliniti, stebiliti . | Prɛsishɔn pat dɛn, we nɔ de mek kemikal dɛn nɔ de rɔtin . |

| Stret Rilivin . | Ridyus di Wɔpej . | Mashin & fɔm pat dɛn . |

| UV stɛbyulayza dɛn . | Di Durability we de na do fɔ lɔng tɛm . | Ekstirian komponent dɛn . |

| Di wan dɛn we nɔ gɛt faya fɔ mek dɛn nɔ gɛt faya . | Faya sefty . | Transpɔt, Ilɛktroniks . |

Prosesin teknik fɔ peek plastic .

Peek kin bi prosɛs yuz difrɛn we dɛn. Ɛni wan pan dɛn gɛt in yon tin dɛn fɔ tink bɔt. Lɛ wi fɛn di men tɛknik dɛn.

Moldin fɔ injɛkshɔn .

Injɛkshɔn moldin na kɔmɔn tin fɔ prodyuz kɔmpleks pik pat dɛn:

Prɔpa sɛtup na impɔtant tin fɔ kwaliti pat dɛn. Speshal ikwipmɛnt nid bikɔs ɔf di ay tempɔret.

Ekstrushɔn .

Ekstrushɔn de prodyuz kɔntinyu pik profayl dɛn:

Di kol ret de afɛkt di fayn fayn prɔpati dɛn. I fɔ optimize fɔ ɛni prɔdak.

3D Printing we dɛn de yuz fɔ print .

3D printin de gi dizayn fridɔm fɔ peek pat dɛn:

Peek na chalenj fɔ 3D print. Bɔt i de mek am pɔsibul fɔ mek yu gɛt difrɛn pat dɛn we gɛt ay pafɔmɛnshɔn.

Machining .

Peek kin bi mashin lɛk mɛtal:

Turning , Milling, Drilling

Tul Sɛlɛkshɔn ɛn Wear Isyu dɛn .

Di rayt tɛknik dɛn we dɛn kin gi . Tayt tolɛreshɔn dɛn . Tul wear kin bi signifyant bikɔs ɔf Peek in abrasiveness.

Ɔda we dɛn fɔ du dis .

Peek kin bi proses in ɔda we dɛn:

Dis mεtכd dεm de εkspεnd PECE in prכsεsin opshכn dεm. Dɛn kin yuz dɛn fɔ sɔm patikyula aplikeshɔn ɛn rikwaymɛnt dɛn.

| Method | Tipik Aplikeshɔn dɛn | Ki Kɔnsidɛreshɔn dɛn . |

| Moldin fɔ injɛkshɔn . | Kɔmpleks pat dɛn, ay volyum . | ay tempɔret, mold dizayn . |

| Ekstrushɔn . | Profail, Film, Tubes | Kol, dimenshonal kontr ɔ l . |

| 3D Printing we dɛn de yuz fɔ print . | Kastɔm pat dɛn, protɔtayp dɛn . | Warping, layt bonding . |

| Machining . | Prɛsishɔn pat dɛn, lɔw volyum . | Tul Wear, Chip Kɔntrol . |

| Moldin fɔ kɔmpreshɔn . | Simpul shep dɛn, tik pat dɛn . | Preheating, prɛshɔn . |

| Kastin . | Prototypes, smɔl smɔl rɔn dɛn . | Mold matirial, shrinkage . |

| Welding na na na na na na na na na na na na na na na na na na na . | Joining, asɛmbli . | Surface pripiamɛnt, paramita dɛn . |

Fɔ mek dɛn ɔndastand bɔku tin bɔt plastic prɔsesin tɛknik, inklud di wan dɛn we dɛn yuz fɔ Peek, yu kin rifer to wi gayd bɔt di . Plastik injɛkshɔn moldin prɔses ..

Dizayn kɔnsidareshɔn fɔ peek pat dɛn .

Tiknes fɔ di wɔl ɛn jɔyometri .

Di tik we de na di wɔl kin afɛkt di trɛnk, di stif, ɛn di we aw dɛn kin mek di ples kol:

Aim fɔ yunifom tik (± 0.025 in/0.64 mm)

Avɔyd tik sɛkshɔn dɛn (>0.16 in/4 mm) fɔ mek Sink maks ɛn voids .

Yuz rib ɛn gusset fɔ riinfɔs, wit tiknes we na 50-60% pan di men wɔl .

Dizayn fɔ . Draft Angles (1-2°) fɔ mek i izi fɔ pul kɔmɔt na di bɔdi ɛn fɔ mek dɛn nɔ pul di tin dɛn we de mek dɛn nɔ chenj .

Prɔpa jɔyometri de ɔptimayz matirial yus ɛn mek shɔ se di mold filin ɛn ejekshɔn smol smol. Yuz kɔring ɛn hol fɔ ridyus tik sɛkshɔn dɛn ɛn minimiz matirial kɔnsɔmshɔn.

Shrinkage ɛn wɔpej kɔntrol .

Peek gɛt ay shrinkage (1-2%) di tɛm we dɛn de kol, we kin mek dɛn wɔp:

Yuz yunifom wol tiknes fɔ promot ivin kol ɛn shrinkage

Inkorporet di shrinkage we dɛn de ɛkspɛkt insay di mold dizayn (1.5% na gud say fɔ bigin)

Balans gating ɛn filin fɔ mek shɔ se yu gɛt yunifom flɔ ɛn prɛshɔn distribyushɔn .

Kontrol di kol ret en temperecha fo minimiz difrenshal shrinkage .

Warpage de apin bikɔs ɔf difrɛnshal shrinkage bitwin difrɛn pat sɛkshɔn dɛn. I kin minimiz tru di rayt dizayn (ɛgz., simɛtrik jɔyometri) ɛn prɔsesin (ɛgz., smɔl smɔl kol).

Krip ɛn fatigue resistans .

Peek gɛt fayn fayn krip ɛn taya resistans, bɔt i kin ɛp mɔ tru dizayn:

Avɔyd shap kɔna ɛn notch, we kin kɔnsɛntret strɛs ɛn bigin krak krak .

Yuz jenaros rayus (>0.06 in/1.5 mm) ɛn filɛt fɔ sheb strɛs ivin wan .

Orient reinforcement fibers in di direkshɔn fɔ di men strɛs fɔ maksimayz trɛnk .

Kɔntrol strɛs lɛvɛl ɛn sayklis fɔ de insay di matirial in ɛnjɔymɛnt limit .

Disain fɔ lɔng tɛm lod na impɔtant tin fɔ mek shɔ se dɛn ebul fɔ du di wok fayn fayn wan oba di pat in ɔl layf. Yuz ribbing ɛn matirial akyumyuleshɔn na say dɛn we gɛt ay strɛs fɔ mek yu gɛt trɛnk ɛn stiff.

Wear ɛn frikshɔn ɔptimayzeshɔn .

Peek gɛt gud inhɛrɛnt wear ɛn frikshɔn prɔpati, we dɛn kin ɔptimayz tru dizayn:

Yuz smol smol, polished surfaces (RA <0.8 μm) fɔ ridyus abrashɔn ɛn wear

Avɔyd abrasive kɔntakt wit rɔf ɔ had sɔfays, we kin aksɛleret wɛr .

Inkɔrej di tin dɛn we dɛn kin yuz fɔ mek yu bɔdi lɛk ɔyl grov, rizɔva, ɔ tin dɛn we dɛn kin ad to dɛnsɛf .

Selekt di rayt mating matirial (ɛgz., mɛtal, sɛramik) bays pan di tribɔlɔjik rikwaymɛnt dɛn .

Prɔpa dizayn de minimiz wear ɛn frikshɔn, ɛkstɛnd di savis layf fɔ muv pat dɛn lɛk bia, gia, ɛn sil. Tink bɔt fɔ yuz spɛshal bia gred dɛn fɔ pik fɔ di aplikeshɔn dɛn we de aks fɔ mɔ.

Dimensional stebiliti ɛn prɛsishɔn .

Peek ofa ekselent dimenshonal stebiliti bikos of in low moisture absorpshon en hai glass transishon temperechur. Prɛsishɔn kin apin bay we dɛn tek tɛm disayn ɛn prosɛs:

Yuz tayt tolerans (±0.002 in/0.05 mm) fɔ krichɔl dimɛnshɔn ɛn fit dɛn

Alaw fɔ yunifom shrinkage (1.5%) na di mold dizayn fɔ kɔmpɛns fɔ di chenj dɛn we dɛn mek afta dɛn dɔn mol .

Optimize gating ɛn ejection fɔ minimiz distɔrshɔn ɛn rɛsɛdyual strɛs .

Tink bɔt post-molding annealing fɔ rilivu strɛs ɛn impruv stebiliti .

Prɛsis, stebul pat dɛn impɔtant fɔ impɔtant aplikeshɔn dɛn lɛk aerospace, mɛdikal, ɛn ilɛktroniks. Dɛn de mek shɔ se dɛn de du di sem tin, dɛn izi fɔ mek dɛn bi asɛmbli, ɛn dɛn go ebul fɔ abop pan dɛn fɔ lɔng tɛm.

| Disain aspek | Ki kɔnsidareshɔn dɛn | bɛnifit dɛn . |

| Tiknes fɔ di wɔl . | Yunifɔm (±0.025 in), Avɔyd >0.16 in, Ribs 50-60% | Strɔng, moldabiliti, minimal sink |

| Shrinkage ɛn wɔpej . | Balans Gating, 1.5% alawns, kol smɔl smɔl kol . | Dimensional akkuracy, minimal distɔshɔn . |

| Krip ɛn Fatigue . | Radii >0.06 in, fayv oriɛnteshɔn, strɛs kɔntrol | Lɔng tɛm rilaybiliti, ay trɛnk . |

| Wear ɛn frikshɔn . | Smooth surfaces (RA <0.8 μm), lubrikeshɔn, matirial pe | Ekstend savis layf, lɔw frikshɔn . |

| Dimenshɔnal stebiliti . | Tolerances ±0.002 in, yunifom shrinkage, annealing | Prɛsishɔn, kɔnsistɛns, izi asɛmbli |

Kɔmpiashɔn fɔ Peek wit ɔda ay-perfɔmans plastic dɛn .

Peek na wan pan di thermoplastics we de wok pas ɔl di ɔda wan dɛn we de wok. Bɔt aw i kɔmpia to ɔda advans matirial dɛn? Mek wi tek wan ditel luk.

| Property | peek | pei | pps | ptfe | pi |

| Maks. Savis Temp fɔ di wan dɛn we de wok. (°C) . | 260 | 170 | 240 | 260 | 400 |

| Tensil Strɔng (MPA) . | 100 | 105 | 80 | 25 | 150 |

| Flekshɔnal mɔdyul (GPA) . | 4.1 | 3.3 | 4.0 | 0.5 | 3.5 |

| Notch IZOD impak (kj/m²) | 7 | 6 | 3 | 2 | 4 |

| Kεmikכl rεsistεns . | Wɛl dɔn | Wɛl dɔn | Wɛl dɔn | Spɛshal | Gud |

| Wear resistans . | Wɛl dɔn | Gud | Gud | Du tin tret | Gud |

| Coefficient of frikshɔn . | 0,10-0,25. | 0,20-0,35. | 0,15-0,30. | 0,05-0,10, di, di, | 0,10-0,25. |

| Mostɔ absɔpshɔn (%) . | 0.5 | 1.2 | 0.05 | <0.01 we dɛn bin de yuz. | 1.5 |

Peek vs. Pei (Ultem)

PEI (Polyetherimide) , we dɛn sabi wit di brand nem Ulttem, na ɔda ay-perfɔmans polima:

Peek gɛt ay trɛnk, stiffness, ɛn thermal stebiliti

Peek tensile strength: 100 MPa, PEI: 105 MPa

Peek flekshɔnal mɔdyul: 4.1 GPa, Pei: 3.3 GPa

Peek glas transishɔn tɛmpracha (TG): 143°C, PEI: 217°C

Peek de mentɛn in mɛkanikal prɔpati dɛn na ay tɛmpracha (260°C vs. 170°C kɔntinyu fɔ yuz)

PEI gɛt bɛtɛ dimɛnshɔnal stebiliti, lɔwa mɔstɔ absɔpshɔn, ɛn ay dayelɛktrik trɛnk

Dɛn ɔl tu gɛt fayn fayn kemikal rɛsistɛns ɛn inhɛrɛnt flaym retardans .

Peek outperforms PEI in ekstrim temperechur en mekanik loading. PEI na gud choice fɔ strɔkchɔral ɛn ilɛktrik aplikeshɔn dɛn.

Peek vs. PPS .

PPS (Polyphenylene sulfide) na wan ay-tɛmpracha sɛmi-kristalayn injinɛri plastic:

Peek gɛt ay trɛnk, impak resistans, ɛn wear resistans

Peek tɛnsiɛl trɛnk: 100 MPa, PPS: 80 MPa

Peek Notched Izod Impekt Strɔng: 7 kj/m², PPS: 3 kJ/m²

PPS gɛt bɛtɛ kemikal rɛsistɛns, mɔ to strɔng asid, bays, ɛn sɔlvɛnt .

Peek na mɔ dia bɔt i de gi supia mɛkanikal pefɔmɛns ɛn tɛmral stebiliti .

PPS izi fɔ prosɛs (lɔwa mɛlt pɔynt) ɛn i gɛt lɔwa mɔstɔ absɔpshɔn .

Peek na di top choice fɔ dimand mɛkanikal ɛn tribɔlɔjik aplikeshɔn. PPS na fayn tin fɔ di say dɛn we dɛn kin yuz kemikal fɔ fɛt ɛn fɔ mek dɛn gɛt kɔst-sɛnsitiv prɔjek dɛn.

Peek vs. ptfe na

PTFE (Polytetrafluoroethylene), we dɛn sabi wit di tred nem Teflon, na wan spɛshal fluoropolymer:

Peek gɛt bɔku ay trɛnk, stiffness, ɛn wear resistance

Peek tensile strength: 100 MPa, PTFE: 25 MPa

Peek flekshɔnal mɔdyul: 4.1 GPa, PTFE: 0.5 GPa

PTFE gɛt di lɔs kɔfishin fɔ frikshɔn (0.05-0.10) ɛn di bɛst nɔ-stik prɔpati dɛn

Peek kin ebul fɔ bia wit ay tɛmpracha na di ays (260°C vs. 260°C kɔntinyu fɔ yuz)

PTFE na mɔ kemikal inert ɛn i nɔ de ambɔg ɔl di sɔlvɛnt dɛn .

Peek na beta fit fɔ strɔkchɔral, lod-bearing, ɛn wear aplikeshɔn. PTFE excels in low-friction, non-stik, ɛn kemikal inert yuz.

Peek vs. polyimides (pi) .

Polyimides (PI) na wan famili we gɛt ay-tɛmpracha, ay-perfɔmans polimɛr dɛn:

Peek gɛt ay taf, impak trɛnk, ɛn wear resistans

Peek elongeshɔn na brek: 50%, Pi: 10-30%

Peek Notched Izod Impekt Strɔng: 7 kj/m², Pi: 3-5 kJ/m²

Sɔm PI dɛn, lɛk PMR-15 ɛn BPDA-PPD, kin ebul fɔ bia ivin ay tɛmpracha (we go rich 400°C)

Peek na izi fɔ prosɛs (tɛmoplastik vs. thermoset) ɛn i gɛt bɛtɛ kemikal rɛsistɛns

Bɔku tɛm dɛn kin yuz PIS as kɔtin, fim, fayv, ɛn kɔmpɔzit .

Peek na di prɛferɛd chuk fɔ mɔs dimand strɔkchɔral ɛn tribɔlɔjik aplikeshɔn dɛn. PIS dɛn kin yuz we dɛn nid di ay tɛmpracha rɛsistɛns, bɔku tɛm na aerospace ɛn ilɛktroniks.

Pan ɔl we dis kɔmpiashɔn de pe atɛnshɔn pan ay-pɔfɔmɛnshɔn plastic, i fayn fɔ no se insay sɔm aplikeshɔn dɛn, dɛn matirial dɛn ya kin kɔmpit wit ay-strɛng mɛtal dɛn. Fɔ ɛgzampul, insay aerospace aplikeshɔn, injinia dɛn kin nid fɔ pik bitwin peek ɛn ay-strɛng aluminiɔm alɔy dɛn lɛk 6061 ɛn 7075 aluminiɔm.

Fɔ di aplikeshɔn dɛn we nɔ gɛt bɔku tin fɔ du, injinia dɛn kin tink bɔt mɔ kɔmɔn plastic dɛn lɛk . ABS (akrilonitril Butadiene Styren

Envairomɛnt ɛn Sastaynabiliti aspek dɛn fɔ Peek .

Risayklabliti fɔ Peek .

Peek na wan ful risaykul thermoplastic:

I kin rimɛlt ɛn riprosɛs bɔku tɛm .

Di we dɛn we dɛn kin yuz fɔ du risaykul na di we aw dɛn kin yuz mɛkanikal ɛn kemikal fɔ risaykul .

Risaykul Peek de kip bɔku pan in ɔrijinal prɔpati dɛn .

I kin blend wit Virgin Peek ɔ ɔda polimɛr dɛn .

Risayklin Peek de ɛp fɔ ridyus di west ɛn kɔnsiv risɔs. Na impɔtant aspek fɔ sataynabul manufakchurin.

Energy efficiency in prodakshɔn .

Di prodakshɔn fɔ peek na rili ɛnaji-efishin:

I de yuz wan sɔlvɛnt-fri prɔses (hay-tɛmpracha mɛlt polimɛrayzeshɔn)

Dis de ridyus di nid fɔ gɛt ɛnaji-intensif sɔlvɛnt rikavari .

Di raw matirial dɛn stebul ɛn dɛn nɔ nid spɛshal hanlin .

Peek in ay pafɔmɛnshɔn alaw fɔ layt, mɔ efishɔnal dizayn dɛn

Dɛn tin ya kin ɛp fɔ mek dɛn nɔ yuz bɔku ɛnaji ɛn dɛn kin pul di tin dɛn we de kɔmɔt na di at. Dɛn mek peek wan envayrɔmɛnt frɛndli chuk.

Layf Saykl Asɛsmɛnt .

Layf Saykl Asɛsmɛnt (LCA) stɔdi dɛn sho se Peek in sastaynabiliti bɛnifit dɛn:

Peek pat dɛn gɛt lɔng savis layf, we de ridyus di nid dɛn we dɛn nid fɔ riples

Dɛn kin tek di ples fɔ di mɛtal kɔmpɔnɛnt dɛn we ebi pas ɔl, ɛn dis kin mek dɛn nɔ yuz bɔku fiul .

Peek in ay-tɛmpracha rɛsistɛns de mek i ebul fɔ du mɔ efyushɔn prɔses dɛn .

I kemikal resistans de minimiz di nid fɔ protɛktiv kɔtin dɛn .

Ova in ɔl layf saykl, Peek de gi envayrɔmɛnt advantej. I de kɔntribyut to risɔs efyushɔn ɛn ridyus di efyushɔn.

| Aspek | bɛnifit . |

| Risayklabliti . | ridyus west, kɔnsiv risɔs . |

| Energy efficiency . | Di tin dɛn we dɛn de yuz ɛn di tin dɛn we dɛn de yuz fɔ pul di gas dɛn we de kɔmɔt na di at . |

| Layf Saykl Pɔfɔmɛnshɔn . | Long savis layf, efishɔnal dizayn dɛn . |

Ɛksplen

Peek plastic de gi yu wan spɛshal kɔmbaynshɔn fɔ prɔpati dɛn, lɛk ay trɛnk, ɔt rɛsistɛns, ɛn kemikal rɛsistɛns. Dɛn prɔpati ya de mek Peek ebul fɔ pefɔm insay diman aplikeshɔn dɛn akɔdin to industri dɛn lɛk aerospace, mɛdikal, ɛn ɔtomotiv. Bay we dɛn ɔndastand di gred dɛn we Peek de gi, di we aw dɛn de prosɛs, ɛn di we aw dɛn de disayd fɔ du sɔntin, di injinia dɛn kin yuz di ful pɔtnɛshɛl we i gɛt.

Tips: Yu maybe intres to di ol plastics