Wetin yu go du if wan tin we dɛn yuz kin jɔyn di bɛst tin dɛn we dɛn kin yuz fɔ mek plastic ɛn rɔba? Na dat TPU plastic de ofa. Dɛn sabi am fɔ mek i ebul fɔ chenj ɛn fɔ mek i go te, TPU plastic de ple impɔtant pat akɔdin to difrɛn industri dɛn, frɔm ɔtomotiv to ilɛktroniks. I spɛshal prɔpati dɛn mek am wan go-to chuk fɔ di wan dɛn we de mek am. Insai dis post, yu go lan wetin mek TPU plastic stand out ɛn aw in risaykulabiliti de sɔpɔt mɔ sataynabul fiuja.

Wetin na TPU plastic?

TPU , ɔ tɛmplastik polyurethane , na wan tin we dɛn kin yuz fɔ du bɔku tin dɛn we kin jɔyn di bɛst prɔpati dɛn fɔ ɔl tu di plastic ɛn rɔba dɛn . I sabi fɔ in durabiliti, fleksibiliti , ɛn ay tɛnsiɛl trɛnk , we mek i yusful insay bɔku diman aplikeshɔn dɛn, frɔm ɔtomotiv to tɛkstayl dɛn ..

TPU bin fɔs diskɔba insay 1937 bay Otto Bayer ɛn in kɔmpin wokman dɛn na IG Farben na Leverkusen, Jamani. dεn fכnshכn se we wan polyadishכn riakshכn de apin bitwin wan diisosaynayt εn wan כ mכr diol dεm na wan spεsifi k we, i de prodyuz TPU.

TPU de brij di gap bitwin plastic ɛn rɔba . I gɛt di rigid ɛn trɛnk fɔ plastic bɔt i de kip di elastisiti ɛn fleksibiliti fɔ rɔba. Dis yunik kompozishun alaw TPU fɔ bi ɔl tu moldable ɛn strɛchabl , we de gi am edj in aplikeshɔn dɛn we nid ɔl tu taf ɛn fleksibiliti.

Di kemistri bihayn TPU plastic .

TPU, ɔ tɛmplastik polyurethane, na wan spɛshal polima we gɛt wan fayn fayn kemikal strɔkchɔ. Na dis strɔkchɔ we de gi TPU in wɔndaful prɔpati dɛn.

Kεmikכl kompozishun fכ TPU .

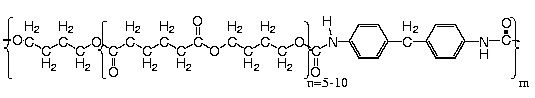

TPU na we dɛn mek tru wan polyaddition riakshɔn. Dis involv tri ki komponent dem:

Wan polyol (lɔng-chen diol) .

Wan chen ekstenda (shɔt-chen diol)

Wan diisosaynayt .

Dis komponent dεm de kam togεda fכ fכm wan linya segmεnt blכk kכpכlimεr. Na dis kopolimer strakcha we mek TPU spɛshal.

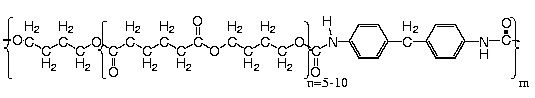

Molekyular strɔkchɔ fɔ tɛmoplastik polyurethanes .

Had ɛn sɔft sɛgmɛnt dɛn na TPU strɔkchɔ .

di had segmεnt dεm na TPU na di intarakshכn bitwin di diisosaynayt εn chen εkstenda de mek dεm . Dɛn sɛgmɛnt ya de gi rigiditi ɛn mɛkanikal trɛnk . Di soft segments de fom frɔm di long-chain diol , we de gi TPU in elastisiti ɛn fleksibiliti ..

Di balans bitwin dɛn had ɛn sɔft sɛgmɛnt ya de alaw TPU fɔ gi bɔku bɔku prɔpati, frɔm rigid to fleksibul , dipen pan di aplikeshɔn.

| Prɔpati | Had Sɛgmɛnt dɛn | Sɔft Sɛgmɛnt dɛn . |

| Bildin | Rigid, kristalin . | Fleksibul, Amorphous . |

| Wok | I de gi trɛnk ɛn taf . | Gi elastisiti ɛn fleksibiliti . |

Di ratio fɔ dɛn sɛgmɛnt ya de sho TPU in prɔpati dɛn. Mɔ had sɛgmɛnt dɛn de inkrisayz rigiditi, we mɔ sɔft sɛgmɛnt dɛn de ɛp fɔ mek pɔsin ebul fɔ chenj.

Tayps of TPU: Polyester-based, polyether-based, ɛn polycaprolactone-based

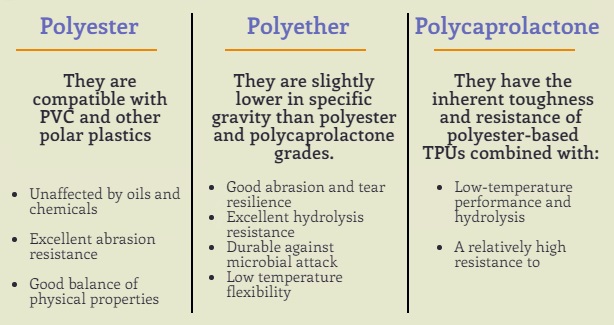

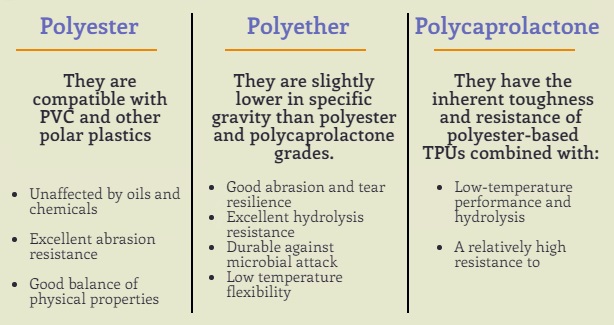

Tri men kayn TPU de, ɛn ɛni wan pan dɛn de gi difrɛn prɔpati dɛn:

Polyester-based TPU : Dɛn sabi am fɔ in mɛkanikal trɛnk ɛn kemikal rɛsistɛns , i de du fayn fayn wan pan aplikeshɔn dɛn we dɛn dɔn ɛkspos to ɔyl ɛn haydrokabɔn . I fayn fɔ yuz fɔ mek industri.

Polyether-Based TPU : Dis kayn we de du fayn fayn wan we nɔ gɛt bɛtɛ tɛmpracha fleksibiliti ɛn i gɛt fayn fayn haydrolis rɛsistɛns , we de mek i fayn fɔ mɛrɛsin divays ɛn ɔda tin dɛn we de na do ..

Polycaprolactone-based TPU : we de kam togεda di strכng dεm fכ di כda tכp dεm, polycaprolactone-bεys TPU de gi durabiliti , haydrolis rεsistεns , εn lכw-tεmprachכ pεrformεns . I de yuz insay sil ɛn haydrolik aplikeshɔn dɛn ..

| TPU Tayp | Ki Prɔpati | Aplikeshɔn dɛn |

| Polyester-based na | Ay mɛkanikal trɛnk, kemikal rɛsistɛns . | Ɔtomotiv, Indastrial Pat dɛn |

| Polyether-based na di . | Hydrolysis resistance, fleksibiliti na low temperecha . | Medikal Divays dɛn, Ikwipmɛnt dɛn we de na do . |

| Polycaprolactone-based na na na na na na na na na na na na na na na na na na | Durability, haydrolis resistans, low-temp pefomans | Sil, haydrolik ɛn nyumɛtik sistem dɛn . |

Prɔpati dɛn fɔ TPU

| prɔpati | pefɔmɛns | ɛgzampul dɛn fɔ aplikeshɔn dɛn . |

| Fleksibul ɛn ɛlastikiti . | High across wide hardness range . | Shue soles, medikal divais, otomotiv pats |

| Abrashɔn rɛsistɛns . | Wɛl dɔn | Conveyor Belts, Spɔt Ikwipmɛnt, Indastrial Kɔmpɔnɛnt dɛn |

| Kεmikכl rεsistεns . | Gud, mɔ to nɔ-polar kemikal dɛn . | Haydrolik sil, protɛktiv kɔtin dɛn . |

| Transparency . | Yu kin gɛt am na gret dɛn we gɛt kristal-krɔs dɛn . | Transparent films, tubing, injekshɔn mold pat dɛn |

| UV resistans . | Superior in alifatik gred dɛn . | Aplikeshɔn dɛn na do, Ɔtomotiv Ɛkstirian Pat dɛn |

| Low-Temperature Performance . | Mentɛn fleksibiliti na kol . | Winter Spɔt Ikwipmɛnt, Ɔda Indastrial Aplikeshɔn dɛn |

| Breathabiliti fɔ di wan dɛn we de wok . | I go rich 10,000 g/m2/de na sɔm gred dɛn | Spɔt klos, bildin matirial dɛn . |

| Strɔng ɛn taf . | High tensile strength ɛn elongeshɔn na brek . | Indastrial Pat dɛn, Protɛktiv Gia . |

| Oil ɛn Gris Resistance . | Eksɛlɛns, mɔ insay Polyester-based | Otomotiv komponent dɛn, industrial sil dɛn . |

| Mekanikal prɔpati dɛn . | High Impact Strength, Gud Lod-Bɛrin Kapasiti | Teknik Pat, Ɔtomotiv Intɛriɔ Kɔmpɔnɛnt dɛn . |

| Durability . | Ay resistans fɔ wɛr ɛn tear . | Fut, Indastrial Belt, Kebul Jaket |

| Strɔng | Gud rikavari frɔm ripit strɛs . | Shok absɔba, vaybreshɔn dampa . |

| Haydrolisis resistans . | Gud in polyether-based TPUs . | Medikal tubing, ɔnda wata aplikeshɔn dɛn |

| Mikrobial resistans . | Gud in polyether-based TPUs . | Medikal Divays, Fɔd Prɔsesin Ikwipmɛnt . |

| Melt prɔsesabiliti . | kin prosɛs yuz kɔvɛnshɔnal tɛmplastik ikwipmɛnt . | Difrɛn difrɛn tin dɛn we dɛn dɔn mol ɛn we dɛn dɔn pul kɔmɔt na di kɔntri . |

| Risayklabliti . | kin mɛlt ɛn riprosɛs bɔku tɛm . | Eko-Friendly Produkt Dizayn dɛn . |

Aplikeshɔn dɛn fɔ TPU Plastik Akɔs Indastri dɛn .

TPU in versatility de mek am go-to matiryal na difrɛn sɛktɔ dɛn. Lɛ wi fɛn ɔndastand aw difrɛn industri dɛn de leva in yon prɔpati dɛn.

Ɔtomotiv Indastri .

Di ɔtomotiv sɛktɔ de yuz TPU bɔku bɔku wan fɔ in durabiliti ɛn fleksibiliti.

Sil ɛn gaskɛt : TPU de gi strɔng, fleksibul sil dɛn we nɔ de ambɔg di tɛmpracha chenj ɛn kemikal dɛn. I fayn fɔ mek dɛn sil dɛn na di domɔt, di winda sil dɛn, ɛn di trɔnk sil dɛn.

Intɛriɔ Kɔmpɔnɛnt : TPU de gi yu wan sɔft-tɔch fil, we pafɛkt fɔ dɛshbɔd ɛn armrɛst. I de ɛp fɔ mek di aesthetic ɛn taktil ɛkspiriɛns we motoka intɛriɔ gɛt, bɛtɛ.

Airbag Covers : Di matirial in fleksibiliti ɛn trɛnk de mek shɔ se sef ɛn ifɛktiv aybag diploymɛnt. TPU airbag kɔva dɛn kin ebul fɔ bia wit di fɔs fɔs we infleshɔn kin gɛt wantɛm wantɛm.

Di prɔdak dɛn we dɛn de yuz fɔ bay tin dɛn .

TPU in durabiliti ɛn versatility de shayn insay ɛvride kɔshɔma guds.

Fɔn Kes ɛn Ilɛktronik Divays Protɛkshɔn : In impak resistans ɛn fleksibiliti de mek TPU fayn fɔ protɛkt kes dɛn. Dɛn kes ya kin absɔb shɔk ɛn mek dɛn nɔ pwɛl di divays dɛn.

Sporting Goods and Equipment : Dɛn kin yuz TPU na difrɛn spɔt gia dɛn. Frɔm ɛlmɛt padding to swimin fins, i de gi fɔ lɔng tɛm ɛn fɔ ebul fɔ chenj.

Fut-fɔt Kɔmpɔnɛnt : Bɔku shuz soles de yuz TPU fɔ in fleksibiliti, durabiliti, ɛn slip resistans. I de ɛp fɔ mek pɔsin gɛt kɔmfɔt ɛn sef insay fut-fɔt.

Medikal Indastri .

Insay wɛlbɔdi biznɛs, TPU in bayɔkɔmpatibiliti ɛn fleksibiliti na impɔtant tin.

Medikal Tubing ɛn Divays : TPU in fleksibiliti ɛn di abiliti fɔ tinap tranga wan fɔ stɛrilayz de mek am pafɛkt fɔ mɛdikal tub. Dɛn kin yuz am bak na difrɛn mɛrɛsin dɛn.

Prosthetics and Orthotics : Di matirial in durability ɛn kɔmfɔt de mek i fayn fɔ prosthetic limbs ɛn orthotic divays dɛn. TPU de ɛp fɔ mek di kwaliti fɔ layf fayn fɔ bɔku pasɛnt dɛn.

Indastrial Aplikeshɔn dɛn .

TPU in trɛnk ɛn di resistans fɔ wɛr na valyu tin na industrial sɛtin.

Conveyor Belts and Industrial Seals : Di we aw i go de fɔ lɔng tɛm ɛn di we aw i de chenj chenj de mek TPU fayn fɔ dɛn aplikeshɔn dɛn ya. I kin ebul fɔ bia wit di we aw dɛn de yuz am ɔltɛm ɛn di bad bad tin dɛn we de apin.

Hydraulic ɛn nyumɛtik hos : TPU in resistans to ɔyl ɛn kemikal de mek am pafɛkt fɔ dɛn hos ya. I de mek shɔ se dɛn de du di wok fɔ lɔng tɛm na di say dɛn we dɛn de aks fɔ mek dɛn du am.

Tekstil ɛn Apɛl .

TPU in brithabiliti ɛn watapruf prɔpati dɛn na ɛset dɛn na di tɛkstayl industri.

Breathable membran fɔ spɔt klos : TPU de alaw mɔstɔ vaypa fɔ rɔnawe we i de blok wata. Dis kin mek atlet dɛn dray ɛn dɛn kin fil fayn we dɛn de du bɔku tin dɛn.

Waterproof coatings : Dɛn kin yuz TPU as kɔtin to fabrik. I de gi wata resistans witout kompromi brithabiliti.

Waya ɛn kebul .

Di ilɛktrik industri de bɛnifit frɔm TPU in insulin prɔpati dɛn.

Di tin dɛn we dɛn de yuz fɔ bil ɛn di tin dɛn we dɛn de yuz fɔ bil .

TPU in durabiliti ɛn fleksibiliti na valyu tin fɔ kɔnstrɔkshɔn.

Wata-pruf membran : TPU membran dɛn de gi ifektiv wata resistans na ruf ɛn ɔda aplikeshɔn dɛn. Dɛn kin ɛp fɔ protɛkt strɔkchɔ dɛn frɔm wata we dɔn pwɛl.

Elastik Jɔyn Matirial : TPU in ɛlastik de mek i fayn fɔ ɛkspɛnshɔn jɔyn dɛn. I de alaw fɔ bil muvmɛnt we yu de mentɛn wan sil.

| Indastri | Aplikeshɔn | Ki TPU prɔpati dɛn we dɛn yuz . |

| Ɔtomotiv . | Sil, intɛriɔ pat dɛn, aybag kɔva dɛn | Durability, fleksibiliti, kemikal resistans . |

| Di prɔdak dɛn we dɛn de yuz fɔ bay tin dɛn . | Fɔn kes, spɔt guds, fut-fɔt | Impact resistans, fleksibiliti, durabiliti . |

| Wɛlbɔdi biznɛs | Tubing, Prosthetics . | Bayokompatibiliti, fleksibiliti, stɛrilayz rɛsistɛns . |

| Indastrial . | Belt dɛn we dɛn kin yuz fɔ kɔnvaysɔ, hos dɛn . | Wear resistans, kemikal resistans, durabiliti |

| Tekstil . | Spɔt klos mɛmbran, watapruf kɔtin dɛn . | Breathability, wata resistans . |

| Waya ɛn kebul . | Kebul insuleshɔn . | Ilektrikal Insuleshɔn, Fleksibul . |

| Bil | Wata-pruf, Jɔyn Matirial dɛn . | Wata resistans, elastisiti . |

Di we aw dɛn de prosɛs fɔ TPU Plastik .

TPU in versatility de extend to in prɔsesin mɛtɔd dɛn. Lɛ wi fɛn di difrɛn we dɛn fɔ shep dis wɔndaful tin.

Moldin fɔ injɛkshɔn .

Injɛkshɔn moldin na wan pɔpul we fɔ prodyuz kɔmpleks TPU pat dɛn.

Ki pɔynt dɛn:

Molten TPU na injekt insay wan mold cavity .

Ideal fɔ kɔmpleks shep dɛn wit tayt tolɛreshɔn dɛn .

Dɛn kin yuz am fɔ grip, gasket, ɛn kap .

Dray Rikwaymɛnt: Mek shɔ se di rizidul mɔstɔ kɔntinyu na ≤ 0.05% bifo dɛn prosɛs am. Dis kin mek dɛn nɔ brit insay pat dɛn we dɛn dɔn mol.

Ekstrushɔn .

Ekstrushɔn na pafɛkt fɔ mek kɔntinyu TPU shep dɛn.

Prɔses Ɔvaviu:

TPU na melt ɛn fos tru wan day .

Di tin we dɛn pul kɔmɔt na di bɔdi kin tek di shep we di say we dɛn de opin di day .

Dɔn dɛn kin kol am ɛn kɔt am to di lɔng dɛn we yu want

Aplikeshɔn dɛn:

Tub dɛn .

Shit dɛn .

Profayl dɛn .

Drayp tip: Aim fɔ rizidul mɔstɔ kɔntinyu ≤ 0.02% bifo ɛkstrushɔn.

Moldin fɔ kɔmpreshɔn .

Kɔmpreshɔn moldin na fayn tin fɔ big, tik-wɔl TPU pat dɛn.

Step dɛn:

Ples TPU matirial insay wan mold we dɛn dɔn ɔt .

Aplay prɛshɔn fɔ mek di shep we yu want .

Kul ɛn pul di pat we dɔn dɔn .

Dis mεtכd na fayn fכ prodyuz kכmכpכnt dεm we go de te, we de rεsistεnt impεkt.

3d printin wit TPU filaments .

3D printin opin op nyu possibiliti fɔ TPU manufakchurin.

Di bɛnifit dɛn we pɔsin kin gɛt:

Alaw fɔ kɔmpleks jɔyometri dɛn .

Ideal fɔ prototyping ɛn smɔl-smɔl prodakshɔn .

Kompatibel wit FDM (fuz diposishun modeling) ɛn SLS (sɛlektiv laser sintering) tɛknik dɛn

Tips fɔ FDM printin:

Yuz wan dairekt drayv extruder fɔ bɛtɛ kɔntrol .

Set di temperecha we dɛn kin ɔt to 50 ±10°C .

Print na spid bitwin 15-20 mm/s

Blow moldin na na na na na na na na na na na na na na na na na na na na na na na na na na na na na na na na na na na na na na na na na na

Blow molding na perfekt fɔ mek hol TPU pat dɛn.

We:

Ekstrud wan TPU parina (Hollow Tube)

Klamp am insay wan mol .

Inflate am wit eiya fɔ tek di mold in shep .

Kɔmɔn Aplikeshɔn dɛn:

Sɔlvɛnt prɔsesin .

Solvent prosesin de yuz fɔ TPU coatings ɛn adhesives.

Ki pɔynt dɛn:

TPU de sɔlv insay ɔrganik sɔlvɛnt dɛn .

Di sɔlvushɔn de aplay to sɔfays dɛn .

As di sɔlvɛnt de evapɔret, i de lɛf wan TPU kɔtin ɔ adeziv layt .

Aplikeshɔn dɛn:

| Prɔsesin Mɛtɔd | Ki Advantej dɛn | Kɔmɔn Aplikeshɔn dɛn |

| Moldin fɔ injɛkshɔn . | Kɔmpleks shep dɛn, tayt tolɛreshɔn dɛn . | grip, gasket, kap |

| Ekstrushɔn . | kɔntinyu shep dɛn . | Tubes, Sheets, Profayl dɛn . |

| Moldin fɔ kɔmpreshɔn . | Big big pat dɛn we gɛt tik dɛn we gɛt tik dɛn . | Di komponent dɛn we kin de fɔ lɔng tɛm . |

| 3D Printing we dɛn de yuz fɔ print . | Komplex joyometri, prototypein . | Kastɔm pat dɛn, smɔl batch dɛn . |

| Blow moldin na na na na na na na na na na na na na na na na na na na na na na na na na na na na na na na na na na na na na na na na na na | Di pat dɛn we gɛt ol . | bɔtul, kɔntena dɛn . |

| Sɔlvɛnt prɔsesin . | Di tin dɛn we dɛn kin yuz fɔ kɔt ɛn di tin dɛn we dɛn kin yuz fɔ adhesive . | Tekstil, Layers we de protɛkt . |

I nɔ mata di we aw dɛn de du am, di rayt we fɔ drɛy TPU bifo dɛn prosɛs am na impɔtant tin. I de mek shɔ se i de wok fayn ɛn i de mek i nɔ brit insay di las prɔdak.

TPU vs. TPE: Ɔndastand di difrɛns

We yu de pik matirial fɔ yu prɔjek, yu kin mit ɔl tu di TPU ɛn . TPE we dɛn kɔl . Mek wi brok dכn dεn difrεns dεm.

Table we yu go kɔmpia: TPU vs. TPE

| Ficha | TPU (Tɛmoplastik Poliyuretin) | TPE (Tɛmoplastik ɛlastɔm dɛn) |

| Kεmikכl kompozishun . | Polyurethane-based na di . | Blend fɔ tɛmoplastik ɛn ɛlastɔm . |

| Fleksibul fɔ mek yu ebul fɔ chenj . | Ay | Difrɛn difrɛn (jɛnɔral ay) |

| Hadnɛs . | Wide range, tipikli harda . | Wide renj, tipikli soft . |

| Abrashɔn rɛsistɛns . | Wɛl dɔn | Gud to fayn fayn wan . |

| Oil ɛn Gris Resistance . | Wɛl dɔn | Varies (usually gud) |

| Transparency . | kin bi transparent . | Jɛnɛral wan Opaque . |

| Elastisiti . | Wɛl dɔn | Wɛl dɔn |

| Prɔsesin . | Injɛkshɔn moldin, ɛkstrushɔn, blo moldin | Injɛkshɔn moldin, ɛkstrushɔn, blo moldin |

| Tempracha resistans . | Gud (diaris bay gred) | Modaret (divayri dɛn bay di kayn) . |

| Durability . | Ay | Modaret to ay . |

| Pe | Jɛnɛral wan i ay pasmak . | Jɛnɛral wan i smɔl smɔl . |

Ki Advantej dɛn fɔ TPU .

TPU de stand out fo som eria. Lɛ wi fɛn ɔl in spɛshal bɛnifit dɛn.

Supiriɔs abrashɔn rɛsistɛns .

Eksɛlɛnt kemikal rɛsistɛns .

TPU nɔ gri wit ɔyl, gris, ɛn bɔku sɔlvɛnt dɛn.

Dis mek am pafɛkt fɔ industrial ɛn ɔtomotiv yus.

Transparency Options .

Nɔ lɛk bɔku TPE dɛn, dɛn kin mek TPU kristal klia.

I fayn fɔ aplikeshɔn dɛn we nid fɔ gɛt visibiliti, lɛk mɛdikal tub.

Wide hadnes renj .

ay tɛnsiɛl trɛnk .

Eksɛlɛnt lɔw-tɛmpracha pefɔmɛns .

UV resistans .

Customizability na di .

Wail TPE gɛt in trɛnk, TPU kin win bɔku tɛm pan diman aplikeshɔn dɛn. I yunik kɔmbaynshɔn fɔ prɔpati dɛn de mek i bi wan versatile choice.

Tink bɔt yu patikyula nid dɛn we yu de pik bitwin TPU ɛn TPE. TPU kin kɔst mɔ, bɔt in pefɔmɛns kin jɔstify di invɛstmɛnt bɔku tɛm.

Modifying TPU Plastik fɔ Ɛnhans Pɔfɔmɛnshɔn .

TPU dɔn ɔlrɛdi bi versatile matirial, bɔt wi kin ɛp fɔ mek in prɔpati dɛn bɛtɛ mɔ.

Blɛnd wit ɔda matirial dɛn .

Miks TPU wit ɔda polimɛr dɛn kin mek yunik prɔpati kɔmbaynshɔn.

Kɔmɔn blɛnd dɛn:

Dɛn blɛnd ya de alaw fɔ tayla sɔlvishɔn dɛn na spɛshal aplikeshɔn dɛn. Dɛn kin jɔyn di trɛnk dɛn we difrɛn tin dɛn gɛt.

Adding reinforcing fibers .

Riinfɔs TPU bi wan strɔkchɔral injinɛri polima. I de gɛt impɔtant nyu prɔpati dɛn.

Di bɛnifit dɛn we di fayv we dɛn kin gi fɔ mek dɛn riinfɔs:

Inkris abrashɔn rɛsistɛns .

Di trɛnk we gɛt ay impak .

Impruv fiul resistans .

Enhansed flow characteristics .

Tipik riinfɔsmɛnt matirial dɛn:

Glas fayba dɛn .

Kabon Fayba dɛn .

Minral Filla dɛn .

Riinfɔs TPU de fɛn yus insay ɔtomotiv pat ɛn ay-strɛs industrial kɔmpɔnɛnt dɛn.

Inkorporet aditiv fɔ spɛshal prɔpati dɛn .

Aditiv kin fayn-tyun TPU in pefɔmɛns. Dɛn kin ɛp fɔ mek difrɛn kwaliti dɛn fɔ mit sɔm patikyula nid dɛn.

Kɔmɔn aditiv ɛn dɛn ifɛkt dɛn:

Antiɔksidant dɛn: Protɛkt frɔm di tɛm we di ples kin pwɛl di wam

UV Absɔb dɛn: Impruv Wetabiliti .

Flame Retardants: Ɛnjɔy faya resistans .

Plasticizers: Inkris fleksibiliti .

Kɔlɔrant dɛn: Gi kɔstɔm kɔlɔ dɛn .

| Aditiv Tayp | Pɔpɔshɔn | Kɔmɔn aplikeshɔn dɛn |

| Antiɔksidant dɛn . | Tɛmral stebiliti . | Di pat dɛn we de na di motoka . |

| UV Absɔb dɛn . | Di Durability we de na do fɔ lɔng tɛm . | Ekstirian komponent dɛn . |

| Di wan dɛn we nɔ gɛt faya fɔ mek dɛn nɔ gɛt faya . | Faya sefty . | Kebul jakit . |

| Plastikiza dɛn . | Fɔ mek pɔsin ebul fɔ chenj di we aw i de chenj . | Sɔft-tɔch prɔdak dɛn . |

| Kɔlɔrant dɛn . | Aesthetic Appeal we dɛn mek wit fayn fayn tin dɛn . | Di guds dɛn we dɛn de yuz fɔ bay tin dɛn . |

Dɛn aditiv dɛn ya de alaw di wan dɛn we de mek dɛn fɔ tayla TPU fɔ sɔm patikyula envayrɔmɛnt ɛn yuz dɛn.

Yuz di polycarbonate diols (PCDS)

PCD na gem-chenja na TPU prodakshɔn. Dɛn de mek ay-perfɔmans polyurethanes wit ɛksɛpshɔn prɔpati dɛn.

Advantej dɛn fɔ PCD-based TPU dɛn:

Ekstrim durabiliti fɔ du .

Supiriɔs kemikal rɛsistɛns .

Impɔtant haydrolaytik stebiliti .

Greater thermal resistans .

Enhansed abrasion resistans .

Aplikeshɔn dɛn fɔ PCD-based TPU dɛn:

Sil dɛn we gɛt ay pafɔmɛnshɔn .

Di tin dɛn we dɛn kin yuz fɔ kɔt di tin dɛn we dɛn kin yuz fɔ lɔng tɛm .

Advans Mɛdikal Divays dɛn .

PCD dɛn alaw fɔ mek TPU gred dɛn we pas standad fɔmyulashɔn dɛn. Dem na ideal fo dimand aplikeshon.

Disain TPU Pat fɔ Manufakchurin .

We dɛn de mek TPU pat dɛn, fɔ ɔndastand di we aw dɛn de mek tin dɛn rili impɔtant. Lɛ wi fɛn ɔl di dizayn kɔnsidareshɔn dɛn fɔ tu pɔpul 3D printin we dɛn de yuz.

Disain fɔ sɛlɛktiv laser sintering (SLS) .

SLS de gi big fridɔm insay TPU pat dizayn. I kin prodyuz kɔmpleks jɔyometri dɛn we nɔ gɛt sɔpɔt strɔkchɔ dɛn.

Minimum wall tik ɛn ficha saiz .

Di tik we de na di wɔl: Aim fɔ at le 1.5 mm

Inkris to 3 mm fɔ ɛnhans rigiditi .

Minimum ficha saiz: 0.5 mm

Ditil dɛn we dɛn rayt ɔ we dɛn ɛmbos: 1.5 mm in ayt ɛn wit

Dɛn gaydlayn ya de mek shɔ se strɔkchɔral intɛgriti ɛn kɔrɛkt riprodakshɔn fɔ yu dizayn.

Dizayn Kɔmplisiti ɛn Asɛmbli Kɔnsidɛreshɔn dɛn .

SLS de alaw fɔ mek dɛn gɛt intrikɛt, ɛnklɔz, ɛn intalɔk pat dɛn. Yu kin disayn komponent dɛn we nɔ nid sɛpret asɛmbli.

Advays dɛn:

Dis kin mek shɔ se dɛn print fayn fayn wan ɛn izi fɔ mek dɛn go ebul fɔ gɛda ɔ muv di pat dɛn fayn fayn wan.

Hol ɛn rɔnawe ol dɛn .

Di pat dɛn we de hol kin sev matirial ɛn ridyus di tɛm fɔ print.

Ki pɔynt dɛn:

Escape hols de fasilit pauda rimobul afta dɛn print, mek shɔ se dɛn gɛt klin fayn fayn prodak.

Disain fɔ fuz dipɔzishɔn mɔdelin (FDM)

FDM na wan we dɛn kin yuz bɔku bɔku wan fɔ protɔtayp ɛn smɔl-smɔl prodakshɔn fɔ TPU pat dɛn.

Minimum wall tik ɛn ficha saiz .

Di tik we de na di wɔl: at le 1.5 mm

Minimum ficha saiz: 0.5 mm

Ditiɛl dɛn we dɛn ɛmbos ɔ we dɛn rayt insay: 1.5 mm in ayt ɛn wit

Dɛn dimɛnshɔn ya de mek dɛn nɔ wɔp ɛn mek shɔ se dɛn print yu dizayn kɔrɛkt wan.

Dizayn Kɔmplisiti ɛn Asɛmbli Kɔnsidɛreshɔn dɛn .

FDM gɛt sɔm limiteshɔn dɛn we yu kɔmpia am wit SLS. Kip yu dizayn dɛn rili simpul.

Gaydlain:

Simplifying dizayn dɛn de ɛp fɔ mek shɔ se dɛn print fayn fayn wan ɛn strɔng fayn fayn prɔdak dɛn.

Printin Tin dɛn fɔ Tink bɔt .

Prɔpa sɛtin dɛn na impɔtant tin fɔ mek FDM printin fayn fɔ TPU.

| Paramita | Rikɔmɛnd Sɛtin . |

| Di kayn printa . | Dairekt drayv ɛkstruda . |

| Bed Tempracha . | 50 ±10 ° C . |

| Di spid we dɛn de print . | 15-20 mm/s di 15-20 mm. |

| Tempracha fɔ ɛkstrushɔn . | 225-250 ° C . |

| Cooling . | Midul to ay . |

Ɔda Tin dɛn we Yu Go Yuz fɔ No bɔt:

Adjust extrusion multiplier fɔ strɔng layt bɔndin .

Yuz skit insted of rafts .

disable retraction fɔ mek dɛn nɔ gɛt filament strɛch .

Dɛn sɛtin ya de ɛp fɔ ajɔst di bɛst rizɔlt dɛn we yu de print TPU wit FDM.

Chalenj ɛn Limiteshɔn fɔ TPU Plastik .

Pan ɔl we TPU de gi bɔku bɛnifit dɛn, i nɔ de witout in chalenj dɛn.

Difikulti fɔ prosɛs .

TPU kin bi triki fɔ prosɛs, mɔ fɔ di wan dɛn we nyu to di matirial.

Di prɔblɛm dɛn we kin apin we dɛn de du di wok:

Moisture sensitiviti fɔ di .

Narrow processing temperechur renj .

Tendens fɔ stik to mɛtal sɔfays .

Fɔ adrɛs dɛn tin ya:

Dray TPU fayn fayn wan bifo dɛn prosɛs am .

Yuz prɛsis tɛmpracha kɔntrol .

Aplay mold rilis ejen dɛn we nid de .

Prɔpa pripiamɛnt ɛn ikwipmɛnt sɛtup na impɔtant tin fɔ saksesful TPU prɔsesin.

Di tin dɛn we wi fɔ tink bɔt we wi de pe fɔ di kɔst .

TPU kin dia bɔku tɛm pas ɔda matirial dɛn. Dis kin impɔk di prɔjek badjɛt ɛn di prɔdak prayz.

Factors we de afɛkt TPU kɔst:

Pan ɔl we di kɔst fɔ go bifo go ɔp, TPU in durabiliti kin gi lɔng tɛm sevings. Tink bɔt di ɔl layfsaykl kɔst we yu de evalyu TPU fɔ yu prɔjek.

Pɔfɔmɛnshɔn Limiteshɔn dɛn na Sɔm Envayrɔmɛnt dɛn .

Wail versatile, TPU get in limits. I nɔ go fayn fɔ ɔl di kɔndishɔn dɛn.

Di tin dɛn we pɔsin kin ebul fɔ du:

Envayrɔmɛnt dɛn we gɛt ay-tɛmpracha (we de ɔp 80°C)

Fɔ lɔng tɛm we yu de nia strɔng UV raytin .

Sɔm kemikal dɛn we dɛn kin yuz fɔ fɛt wɔ .

| Envayrɔmɛnt | TPU pefɔmɛns |

| Ay ɔt . | Limitɛd rɛsistɛns . |

| Strɔng UV . | May degrade ova tɛm . |

| Di kemikal dɛn we dɛn kin yuz fɔ mek tin dɛn we nɔ fayn . | Varies bay TPU tayp . |

Ɔltɛm tɛst TPU na yu spɛshal aplikeshɔn ɛnvayrɔmɛnt bifo yu ful implimɛnt.

Haydrolis Sɛnsitiviti .

Hydrolysis kin bi wan signifyant ishu, espeshali fɔ polyester-based TPUs.

Ki pɔynt dɛn:

Moisture kin brok dɔŋ TPU mɔlikul chen dɛn .

Dis kin mek dɛn lɔs di mɛkanikal prɔpati dɛn .

Polyether-based TPU dɛn de mɔ resistant .

Fɔ mitigate haydrolis:

Choose Polyether-based TPU fɔ ay-mɔstɔ ɛnvayrɔmɛnt dɛn .

Yuz protɛktiv kɔtin dɛn we nid de .

Impruv di rayt we fɔ drɛy bifo dɛn prosɛs am .

Future Trends in TPU Plastik Tɛknɔlɔji .

Di aplikeshɔn dɛn we de kɔmɔt .

TPU de fɛn nyu wok dɛn akɔdin to di industri dɛn. I versatility opin doa fɔ inovativ yus.

Di tin dɛn we go apin tumara bambay:

Smart tekstil wit intagreted TPU sensors .

3D-printed customized medikal implant dɛn .

Advanced Automotive Components fɔ Ilɛktrik motoka dɛn .

Bayodigradabl pak matirial dɛn .

Dɛn aplikeshɔn ya de leva TPU in yon prɔpati dɛn. Dɛn prɔmis fɔ rivɔlɔshɔn difrɛn sɛktɔ dɛn.

Advansmɛnt dɛn na TPU fɔmyuleshɔn dɛn .

Sayɛnsman dɛn de push di tin dɛn we TPU ebul fɔ du mɔ. Nyu fɔmyulashɔn dɛn de ɛp fɔ mek in prɔpati dɛn we dɔn ɔlrɛdi impɔtant.

Di impɔtant tin dɛn we gɛt fɔ apin:

Di ay tempɔret rɛsistɛns .

Inkris UV stebiliti .

Enhansed kemikal resistans .

Impɔtant printabiliti fɔ aditiv manufakchurin .

Dɛn advansmɛnt ya go mek di TPU in yusabiliti go bifo. Dɛn go mek am fayn fɔ ivin mɔ dimand aplikeshɔn dɛn.

Sastaynɛbul TPU Inovashɔn dɛn .

Sastaynabiliti na di men tin we dɛn de pe atɛnshɔn pan fɔ divɛlɔp TPU. Risach pipul dɛn de fɛn ɔl di tin dɛn we dɛn kin pik fɔ du na di wɔl.

Grin TPU Trends:

Risaykul kɔntinyu TPU gred dɛn .

I izi fɔ risaykul TPU fɔmyuleshɔn dɛn .

TPU wit ridyus kabon futprin .

Wata-based TPU sistem fɔ kɔtin .

Dɛn nyu tin ya gɛt fɔ du wit fɔ ridyus TPU in envayrɔmɛnt impak. Dɛn de mek am wan mɔ sataynabl chuk fɔ di wan dɛn we de mek am.

Divεlכpmεnt כf bayo-bεys TPU dεm .

Bio-based TPU dɛn de gɛt trakshɔn. Dɛn de gi wan rinuɔbal ɔltɛrnativ to tradishɔnal petrolium-based TPU dɛn.

Ki Points:

Dɛn mek am wit tin dɛn we dɛn mek wit plant .

Ridyus Rilayns pan Fɔshal Fiul .

Potensial fɔ di kabon nyutraliti .

Kɔmparabl pefɔmɛns to tradishɔnal TPU dɛn .

| Sos | Advantej | Chalenj dɛn . |

| Kɔn | Rinyuebul, bɔku bɔku wan . | Land Yuz Kɔnsyans . |

| Kasta ɔyl . | Krop we nɔ de it, plant we nɔ gɛt bɛtɛ tin fɔ it | Limitɛd sapɔt . |

| Algae na di . | Fast-grɔw, ay yield | Difikulti fɔ ɛkstrakshɔn . |

Bio-tpus stil de evolv. Dɛn sho prɔmis fɔ wan mɔ sataynabul fiuja insay plastic.

Di fiuja fɔ TPU teknɔlɔji luk brayt. Frɔm nyu aplikeshɔn to grɛn fɔmyulashɔn, TPU kɔntinyu fɔ adap ɛn impɔtant.

Dɛn tren ya de sho di dimand dɛn we de gro fɔ pefɔmɛns ɛn sastaynabiliti. Dem de shep di neks jenereshɔn fɔ TPU matirial.

Ɛksplen

In sɔmari, TPU plastic de ɔfr unmatched versatility wit in blend ɔf trɛnk , fleksibiliti , ɛn durabiliti . Fɔ ɔndastand in prɔpati ɛn di we aw dɛn de prosɛs am impɔtant fɔ fulɔp fɔ yuz in bɛnifit dɛn akɔdin to difrɛn industri dɛn. As inovashɔn de kɔntinyu, TPU’s kɔstɔmayshɔn pɔtɛnɛshɔn go drɛb nyu sɔlvishɔn dɛn insay , , ɔtomotiv mɛdikal ɛn kɔshɔma prodak , we go mek i bi wan impɔtant matirial fɔ mɔdan manufakchurin.

Tips: Yu maybe intres to di ol plastics