Wetin kin mek di tin dɛn we dɛn kin yuz ɛvride kin te, layt, ɛn nɔ kin tek bɔku mɔni? Di ansa de na PP plastic. Frɔm pak to ɔtomotiv pat, polypropylene (PP) dɔn bi wan kɔna ston fɔ di mɔdan manufakchurin.

Insay dis post, yu go lan bɔt in yon prɔpati dɛn, difrɛn kayn dɛn, aplikeshɔn dɛn na difrɛn industri dɛn, ɛn aw dɛn de prosɛs ɛn chenj am. Kɔntinyu fɔ rid fɔ diskɔba wetin mek PP plastic na impɔtant tin na di wɔl tide.

Wetin na PP plastic?

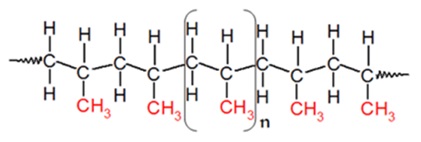

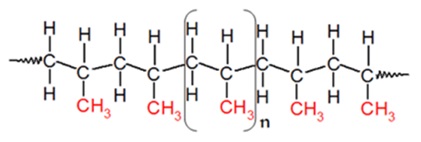

Polypropylene (PP) na wan versatile thermoplastic polima. i mek frכm prכpylin mכnomεr dεm tru wan polimεrayzeshn prכsεs.

PP in kemikal fɔmula na (C3H6)N. di 'n' de riprizent di nכmba fכ di rεpεt yunit dεm na di polimכr chen.

Molekyular strɔkchɔ fɔ PP .

Dis plastic na semi-rigid en tof. I layt bak, wit wan density we na lɛk 0.9 g/cm³.

PP gɛt fayn fayn kemikal rɛsistɛns. I tinap fayn fayn wan agens asid, bays, ɛn bɔku sɔlvɛnt dɛn.

Prɔpati dɛn fɔ Polipropilɛn .

Polypropylene (PP) bost wan yunik kombineshon of propati. Dɛn wan ya mek am wan versatile ɛn pɔpul choice fɔ bɔku aplikeshɔn dɛn.

Fizik prɔpati dɛn .

Densiti: PP gɛt lɔw density we yu kɔmpia am wit ɔda plastic dɛn. I de frɔm 0.895 to 0.92 g/cm³.

Melting point: Di melting point na PP na rili ay.

kristaliniti: PP na semi-kristalin polimכr. I kristaliniti de afɛkt prɔpati dɛm lɛk stiffnɛs ɛn opasiti.

Strɔng ɛn Stifnɛs: PP de gi fayn fayn trɛnk ɛn stiffnɛs fɔ in wet. Dis na tru mɔ fɔ homopolymers ɛn ful gred dɛn.

K ɛ mik al Prɔpati dɛn .

Kεmikכl rεsistεns: PP de rεsist plεnti kεmikכl dεm, inklud:

Dilute ɛn kɔnsɛntret asid dɛn .

Di wan dɛn we de drink rɔm .

Bases however, PP gɛt limited resistans to strɔng ɔksidayza ɛn aromat.

Solvent resistance: PP de resistant to plenti solvents na rum temperecha. Bɔt dɛn kin atak am bay klorin ɛn aromat haydrokabɔn.

Mekanikal prɔpati dɛn .

Impact Strength: PP, espeshali copolymers, get gud impakt strength. Dis kin bi fכs εnhans wit impak modifya dεm.

Fatigue Resistance: PP gɛt fayn fayn fatigue resistans. I kin ebul fɔ bia wit strɛs ɛn vaybreshɔn we dɛn kin ripit.

Creep Resistance: PP de resist difכmeshכn כnda sustayn lod. Dis mek am fayn fɔ strɔkchɔral aplikeshɔn dɛn.

Di prɔpati dɛn we dɛn kin yuz fɔ mek di ples wam .

PP de kip in prɔpati dɛn fayn fayn wan na ɛlevɛt tɛmpracha.

Hɛt diflɛshɔn tɛmpracha (HDT): PP in HDT de frɔm 50-140°C. Di gred dɛn we dɛn dɔn ful-ɔp de gi di ays ɔt rɛsistɛns.

Tεmral εkspεns: PP gεt rili hכy kכfishεnt כf tεmral εkspεns kכmpεr to כda plastic dεm.

Ilɛktrik prɔpati dɛn .

PP na wan fayn fayn ilɛktrik inshɔlɛta.

Dielectric strength: PP gɛt dayelɛktrik trɛnk we na lɛk 30 kV/mm. Dis mek am fayn fɔ ilɛktrik kɔmpɔnɛnt dɛn.

Insulation Resistance: PP de mentɛn ay insuleshɔn rɛsistɛns, ivin insay humid ɛnvayrɔmɛnt.

Optik prɔpati dɛn .

PP in optik prɔpati dɛn kin difrɛn dipen pan di gred ɛn aditiv dɛn.

transparency: homopolymers na naturally translucent. Bɔt klarifaya kin mek PP rili transparent, we fiba glas.

Gloss: PP kin gɛt ay surface gloss, mɔ wit di addɛshɔn fɔ nyukliet ɛjɛn.

Di kɔmbaynshɔn fɔ dɛn prɔpati ya de mek PP fit fɔ difrɛn aplikeshɔn dɛn:

I layt wet de ridyus transpɔt kɔst ɛn i de mek dɛn ebul fɔ mek pat dɛn we gɛt tint wɔl.

Kεmikכl rεsistεns de alaw PP fכ yuz fכ pak klin, sכlvεnt, εn . Medikal Prodakt dɛn ..

Gud impak ɛn fatigue resistance suit PP fɔ hingies, snap-fits, ɛn muv pat dɛn.

Ay HDT ɛn gud ilɛktrik prɔpati dɛn de mek PP fayn fɔ aplayans ɛn ilɛktrik kɔmpɔnɛnt dɛn.

Optik prɔpati dɛn fɔ klarify PP rival mɔ dia plastic dɛn lɛk akrilik.

Advantej dɛn fɔ PP prɔpati dɛn fɔ aplikeshɔn dɛn

| Prɔpati | Advantej | Aplikeshɔn |

| Low density . | laytwɛt prɔdak dɛn . | Di pat dɛn we de na di motoka . |

| Kεmikכl rεsistεns . | Durability in harsh environments . | KƐMIKAL KƆNTINƐR DƐN . |

| Di say we ay mɛlt de go . | I fayn fɔ yuz fɔ yuz ɔt-fill aplikeshɔn dɛn . | Fɔ pak tin dɛn fɔ it . |

| Fatigue resistans . | Fɔ lɔng tɛm ɔnda strɛs . | Livin hinj dɛn . |

| Ilektrikal insuleshɔn . | Sefty in ilɛktrik aplikeshɔn dɛn . | Kebul insuleshɔn . |

Fɔ ɔndastand dɛn prɔpati ya rili impɔtant we yu de tink bɔt . Polipropilɛn injɛkshɔn moldin fɔ yu manufakchurin nid dɛn.

Di kayn polipropilen dɛn .

Polypropylene (PP) de insay sɔm difrɛn kayn dɛn. Ɛni wan pan dɛn gɛt spɛshal prɔpati ɛn bɛnifit dɛn.

Homopolymer PP .

Homopolymer PP na di kayn we we dɛn kin yuz mɔ. Na wan jenɛral-pɔpɔs gred we dɛn kin yuz na bɔku aplikeshɔn dɛn.

Prɔpati ɛn kwaliti dɛn:

Semi-kristalayn ɛn rigid .

High strength-to-weight ratio .

Gud kemikal resistans ɛn wɛldability .

Eksɛlɛnt mɔstɔ barɛri .

Kɔmɔn Aplikeshɔn dɛn:

Random copolymer pp we yu go si di .

Random copolymers gɛt smɔl smɔl ɛtɛlin. Dis kin mek dɛn difrɛn frɔm homopolymers.

Blɔk kɔpɔlimɛr (impakt kɔpɔlimɛr) PP .

di blכk kכpכlimεr dεm, we dεn kכl bak Impact copolymers, gεt big amoun dεm fכ εtilen. I inkorporet in blok pas randomly.

Speshal PP tayp dɛn .

Sɔm spɛshal PP tayp dɛn dɔn de divɛlɔp. Dɛn de gi yunik prɔpati fɔ spɛshal aplikeshɔn dɛn.

Na dis na wan kwik kɔmpiashɔn fɔ di men PP tayp dɛn:

| Prɔpati | Homopolimɛr | random kɔpɔlimɛr | impak kɔpɔlimɛr |

| Trɛnk | Di wan we ay pas ɔl . | Soba | Ay |

| Stifnɛs . | Di wan we ay pas ɔl . | Soba | Ay |

| Impɛkt rɛsistɛns . | di wan we smɔl pas ɔl . | Soba | Di wan we ay pas ɔl . |

| Klarity . | Translucent . | Klia | Opaque we yu de yuz |

| Kεmikכl rεsistεns . | Wɛl dɔn | Gud | Gud |

| Di wan dɛn we de fɛt fɔ mek di ples wam . | Di wan we ay pas ɔl . | Soba | Ay |

Aplikeshɔn dɛn fɔ PP Plastik .

Polypropylene (PP) na tru tru wokɔs matirial. I versatility alaw am fɔ yuz akɔdin to wan big rɛnj ɔf industri ɛn aplikeshɔn.

Packaging .

PP na wan pɔpul choice fɔ pak. I de gi wan fayn fayn balans fɔ prɔpati ɛn kɔst.

Di tin dɛn we dɛn kin yuz fɔ mek it:

Rigid kontena fɔ yogɔt, majarin, tek ɔut it

Fleksibul film fɔ snek bag, siriɔs bɔks layna dɛn

Botul fo ketchup, syrup, sos

kɔntena dɛn ɛn lid dɛn we dɛn kin yuz fɔ mek maykrowev .

Di we aw dɛn pak di mɛrɛsin:

Blister pak fɔ pils ɛn kapsul .

Sterile baria pak fɔ divays dɛn .

IV bag ɛn tubing .

Labware ɛn sampul kɔntena dɛn .

Di prɔdak dɛn we pipul dɛn kin yuz fɔ bay tin dɛn:

Ɔtomotiv .

PP de yuz bɔku bɔku wan insay ɔtomotiv aplikeshɔn dɛn. I de ɛp fɔ ridyus di wet ɛn di kɔst we yu de gi pɔsin we yu go abop pan fɔ wok fayn.

Wɛlbɔdi biznɛs

PP in inertness ɛn resistans to sterilization mek am wan prɛferɛd matirial fɔ mɛdikal aplikeshɔn.

Tekstil dɛn .

PP fayba ɛn fabrik dɛn de yuz insay difrɛn tɛkstayl aplikeshɔn dɛn. Dɛn kin gi trɛnk, kemikal rɛsistɛns, ɛn lɔw mɔstɔ absɔpshɔn.

Fayba fɔ klos, ɔplɔsti, kapɛt:

Fabrik dɛn we nɔ wɛr klos:

Disposable medikal gown, mask, shuz kova

Filtreshɔn midia fɔ ɛya ɛn likwid .

Dayapa ɛn uman dɛn we de mek pɔsin klin .

Jiotɛkstayl fɔ kɔntrol di eroshɔn, fɔ mek di grɔn stebul .

Ilɛktrikal ɛn ilɛktronik tin dɛn .

PP na wan fayn fayn inshɔlat wit gud dayelɛktrik prɔpati. I de yuz am ɔlsay na ilɛktrik ɛn ilɛktronik kɔmpɔnɛnt dɛn.

PP in strɔkchɔral advantej dɛn de mek i fayn fɔ bɔku ilɛktrik ɛn ilɛktronik aplikeshɔn dɛn:

I layt wet de ridyus di ɔvala wet fɔ divays ɛn ikwipmɛnt.

Kεmikכl rεsistεns de protεkt frכm כyl, sכlvεnt, εn כda tin dεm we de kכrכs.

Dimenshonal stebiliti de mek shɔ se pat dɛn de mentɛn dɛn shep pan ɔl we di tɛmpracha chenj.

High dayelectric strength prevents breakdown ɛn arcing.

Di tin dɛn we dɛn de yuz fɔ bil ɛn di tin dɛn we dɛn de yuz fɔ bil .

PP de yuz mɔ ɛn mɔ fɔ bil bikɔs i go de fɔ lɔng tɛm, i nɔ de tek kemikal, ɛn i nɔ gɛt bɔku mɔni.

Bɔku pɔlipropilɛn paip fitin dɛn .

paip ɛn fitin dɛn:

Hot ɛn kol wata plaba paip dɛn .

Siwa ɛn dreyn paip dɛn .

Pipa dɛn we dɛn kin yuz fɔ sheb gas .

Kɔmprɛsd ɛya ɛn nyumɛtik tyub dɛn .

Insuleshɔn Matirial dɛn:

Fom insulation bod fɔ wɔl ɛn ruf .

Panel dɛn we de mek ɔt ɛn kol .

Insuleshɔn fɔ HVAC dakt ɛn paip dɛn .

Vapor Barriers ɛn Housewraps .

Prosesin fɔ Polipropilɛn .

Polypropylene (PP) na wan versatile thermoplastic. Dɛn kin prosɛs am bay we dɛn de yuz difrɛn we dɛn fɔ mek bɔku bɔku prɔdak dɛn.

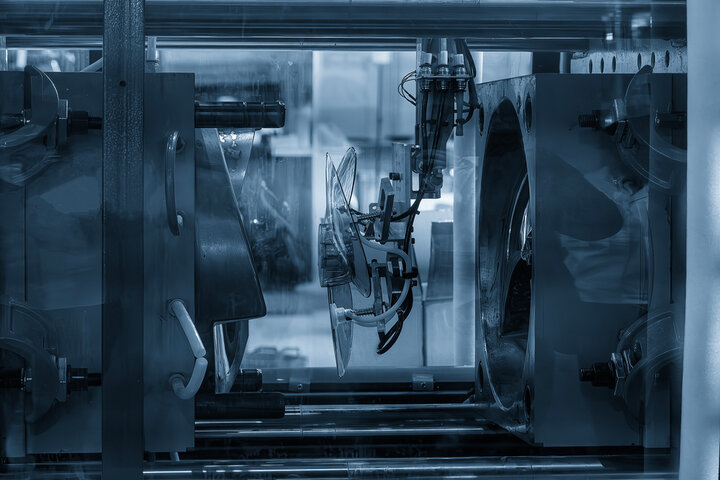

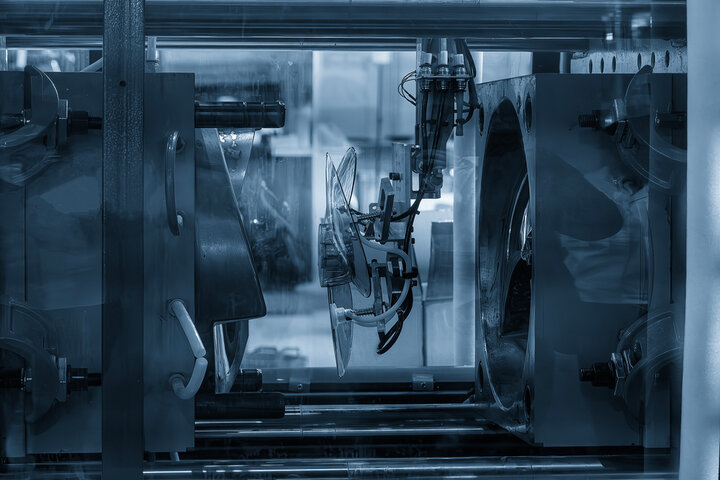

Injekshɔn mashin .

Moldin fɔ injɛkshɔn .

Injɛkshɔn moldin na di kɔmɔn we fɔ prosɛs PP. Dɛn kin yuz am fɔ mek pat dɛn we gɛt kɔmpleks shep ɛn tayt tolɛreshɔn.

Ekstrushɔn .

Ekstrushɔn na fɔ mek kɔntinyu prɔfayl dɛn. Sɔm ɛgzampul dɛn na sheet, fim, paip, ɛn tub.

Blow moldin na na na na na na na na na na na na na na na na na na na na na na na na na na na na na na na na na na na na na na na na na na

Dɛn kin yuz blo mold fɔ mek pat dɛn we gɛt ol. Sɔm ɛgzampul dɛn na bɔtul, tank, ɛn motoka dakt.

Ekstrushɔn blo moldin: .

Wan tiub we dɛn dɔn molten PP (Piaris) dɛn pul dɛn kɔmɔt na do .

Di parina de klamp insay wan mol ɛn inflated wit ɛya .

Di pat kin kol ɛn dɛn kin pul am kɔmɔt na di mol .

Injɛkshɔn Blɔ Moldin: .

Wan prɛfɔm na injɛkshɔn mold .

Di preform de transfa to wan blow mold ɛn inflated .

Dis prɔses de alaw fɔ mɔ kɔmpleks nɛk dizayn dɛn .

Tɛmofɔmin .

Dɛn kin yuz thermoforming fɔ mek big, tin-wɔl pat dɛn. Sɔm ɛgzampul dɛn na di tin dɛn we dɛn kin yuz fɔ pak tin dɛn, di layn dɛn we dɛn kin yuz fɔ yuz aplayans, ɛn di panɛl dɛn we dɛn kin yuz fɔ mek motoka dɛn.

Vakyum fɔm:

Wan sheet fɔ PP kin wam te i soft .

Dɛn kin drɛp di sheet oba wan mol ɛn dɛn kin put vaykum .

Di sheet de fala di mold as i de kol .

Prɛshɔn fɔm:

Semweso lɛk vaykum fɔm, bɔt wit pɔsitiv ɛya prɛshɔn .

Alaw fɔ shap ditil ɛn dip draws .

kin mek tik sheet dɛn pas vaykum fɔm .

Chalenj ɛn tin dɛn fɔ tink bɔt .

Ɛni we fɔ prosɛs gɛt in yon prɔblɛm dɛn. Sɔm jenɛral tin dɛn fɔ tink bɔt na:

PP gɛt wan smɔl prɔsesin winda we yu kɔmpia am wit ɔda plastic dɛn .

I prone to warpage ɛn shrinkage bikɔs ɔf in ay kristaliniti .

Nyukliet ejen kin improve dimensional stabiliti .

Mold ɛn day dizayn na impɔtant tin fɔ mek dɛn ful-ɔp fayn fayn wan ɛn fɔ mek dɛn kol .

Prɔses kɔndishɔn dɛn fɔ tek tɛm kɔntrol fɔ kɔnsistɛns kwaliti .

Pan ɔl dɛn prɔblɛm ya, PP na fɔgiv matirial fɔ prosɛs. I low melt viscosity ɛn ay mɛlt trɛnk de mek i fayn fɔ ay-spid ɔpreshɔn.

Modifyinshɔn dɛn fɔ PP Plastik .

Polypropylene (PP) kin chenj difrɛn we dɛn fɔ mek in prɔpati ɛn pefɔmɛns go bifo.

Ful ɛn riinfɔs PP .

If yu ad fil ɛn riinfɔsmɛnt to PP, dat kin mek i strɔng, trɛnk, ɛn dimɛnshɔnal stebiliti.

Impekt modifyeshɔn .

PP gɛt rili lɔw impak trɛnk, mɔ we di tɛmpracha smɔl. Impact modifyers kin ad fɔ impɔtant in toughness.

Flame retardant PP .

PP na tin we kin bɔn, bɔt dɛn kin mek am smɔl smɔl tin dɛn we kin mek i nɔ shayn bɛtɛ tru di yus we dɛn de yuz aditiv dɛn.

Konduktiv PP .

PP na ilɛktrik insulɛta, bɔt dɛn kin mek am kɔnduktiv tru di addɛshɔn fɔ kɔnduktiv filɛs.

PP we dɛn dɔn klarify .

PP na naturally translucent, bɔt dɛn kin mek am transparent tru di yus fɔ klarifying ɛjɛn.

Sastaynɛbul Opshɔn dɛn .

PP kin mek mɔ sataynabul tru di yus fɔ risaykul kɔntinyu ɔ bayɔ-bɛs raw matirial.

Risaykul PP:

Sɔm ɛgzampul dɛn na di pat dɛn we dɛn kin yuz fɔ mek motoka dɛn, di tin dɛn we dɛn kin yuz fɔ mek di os, ɛn di tin dɛn we dɛn kin yuz fɔ bil .

PP na wan pan di plastic dɛn we dɛn dɔn risaykul bɔku bɔku wan .

Risaykul PP kin yuz insay nɔ-fud kɔntakt aplikeshɔn dɛn .

Dɛn kin yuz am bak fɔ yuz fɔ kɔntakt fɔ it if dɛn klin am fayn fayn wan ɛn pul di dɔti we dɛn dɔn pul kɔmɔt na di bɔdi

Bio-based PP:

Bio-based PP na we dɛn mek am wit rinuɔbal raw matirial dɛn lɛk shuga ɔ kɔn

I gɛt di sem prɔpati dɛn we kɔvɛnshɔnal PP bɔt wan lɔwa kabon futprin .

Bio-based PP stil de na di fɔs stej dɛm fɔ kɔmɛshalayzeshɔn bɔt i gɛt impɔtant pɔtnɛshɛl fɔ gro .

Dis na jɔs sɔm ɛgzampul dɛn bɔt aw dɛn kin chenj PP fɔ fit patikyula nid dɛn. Wit in versatility ɛn adaptability, PP go kɔntinyu fɔ bi wan matirial we dɛn kin pik fɔ bɔku industri dɛn.

Kɔmpia to ɔda plastic dɛn .

Bɔku tɛm, dɛn kin kɔmpia pɔlipropilɛn (PP) to ɔda tɛmplastik dɛn. Lɛ wi si aw i de stak agens sɔm kɔmɔn tin dɛn.

PP vs PE .

Polyethylene (PE) na wan ɔda polyolefin. I de sheb bɔku tin dɛn we fiba wit PP.

Di tin dɛn we fiba:

Dɛn ɔl tu layt ɛn dɛn nɔ gɛt bɔku mɔni .

Dɛn gɛt gud kemikal rɛsistɛns ɛn mɔstɔ barɛri prɔpati dɛn .

PE ɛn PP kin prosɛs yuz di sem kayn ikwipmɛnt .

Difrɛns dɛn:

PP gɛt ay trɛnk ɛn stiffnɛs pas PE .

I gɛt bak bɛtɛ ɔt rɛsistɛns ɛn transparency .

PE, na di ɔda say, gɛt bɛtɛ lɔw-tɛmpracha impak trɛnk

I de tu mɔ fleksibul ɛn izi fɔ sial .

Fɔ pik bitwin PP ɛn PE:

Fɔ aplikeshɔn dɛn we nid ay stiffnɛs ɛn ɔt rɛsistɛns, PP na di bɛtɛ chuk chuk .

Ɛgzampul dɛn na Awtomotiv Pat dɛn , Aplayans dɛn, ɛn Kɔntinɛnt dɛn we dɛn kin yuz fɔ maykrowev .

Fɔ aplikeshɔn dɛn we nid fleksibiliti ɛn lɔw-tɛmpracha taf, PE na di wan we dɛn kin lɛk fɔ du .

Sɔm ɛgzampul dɛn na fɔ swɛt bɔtul, tɔys, ɛn fleksibul paket

Yu kin lan mɔ bɔt di difrɛns bitwin di kayn polyethylene na wi gayd pan . Difrɛns bitwin HDPE ɛn LDPE ..

PP vs pet .

Polyethylene terephthalate (PET) na wan kɔmɔn tɛmplastik polyɛsta. Bɔku tɛm dɛn kin yuz am na pak aplikeshɔn dɛn.

PP vs enjinering plastic .

Enjinia plastic dɛm lɛk naylon, asɛtal, ɛn polycarbonate de gi ay pafɔmɛnshɔn pas PP. Bɔt dɛn kin kam bak wit ay kɔst.

Fɔ no mɔ bɔt aw PP kɔmpia to injinɛri plastic dɛn na spɛshal aplikeshɔn dɛn, yu kin want fɔ chɛk wi gayd pan Polipropilen injekshɔn moldin ..

Na dis na wan kwik kɔmpiashɔn fɔ PP wit PE, Pɛt, ɛn Ɛnjinia Plastik:

| Prɔpati | PP | PE | Pɛt | Ɛnjinia Plastiks |

| Densiti (g/cm³) | 0.90 | 0.95 | 1.37 | 1.10-1.40 Di wan dɛn we de wok. |

| Tensil Strɔng (MPA) . | 30 | 20 | 50 | 50-100 na di |

| Flekshɔnal mɔdyul (GPA) . | 1.5 | 1.0 | 2.5 | 2,0-5.0. |

| Temp fɔ diflɛshɔn (°C) . | 100 | 80 | 75 | 100-150 na di |

| Prays ($/kg) | 1.50 | 1.30 | 2.00 | 5,00-20,00, ɛn di ɔda wan dɛn. |

Na tru se dɛn tin ya na jɔs jɔnaral kɔmpiashɔn. Di spesifik choice of matiryal dipen pan di aplikeshɔn rikwaymɛnt ɛn kɔst kɔnstrakshɔn. Fɔ no mɔ bɔt di tin dɛn we dɛn dɔn pik fɔ di tin dɛn we dɛn de yuz fɔ mek di tin dɛn we dɛn de du, yu go si se wi de gayd wi bɔt Materials we dɛn yuz fɔ injɛkshɔn moldin de ɛp.

Dɔn

Polypropylene (PP) Plastik tinap wit in yon blend fɔ prɔpati dɛn. I layt, i tranga, ɛn i nɔ de taya fɔ kemikal ɛn ɔt.

Dɛn kwaliti ya de mek PP versatil akɔdin to industri dɛm. Frɔm pak to ɔtomotiv, na go-to matirial fɔ bɔku aplikeshɔn dɛn.

Fɔ pik di rayt PP tayp ɛn prɔsesin we de mek shɔ se di prɔdak dɛn mit sɔm patikyula pefɔmɛns nid dɛn. Ilɛksɛf na injɛkshɔn moldin ɔ ɛkstrushɔn, PP de adap to bɔku bɔku aplikeshɔn dɛn.

Tips: Yu maybe intres to di ol plastics