Tapped holes na threaded openings in materials. Dɛn impɔtant fɔ mek ɛn asɛmbli prɔses. Dɛn ol dɛn ya kin mek dɛn ebul fɔ tay skru ɔ bolt dɛn fayn fayn wan.

Imajin wan nat wit intanɛnt trɛd dɛn. Naw, pikchɔ da trɛd patɛn de dairekt insay wan wokpies. Dat na wan tap ol!

Dis atikul go sho di ficha dɛn(difinishɔn, matirial, saiz,tayp,etc.) fɔ tap ol dɛn bifo dɛn sho di prosidur ɛn tɛknik dɛn we dɛn de put am na prɔsis, so dat i go wej di gud ɛn bad tin dɛn we dis prɔdak gɛt fɔ mek i bɛtɛ fɔ sav mɔtalman in nid dɛn.

Wetin dɛn tap ol dɛn?

Wan ol we dɛn tap na wan ol we dɛn dɔn drɔ to wan patikyula dayamita ɛn afta dat dɛn kin trɛd am bay we dɛn yuz wan tin fɔ kɔt we dɛn kɔl tap . Dis prɔses de mek intanɛnt trɛd dɛn we dɛn kin yuz fɔ akɔmod skru ɔ bolt, we kin alaw fɔ mek dɛn fasten dɛn we go mek dɛn sikrit. Di prɛsishɔn fɔ di ol we dɛn tap na impɔtant tin, bikɔs di trɛd dɛn fɔ mach di dimɛnshɔn dɛn fɔ di fastɛns fɔ mek shɔ se dɛn gɛt di rayt ɛnjɔymɛnt ɛn distribyushɔn fɔ lod. Dɛn kin yuz ol dɛn we dɛn tap bɔku tɛm na mɛkanikal sistem ɛn asɛmbli usay dɛn nid fɔ tay di kɔmpɔnɛnt dɛn fayn fayn wan ɛn dɛn kin ebul fɔ bia wit bɔku strɛs ɔ vaybreshɔn .

Materials fɔ di ol dɛn we dɛn dɔn tap .

Dɛn kin mek ol dɛn we dɛn tap insay bɔku bɔku tin dɛn:

Metals: Stilin, Aluminium, Brass, Titanium

Plastik: Naylon, polycarbonate, ABS

Wud: Had wud, sɔft wud

Kɔmpɔzit dɛn: fayv glas, kabɔn fayba .

Sizing Tapped Hols .

Tapped holes de fala sɔm kɔmɔn standad dɛn:

· Mɛtrik (ISO) : M6x1.0, M8x1.25.

· Yunifayd Thread Standart (UNC) : 1/4-20, 3/8-16.

· British Standart Witworth (BSW) : 1/4' BSW, 3/8' BSW

Tapped hol saiz dem na impɔtant tin fɔ fit fayn fayn wan. Dɛn kin tipikul fɔ diskrayb bay:

1. Thread saiz (big big dayamita) .

2. Threads per inch (TPI) ɔ pitch .

3. Dip na di pat we gɛt trɛd

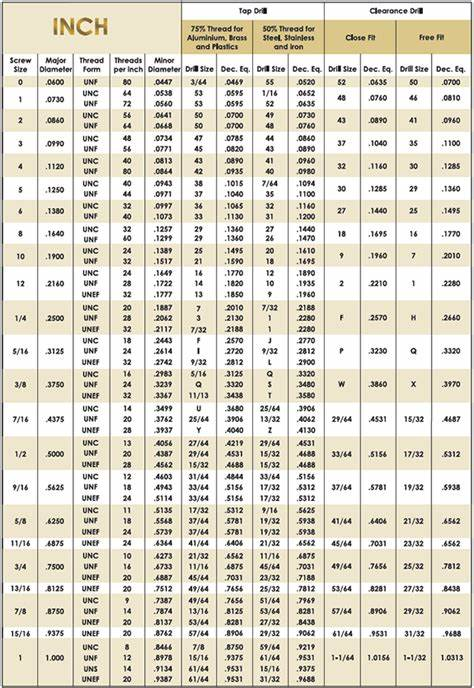

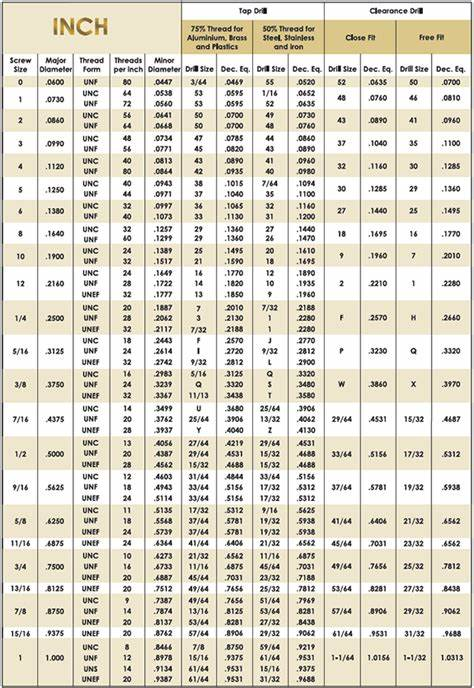

Na wan kwik rifrɛns tebul fɔ kɔmɔn saiz dɛn:

| trɛd saiz | TPI | tipik aplikeshɔn dɛn . |

| #4-40 we dɛn de ple. | 40 | Smɔl Ilɛktroniks . |

| 1/4-20. | 20 | Jɛnɛral Pɔpɔshɔn . |

| M6 x 1,0. | 1.0 | METRIK STANDARD . |

Tapped Holes Chart .

Tayp dɛn fɔ ol dɛn na mashin .

1. Tru ol dɛn : Dɛn drɔ am ɔltogɛda tru di matirial.

2. Blaynd ol : Dɛn drɔ am to wan patikyula dip we nɔ go brok tru.

3. Counterbore holes : gɛt silinda rɛs fɔ flush-fit fastɛns.

4. Riam ol : dril ɔndasayz ɛn afta dat dɛn rim am fɔ prɛsishɔn.

Kɔmpia di Threaded Hol Types

| Tayp | Krieshɔn Mɛtɔd | Suitabl Matirial dɛn | Strɔng |

| Tapped Holes . | Tapped afta drilling . | Bɔku pan di tin dɛn we dɛn yuz fɔ mek di tin dɛn . | Ay |

| Skru ol dɛn we de tap dɛnsɛf . | Dɛn mek am bay we dɛn put skru insay . | Matirial dɛn we Sɔft . | Lukin-grɔn uman |

| Insɛt dɛn we gɛt trɛd . | Insɛt dɛn we dɛn dɔn yuz bifo tɛm . | Materials wit poor thread retention . | Ay |

| Hɛlikal insɛt dɛn (Hɛlikɔyl dɛn) . | Koiled waya insɛt dɛn . | Soft matirial, ay-stress aplikeshɔn dɛn . | Na rili ay . |

| ol dɛn we dɛn dɔn tap bifo tɛm . | Mashin di tɛm we dɛn de mek di tin dɛn we dɛn de mek . | Bɔku pan di tin dɛn we dɛn yuz fɔ mek di tin dɛn . | Ay |

Di ol dɛn we dɛn tap de gi strɔng, kɔrɛkt trɛd fɔ di say dɛn we gɛt ay strɛs. Dɛn kin yuz bɔku bɔku tin dɛn ɛn dɛn kin mek dɛn insay bɔku bɔku tin dɛn. Di choice bitwin difrɛn threaded hole types dipen pan di spesifik aplikeshɔn, matirial prɔpati, ɛn rikwayd trɛnk.

Tapping Process we dɛn de du .

Fɔ mek prɛsis ɛn rilibul tap ol dɛn nid fɔ gɛt wan sistamɛtik we we go kɔba sɔm impɔtant step dɛn. Di wan dɛn we de kam biɛn na ditayli gayd fɔ di tap prɔses, we de mek shɔ se di rizɔlt dɛn fayn fayn wan:

· Step 1: Gayd Tul ɛn Matirial : Dril, Taps, Kɔt Fluid, Sefty Gia.

· Step 2: Selekt di kɔrɛkt tap ɛn drɔl bit : Yuz wan tap drɔl chɔt fɔ di rayt saiz.

· Step 3: Dril di ol : akchual drilin, perpendikul alayns, en kot fluid aplikeshon.

· Step 4: Pripia fɔ tap : Klin di ol, pul di dɔti, ɛn inspɛkt di dip.

· Step 5: Tap di ol : Kɔrɛkt alaynɛshɔn, yuz lɔbrik, ɛn chip rimɔv fɔ mek shɔ se dɛn kɔt klin wan.

· Step 6: Kwaliti Kɔntrol : Inspek di trɛd dɛn we yu de yuz gej fɔ mek shɔ se prɛsishɔn.

Tin dɛn fɔ tink bɔt ɛn advays dɛn fɔ mek dɛn yuz ol dɛn we dɛn dɔn tap fɔ mek mashin .

Fɔ mek shɔ se strɔng, prɛsis threaded kɔnɛkshɔn dɛn we dɛn de mashin tap ol dɛn, tink bɔt dɛn tin ya:

Material Hardness .

Di tin dɛn we at fɔ yuz nid fɔ gɛt mɔ pawa ɛn di rayt tul dɛn, lɛk di tap dɛn we dɛn kin yuz fɔ kɔt kabɔd .

Ridyus di spid we dɛn de kɔt fɔ di tin dɛn we at fɔ yuz fɔ mek di tul nɔ brok .

Prɛsis plesmɛnt .

dayamita ɛn trɛd ɛnjɔymɛnt .

Hol dayamita de sho di trɛnk we di kɔnɛkshɔn gɛt .

Tu smɔl: trɛd dɛn nɔ go ɛnjɔy fayn, we go mek dɛn gɛt wan lɔs jɔyn .

Tu big: Insufisɛnt matirial fɔ trɛd fɔ bayt insay, kɔmprɔmis intɛgriti

Rif to dizayn spɛsifikɛshɔn dɛn ɛn yuz di kɔrɛkt drɔl bit saiz .

Surface dɛn we gɛt angul .

Machining threaded holes in angled surfaces prɛzɛnt yunik chalenj dɛn .

Yuz wan tap ɔlda we de flɔt ɔ kɔstɔm fiks fɔ mek i kɔntinyu fɔ gɛt ol dip ɛn alaynɛshɔn .

Verify di fayn ol dip mit di dizayn spesifikeshɔn dɛn .

Lubrikeshɔn ɛn chip ɛvakyushɔn .

If yu gɛt di rayt lɔbrik, dat de mek di frikshɔn nɔ bɔku, i de mek di ples wam, ɛn i de mek yu nɔ ebul fɔ tap di tap .

Lubrikeshɔn de ɛp fɔ pul di chips dɛn we de fa, we de mek dɛn nɔ ebul fɔ lɔk .

Yuz tap fluid wit gud flushing prɔpati .

Tink bɔt spiral pɔynt tap fɔ bɛtɛ chip ɛvakyushɔn insay dip ol dɛn .

Pros ɛn bad tin dɛn we dɛn dɔn tap fɔ du .

Pros dɛn .

Sɔlid Kɔnɛkshɔn .

Tap ol dɛn de gi wan strɔng ɛn rilibul we fɔ fastɛn kɔmpɔnɛnt dɛn togɛda. Dɛn de mek wan sikyuɔr kɔnɛkshɔn we kin ebul fɔ bia wit impɔtant fɔs ɛn vaybreshɔn, so dat de mek shɔ se di strɔkchɔral intɛgriti fɔ di pat dɛn we dɛn dɔn gɛda.

Space efficiency fɔ mek di ples fayn .

Spays Efisiɛns de pul di nid fɔ ɔda hadwɔd lɛk nɛt ɔ was. We dɛn thread dairekt insay di matirial, tap ol dɛn sev ples ɛn simpul di asɛmbli prɔses.

Versatility na di .

Tap ol dɛn kin akɔmod difrɛn kayn skru ɛn bolt dɛn, we kin mek dɛn fayn fɔ bɔku bɔku aplikeshɔn dɛn. Dɔn bak, dɛn kin yuz dɛn na difrɛn tin dɛn, lɛk mɛtal, plastic, ɛn kɔmpɔzit.

I izi fɔ Asɛmbli ɛn Disassembly .

Tapped holes fasilitet izi asembli en disassembly of komponents. Dɛn kin alaw fɔ mek dɛn put ɔ pul di skru ɔ bolt dɛn kwik ɛn stret, we kin pruv se dɛn fayn we dɛn de mek dɛn, dɛn kin mek dɛn fayn, ɔ dɛn kin ɔpgrɛd dɛn.

Thread Riinfɔsmɛnt .

Sɔntɛnde, dɛn kin riinfɔs di ol dɛn we dɛn dɔn tap wit insɛt ɔ ɛlikɔyl. Dɛn kin instɔl dɛn ɛlimɛnt ya insay di ol we dɛn tap fɔ gi ɔda trɛnk ɛn fɔ mek di trɛd dɛn go te ɛn fɔ mek dɛn go de fɔ lɔng tɛm. Thread reinforcement de prolong di layf fɔ di ol we dɛn tap, mɔ na soft matirial ɔ ay-stress aplikeshɔn.

Di tin dɛn we de apin .

Thread Wear .

Wan potential drawback of taped holes na thread wear. If yu put ɛn pul di skru ɔ bolt dɛn bɔku tɛm, i kin mek di trɛd dɛn wet smɔl smɔl, mɔ na di tin dɛn we soft. As tɛm de go, dis we aw dɛn kin wɛr am kin mek di kɔnɛkshɔn nɔ de igen ɔ i kin at fɔ mek dɛn ebul fɔ gɛt tayt fit.

Krɔs-thrɛdin .

Krɔs-thrɛd na ɔda tin we de mɔna pipul dɛn wit ol dɛn we dɛn tap. I kin apin we di skru ɔ bolt nɔ alaynɛd wit di trɛd dɛn we dɛn de put am insay. Dis misalignment kin mek di thread dem damej, we kin kompromi di integriti of di konekshon. Fɔ tek tɛm alaynɛshɔn ɛn di rayt we fɔ du di wok impɔtant fɔ mek yu nɔ krɔs-thrɛd.

Tap Breakage .

We dɛn de tap di tin dɛn, mɔ na di had matirial dɛn, risk de fɔ mek dɛn brok di tap. If wan tap brok insay di ol, i kin tranga fɔ pul, we kin mek i delay ɛn i kin pwɛl di wok. Di rayt tap sɛlɛkshɔn, lɔbrikeshɔn, ɛn tɛknik de ɛp fɔ mek di risk fɔ tap brok nɔ bɔku.

Limitɛd lod kapasiti .

Tapped holes in soft materials kin gɛt limited lod kapasiti kɔmpia to ɔda fastɛns mɛtɔd dɛn. Di trɛd dɛn we de insay sɔft matirial dɛn nɔ go gi dɛn pawa we go du fɔ ol dɛn ɔnda ebi ebi lod ɔ ay-stress kɔndishɔn. Insay dɛn kayn tin ya, dɛn kin nid fɔ yuz ɔda we fɔ fast ɔ fɔ mek dɛn riinfɔs di trɛd.

Aplikeshɔn dɛn fɔ di ol dɛn we dɛn dɔn tap .

Di ol dɛn we dɛn dɔn tap kin si se dɛn de yuz am ɔlsay akɔdin to difrɛn difrɛn industri dɛn. Dɛn ebul fɔ mek strɔng, detachable jɔyn dɛn de mek dɛn indispensable insay bɔku bɔku prɔdak ɛn aplikeshɔn dɛn. Lɛ wi fɛn sɔm impɔtant eria dɛn usay tap ol dɛn de ple impɔtant pat.

Di pat dɛn we de na di motoka .

Di ɔtomotiv industri rili dipen pan tap ol dɛn fɔ assemble ɛn mawntin kɔmpɔnɛnt dɛn. Frɔm injin blɔk to bɔdi panɛl, tap ol dɛn de gi sikrit atɛshmɛnt pɔynt dɛn. Dɛn de mek dɛn ebul fɔ fast di pat dɛn lɛk:

Miro dɛn .

Brakɛt dɛn .

Laysens plet dɛn .

Intɛriɔ trim pis dɛn .

Di yus fɔ di ol dɛn we dɛn dɔn tap de alaw fɔ mek i izi fɔ instɔl, mentenɛns, ɛn chenj dɛn kɔmpɔnɛnt dɛn ya. Dɛn de kɔntribyut to di ɔvala strɔkchɔral intɛgriti ɛn funkshɔnaliti fɔ motoka dɛn.

Fɔnicha Asɛmbli .

Dɛn kin yuz ol dɛn we dɛn kin tap fɔ mek dɛn fɔ mek di fɔnicha dɛn. Dɛn kin gi yu wan fayn ɛn rili fayn we fɔ jɔyn wud ɔ mɛtal pat dɛn. Sɔm ɛgzampul dɛn na:

We dɛn kin tay leg dɛn na tebul ɛn chia dɛn .

Fɔ mek shɔ se dɛn gɛt shelf dɛn to kabinɛt dɛn .

Fastening drawa slayd ɛn hinj dɛn .

Fɛnichɔ we de yuz di ol dɛn we dɛn dɔn tap kin izi fɔ gɛda ɛn disassembl fɔ transpɔt ɔ stɔrɔj. Dis ficha de enhans di versatility en praktis of furniture pies.

Ilɛktronik Divays dɛn .

Insay di ilɛktroniks industri, dɛn kin yuz ol dɛn we dɛn tap fɔ mek di kɔmpɔnɛnt dɛn ɛn di asɛmbli dɛn we de insay di divays dɛn, gɛt dɛn. Dɛn de gi mawntin pɔynt dɛn fɔ:

Sakit Bɔd dɛn .

HeatSinks na di .

Kɔnɛkta dɛn .

Enclosures .

Tapped hols alaw fɔ prɛsis pozishɔn ɛn stebul atakshɔn fɔ dɛn komponent ya. Dɛn de mek shɔ se dɛn de wok fayn ɛn protɛkt di dilik ilɛktronik pat dɛn frɔm damej bikɔs ɔf vaybreshɔn ɔ muvmɛnt.

Indastrial mashin dɛn .

Indastrial mashin dɛn kin rili dipen pan ol dɛn we dɛn dɔn tap fɔ asembli ɛn mentenɛns. Dɛn kin yuz dɛn fɔ fasten kɔmpɔnɛnt dɛn lɛk:

Gia dɛn .

Biɛrin dɛn .

Aktyuator dɛn .

Sensor dɛn .

Tapped holes de fasilit di sikyuɔr kɔnɛkshɔn fɔ muv pat dɛn ɛn di mawntin fɔ ikwipmɛnt pan sɔpɔt strɔkchɔ dɛn. Dɛn de ple wan impɔtant pat fɔ mek shɔ se dɛn gɛt di rilaybiliti ɛn lɔng layf we di industrial mashin dɛn gɛt.

Dɔn

Bay we dɛn de gi sikrit ɛn rimovable kɔnɛkshɔn, tap ol dɛn de gi bɔku bɛnifit akɔdin to dɛn difrɛn aplikeshɔn dɛn ya.Frɔm ɔtomotiv pat to fɔnicha, ilɛktronik divays to industrial mashin, tap ol na wan fondamental fastɛns sɔlvishɔn. Dɛn versatility ɛn rilaybiliti mek dɛn bi wan impɔtant aspek fɔ dizayn ɛn manufakchurin akɔdin to industri dɛm.

FAQ dɛn .

Wetin na di difrɛns bitwin wan ol we dɛn tap ɛn wan ol we gɛt trɛd?

Wan tap ol na wan ol we dɛn drɔ ɛn afta dat dɛn kin trɛd insay di trɛd bay we dɛn yuz tap. Wan ol we gɛt trɛd kin rifer to ɛni ol we gɛt insay trɛd, ilɛk aw dɛn mek dɛn (lɛk fɔ tap, fɔ mil di trɛd, ɛn ɔda tin dɛn). Essentially, ɔl di ol dɛn we dɛn tap na ol dɛn we dɛn dɔn trɛd, bɔt nɔto ɔl di ol dɛn we dɛn dɔn trɛd dɛn tap.

Aw yu kin no di kɔrɛkt tap drɔl saiz?

Fɔ no di kɔrɛkt tap drɔl saiz, no di trɛd saiz ɛn pitch yuz wan trɛd gej. Ɔltɛm pik wan drɔl saiz we smɔl smɔl pas di men dayamita fɔ alaw di rayt trɛd ɛnjɔymɛnt.

Us matirial dɛn fayn fɔ tap?

Dɛn kin mek ol dɛn we dɛn tap pan difrɛn tin dɛn, lɛk mɛtal (ɛgz., stɛl, aluminiɔm, bras) ɛn sɔm plastic dɛn. Fɔ tin dɛn we at fɔ yuz lɛk stenlɛs stiɛl, dɛn kin advays fɔ mek dɛn yuz ay spid stɛl (HSS) ɔ fɔ tap di kabɔd, ɛn di tin dɛn we dɛn kin yuz fɔ mek tin dɛn kin nid spɛshal tap dɛn fɔ mek dɛn nɔ gɛt di fayn fayn tin dɛn we de na di trɛd.

Wetin na di difrɛns bitwin wan sɛlf-tap skru ɛn wan tap ol?

Wan skru we de tap insɛf de mek in yon trɛd dɛn we dɛn de drayv am insay wan matirial, we de pul di nid fɔ di ol dɛn we dɛn dɔn drɔ ɔ tap. Di ol dɛn we dɛn tap, na di ɔda say, nid fɔ tap fɔ kɔt trɛd bifo tɛm. Bɔku tɛm dɛn kin yuz skru dɛn we de tap dɛnsɛf fɔ mek tin dɛn we gɛt sɔft tin dɛn lɛk wud ɔ plastic, ɛn di ol dɛn we dɛn tap kin fayn fɔ mek dɛn mek mɛtal ɛn say dɛn we gɛt ay strɛs.

Wetin mek lɔbrik impɔtant fɔ tap?

Lubrikeshɔn de ridyus frikshɔn ɛn ɔt, ɛp fɔ mek tap brok ɛn mek shɔ se klin, mɔ prɛsis trɛd dɛn. I de ɛkstɛnd bak di layf fɔ di tap ɛn i de impruv di ɔvala kwaliti fɔ di ol we gɛt trɛd.

Aw dip wan tap ol fɔ bi?

Di dip we wan ol we dɛn tap de dipen pan di dayamita we dɛn de yuz di fastɛn we dɛn de yuz. Wan jenɛral lɔ na fɔ mek di trɛd dip at le 1.5 tɛm di dayamita fɔ di fastɛn fɔ optimal trɛnk. Fɔ ɛgzampul, 1/4-inch skru fɔ gɛt ol we at le 3/8 inch dip.