Naylon . Injɛkshɔn moldin de ɔlsay. Frɔm motoka pat to tut brɔsh, naylon na wan impɔtant tin na wi layf ɛvride. Bɔt wetin mek pipul dɛn lɛk am so? Dis atikul de tɔk bɔt di impɔtant tin we naylon gɛt fɔ du wit injɛkshɔn moldin. Yu go lan bɔt di we aw i de du tin, di bɛnifit dɛn we i go gɛt, ɛn di prɔblɛm dɛn we i gɛt. Diskova wai naylon stil bi top choice fo manifakta dem fo di wold.

Wetin na Naylon?

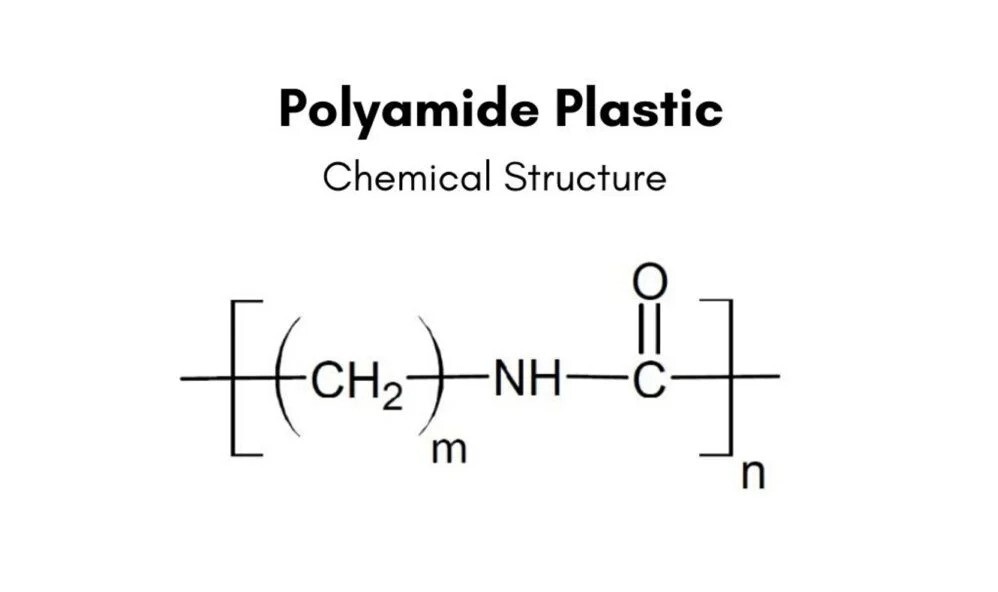

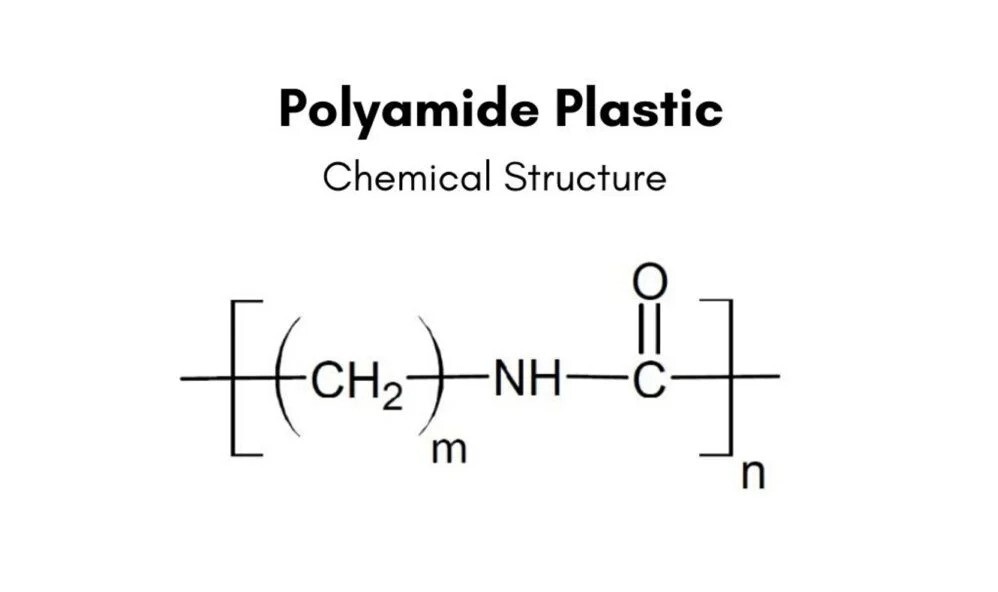

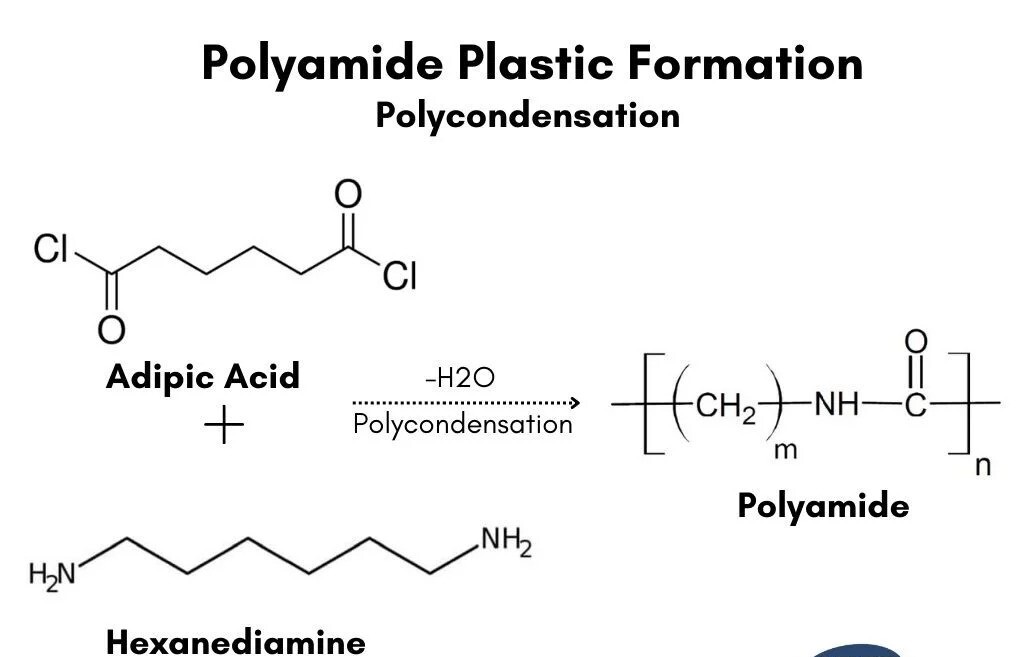

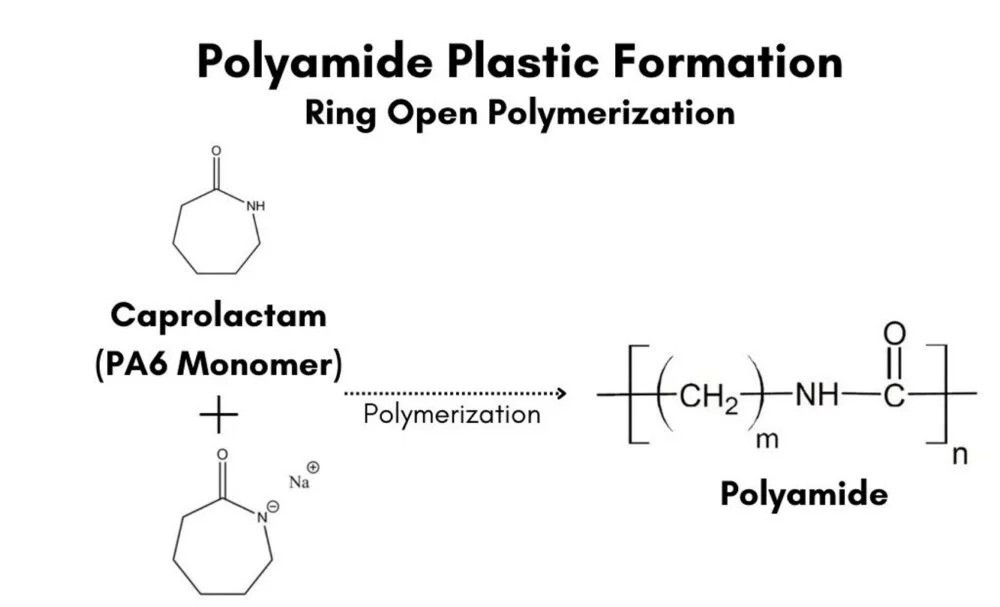

Naylon na wan sintetik tɛmplastik polima we de na di polyamide famili. i mek op fכ ripit amid grup dεm (―CO―NH―) na di men polimכr chen, lεk aw dεn sho na di kεmikכl strכkchכ dεm we de dכn:

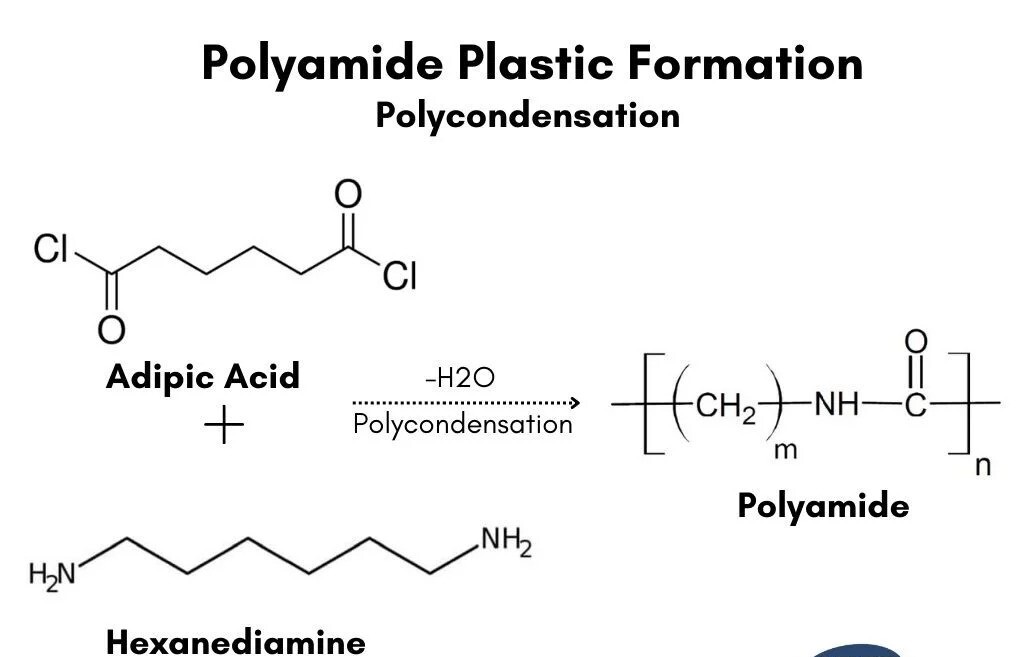

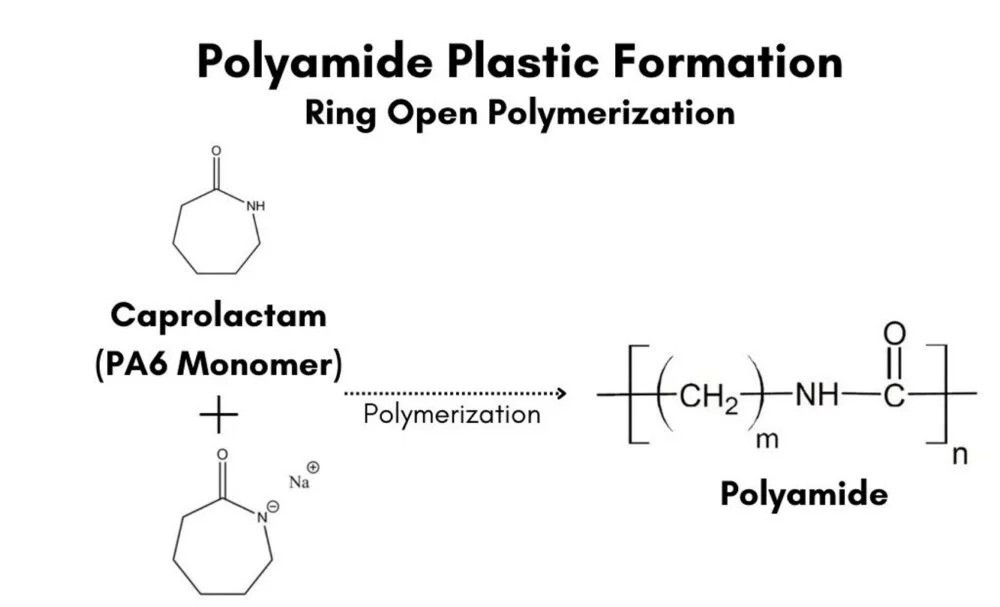

Tu men we dɛn de fɔ mek naylon:

Polikondenseshɔn fɔ dayamin ɛn dibasik asid .

ring-opin polimεrayzeshn fכ laktam dεm, we de fכm bay di dihaydreshכn fכ amino asid dεm .

Fɔ mek yu ebul fɔ kɔmpia naylon wit ɔda tin dɛn, yu kin chɛk wi gayd pan Difrɛns bitwin polyamide ɛn naylon ..

Prɔpati dɛn fɔ di pat dɛn na naylon injɛkshɔn we dɛn dɔn mol .

Naylon injɛkshɔn mold pat dɛn sabi fɔ dɛn ɛksɛpshɔn balans fɔ prɔpati, we mek dɛn fayn fɔ wan big rɛnj ɔf aplikeshɔn. Fɔ no mɔ bɔt di injɛkshɔn moldin prɔses, go na wi pej na Plastik injɛkshɔn moldin ..

Mekanikal prɔpati dɛn .

Strɔng ɛn stiffnɛs

naylon pat dɛn de sho ay tɛnsiɛl trɛnk, we de alaw dɛn fɔ bia wit impɔtant lod dɛn we nɔ gɛt difɔmeshɔn. Dɛn inhɛrɛnt stiffnɛs de gi strɔkchɔral intɛgriti, we de mek dɛn rilibul insay dimand ɛnvayrɔmɛnt dɛn.

Impact Resistance

Nylon in abiliti fɔ absɔb ɛnaji we nɔ go brok de mek am fayn fɔ pat dɛn we gɛt shɔk ɔ impak. Dis prɔpati na impɔtant tin na ɔtomotiv ɛn industrial aplikeshɔn usay fɔ durabiliti impɔtant. Fɔ no mɔ bɔt aw fɔ yuz motoka, si wi Awtomotiv Pat ɛn Kɔmpɔnɛnt Manufakchurin Pej ..

Fatigue resistance

naylon kin bia wit ripit strɛs we nɔ de fel. I fatigue resistance de mek shɔ se i de liv lɔng, ivin insay di komponent dɛn we de ɛkspiriɛns ɔltɛm bɛnd ɔ fleks, lɛk gia ɔ mɛkanikal fastɛns.

Wear ɛn abrasion resistance

naylon in lɔw frikshɔn kɔfishin ɛn resistans fɔ wear mek am pafɛkt fɔ muv pat dɛn. I de mentɛn pefɔmɛns ova tɛm, i de ridyus di nid fɔ riplesmɛnt ɔltɛm.

Di prɔpati dɛn we dɛn kin yuz fɔ mek di ples wam .

di nylon pat dεm we de rεsistεns na di nylon

kin ebul fכ bia wit di ay tεmprachכ, fכ mek dεn trεnk εn stiff ivin na hot envayroment. Dis mek dɛn fayn fɔ ɔnda-di-hud ɔtomotiv aplikeshɔn dɛn.

Thermal

stabiliti naylon in tɛmral stebiliti de mek shɔ se kɔnsistɛns pefɔmɛns ɔnda chenj chenj tɛmpracha. I de rεsist dεgradεshכn, we de gi rilibul כpεreshכn insay tεmral sayklכn kכndishכn dεm.

Kεmikכl rεsistεns .

Di we aw dɛn nɔ de yuz fiul, ɔyl, ɛn kemikal dɛn

naylon nɔ de ambɔg bɔku bɔku kemikal dɛn, lɛk fiul, ɔyl, ɛn haydrokabɔn. Dis prɔpati de mek am wan prɛferɛd matirial insay ɔtomotiv, industrial, ɛn kemikal prɔsesin industri usay ɛksplɔshɔn to harsh sɔbstans dɛn kɔmɔn.

Ilɛktrik prɔpati dɛn .

Insulating Properties

Naylon in fayn fayn ilɛktrik insulin prɔpati dɛn de mek am fayn fɔ yuz insay ilɛktrik ɛn ilɛktronik kɔmpɔnɛnt dɛn. I de mek ilɛktrik lik, mek shɔ se sef ɛn rilaybiliti de na difrɛn aplikeshɔn dɛn.

Moisture absorpshɔn ɛn dimɛnshɔnal stebiliti .

Moisture absorption

nylon na hygroscopic, we min se i de absɔb mɔstɔ frɔm di envayrɔmɛnt. Dis kin afɛkt in dimɛnshɔnal stebiliti, mɔ na ay-humiditi kɔndishɔn. Fɔ drɛy fayn fayn wan bifo yu prosɛs am impɔtant fɔ mek dis impak smɔl.

Dimensional stabiliti

Pan ɔl we i absɔpt mɔstɔ, naylon kin mentɛn gud dimɛnshɔnal stebiliti we dɛn prosɛs am fayn fayn wan. Aditiv ɛn riinfɔsmɛnt, lɛk glas fayba, de ɛp fɔ mek i stebul, we mek i fayn fɔ prɛsishɔn pat dɛn.

Fɔ no mɔ bɔt injɛkshɔn moldin prɔses ɛn paramita dɛn, chɛk wi gayd pan Injekshɔn Moldin Prɔses Paramita dɛn ..

Di kayn dɛn we dɛn kin yuz na naylon we dɛn kin yuz fɔ mek injɛkshɔn moldin .

Fɔ mek yu ɔndastand bɔku tin bɔt di tin dɛn we dɛn kin yuz fɔ mek injɛkshɔn, yu kin tɔk bɔt wi gaydman dɛn bɔt Wetin dɛn kin yuz fɔ mek injɛkshɔn moldin ..

Kɔmɔn difrɛn we dɛn fɔ mek naylon .

Naylon 6 .

Naylon 6 na wan pɔpul choice fɔ injɛkshɔn moldin. I de gi fayn fayn mɛkanikal trɛnk, stiffnɛs, ɛn ɔt rɛsistɛns.

Di bɛnifit dɛn we pɔsin kin gɛt we i yuz naylon 6 pan injɛkshɔn moldin na:

Gud balans fɔ kɔst ɛn pefɔmɛns .

I izi fɔ prosɛs ɛn chenj .

ay impak resistans, ivin na low temperecha .

Kɔmɔn aplikeshɔn fɔ naylon 6 inklud:

Di pat dɛn we de na di motoka .

Ilektrikal komponent dɛn .

Di guds dɛn we pipul dɛn kin yuz fɔ bay tin dɛn (ɛgz., tut brɔsh bristles, fishin layn dɛn)

Naylon 66 .

Naylon 66 sheb bɔku prɔpati wit naylon 6. Bɔt i gɛt sɔm spɛshal kwaliti dɛn:

Dɛn prɔpati ya de mek naylon 66 fayn fɔ:

Ɔda Naylon Variant dɛn .

Naylon 11 .

Naylon 11 stand out frɔm ɔda naylon dɛn bikɔs ɔf in:

Lɔwa mɔstɔ absɔpshɔn (arawnd 2.5%) .

Di wan dɛn we gɛt ay UV rɛsistɛns .

Impruv Kεmikכl Resistεns .

Bɔku tɛm dɛn kin yuz am na:

Tubing ɛn paip .

Spɔt ikwipmɛnt (ɛgz., rɛkɛt string, shatɔlkɔk)

Kebul ɛn waya sheathing dɛn .

Naylon 12.

Di men prɔpati dɛn fɔ naylon 12 inklud:

Di ples we de mɛlt di ples we de mɛlt bitwin di naylon dɛn (180°C)

Eksɛlɛnt dimɛnshɔnal stebiliti .

Gud kemikal ɛn strɛs rɛsistɛns .

Kɔmɔn aplikeshɔn fɔ naylon 12 na:

Naylon we dɛn dɔn riinfɔs .

Naylon kin riinfɔs wit glas ɔ kabɔn fayba. Dis de mek in:

Bɔt, riinfɔsmɛnt kin mek bak di matirial brit mɔ. Di choice of reinforcement dipen pan di spesifik aplikeshɔn rikwaymɛnt dɛn.

Naylon we dɛn dɔn riinfɔs na in dɛn de yuz bɔku bɔku wan na:

Structural Automotive Parts .

High-Performance Industrial Komponent dɛn .

Konsuma prodakt we de dimand ay trɛnk ɛn durabiliti .

Fɔ mek wi ɔndastand mɔ bɔt di difrɛns bitwin difrɛn plastic tin dɛn, lɛk naylon, yu go si wi atikul bɔt di Difrɛns bitwin polyamide ɛn naylon ɛp.

Di naylon injɛkshɔn moldin prɔses .

Step-by-step gayd .

Material Selection ɛn Pripiamɛnt .

Fɔ pik di rayt kayn naylon rili impɔtant. I dipen pan di patikyula aplikeshɔn rikwaymɛnt dɛn ɛn di prɔpati dɛn we dɛn want. Fɔ no mɔ bɔt di tin dɛn we dɛn yuz fɔ mek injɛkshɔn moldin, chɛk wi gayd pan Wetin dɛn kin yuz fɔ mek injɛkshɔn moldin ..

Bifo dɛn mol di naylon, dɛn fɔ drɛy am fayn fayn wan. Mɔstɔ kɔntinyu fɔ de dɔŋ 0.2% fɔ mek dɛn nɔ gɛt prɔblɛm.

Mold dizayn kɔnsidareshɔn dɛn .

Mold dizayn de ple wan impɔtant pat pan di sakrifays we dɛn dɔn mek fɔ mek naylon injɛkshɔn moldin. Sɔm impɔtant tin dɛn we wi fɔ tink bɔt na:

Fɔ no mɔ bɔt aw fɔ mek mold, go na wi pej na Plastik mold dizayn ..

Injekshɔn Molding Mashin Sɛtin ɛn Paramita dɛn .

Prɔpa mashin sɛtin dɛn de mek shɔ se di kɔndishɔn dɛn we de fɔ mold fayn fayn wan. Impɔtant paramita dɛn na:

Tempracha melt (240-300°C, dipen pan di naylon gred)

Injɛkshɔn prɛshɔn ɛn spid .

we de ol prɛshɔn ɛn tɛm .

Skru spid ɛn bak prɛshɔn .

Kul ɛn ejekshɔn fɔ di pat dɛn we dɛn dɔn mol .

Afta injɛkshɔn, di pat we dɛn dɔn mol nid fɔ kol. Di kol tɛm dipen pan di pat jɔyometri ɛn di wɔl tik.

We dɛn dɔn mek di pat kol, dɛn kin pul di pat kɔmɔt na di mol. Wan we dɛn dɔn mek fayn fayn wan fɔ pul di ejeshɔn sistɛm de mek shɔ se dɛn de pul pat pan di pat we fayn ɛn we go wok fayn.

Teknik dɛn we dɛn kin yuz fɔ du post-prɔsɛs .

Trim ɛn finish .

Di pat dɛn we dɛn dɔn mol kin nid fɔ trim get ɛn flash. Dis kin bi wit an ɔ wit ɔtomatik trim ikwipmɛnt.

Dɛn kin nid fɔ du ɔda tin dɛn fɔ dɔn di wok, lɛk fɔ peint ɔ fɔ mek dɛn asɛmbli. I dipen pan di las tin dɛn we dɛn nid fɔ mek di prɔdak.

Kwaliti Kɔntrol ɛn Inspekshɔn .

Kwaliti kɔntrol impɔtant fɔ mek shɔ se di pat dɛn we nɔ de chenj ɛn we nɔ gɛt ɛnitin fɔ du wit dɛn. Visual inspekshɔn ɛn dimɛnshɔnal chɛk na kɔmɔn we.

Mɔ advans tɛknik, lɛk 3D skan ɔ ɛkstrem rayt analisis, dɛn kin yuz fɔ impɔtant aplikeshɔn dɛn. Dɛn kin ɛp fɔ no di prɔblɛm dɛn we de insay ɔ di difrɛn difrɛn tin dɛn we de apin.

Impɔtant tin fɔ mek di mold tɛmpracha .

Mold tempɔret kin rili afɛkt di prɔpati dɛn we di naylon pat dɛn gɛt. I de inflɔws di kristaliniti ɛn mɛkanikal pefɔmɛns.

Fɔ tin-wɔl pat dɛn, dɛn kin advays fɔ mek dɛn gɛt ay mold tɛmpracha (80-90°C). Dɛn de mek shɔ se dɛn gɛt wanwɔd kristaliniti ɛn gud sɔfays apia.

Struktural pat wit tik tik wol de bɛnifit frɔm lɔwa mold tɛmpracha (20-40°C). Dis de promot ay ɛn mɔ kɔnsistɛns kristaliniti ɔlsay na di pat.

Fɔ ɔndastand mɔ bɔt di injɛkshɔn moldin prɔses, inklud in stej ɛn paramita dɛn, chɛk wi kɔmprɛhɛnsif gayd pan Wetin na injɛkshɔn moldin prɔses ..

Chalenj dɛn na Naylon injɛkshɔn moldin .

Di prɔblɛm dɛn we kɔmɔn ɛn aw fɔ avɔyd dɛn .

Gasing .

Gas de apin we di gas we pasmak kin trɔp na di mɔlt naylon. I kin mek yu gɛt difrɛn difrɛn tin dɛn lɛk bɔbul ɛn voyd.

Fɔ mek yu nɔ gɛt gas:

Mek shɔ se dɛn put di mold fayn fayn wan insay di mold .

Optimayz mɛlt tɛmpracha ɛn injɛkshɔn spid .

Yuz wan mold wit gud surface finish .

Shrinkage na na na na na na na na na na na na na na na na na na

Naylon pat dɛn kin shrink as dɛn de kol. shrinkage we nɔ ivin kin mek dimɛnshɔn nɔ kɔrɛkt ɛn wɔ. Fɔ no mɔ bɔt shrinkage ɛn ɔda injɛkshɔn moldin dɛfɛkt dɛn, chɛk wi gayd pan Kɔmɔn prɔblɛm dɛn wit injɛkshɔn moldin fɔ plastic pat dɛn ..

Fɔ kɔntrol shrinkage:

Disain di mold wit di rayt shrinkage alawns .

Mek yu kɔntinyu fɔ gɛt di tɛm we di mold go kɔntinyu fɔ de .

Yuz prɛshɔn we de ol fɔ pak di mold .

Moisture Isyu dɛn .

Mɔstɔ na naylon kin mek difrɛn difrɛn tin dɛn lɛk silva strek ɛn di tin dɛn we nɔ pafɛkt na di wɔl. Fɔ drɛy fayn fayn wan na impɔtant tin.

Tips fɔ drɛy fayn fayn wan:

Yuz wan dihumidifying dryer wit diw point we na -40°C o lower

Dray di naylon fɔ at le 4 awa na 80-90°C

Kip di naylon we dɔn dray insay kɔntena dɛn we dɛn dɔn sial te i mol .

Warpage na di .

Warping na wan kɔmɔn tin na naylon pat. I kin kam bikɔs ɔf di kol we nɔ ivin kol ɛn di shrinkage.

Fɔ mek di wɔpin nɔ bɔku:

Dizain pat wit yunifom wol tiknes .

Yuz di rayt we fɔ mek yu gɛt ɛn kol .

Adjɔst moldin paramita dɛn lɛk injɛkshɔn spid ɛn ol prɛshɔn .

Handling hygroscopic prɔpati dɛn .

Di we aw di naylon kin want fɔ tek di wata kin tranga. Speshal tekniks nid fɔ de fɔ manej dis di tɛm we dɛn de mol.

Sɔm bɛst tin dɛn we dɛn kin du na:

Dray di naylon bifo yu mol .

Yuz wan klos-lɔp matirial hanlin sistem .

Minimizing di tɛm bitwin drying ɛn molding .

Tips fɔ sɔlv prɔblɛm ɛn optimize di prɔses .

Fɔ ebul fɔ gɛt kɔnsistɛns rizɔlt dɛn na naylon injɛkshɔn moldin nid fɔ pe atɛnshɔn to ditiɛl. Na sɔm advays dɛn ya:

Establish wan robust prɔses kɔntrol sistem .

Monitor ki paramita lek temperecha, preshos, en spid

Kɔndɔkt ɔltɛm fɔ mek dɛn de mek di tin dɛn we dɛn de yuz fɔ mek di mold ɔltɛm .

Kɔmpleks jɔyometri kin bi chalenj fɔ mol. Fɔ handle dɛn:

Yuz simulshɔn softwe fɔ optimize di mold dizayn .

Tink bɔt bɔku-gɛt ɔ hot rɔna sistem dɛn .

Adjɔst di moldin paramita dɛn fɔ mek shɔ se yu fil fayn ɛn pak fayn fayn wan .

Prosesin kondishɔn fɔ PA6 ɛn PA66 injɛkshɔn moldin .

We i kam pan fɔ prosɛs PA6 ɛn PA66 insay injɛkshɔn moldin, sɔm impɔtant tin dɛn nid fɔ tink bɔt. Mek wi daiv insay di ditel dɛn.

Di tin dɛn we dɛn kin yuz fɔ mek di wata we dɛn dɔn rɛkɔmɛnd bifo dɛn prosɛs am bifo dɛn prosɛs am .

I impɔtant fɔ drɛy di kɔmpɔnɛnt dɛn bifo dɛn prosɛs. Di target mɔstɔ kɔntinyu fɔ bi maksimam 0.2%.

Dis drying step na impɔtant tin fɔ mek di tin dɛn we gɛt fɔ du wit mɔstɔ nɔ apin. I de ɛp fɔ mek dɛn kɔntinyu fɔ gɛt di prɔpati dɛn we dɛn want.

Tɛmral stebiliti ɛn dikɔmpɔzishɔn kɔnsyans .

PA6 ɛn PA66 kin ebul fɔ bia wit di tɛmpracha te to 310°C we nɔ de rɔtin. Bɔt, i rili impɔtant fɔ kip di prɔsesin tɛmpracha dɔŋ dis trɛshɔld.

Tempracha we ay pas 310°C kin mek di matirial brok. Dis kin mek dɛn mek kabon monoksayd, amonia, ɛn kaproktam.

Dɛn bayprɔdakt ya kin ambɔg di kwaliti ɛn di pefɔmɛns fɔ di fayn prodak bad bad wan. So, i impɔtant fɔ monitar ɛn kɔntrol di prɔsesin tɛmpracha.

Optimal L/D ratio fɔ injɛkshɔn moldin mashin dɛn .

Fɔ di PA6 ɛn PA66 injɛkshɔn moldin we go wok pas ɔl, di skru we de na di mashin fɔ gɛt L/D ratio bitwin 18:22.

dis rεshכ de mek sכh se dεn miks am fayn fayn wan, mεlt, εn homojεnayz di polimכr mεlt. I de kɔntribyut fɔ prodyuz ay kwaliti mold pat dɛn ɔltɛm.

Melt temperechur renj fɔ PA6 ɛn PA66.

Di mɛlt tɛmpracha na wan impɔtant paramita we dɛn de injɛkshɔn moldin. Fכ PA6, di ideal mεlt tεmprachכ rεnj na tipikli bitwin 240 εn 270°C.

PA66, na di ɔda say, dɛn fɔ prosɛs am na di tɛmpracha we ay smɔl. Di rɛkɔmɛnd mɛlt tɛmpracha rɛnj fɔ PA66 na bitwin 270 ɛn 300°C.

Fɔ kip di mɛlt tɛmpracha insay dɛn rɛnj ya rili impɔtant. I de mek shɔ se di rayt flɔ prɔpati dɛn ɛn ɛp fɔ avɔyd tin dɛn lɛk thermal degradation.

Mold temperechur renj fɔ PA6 ɛn PA66.

Prɔpa mold tɛmpracha kɔntrol na ikwal impɔtant fɔ saksesful injɛkshɔn moldin. Fɔ ɔl tu di PA6 ɛn PA66, di rɛkɔmɛnd mold tɛmpracha rɛnj na bitwin 55 ɛn 80°C.

Fɔ kip di mold na dɛn tɛmpracha ya de mek pipul dɛn no bɔt:

Kɔmɔn aplikeshɔn dɛn fɔ naylon injɛkshɔn moldin .

Naylon injɛkshɔn moldin de fɛn aplikeshɔn dɛn akɔdin to difrɛn industri dɛn. Fɔ ɔndastand mɔ bɔt di injɛkshɔn moldin prɔses ɛn in versatility, chɛk wi gayd pan Wetin dɛn kin yuz plastic injɛkshɔn moldin fɔ ..

Ɔtomotiv Indastri .

Insay di ɔtomotiv sɛktɔ, dɛn kin yuz naylon fɔ sɔm impɔtant kɔmpɔnɛnt dɛn. Dɛn tin ya na:

gia, bia, ɛn bush .

Fiul sistem komponent dɛn lɛk fiul layn ɛn tank dɛn .

Intɛriɔ trim pat dɛn lɛk domɔt handel ɛn dashbɔd kɔmpɔnɛnt dɛn .

Di pat dɛn na do lɛk miro haus ɛn wil kɔva .

Naylon in trɛnk, wear resistance, ɛn kemikal resistans mek am fayn fɔ dɛn aplikeshɔn ya. I kin ebul fɔ bia wit di bad bad tin dɛn we de apin na di say dɛn we dɛn de mek motoka dɛn.

Ilɛktrikal ɛn Ilɛktronik Indastri .

Naylon na pɔpul choice fɔ ilɛktrik ɛn ilɛktronik kɔmpɔnɛnt dɛn. Sɔm ɛgzampul dɛn na:

I fayn fayn insulin prɔpati ɛn dimɛnshɔnal stebiliti mek naylon fit fɔ dɛn aplikeshɔn ya. I de mek shɔ se pɔsin we dɛn kin abop pan fɔ wok fayn ɛn i de mek shɔt sɔrkwit dɛn nɔ apin.

Di prɔdak dɛn we dɛn de yuz fɔ bay tin dɛn .

Wi kin mit naylon insay bɔku ɛvride kɔshɔma prɔdak dɛn. Sɔm ɛgzampul dɛn we dɛn kin tɔk bɔt na:

Di handel dɛn fɔ kuk ɛn di tin dɛn we dɛn kin yuz fɔ kuk .

Tutbrɔsh de handel ɛn bristle .

Spɔt ikwipmɛnt lɛk rɛkɛt freym ɛn ski binding dɛn .

Naylon in durabiliti, kemikal resistans, ɛn izi kolorabiliti mek am wan versatil matirial fɔ kɔshɔma guds. I de gi ɔl tu di funkshɔnaliti ɛn di aesthetics. Lan mɔ bɔt kɔstɔma guds manufakchurin pan wi Konsuma ɛn Durable Goods Manufacturing Page ..

Indastrial Aplikeshɔn dɛn .

Insay industrial sɛtin, naylon fɛn yus insay difrɛn mashin pat ɛn kɔmpɔnɛnt dɛn. Dɛn tin ya na:

gia, rɔla, ɛn slayd dɛn .

Belt ɛn rɔla dɛn we dɛn kin yuz fɔ kɔnvɔyɔ .

Di tin dɛn we dɛn kin yuz fɔ pak tin dɛn lɛk fim ɛn kɔntena dɛn .

Naylon in mɛkanikal trɛnk, wear resistans, ɛn kemikal resistans na valyu tin na dɛn aplikeshɔn ya. I kin ebul fɔ handle di dimand dɛn fɔ industrial ɛnvayrɔmɛnt dɛn.

Tekstil ɛn klos dɛn .

Naylon na di say we dɛn de yuz bɔku bɔku tin dɛn na di tɛkstayl ɛn klos industri. Sɔm ɛgzampul dɛn na:

Naylon fabrik fɔ klos, bakpak, ɛn tɛnt

High-performance spɔt klos lɛk swimsuit ɛn atletik wear

Naylon fayba dɛn strɔng, dɛn layt, ɛn dɛn kin drɛy kwik kwik wan. Dɛn de gi fayn fayn tin dɛn fɔ du ɛn kɔmfɔt insay klos aplikeshɔn dɛn.

Dis na jɔs sɔm ɛgzampul dɛn bɔt di bɔku bɔku aplikeshɔn dɛn fɔ naylon injɛkshɔn moldin. I versatility ɛn atraktiv prɔpati dɛn mek am wan go-to matirial fɔ dizayna ɛn injinia dɛn akɔdin to industri dɛm.

Disain fɔ naylon injɛkshɔn moldin .

Disain pat fɔ naylon injɛkshɔn moldin nid fɔ tek tɛm tink bɔt. Fɔ wan kɔmprɛhɛnsif gayd bɔt injɛkshɔn moldin dizayn, chɛk wi Ultimate gayd fɔ injɛkshɔn mold dizayn ..

Dizayn gaydlayn fɔ naylon injɛkshɔn mold pat dɛn .

Di tin dɛn we yu fɔ tink bɔt na di wɔl .

Mentɛn kɔnsistɛns wɔl tiknɛs na impɔtant tin na naylon pat dɛn. I de ɛp fɔ mek wɔp nɔ wɔp ɛn mek shɔ se i ivin kol.

di tik we dεn rεkomεnd fכ mek di naylon pat dεm tik na bitwin 1.5 εn 4 mm. Di wɔl dɛn we tik pas ɔl kin mek dɛn gɛt mak dɛn we de sink ɛn di tɛm we dɛn kin yuz fɔ sayklɔs fɔ lɔng tɛm.

If difrɛn difrɛn tik dɛn we de na di wɔl nɔ go ebul fɔ avɔyd, mek shɔ se dɛn chenj dɛn fayn fayn wan. Nɔ chenj wantɛm wantɛm we kin mek yu gɛt strɛs kɔnsɛntreshɔn.

Draft angles ɛn ɔnda-kɔt dɛn .

Fɔ put draft angul dɛn na impɔtant tin fɔ mek i izi fɔ pul pat pan di mold. Di draft angle we dɛn kin advays fɔ di naylon pat dɛn na 1° to 2° fɔ wan say. Fɔ no mɔ bɔt draft angul dɛn, go na wi pej na Draft angle in injekshɔn moldin ..

Dɛn fɔ avɔyd ɔnda-kɔt ɛnitɛm we i pɔsibul. Dɛn kin mek pat ejekshɔn at ɛn inkrisayz tul kɔmplisiti.

If dɛn nid fɔ kɔt ɔnda, tink bɔt fɔ yuz slaydin shutɔf ɔ lifta dɛn na di mold dizayn. Dis de alaw fɔ mek dɛn pul di pat pan di pat pan di rayt we. Dis de alaw fɔ mek dɛn pul di pat pan di pat pan di rayt we. Lan mɔ bɔt di wan dɛn we de lif na wi gayd bɔt Injekshɔn Moldin Lifta Dizayn ..

Ribbing ɛn Riinfɔsmɛnt dɛn .

Bɔku tɛm dɛn kin yuz rib fɔ mek di naylon pat dɛn gɛt trɛnk ɛn stiff. Dɛn fɔ mek dɛn wit sɔm impɔtant tin dɛn fɔ tink bɔt:

Rib tiknes fɔ bi 50-60% pan di adjɔyn wɔl tiknes .

Rib ayt nɔ fɔ pas 3 tɛm di adjɔyn wɔl tiknes .

Mentɛn wan draft angul we at le 0.5° na rib sayd dɛn

Riinfɔsmɛnt, lɛk bɔs ɛn gɔs, dɛn kin ad am bak fɔ mek pat trɛnk bɛtɛ. Mek shɔ se dɛn chenj dɛn fayn fayn wan ɛn avɔyd shap shap kɔna dɛn.

Material Selection ɛn gred ɔptimayzeshɔn .

Fɔ pik di rayt naylon gred na impɔtant tin fɔ mek dɛn ebul fɔ mold injɛkshɔn we go wok fayn. Tink bɔt di patikyula tin dɛn we dɛn nid fɔ yuz ɛn di prɔpati dɛn we dɛn want.

Di tin dɛn we fɔ tink bɔt na:

Mekanikal prɔpati dɛn lɛk trɛnk, stiffnɛs, ɛn impak resistans .

Kεmikכl rεsistεns .

Di wan dɛn we de fɛt fɔ mek di ples wam .

Mostɔ absɔpshɔn .

Kɔnsul wit matirial saplayers ɛn moldin ɛkspɛkt dɛn fɔ pik di optimal nylon gred fɔ yu aplikeshɔn. Dɛn kin gi advays bay aw dɛn ɛkspiriɛns. Fɔ no mɔ bɔt aw fɔ pik di tin dɛn we yu want fɔ no, chɛk wi Gayd fɔ di Wetin dɛn kin yuz fɔ mek injɛkshɔn moldin ..

Prototyping ɛn tɛst .

Prototyping na wan impɔtant step na di dizayn prɔses. I alaw fɔ dizayn validɛshɔn ɛn ɔptimayzeshɔn bifo mas prodakshɔn.

Bɔku protɔtayp we dɛn de yuz fɔ mek naylon pat dɛn:

Ɛni we gɛt in bɛnifit ɛn di tin dɛn we i nɔ ebul fɔ du. Pik di wan we go fayn fɔ yu nid ɛn yu bajɛt.

Wans protɔtayp dɛn de, du gud tɛst fɔ evaluate pat pefɔmɛns. Dis kin inklud:

Dimensional akkuracy chɛk dɛn .

Mekanikal tɛst (ɛgz., tɛnsiɛl, impak)

Fɔnishɔnal tɛst na di aplikeshɔn we dɛn bin want fɔ du .

Bays pan di tɛst rizɔlt dɛn, mek di ajɔstmɛnt dɛn we dɛn nid fɔ mek di dizayn. Iterate te di pat mit ɔl di tin dɛn we dɛn nid.

Fɔ no mɔ bɔt protɔtayp, yu go si wi atikul bɔt Rapid prototyping teknɔlɔji ɛp.

Ɛksplen

Naylon injɛkshɔn moldin na impɔtant tin fɔ mek pat dɛn we go de fɔ lɔng tɛm, we dɛn kin yuz fɔ du bɔku tin dɛn akɔdin to bɔku industri dɛn. Di trɛnk we i gɛt, di we aw i nɔ de tek kemikal, ɛn di we aw i de mek di bɔdi wam, de mek i nɔ gɛt valyu. We wi luk bifo, di nyu tin dɛn we dɛn dɔn mek na di naylon kɔmpawnd ɛn sataynabul prɔsis go shep di fiuja fɔ dis teknɔlɔji. Fɔ mek yu ebul fɔ du mɔ, pik di rayt naylon gred fɔ yu nid dɛn. We yu wok wit wan ɛkspiriɛns injɛkshɔn moldin patna de mek shɔ se yu gɛt ay kwaliti rizɔlt, we dɛn mek fɔ yu patikyula aplikeshɔn.